By Austin Weber, Senior Editor

New Process Enables Fast, Low-Cost Battery Production

AV/EV tech trends

A new fabrication technique could make solid-state batteries using production facilities and infrastructure developed for lithium-ion. Photo courtesy Georgia Institute of Technology

Solid-state batteries appeal to automotive engineers searching for a more powerful, lighter, less expensive and safer alternative to lithium-ion chemistries. But, the EV industry is still seeking a breakthrough that would enable manufacturers to use their existing production facilities and infrastructure.

Engineers at the Georgia Institute of Technology believe a new fabrication technique could allow solid-state batteries to adopt nonflammable ceramic electrolytes using the same production processes as batteries made with conventional liquid electrolytes. They have developed melt-infiltration technology that uses electrolyte materials that can be infiltrated into porous yet densely packed, thermally stable electrodes.

“The one-step process produces high-density composites based on pressureless, capillary-driven infiltration of a molten solid electrolyte into porous bodies, including multilayered electrode-separator stacks,” says Gleb Yushin, a professor of materials science and engineering at Georgia Tech. “While the melting point of traditional solid-state electrolytes can range from 700 C to over 1,000 C, we operate at a much lower temperature range.

“Depending on the electrolyte composition, [this would be] roughly 200 to 300 C,” explains Yushin. “At these lower temperatures, fabrication is much faster and easier. Materials at low temperatures don’t react. The standard electrode assemblies, including the polymer binder or glue, can be stable in these conditions.”

According to Yushin, the new production technique could allow large automotive-grade batteries to be safely made with 100 percent solid-state nonflammable ceramic. As a result, high-quality multi-layered cells of any size or shape could be rapidly manufactured at scale using proven tools and processes developed over the last 30 years for lithium-ion batteries.

“Melt-infiltration technology is the key advance,” claims Yushin. “The cycle life and stability of lithium-ion batteries depend strongly on the operating conditions, particularly temperature.”

If batteries are overheated for a prolonged period, they commonly begin to degrade prematurely, and overheated batteries may catch on fire. That has prompted nearly all EVs to include complex, expensive cooling systems. In contrast, Yushin says solid-state batteries may only require heaters, which are significantly less expensive than cooling systems.

Last year, battery cell prices hit $100 per kilowatt hour for the first time. But, they will need to drop below $70 per kilowatt hour before the consumer EV market can fully blossom. Yushin and his colleagues are currently developing other electrolytes that will have lower melting points and higher conductivities that promise to help drive down production costs.

“So many incredibly smart scientists are focused on solving very challenging problems while completely ignoring economic and technical practicality,” notes Yushin. “They are studying and optimizing very high-temperature electrolytes that are not only dramatically more expensive to use in cells, but are also up to five times heavier compared with liquid electrolytes. My goal is to push the research community to look outside that chemical box.”

Army R&D Advances Autonomous Off-Road Navigation

Autonomous vehicles are learning how to traverse off-road environments that are unpredictable and constantly changing. Photo courtesy Army Research Laboratory

Soldiers navigate a wide variety of terrain to successfully complete their missions. As artificial intelligence and sensor technology advances, the same flexibility will be required for autonomous vehicles to maneuver across diverse landscapes.

Existing autonomy data sets either represent urban environments or lack multimodal off-road data. To address the issue, engineers at the Army Research Laboratory have developed a system that provides the resources needed to develop more advanced algorithms that enhance robotic navigation.

As part of RELLIS-3D research conducted for the lab’s Artificial Intelligence for Maneuver and Mobility program, they have created the data needed for autonomous vehicles to traverse rugged environments with characteristics similar to those encountered on battlefields.

“Autonomous navigation systems that rely solely on lidar lack higher-level semantic understanding of the environment that could make path planning and navigation more efficient,” says Maggie Wigness, Ph.D., a computer scientist at the U.S. Army Combat Capabilities Development Command. “Urban environments provide many structural cues, such as lane markings, crosswalks, traffic signals, roadway signs and bike lanes, that can be used to make navigation decisions. These decisions often need to be in alignment with the rules of the road.

“These structured markings are designed to cue the navigation system to look for something such as a pedestrian in a crosswalk, or to adhere to a specification such as stopping at a red light,” explains Wigness. “In off-road environments, this is not necessarily the case, which can cause a much more significant class imbalance than those seen in urban datasets.”

Off-road data sets contain non asphalt surfaces that present completely different traversability characteristics than roadways. For example, Wigness says an autonomous vehicle might have to decide between navigating through grass, sand or mud, any of which could present challenges. Tall grass vs. short grass is also very different in terms of traversability, with tall grass potentially hiding unseen obstacles, holes or other hazards.

Additionally, while roadway driving is not universally flat, for the most part roads are relatively smooth and flat. In sharp contrast, off-road driving can contain uneven hills and sudden drops, and there are a larger number of potentially dangerous conditions that could cause unsafe decisions from a navigation planner.

“These sudden and constant changes in terrain require an off-road navigation system to constantly re-evaluate its planning and control parameters,” warns Wigness. “This is essential to ensure safe, reliable and consistent navigation.”

RELLIS-3D provides data that can be used to evaluate navigation algorithms, including SLAM (simultaneous localization and mapping), in challenging off-road conditions, such as climbing and then descending a large hill. It also provides annotated lidar and camera data that can be used to train machine learning networks to better understand the terrain conditions in front of a robot, which can facilitate improved path planning based on semantic information.

Two years ago, Wigness and her colleagues released a data set called Robot Unstructured Ground Driving (RUGD). It is comprised of annotations for imagery only, but was designed to provide the necessary resources to get academic and industry researchers thinking about perception for autonomous navigation in off-road and unstructured environments.

“RELLIS-3D takes the next step by publicly providing an entire sensor suite of data for off-road navigation,” says Wigness. “This allows [us] to leverage multimodal data for algorithm development. It can also be used to evaluate mapping, planning and control, in addition to perception components.”

New Material Is Next Step Toward Sodium-Ion Batteries

Sodium-ion batteries may become popular in the future, because unlike lithium, sodium is inexpensive and readily available. Engineers at the University of California San Diego have been coordinating a research project that is studying the technology.

They recently designed and manufactured a new sodium-ion conductor for solid-state batteries that is stable when incorporated into higher-voltage oxide cathodes. The new solid electrolyte could dramatically improve the efficiency and life span of this class of batteries.

A proof-of-concept battery built with the new material lasted more than 1,000 cycles while retaining 89 percent of its capacity—a performance unmatched by other solid-state sodium batteries to date.

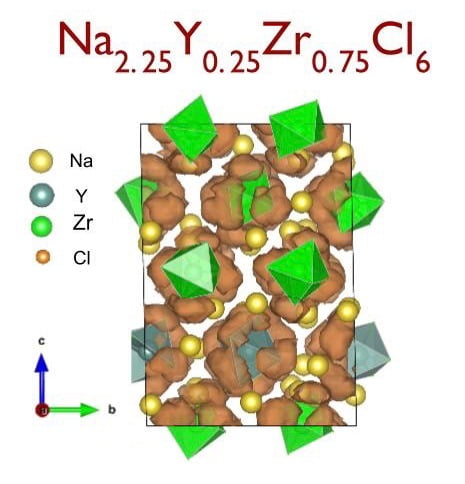

The engineers developed a class of halide sodium conductors made up of sodium, yttrium, zirconium and chloride. The material, which they named NYZC, is both electrochemically stable and chemically compatible with the oxide cathodes used in higher voltage sodium-ion batteries.

“NYZC is based on Na3YCl6, a well-known material that is unfortunately a very poor sodium conductor,” says Shyue Ping Ong, Ph.D., a professor of nanoengineering. One of his colleagues suggested substituting zirconium for yttrium because it would create vacancies and increase the volume of the cell battery unit—two approaches that increase the conduction of sodium ions.

New materials could enable sodium-ion batteries to be safer, cheaper and longer lasting that lithium-ion alternatives. Illustration courtesy University of California San Diego

“In conjunction with the increased volume, a combination of zirconium and chloride ions in this new material undergoes a rotating motion, resulting in more conduction pathways for the sodium ions,” explains Ong. “In addition to the increase in conductivity, the halide material is much more stable than materials currently used in solid-state sodium batteries.

“These findings highlight the immense potential of halide-ion conductors for solid-state sodium-ion battery applications,” claims Ong. “It also highlights the transformative impact that large-scale material data computations coupled with machine learning can have on the materials discovery process.

“Next steps include exploring other substitutions for these halide materials and increasing the battery’s overall power density, along with working to scale up the manufacturing process,” adds Ong.

may 2021 | ASSEMBLYMAG.com

ASB-AEM // May 2021