Automated Assembly

A CRITICAL APPLICATION OF MIDDLESEX CONVEYORS

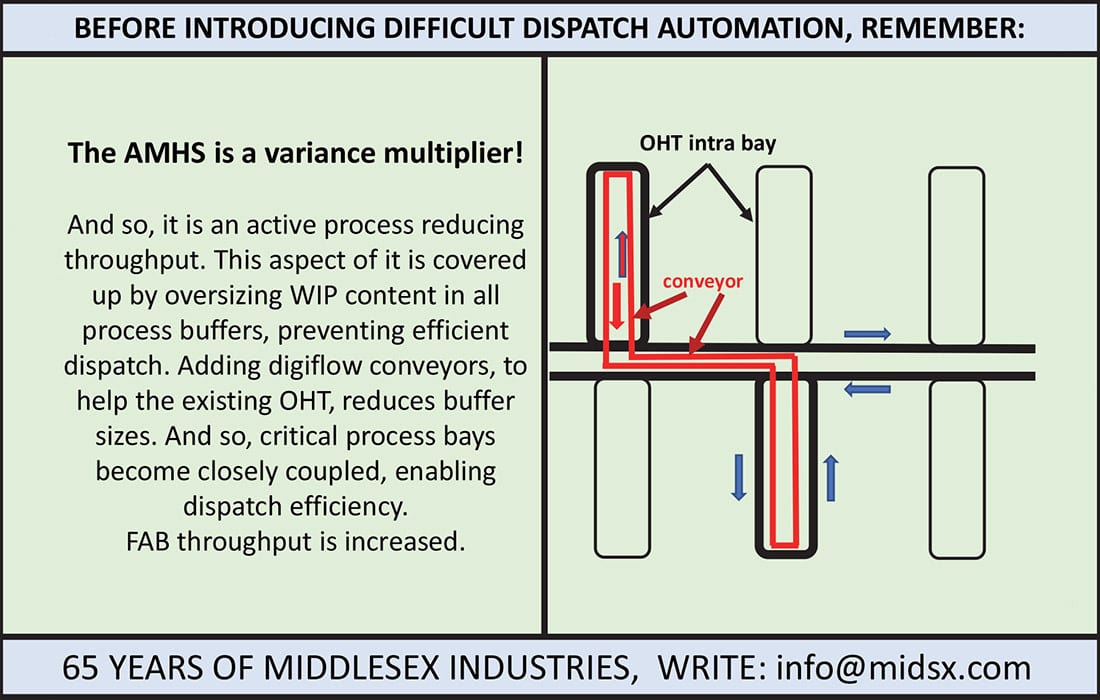

An IC manufacturer required the installation of logistics in front end wafer level production of high flexibility and asynchronous transport between value-add tools. Concurrent requirement was the prohibition of frictionally generated particles, as this would contaminate the product. Middlesex provided the solution which expanded to a conveyor network of 2+ kilometers. The installation transports work in process, which move on the network independent of each other and collision free. The technology can provide solutions in instrument assembly, medical device assembly, injection nozzle assembly in automotive, and in numerous critical robotic assembly stations.

65 YEARS OF MIDDLESEX INDUSTRIES