By Austin Weber // Senior Editor // webera@bnpmedia.com

New Battery Structure Could Lead to Safer Electric Vehicles

AV/EV tech trends

A new chemical process suppresses the growth of lithium dendrites in EV batteries. Illustration courtesy University of Maryland

Solid-state lithium-ion batteries offer a variety of benefits over alternatives. However, when these devices are operated at the high capacities and charging-discharging rates that electric vehicles demand, lithium dendrites grow toward the cathode side, causing short circuits and a decay in capacity.

To address the issue, engineers at the University of Maryland have developed a new technology that could enable next-generation EVs to be less prone to battery fires while increasing energy storage. Their process stops dendrite formation.

“We redesigned the interlayers [to] effectively suppress the lithium dendrite growth,” says Chunsheng Wang, Ph.D., a professor of chemical and biomolecular engineering at the University of Maryland. “It could open the door for production of viable all-solid-state batteries for EVs.”

The process is unique, because of the interfaces between the solid electrolyte and the anode and the electrolyte and the cathode. The new battery structure adds a fluorine-rich interlayer that stabilizes the cathode side, as well as a modification of the anode’s interlayer with magnesium and bismuth, which suppresses the lithium dendrite.

“Solid-state batteries are next-generation, because they can achieve high energy and safety,” explains Wang. “In current batteries, if you achieve high energy, you’ll sacrifice safety.”

However, Wang and his colleagues have a variety of challenges to solve before the product enters the market.

To commercialize all-solid-state batteries, the engineers will have to scale down the solid electrolyte layer to achieve a similar thickness to the lithium-ion batteries’ electrolyte, which will improve energy density. High costs of basic materials are another challenge.

Aiming to release the new batteries to the market by 2026, battery manufacturer Solid Power plans to begin trials of the new technology to assess its potential for commercialization. The company, which is working with BMW and Ford to develop solid-state batteries, recently opened a new 75,000-square-foot factory in Thornton, CO.

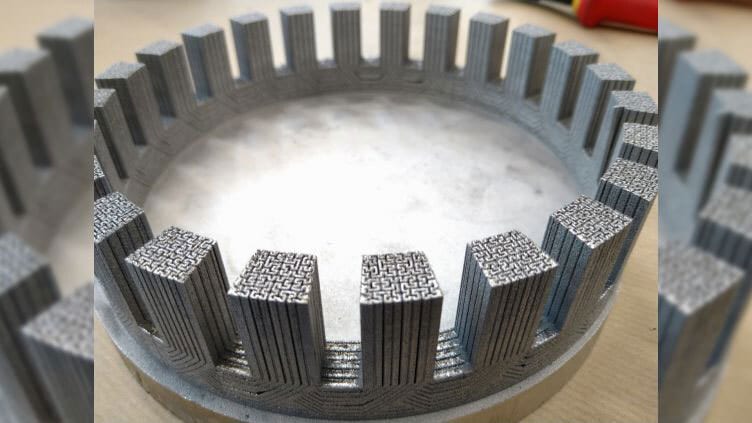

Electric Motor Features Printed Metal Parts

This motor stator was made with metal additive manufacturing technology. Photo courtesy University of Sheffield

To increase range and power, electric vehicles need to be lighter. One way to do that is by using new materials in motors and other components.

Engineers at the University of Sheffield and the University of Wisconsin-Madison recently developed a motor that features stators produced with additive manufacturing technology. It uses a higher-percentage silicon electrical steel that reduces energy losses.

The biggest design difference between the prototype and traditional stators can be seen in the prongs themselves—they feature an intricate design of thin geometric lines meant to reduce energy loss.

Traditional methods of creating stators in electric motors use a lamination process, where sheets of electrical steel are stamped out. That method, though easily replicated, tends to rely on using an electrical steel alloy with 3 percent silicon in it, which leads to higher rates of energy loss and less efficiency.

An electrical steel alloy made with 6.5 percent silicon, recommended by the U.S. Department of Energy, reduces energy losses but is more brittle and is less likely to withstand the traditional lamination process. However, with 3D printing, there’s no need for tons of pressure to be exerted during rolling and the machine can print the delicate pattern on the small 10-kilowatt prototype stator within 20 hours.

While that wouldn’t be enough energy to run an electric vehicle, the model could be easily scaled up to reach 40 kilowatts and printed faster on an industrial printer.

"This project has shown the large potential that additive manufacturing has for electrical machines, with lightweight, efficient structures that have never before been possible using any other manufacturing technique,” says Alexander Goodall, a doctoral student in the Department of Materials Science and Engineering at the University of Sheffield who worked on the motor.

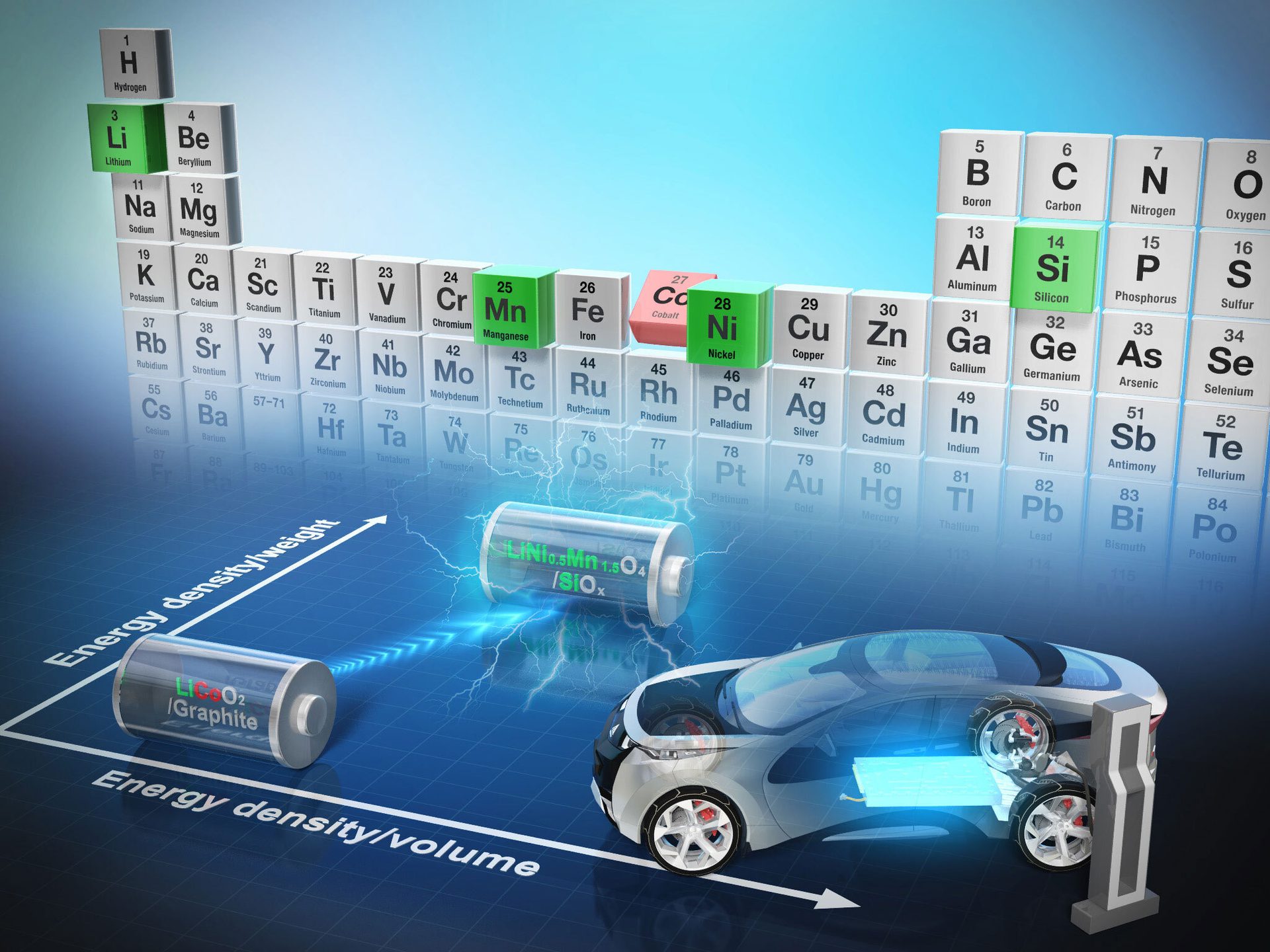

Cobalt-Free Battery Improves Energy Density

A viable alternative to cobalt can survive a large number of recharge cycles. Illustration courtesy University of Tokyo

Cobalt is an essential ingredient of lithium-ion batteries, but it’s also quite controversial, with a variety of environmental, economic and social issues. It’s a rare element that’s mined in the Democratic Republic of Congo. Many issues have been reported over the years about the environmental consequences of these mines, as well as the labor conditions there, including the use of child labor.

Engineers at the University of Tokyo have developed a viable alternative to cobalt that can survive a large number of recharge cycles. It uses a novel combination of elements in the electrodes, including lithium, nickel, manganese, silicon and oxygen—all far more common and less problematic elements to produce and work with than cobalt.

The new electrodes and electrolyte are not only devoid of cobalt, but they actually improve upon current battery chemistry in some ways. The new lithium-ion battery’s energy density is about 60 percent higher, which could equate to longer life, and it can deliver 4.4 volts, as opposed to 3.2 to 3.7 volts in typical batteries.

In addition, the new technology improves recharge characteristics. Test batteries with the new chemistry were able to fully charge and discharge more than 1,000 cycles (simulating three years of full use and charging), while only losing about 20 percent of their storage capacity.

“We are delighted with the results so far, but getting here was not without its challenges,” says Atsuo Yamada, Ph.D., a chemical engineering professor at the University of Tokyo. “It was a struggle trying to suppress various undesirable reactions that were taking place in early versions of our new battery chemistries.

“We still have some way to go, as there are lingering minor reactions to mitigate in order to improve the safety and longevity even further,” explains Yamada. “At present, we are confident that this research will lead to improved batteries for many applications. But some, where extreme durability and lifespan are required, might not be satisfied just yet.”

DECEMBER 2023 | ASSEMBLYMAG.com