New tools and technology help battery-powered vehicles control heat.

Keeping it Cool

By John Challen // Contributing Writer

Battery thermal management is a huge challenge in electric vehicles. Illustration courtesy Audi AG

Battery thermal management is a huge challenge in electric vehicles. In addition to increasing the risk of fire, high temperatures can have a direct influence on range. By efficiently controlling EV temperature levels, battery range can be maximized.

Just like internal-combustion engine vehicles, when an electric power train works harder, it gets hotter. Therefore, EVs require effective, efficient and durable cooling systems. Heat management can have a major impact on not only the components within a vehicle, but also its overall performance.

Heat management in EVs is a delicate balancing act. Fortunately, automotive engineers have a variety of options to choose from.

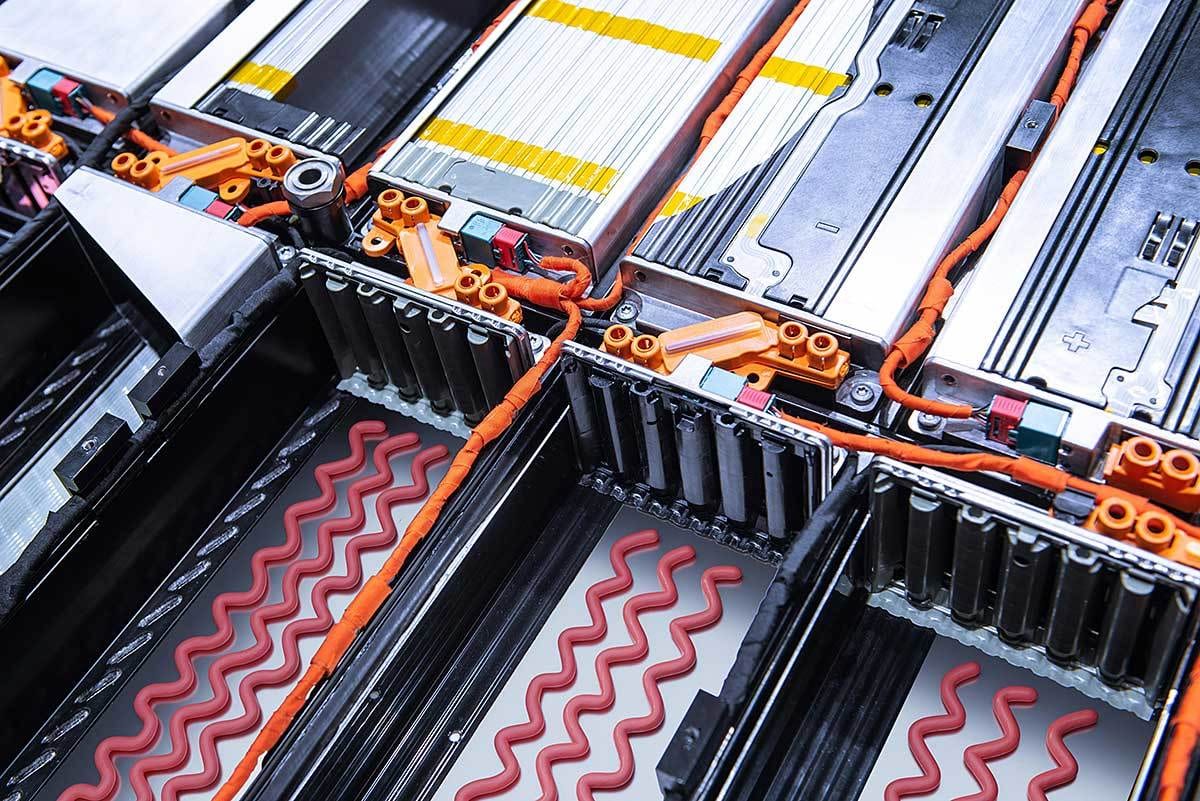

Electric vehicles require effective, efficient and durable cooling systems. Photo courtesy ESI Automotive

“In EVs, higher energy density batteries, smaller more powerful e-motors and ultra-fast charging create thermal management challenges for both safety and efficiency,” says Gilles Le Borgne, executive vice president of engineering at the Renault Group, which is a leading producer of electric vehicles, such as the newly launched Mégane eVision. “As a result, thermal management for battery modules is essential to safety and long service life.”

Renault engineers have worked with DuPont Mobility & Materials to tackle several heat-related issues. For instance, they rely on Betatech thermal interface material to help safely manage and control heat from higher-density batteries during both charging and operation of EVs.

According to Le Borgne, this is accomplished by maintaining thermal conductivity through good contact with no gaps between the battery cells and the cooling plate over a wide operating temperature range. Betatech thermal interface material is available as a one-part or two-part dispensable thermal-conductive polyurethane product applied between the battery module and heatsink. It’s formulated for fast-dispensing in high-volume assembly environments.

Thermal management is essential to the safety and long service life of battery modules. Photo courtesy Renault Group

Cool Products

Another supplier helping EV automakers stay cool is Webasto Group, which has been developing new types of batteries and charging systems.

“The optimum temperature range for lithium-ion cells is between 10 and 45 C,” says Michael Poehner, manager of system engineering and battery systems at Webasto. “If the cell temperatures rise any higher, the battery’s aging process will accelerate at first. Temperatures well above 100 C could lead to dangerous situations, such as thermal runaway of the battery and, ultimately, self-ignition.

Poehner also warns that if the operating temperature drops well below 0 C, the maximum possible power output and power consumption (charging) decrease. “If such a cold battery is nevertheless charged with high power, lithium plating can occur,” he points out. “This causes metallic lithium to form and accumulate, which reduces the service life and, in extreme cases, could even lead to short circuits and fires.”

Webasto offers several products to tackle high temperatures. First, there’s the eBTM2.0 battery thermal management unit, which provides optimal cooling when battery packs are under stress or used during hot weather conditions.

This high-voltage coolant heater solves two problems in a single device. Photo courtesy BorgWarner Inc.

In addition, it delivers heat during extremely cold ambient conditions and sets the perfect temperature for battery cells during charging phases or before operation. The unit can also adjust the temperature during different driving phases, while plug-and-play installation is possible thanks to standardized connections.

Webasto’s eBTM thermal management system is specifically designed for use in commercial vehicles. Modular in design, it provides optimum temperature conditions for drivers, as well as components such as e-drives, traction battery packs and electronics. Within the system, thermal energy can be shared between the system components. Therefore, energy consumption is reduced, leading to vehicle range improvements of more than 25 percent.

A high-voltage heater (HVH) preheats batteries to get the most out of their performance. Thanks to efficient coating heating technology, it converts the stored electrical energy into heat with almost no loss and with an efficiency of more than 95 percent.

The new Zeekr 001 electric sedan features a high-voltage coolant heater to improve battery performance. Photo courtesy Zeekr Intelligent Technology Co.

Engineers at BorgWarner Inc. recently developed an advanced high-voltage coolant heater (HVCH) that will be used in the new Zeekr 001 electric sedan being produced in China by the Geely Auto Group. It solves two problems in a single device.

The HVCH helps improve range by controlling the battery temperature at an optimal level, while addressing passenger comfort by delivering an ideal interior climate. By offering consistent temperature distribution inside the battery pack and its cells, the heaters can also improve battery energy performance.

“HVCH technology was developed to meet the demand for fast-acting solutions as the thermal management systems of vehicles increasingly become decoupled from the internal combustion engine—permanently in the case of EVs and for longer parts of the drive cycle in hybrid electric vehicles,” says Joe Fadool, president and general manager of BorgWarnerv Emissions, Thermal and Turbo Systems.

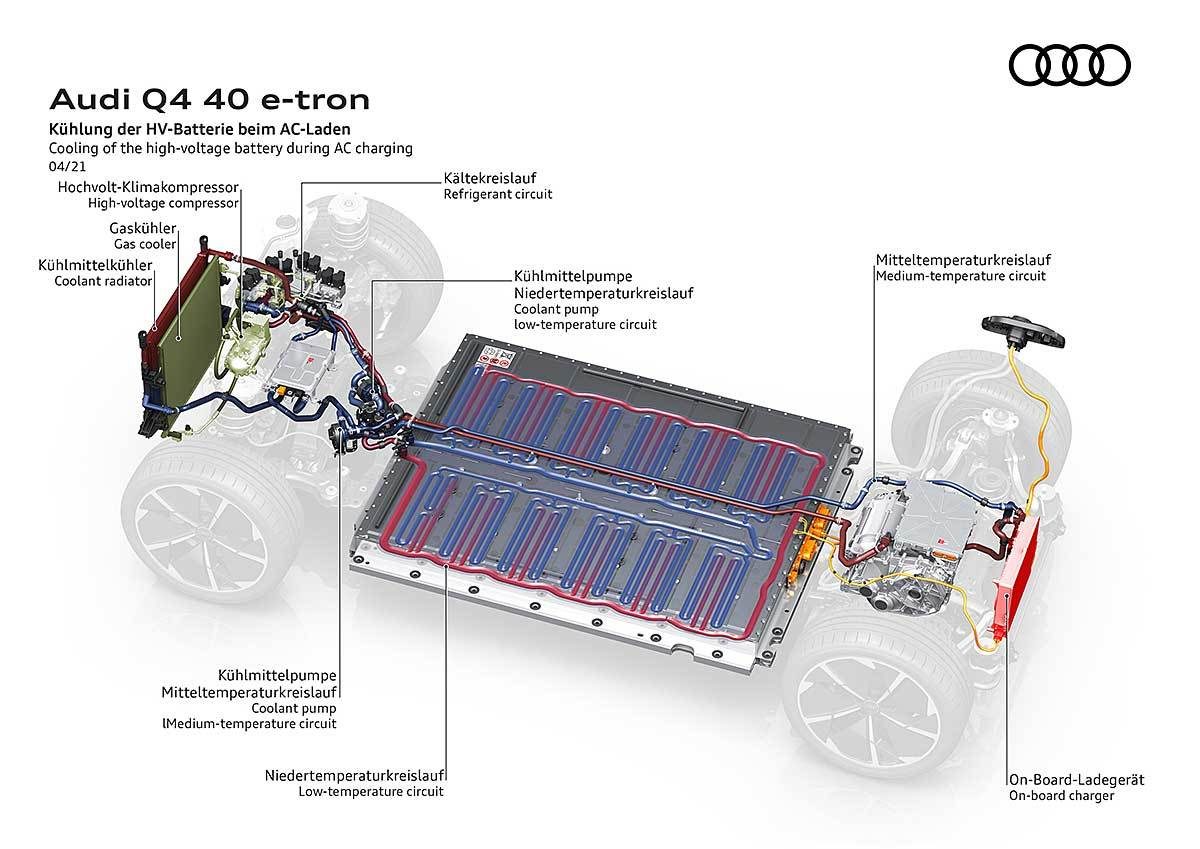

How Audi Tackles Heat

The lithium-ion battery system used in Audi’s e-tron GT quattro and RS e-tron GT relies on a complex thermal management system. It integrates 33 cell modules, each of which comprises 12 pouch cells with flexible outer skin. Each module is fitted with its own computer that monitors temperature and voltage.

The inner structure of the battery housing, the frame surrounding it and the upper cover plate are made of aluminum. Beneath the cell space of the battery, there is a compound structure of flat extruded sections through which a glycol-water mixture flows. The mixture circulates in its own low-temperature circuit.

The temperature is transferred between the cooling plates and the cell space via a heat-conducting paste. The battery’s optimal temperature is between 30 and 35 C, while its operating range extends from -30 C to 50 C.

Four separate coolant circuits, each at its own temperature level, regulate temperature in the high-voltage components precisely and quickly. They can be interconnected flexibly as required. If the driver demands a high output several times in a row, valves couple the coolant circuit of the battery with the refrigerant circuit of the air-conditioning system. This intensive cooling keeps the performance of the drive at a consistently high level.

The refrigerant circuit also helps with cooling during fast DC charging, which can heat the battery up to 50 C. The thermal management system is connected to the navigation system.

When the driver sets an HPC (high power charging) terminal as the destination, the cooling of the battery is already intensified on the way to the charging station so that it can be charged as quickly as possible. Should the battery still be very cold shortly after the car is started in winter, it is heated for fast charging.

Four separate coolant circuits regulate temperature in the high-voltage components. Illustration courtesy Audi AG

“In addition, it allows comfortable cabin temperatures to be generated in a short time, enabling a better driving and passenger experience,” claims Fadool. “With high thermal power density and fast response time due to their low thermal mass, these heaters also extend pure electric driving range as they use less power from the battery.”

The HVCH features state-of-the-art thick film element technology. Heating elements are immersed in coolant so that power losses are minimized. The technology also enables direct temperature sensing.

“The HVCH is available in two versions—single plate and dual plate—both integrated into robust aluminum housings that provide excellent electromagnetic shielding,” explains Fadool. “Suitable for applications with supply voltages between 180 and 800 volts, the HVCH offers a power range of 3 to 10 kilowatts. The devices are protected from overheating, as the system switches off automatically in the event of a failure occurring.”

Silver sintering technology can improve the thermal conductivity of electric vehicles. Illustration courtesy ESI Automotive

Immersion Cooling

M&I Materials Ltd. is leading the development of immersion-cooled battery technology. Project i-CoBat, which also involves Ricardo Ltd. and Warwick Manufacturing Group at the University of Warwick, hopes to create a novel approach to thermal management.

The core technology is a biodegradable dielectric fluid called MIVOLT. This fluid allows faster charging than conventional systems, as well as a higher performance EV battery. The liquid is environmentally friendly, cost effective and expected to have a long service life, with few maintenance requirements.

“With immersion cooling, we can get charging down to less than seven minutes for 200 miles in range: enough for you to plug in your EV, go and have a coffee, and have enough charge to be well on your way,” says Mark Lashbrook technical director at M&I Materials.

“Immersion cooling’s first application [will involve a luxury vehicle], but this project will also address the challenges of applying it to mainstream applications,” claims Lashbrook. “Validation of the new cooling concept and fluid will be achieved through modelling and testing against the current cold plate cooling method used widely in the automotive industry. In addition, testing will be conducted to evaluate the ability of immersion cooling with ester liquid to prevent thermal runaway within a battery module.”

Faraday Future’s FF 91 will use a liquid cell submerged onboard cooling system. Photo courtesy Faraday Future Intelligent Electric Inc.

M&I Materials has been working with engineers at Faraday Future Intelligent Electric Inc. on the startup company’s FF 91 luxury EV, which will feature a fully submerged battery cooling system. Production on the much-anticipated vehicle is scheduled to begin in July 2022 at a state-of-the-art factory in Hanford, CA.

MIVOLT’s advanced dielectric coolant materials will be used in Faraday Future’s patented liquid cell submerged onboard cooling system, which includes a self-contained and fail-safe architecture battery pack design.

“We are working with leading-edge technology partners to advance our technological innovations and MIVOLT continues to build on a reputation for innovative products and superior technical knowledge,” says Bob Kruse, senior vice president, product execution and vehicle engineering at Faraday Future.”

Immersion cooling can be used to decrease battery size and shorten charging times. Illustration courtesy Mahle GmbH

“[We] explored numerous cooling methods as [our] variable platform architecture was designed,” explains Kruse. “[We] eventually devised a fully submerged system where all major battery components are submerged in coolant.

“Battery cells perform their best at room temperature, but as they release or store energy, they tend to get hot,” Kruse points out. “Therefore, the cooling scheme becomes crucial to ensure top performance during the useful life of the vehicle. The coolant [we] chose is a nonconductive liquid with thermal properties that allows the battery pack to have uniform temperature across all its components.”

The cooling system also eliminates potential risk of corrosion, because all electrical components and their connections are submerged in the fluid. Faraday Future engineers reduced the spacing between cells and increased the total energy density of the pack so the coolant can flow freely.

It also provides a natural dampening effect relative to component vibration. The battery pack used in the FF 91 incorporates an innovative coolant flow design that enables each cell to be individually cooled.

Engineers at Mahle GmbH are also developing immersion cooling technology to allow faster vehicle charging.

“[Our] immersion cooling concept includes an electrically nonconductive coolant that flows around the cells,” says Martin Berger, vice president of corporate research and advanced engineering at Mahle. “This coolant ensures that the maximum temperature of the battery drops markedly during charging. As a result, the overall temperature is distributed much more homogeneously.

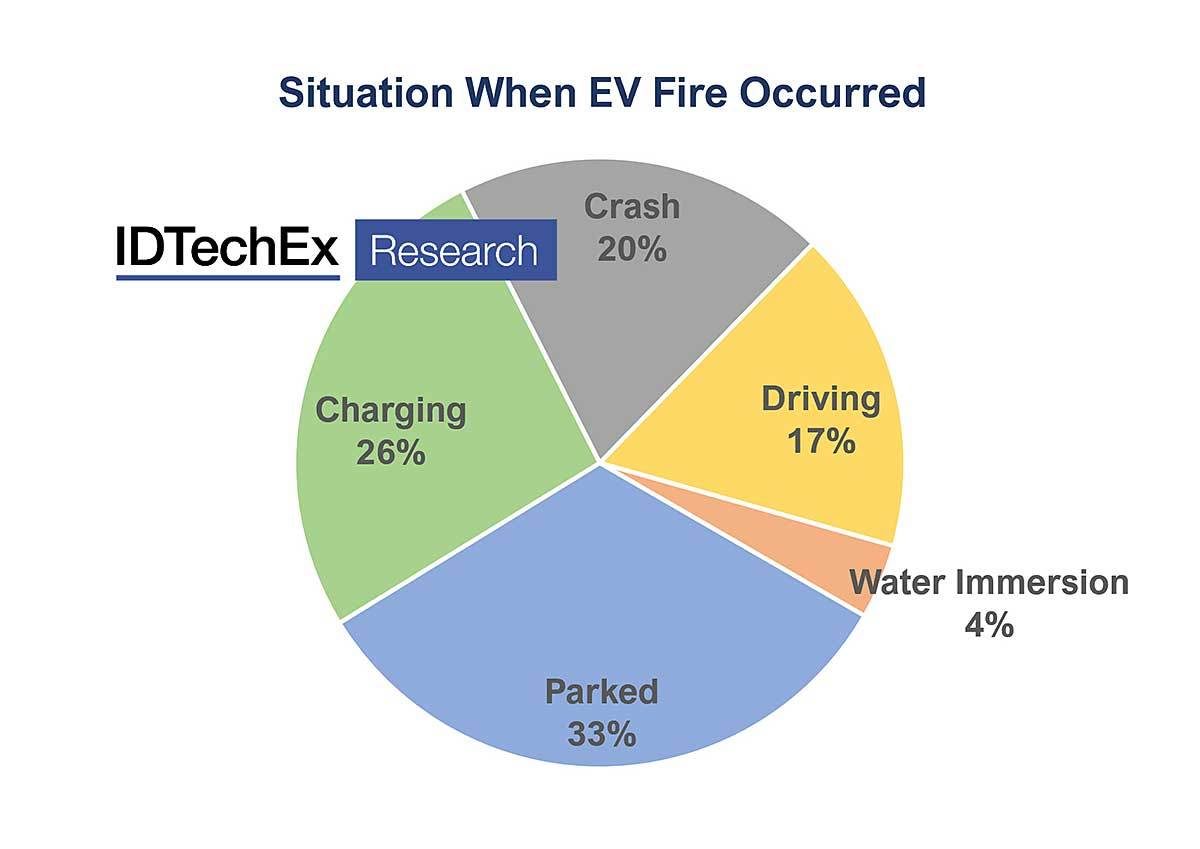

EV Fire Risk on the Road

A recent report from IDTechEx illustrates the risks posed by insufficient attention to and investment in EV thermal management technology.

While a fire might be expected after a crash or battery damage, one-third of EV fires occur when a vehicle is stationary. Fires also take place when batteries are not charging and often there is no obvious trigger.

This situation presents opportunities for component and materials suppliers, argues IDTechEx. Thermal interface materials, flame-retardant materials or fire protection materials all have a role to play.

Thermal interface materials, for example, can help with the thermal management of EV batteries, making it less likely they will overheat. Fire-retardant construction materials and fire protection materials are beneficial to enclose a fire or prolong the time between a thermal runaway event and the fire exiting the battery pack.

Illustration courtesy IDTechEx

“Immersion cooling paves the way for a whole new generation of battery systems,” claims Berger. “Because immersion cooling shortens the charging times in electric cars, batteries can be smaller. Therefore, electric cars can become cheaper and more resource-efficient.”

At the recent Battery Show in Novi, MI, ESI Automotive showcased a system that could also have a major impact on EV efficiency. The company uses silver sintering to help OEMs achieve up to a sixfold improvement in thermal conductivity of a die bond in an EV’s inverter.

The application uses ESI Automotive’s Alpha Argomax silver sintering technology, which helps improve vehicle performance and reduces production cost.

“Thermal conductivity is one area where silver sintering can make a difference in EVs,” says Chris Klok, director of vehicle electrification at ESI Automotive. “Research has shown that silver sintering can produce a bulk silver bond with a melting point of 962 C and extremely high thermal conductivity, in the range of 200 to 300 watts per meter-kelvin (W/m-K), compared with 26 to 55 W/m-K for solders.

“Argomax can improve efficiency by 40 percent and reduce die count and inverter weight by up to 75 percent and 34 percent, respectively,” claims Klok. “In addition, it can double the power density of a product, increase peak power and deliver reliable performance through 2 million power cycles.”

DECember 2021 | ASSEMBLYMAG.com

Scroll to

read full story