BYD Is Now World’s Largest EV Manufacturer

NEWS

BYD Auto Co. has surpassed Tesla Inc. to become the world’s largest manufacturer of electric vehicles. Photo courtesy BYD Auto Co.

NEW YORK—According to Statistica Inc., BYD Auto Co. has surpassed Tesla Inc. to become the world’s largest manufacturer of electric vehicles. In 2024, Tesla made 1,774,442 EVs vs. BYD’s 1,777,965.

During the fourth quarter of 2024, China’s No. 1 car brand out produced Tesla by almost 150,000 vehicles. The automaker is a division of BYD Group, a Shenzhen-based conglomerate that also dabbles in electronics, rail transit and renewable energy.

BYD, an acronym for “Build Your Dreams,” has been China’s largest EV producer for several years. It is currently taking the European market by storm, offering five models, including sedans, hatchbacks and sport utility vehicles.

The company, which operates several assembly plants in China, recently opened a factory in Thailand and is currently building a facility in Hungary (the first plant in Europe by a Chinese automaker).

BYD plans to build a similar facility in Mexico sometime in the near future. The company has operated an electric bus factory in Lancaster, CA, for several years.

NHTSA Proposes National Program for Vehicles with Automated Driving Systems

The NHTSA has proposed a voluntary national framework for the evaluation and oversight of vehicles equipped with automated driving systems. Photo by Austin Weber

WASHINGTON—The National Highway Traffic Safety Administration (NHTSA) has proposed a voluntary national framework for the evaluation and oversight of certain vehicles equipped with automated driving systems (ADS).

The ADS-equipped Vehicle Safety, Transparency, and Evaluation Program (AV STEP) would establish a voluntary review and reporting framework for participating ADS-equipped vehicles. The program would be open to all companies that operate or plan to operate compliant ADS-equipped vehicles on public roads, as well as those requiring NHTSA exemptions to operate non-compliant vehicles.

“AV STEP would provide a valuable national framework at a pivotal time in the development of ADS technology,” says Adam Raviv, chief counsel at NHTSA. “Safe, transparent and responsible development is critical for this technology to be trusted by the public and reach its full potential. This proposal lays the foundation for those goals and supports [our] safety mission.

According to Ravid, this enhanced transparency would promote the responsible development of ADS technology, as well as offer a way for vehicle manufacturers, operators, municipalities, researchers and policymakers to benefit from greater opportunities for public awareness and accelerated learning into the technology. Under AV STEP, NHTSA’s assessment of an application would be informed by the views of an independent third-party assessor.

Archer Aviation Completes Construction of Air Taxi Assembly Plant

Archer Aviation is ramping up production at its new factory in Georgia. Photo courtesy Archer Aviation Inc.

COVINGTON, GA—Archer Aviation Inc. has received the certificate of occupancy for its new 400,000-square-foot assembly plant here. The start-up air taxi company Archer is now installing tooling and equipment at the facility, which is located next to Covington Municipal Airport. Production is planned to begin in early 2025, with the goal of ramping up to a rate of two aircraft per month by the end of the year.

Archer built the facility in close partnership with Stellantis, and the two companies are continuing to progress their plans to mass-produce Archer’s Midnight aircraft. Stellantis is contributing capital, advanced manufacturing technology and expertise and experienced personnel with a goal of scaling up production to 650 aircraft annually by 2030.

“The completion of this facility is a testament to the state of the industry—shifting from R&D into commercialization,” says Adam Goldstein, CEO of Archer. “With construction now complete, our team is focused on the start of production planned for early next year.

“From there, it’s all about execution and scaling,” notes Goldstein. “I’m incredibly proud of the Archer team and our partners for getting this done so fast and on budget, and can’t wait to see our facility begin producing aircraft.”

“Supporting Archer’s electric aircraft growth with our deep manufacturing expertise is a great opportunity for the two companies,” adds Arnaud Deboeuf, chief manufacturing and supply chain officer at Stellantis. “Congratulations to the Archer team for this milestone. It is a significant step in our journey together as we take clean mobility to the sky.”

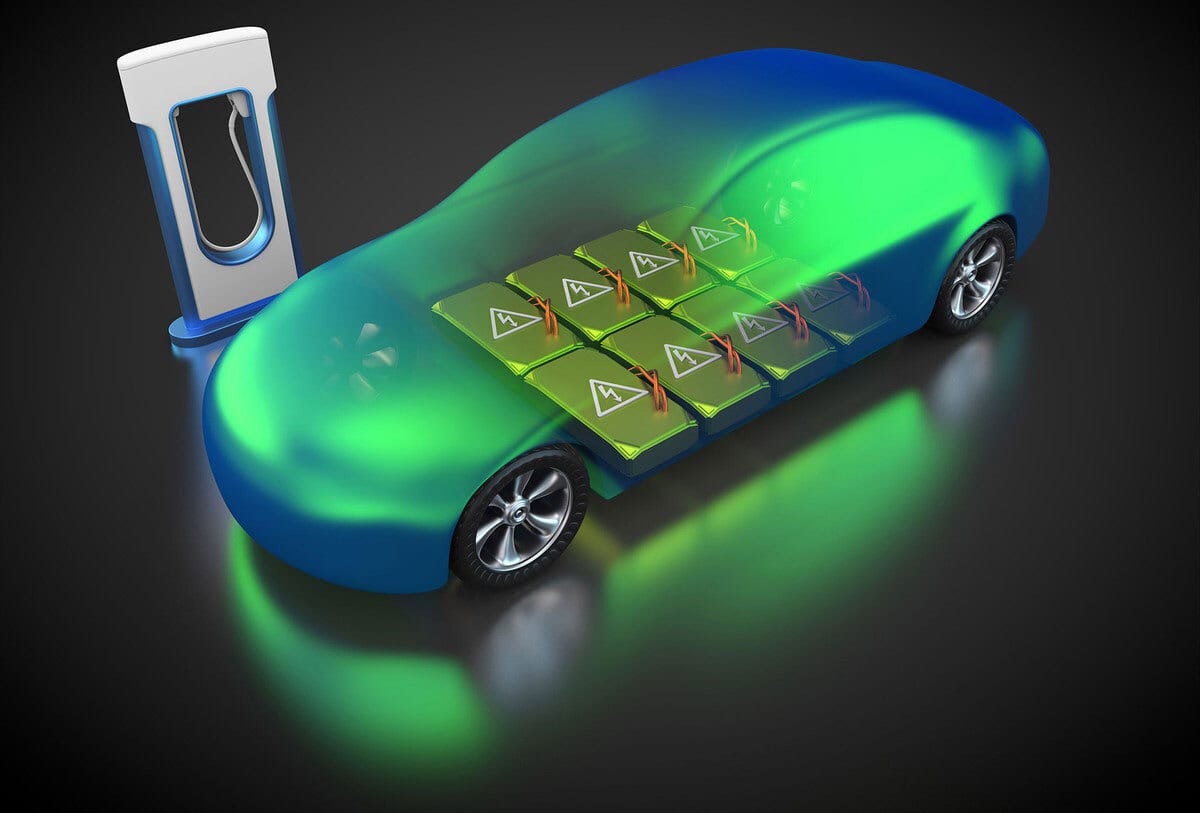

EV Batteries May Last Longer Than Expected

Electric vehicle batteries may last up to 40 percent longer than expected. Photo courtesy SLAC-Stanford Battery Center

PALO ALTO, CA—Electric vehicle batteries may last up to 40 percent longer than expected, according to a new study conducted by the SLAC-Stanford Battery Center. Real-world stop-and-go driving actually benefits EV batteries more than the steady use simulated in many laboratory tests of new battery designs. In fact, batteries subjected to heavy traffic, long highway trips and short local trips could last about one-third longer than researchers have generally forecast.

Traditionally, engineers have tested the cycle lives of new battery designs in labs using a constant rate of discharge followed by recharging. They repeat this cycle rapidly many times to learn quickly if a new design is good or not for life expectancy, among other qualities.

“We have not been testing EV batteries the right way,” says Simona Onori, Ph.D., an associate professor of energy science and engineering at Stanford University. “To our surprise, real driving with frequent acceleration, braking that charges the batteries a bit, stopping to pop into a store and letting the batteries rest for hours at a time, helps batteries last longer than we had thought based on industry standard lab tests.”

Onori and her colleagues designed four types of EV discharge profiles, from standard constant discharge to dynamic discharging based on real driving data. They tested 92 commercial lithium-ion batteries for more than two years across various discharge profiles. In the end, the more realistically the profiles reflected actual driving behavior, the higher EV life expectancy climbed.

According to Onori, several factors contribute to this unexpected longevity. For example, there’s a correlation between sharp, short EV accelerations and slower degradation. This is contrary to long-held assumptions of battery engineers that acceleration peaks are bad for EV batteries.

“Pressing the pedal with your foot hard does not speed up aging,” explains Onori. “If anything, it slows it down.”

February 2025 | ASSEMBLYMAG.com