Mack Begins Assembling Electric Trucks in Pennsylvania

NEWS

Mack Trucks has ramped up production of its first electric vehicle. Photo courtesy Mack Trucks Inc.

MACUNGIE, PA—Mack Trucks Inc.’s Lehigh Valley Operations facility here has ramped up production of the LR Electric. The company’s first fully electric Class 8 vehicle is designed for refuse haulers.

Equipped with four nickel manganese cobalt oxide lithium-ion batteries, the LR Electric is charged by a 150-kilowatt SAE J1772-compliant charging system. The batteries provide vehicle propulsion and power for all onboard accessories driven through 12-, 24- and 600-volt electric circuits. A three-mode regenerative braking system helps recapture the energy from the hundreds of stops the vehicle makes throughout the day.

The Mack LR Electric may be fitted with equipment bodies from numerous manufacturers based on each customer's needs. And, it features the same interior configurations as the traditional diesel-powered LR model. However, a copper-colored bulldog hood ornament, signifying the fully electric drivetrain, is featured prominently on the front of the truck.

“Mack has long been a leader in the refuse segment, and we couldn’t be more pleased to now be producing LR Electric vehicles to help our customers meet their sustainability goals,” says Jonathan Randall, senior vice president of sales and commercial operations at Mack Trucks. “Customer response to the [electric truck] has been overwhelmingly positive, and we look forward to putting more into fleet operations now that we are in production.”

Plastic Battery Enclosures Reduce Weight

Battery enclosure made from plastic are a lightweight substitute for traditional aluminum and steel housings. Photo courtesy Lanxess AG

COLOGNE, Germany—Engineers at Lanxess AG and Kautex Textron GmbH & Co. are developing plastic housings for high-voltage EV batteries. The goal of the R&D effort is to find a lightweight substitute for aluminum and steel that is cost effective, functional and electrically insulated.

Today, battery enclosures are primarily made out of extruded steel or aluminum profiles. Depending on the vehicle class, housings can be more than 6-feet long and 5-feet wide.

“The size, number of components and numerous manufacturing and assembly steps make metal housings very cost-intensive,” says Christopher Hoefs, Ph.D., e-power train project manager at Lanxess. “For example, complex structures made from strand press profiles require many secondary work steps, such as welding, punching and riveting. In addition, the metallic components must be protected against corrosion in an additional process step by cathodic dip coating.

“Plastics, on the other hand, can fully exploit their design freedom,” claims Hoefs. “By integrating functions, such as fasteners and thermal management components, the number of individual components of a battery housing can be greatly reduced. This simplifies assembly and logistical effort, which reduces production costs.

“Plastics are also corrosion-resistant and electrically insulating,” explains Hoefs. “The latter ensures that there is a reduced risk of the system short-circuiting. The low density of plastics and their potential for lightweight construction lead to significantly lighter housings, which benefits the range of electric vehicles.”

Battery housings must meet a variety of highly demanding technical requirements. For example, they must be stiff and strong, yet be able to absorb a significant amount of energy in the event of a crash. Enclosures must also be flame-retardant in the event of a vehicle fire or thermal run-away of the electrical cells. In addition, battery housings must be integrated into the vehicle structure.

The prototype plastic enclosure is based on the battery housing of a C-segment, or midsized, electric vehicle. It consists of a tray with crash structure, a cover and underbody protection. The housing’s components can be produced in a single-stage direct long fiber thermoplastic molding process.

“As a first step, we have completely dispensed with the use of metallic reinforcement structures while proving we can commercially produce these complex large components,” says Felix Haas, director of product development at Kautex Textron. “Going forward, [we] want to enter into development projects for series production with automotive manufacturers.”

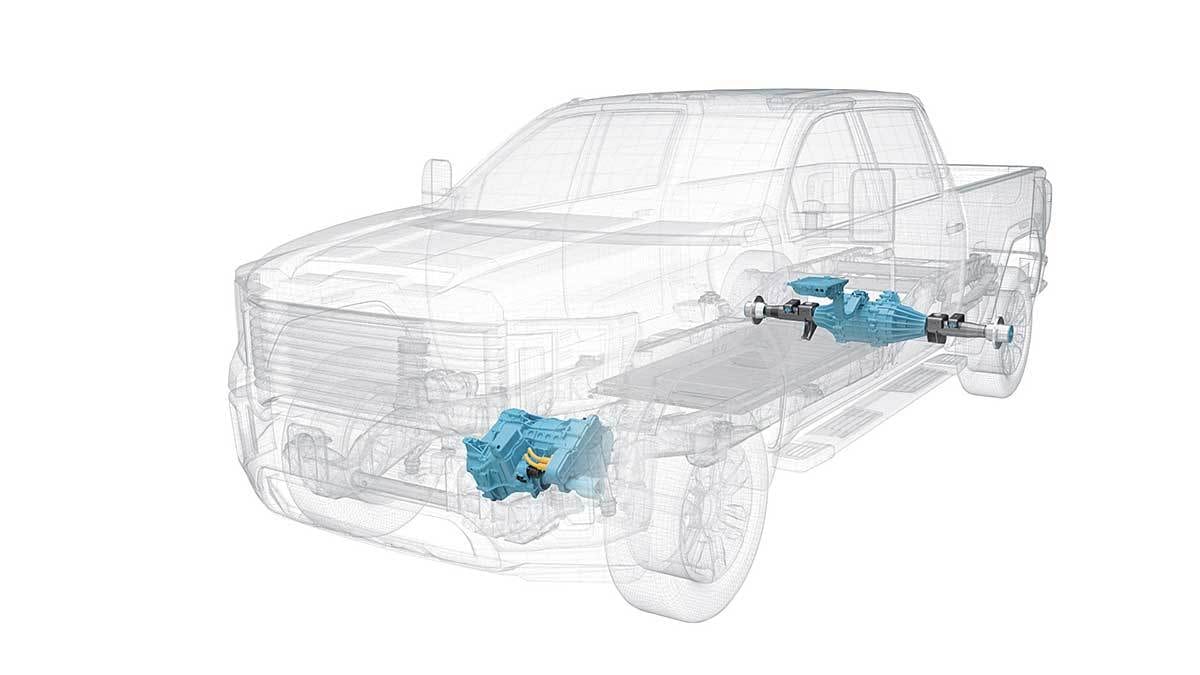

Magna Develops Four-Wheel Drive EV Power Train

EtelligentForce is a four-wheel drive electric power train system for pickup trucks and light commercial vehicles. Illustration courtesy Magna International Inc.

AURORA, ON—Magna International Inc. has developed a four-wheel drive electric power train system for pickup trucks and light commercial vehicles. EtelligentForce is designed to maintain full vehicle capabilities without compromising payload or towing capacities.

EtelligentForce features Magna’s eDrive technology at the front and its eBeam electrified beam axle at the rear. It is designed for high-payload vehicles capable of towing up to 14,500 pounds, which is comparable to traditional internal combustion engine (ICE) trucks. It provides a total peak power of up to 430 kilowatts from the rear eBeam and 180 kilowatts from the front eDrive. The eBeam will also replace traditional beam axles and accommodates existing suspension and brake systems, which will enable OEMs to avoid the need to redesign existing truck platforms.

“These benefits [will] help automakers simplify the transition toward electrification of these vehicle segments,” says Tom Rucker, president of Magna Powertrain. “With fewer moving parts than a traditional ICE power train, the EtelligentForce requires less maintenance, a direct benefit to truck owners over the life of the vehicle.

“EtelligentForce comes at a pivotal time—particularly in the North American auto industry, where pickup trucks are at their height of popularity and one of the last segments to become fully electric,” explains Rucker. “The beauty of this powerful system is that it delivers the environmental benefits of an electric power train while maintaining the capability and utility of conventional trucks.”

John Deere Plans to Produce an Autonomous Tractor

John Deere plans to begin assembling autonomous tractors later this year. Photo courtesy Deere & Co.

MOLINE, IL—Deere & Co. plans to begin assembling a driverless tractor later this year at its flagship factory in Waterloo, IA. The machine, based on the company’s popular 8R row crop tractor, will feature a GPS guidance system and advanced autonomous technologies designed for plowing and tilling applications.

Six pairs of stereo cameras will enable 360-degree obstacle detection and the calculation of distance. Images captured by the cameras will be passed through a deep neural network that classifies each pixel in approximately 100 milliseconds and determines if the machine continues to move or stops, depending on if an obstacle is detected. The autonomous tractor will continuously check its position relative to a geofence—ensuring it is operating where it is supposed to—accurate to within less than 1 inch.

While the machine is working, farmers will be able to leave their field to focus on other tasks while monitoring the machine’s status from a mobile device. The John Deere Operations Center will provide access to live video, images, data and metrics that will enable farmers to adjust performance variables such as speed.

Audi EVs Tackle the Dakar Rally

A team of Audi RS Q e-trons recently competed in the grueling Dakar Rally. Photo courtesy Audi AG

RIYADH, Saudi Arabia—The Dakar Rally is one of the most famous off-road races in the world. The two-week event in early January is held among huge sand dunes and desert terrain.

Several electric vehicles tackled this year’s grueling event, including a team of Audi RS Q e-trons. The automobile class is one of five vehicle categories alongside dune buggies, motorcycles, quads and trucks.

“The Dakar Rally is the biggest conceivable challenge for our innovative electric drive with high-voltage battery and high-efficiency energy converter,” says Julius Seebach, managing director of Audi Sport GmbH. “Never before have we [developed] such a complex vehicle in such a short time. Our first endurance test under competitive conditions is the world’s longest and most demanding rally.”

All three RS Q e-tron cars completed the 2022 Dakar Rrally, which covered approximately 24,000 kilometers. They competed in the new T1 Ultimate class for low-emission vehicles.

“Our driver teams won four stages and clinched a total of 14 podium results in the daily classifications,” explains Seebach. “This clearly [exceeded] our expectations. Audi is thus the first team to achieve a stage victory with an electric drive concept. After this performance, overall victory at the next Dakar Rally is our goal.”

Doosan Bobcat Unveils All-Electric Compact Machine

A fully electric compact track loader eliminates hydraulics and noise associated with traditional diesel-powered construction equipment. Photo courtesy Doosan Bobcat Inc.

LAS VEGAS—Doosan Bobcat Inc. has unveiled a new all-electric compact track loader. The T7X is the first machine of its kind to fully eliminate all hydraulics and components. It provides the same power and performance associated with traditional diesel-powered machines.

The fully electric machine features a 62-kilowatt lithium-ion battery and operates with zero emissions, reduced sound levels, limited vibrations and lower daily operating costs. Its power management system is programmed to sense when loads are increasing, automatically backing off power when not needed to preserve total energy use and extend the machine’s runtime.

Traditional hydraulic components have been completely replaced with a drive system that consists of electric cylinders and electric drive motors. The machine also uses only one quart of eco-friendly coolant compared to 57 gallons of fluid in its diesel-hydraulic equivalent counterpart.

The all-electric platform enables instantaneous power and peak torque available at every operating speed. Operators no longer have to wait for the standard hydraulic system to build up power.

“This machine is a technological feat for Bobcat and for the entire industry,” says Joel Honeyman, vice president of global innovation at Doosan Bobcat. ”We challenged the status quo to deliver a connected, all-electric machine designed for power and performance that previously was not possible. We are excited to share this advancement with the world and proud of the hard work that has gone into making this a reality.”

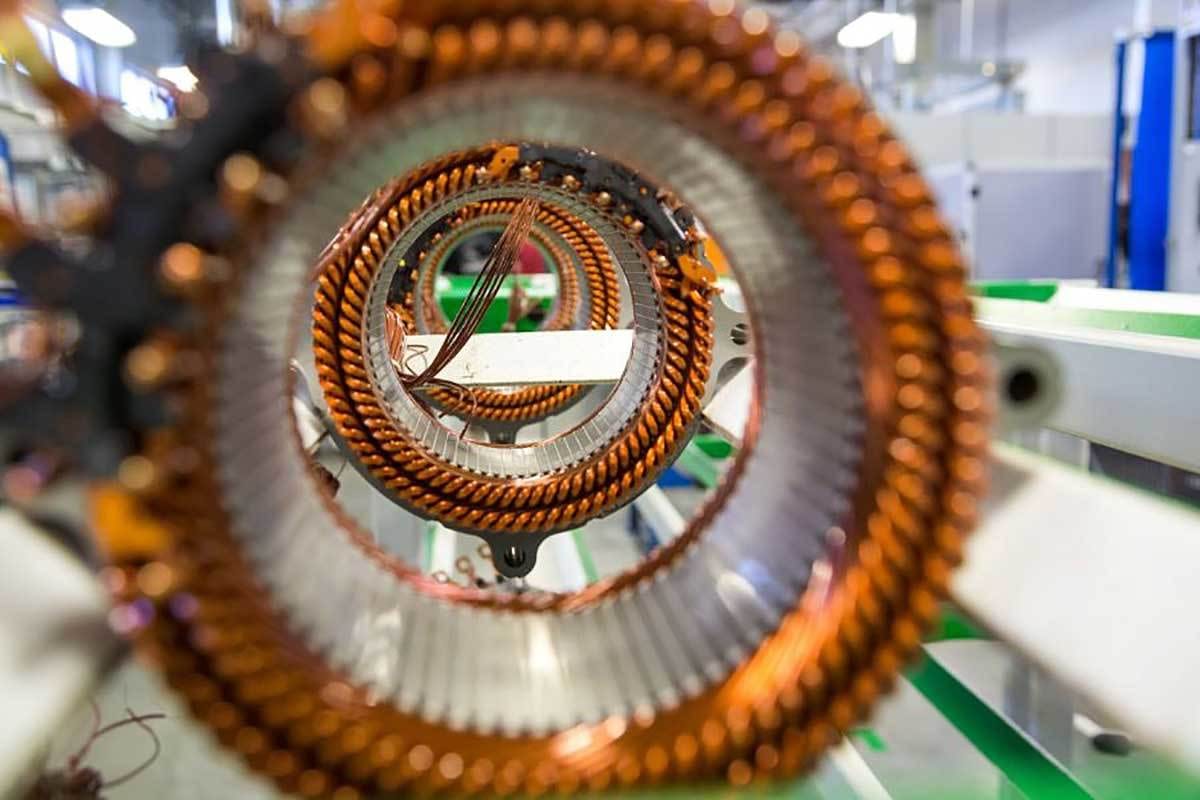

Steel Shortage Could Thwart EV Production Plans

In a few years, there could be a shortage of steel needed to make motor and other EV components. Photo courtesy General Motors

SOUTHFIELD, MI—While major steel producers are investing millions to increase electrical steel production capacity, the rapid growth of the hybrid and electric vehicle segment could potentially cause material demand to outpace supply from 2025, claims a new report from IHS Markit.

As the automotive industry battles the semiconductor shortages, which have prevented the production of more than 9 million units, the rapid expansion in growth of EV sales raises questions about the future availability of sufficient electrical steel needed to produce electric motors to meet the electrification targets set by regulators and OEMs around the globe.

Electrical steel, or silicon steel, is an iron-silicon alloy that possesses superior magnetic properties to other types of steel alloys, making it optimized for a variety of electrical machines ranging from power and distribution transformers to electric motors.

While electrical steel is estimated by IHS Markit to account for only 1 percent of the 2 billion metric ton 2020 global steel market, its supply is being considered as an increasingly critical input to OEMs' electrification plans, as well as various energy transition initiatives.

The commercial electrical steel market is divided in two major categories: grain-oriented electrical steel (GOES) and non-oriented electrical steel (NOES). GOES is used in static machinery, such as transformers, which require unidirectional magnetization, while NOES is used in rotating machinery like motors and generators, which require multidirectional magnetization.

GM to Offer EV Components to Commercial Customers

General Motors will supply batteries, motors and other components needed to electrify baggage tractors and belt loaders used at airports. Photo courtesy Textron Ground Support Equipment Inc.

DETROIT—General Motors is adopting an “everybody in” approach to electric vehicle technology. As part of the initiative, it plans to market EV components to commercial customers, including companies that manufacture off-highway vehicles such as airport ground support equipment.

“GM has an established strategy, network of integrators and co-development agreements to apply an extensive array of components and solutions to a broad range of customers and use cases,” says Travis Hester, vice president of electric vehicle growth operations. “As companies across many industries look to reduce their environmental impact, [we are] uniquely positioned to serve as a leader not only through exciting new EVs across our brands, but through additional technology applications, and we look forward to bringing customers—existing and new—along with us on our zero-emissions journey.”

According to Hester, the total addressable market for electrification components could near $20 billion by 2030, as a growing number of industries introduce their own emissions reduction goals.

GM has already formed a strategic partnership with Textron Ground Support Equipment Inc. that will provide batteries, motors and other components needed to electrify the company’s line of baggage tractors, cargo tractors and belt loaders, which are used at airports around the world.