Fast-paced competition will improve the breed and lead to new technology.

Racing Into the Future

By Austin Weber, Senior Editor

Formula E is the oldest and most prestigious form of electric car racing. Photo courtesy BMW AG

Traditionally, early summer is when the motor sports world shifts into high gear. May is the month when some of the crown jewels on the annual motor racing calendar take place, including the Indianapolis 500 and the Monaco Grand Prix. And during June, speed enthusiasts annually anticipate classic events such as the LeMans 24-hour sports car race and the Isle of Man motorcycle road race.

For decades, motor racing has been the best way to improve the breed, develop new technology and debut cutting-edge ideas, not to mention “sell metal.” Today, as the age of the internal combustion engine begins to wane, a variety of electric-powered racing series are on the horizon. They promise to push the technical envelope while testing the skill of competitors.

As automakers and suppliers shift their focus to autonomous and electric vehicles, technology tested extensively under the pressures of the racetrack will play a key role in solving complex electrification challenges.

Many companies view motor racing as a test bed for next-generation technology, with tangible applications in future AVs and EVs. It’s a time-proven way for engineers to test new materials, reduce weight, improve heat and thermal management, and make vehicles safer.

“Being at the forefront of motor sports technologies requires a continuous drive for innovation, based on a constant search for the most efficient materials and solutions,” says Riccardo De Filippi, senior vice president and CEO of Marelli Motorsport, which has deep roots in racing that stretch back more than 100 years. “Our mission is to promote technological advancements that can first of all be decisive on racetracks, and at the same time enable next-generation technologies for the road cars of tomorrow.”

As a result of its involvement in motor racing, Marelli recently developed a new power module that is based on silicon carbide (SiC) technology. The EDI (enhanced direct-cooling inverter) module features an innovative structural design that reduces the thermal resistance between the SiC components and the liquid coolant. The new technology enables conversion efficiencies of up to 99.5 percent, a 50 percent reduction in weight and size, and 50 percent higher heat dissipation.

Here’s a brief look at 10 fast-paced racing series that will push the envelope for autonomous and electric vehicles on land, sea and air.

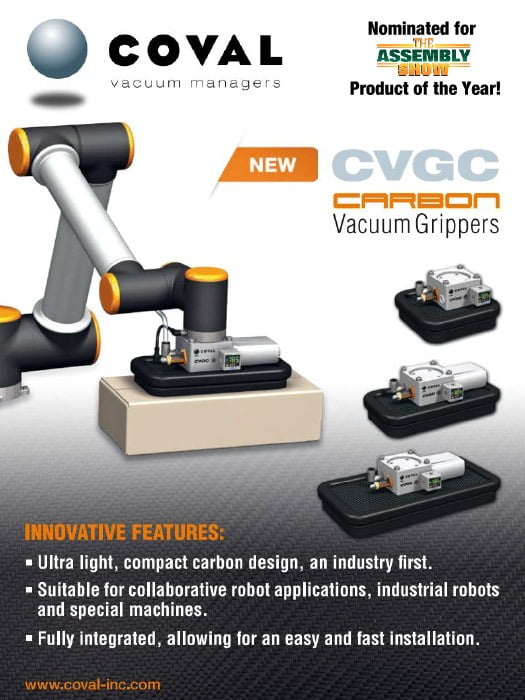

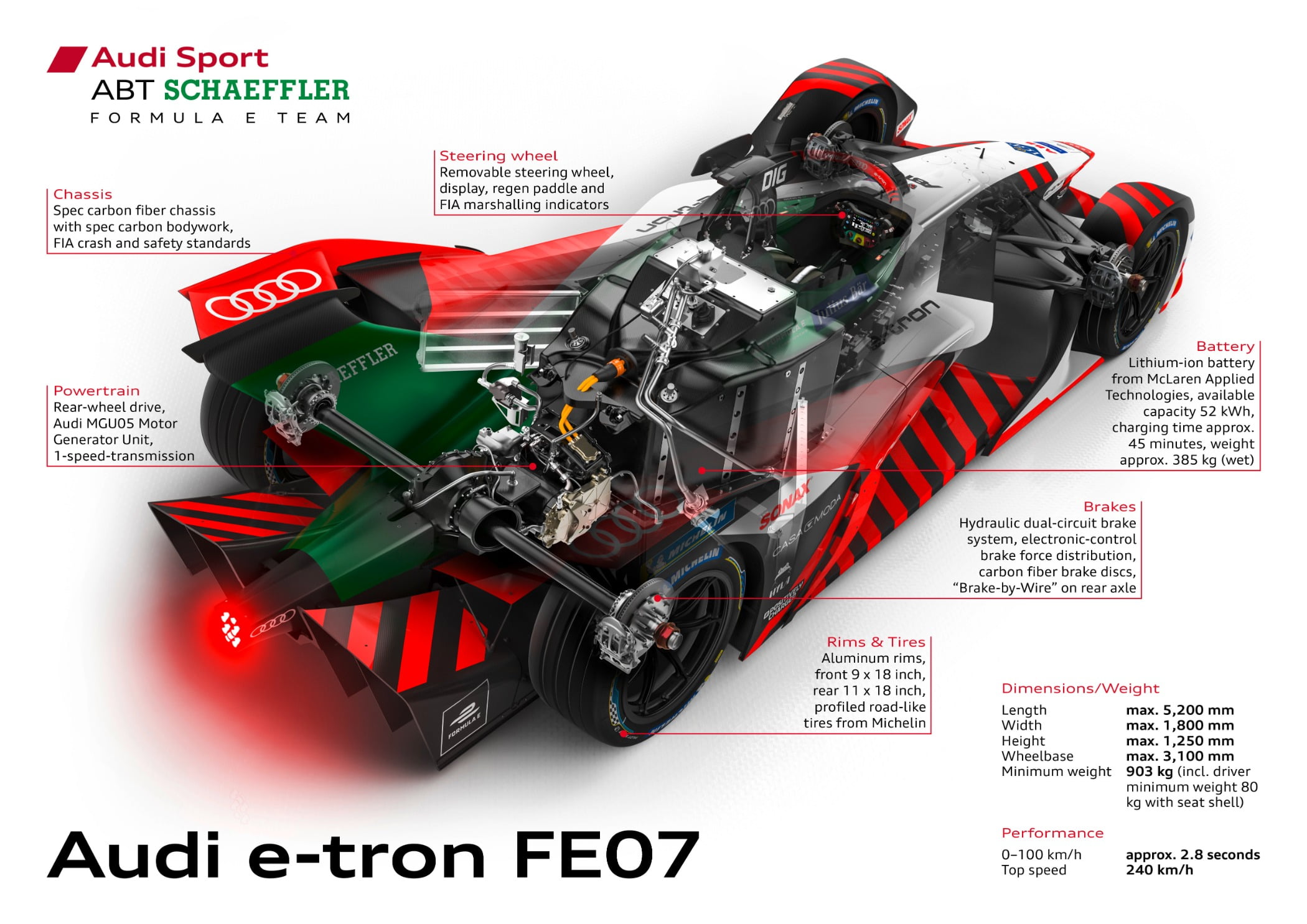

Formula E machines feature cutting-edge battery and power train technology. Illustration courtesy Audi AG

Formula E

The oldest and most prestigious electric racing series is Formula E. The popular single-seater competition sponsored by ABB is in the midst of its seventh season.

Automakers such as Audi, BMW, Daimler, DS (Citroen), Jaguar, Mahindra, Nissan, Porsche and Renault actively participate in Formula E. It has also attracted the attention of leading suppliers, including Bosch, DuPont, Magna, Schaeffler and ZF. In addition, several highly successful racing organizations, such as Andretti and Penske Autosport, are involved in the series.

The action-packed races take place on the streets of major cities such as Berlin, London, New York, Paris and Rome. Each race lasts 45 minutes. This year, there are 12 two-car teams competing in the Formula E world championship, where cars can reach speeds of more than 170 mph.

To control costs, the carbon-fiber chassis and battery are common components and the same for all the teams. This allows the focus to be on developing power trains and suspensions that are efficient and lightweight.

Formula E cars feature motors, inverters and control units developed by McLaren Applied Technologies and 250-kilowatt battery packs supplied by Atieva (the technology division of Lucid Motors). Spark Racing Technology produces a spec chassis for all the teams, while tires are supplied by Michelin.

“The ABB FIA Formula E World Championship not only brings attractive motor sport to major cities but also dispels still widespread reservations about electric cars,” says Jean Todt, president of FIA, the governing body of worldwide motor sport. “Formula E offers innovative cars and exciting races. In this way, it raises public awareness about the important role of electric cars in future mobility.”

“As technology develops, electric cars will be able to go faster and further,” adds Lucas di Grassi, a leading Formula E driver from Brazil who drives for Audi. “The pace of development is incredible. The point at which electric cars are cheaper, safer and easier to operate than combustion-engine cars is not far away at all and Formula E is accelerating that process.”

The 2020-21 Formula E season kicked off earlier this year in Diriyah, Saudi Arabia. The event was split into two races: the first was won by Mercedes and the second by Jaguar. Upcoming events include races in Monte Carlo (May 8), Marrakesh, Morocco (May 22), and Santiago, Chile (June 5).

Beginning with the 2022-23 season, Formula E will enter a new era called Gen3. It will mark the introduction of lighter, faster, more powerful cars and new cost control measures. In addition, Williams Advanced Engineering Ltd. will create a 350-kilowatt battery pack that will enable faster charging.

Racing contributes to next-generation technologies that are used in the road cars of tomorrow. Photo courtesy Penske Dragon Penske Autosport

Formula E races are held on urban street circuits around the world. Photo courtesy Daimler AG

Extreme E

Off-road racing in extreme environments is the concept behind Extreme E, which was founded by the same person behind Formula E. Its goal is to bring car racing to some of the most remote corners on earth to highlight the climate change challenges faced by different ecosystems, while showcasing the performance of all-electric SUVs in extreme conditions.

Extreme E will consist of five races that include the Desert X Prix in Al Ula, Saudi Arabia; the Ocean X Prix in Lac Rose, Senegal; the Arctic X Prix in Kangerlussuaq, Greenland; the Amazon X Prix in Para, Brazil; and the Glacier X Prix in Patagonia, Argentina.

A support ship called the “St. Helena” will transport the cars and serve as a floating pit and paddock for the nine teams competing in the inaugural season. Batteries will be recharged with a portable fuel cell power system built in England by AFC Energy.

Another unique aspect of the race series is that teams will be composed of a male and a female driver who will compete together in every two-lap race as driver and co-driver. Each will complete one lap behind the wheel of an electric vehicle, with a changeover incorporated into the race format.

All teams will drive a standardized SUV called the Odyssey 21, which features a niobium-reinforced steel alloy tubular frame built in France by Spark Racing Technology. Williams Advanced Engineering produced batteries for the cars. The battery and a mid-mounted motor will provide a power output of 400 kilowatts (kW) to propel the 1,650-kilogram machines from 0 to 62 mph in less than 5 seconds.

Extreme E features teams that are composed of male and female drivers. Photo courtesy Continental AG

The goal of Extreme E is to bring car racing to some of the most remote corners on earth and highlight environmental issues. Photo courtesy Continental AG

Pure ETCR

Four- and five-door production cars are the stars of the Pure Electric Touring Car Racing (ETCR) championship, which kicks off this summer. The series is scheduled to begin at the Vallelunga road circuit in Italy on June 18-20. Other races will be held in Denmark, Holland, South Korea and Spain.

ETCR has attracted teams from several automakers, including Alfa Romeo, Cupra (a Volkswagen brand) and Hyundai. Cars will use a 798-volt battery pack designed and built by Williams Advanced Engineering.

Each battery pack provides 500-kW of peak power and 300-kW of continuous power with a 62-kilowatt-hour (kWh) capacity. The pack can be recharged in less than an hour from 10 percent to 90 percent at 60-kWh. The pack will also allow four “push-to-pass” events over the 21-minute race distance.

One of the most unique aspects of ETCR will be how the races start. Instead of a traditional starting grid and red-to-green countdown lights, four cars at a time will line up side by side inside a giant starting gate that stretches across the width of the track, similar to what’s used in horse racing. After the gates open, each driver will be able to unleash extra push-to-pass power to give them a chance to overtake the car ahead.

Before each 10-kilometer race, drivers will be drawn randomly into “battle groups” before charging off against each other in a flat-out, door-bashing format similar to NASCAR.

Autonomous Indy Car

One of the most anticipated events on the 2021 racing calendar will feature no drivers behind the wheel. The Indy Autonomous Challenge (IAC) on Oct. 23 will be the world’s first head-to-head, high-speed autonomous race. It will feature a $1.5 million prize purse from sponsors such as Ansys, Aptiv, Bridgestone, Microsoft and Schaeffler.

The Indy Autonomous Challenge will be the world’s first head-to-head, high-speed autonomous race. Photo courtesy Indy Autonomous Challenge

Pure ETCR will feature a unique format, including a starting gate. Photo courtesy Eurosport Events

Teams comprised of college students will program the cars that compete at the Indianapolis Motor Speedway, the home of the world-famous Indy 500. Thirty teams made up of academic institutions from four continents, 11 countries and 14 U.S. states plan to participate.

“[This] race car is the most advanced, fastest autonomous vehicle ever developed,” claims Paul Mitchell, president and CEO of Energy Systems Network, co-organizer of the IAC. “Our sponsors are providing radar, lidar, optical cameras and advanced computers, bringing the value of each vehicle to $1 million.

“The primary goal of the IAC is to advance technologies that can speed the commercialization of fully autonomous vehicles and advanced driver-assistance systems, leading to increased safety and performance,” explains Mitchell. “In addition, the IAC is a challenging competition to excite the best and brightest university students from around the world to engage in hands-on engineering firsts.”

The sleek open-wheel vehicles that will compete in the event are being built by Dallara Automobilli at its factory in Varano de Melegari, Italy. No physical modifications to the vehicle are allowed. All teams will bring their own software and download it on the computers within the car prior to testing or race events.

“The modified Dallara IL-15 is retrofitted with hardware and controls to enable automation to enhance safety, control and performance,” says Stefano dePonti, CEO and general manager of Dallara USA. “Components include rugged-edge onboard computing, vehicle-to-vehicle communications, perception systems, high-end graphics processing units, drive-by-wire, artificial intelligence and powerful central processing units to run IAC teams’ software and algorithms.”

MotoE competitors will reach speeds of more than 150 mph on electric motorcycles. Photo courtesy Energica Motor Co.

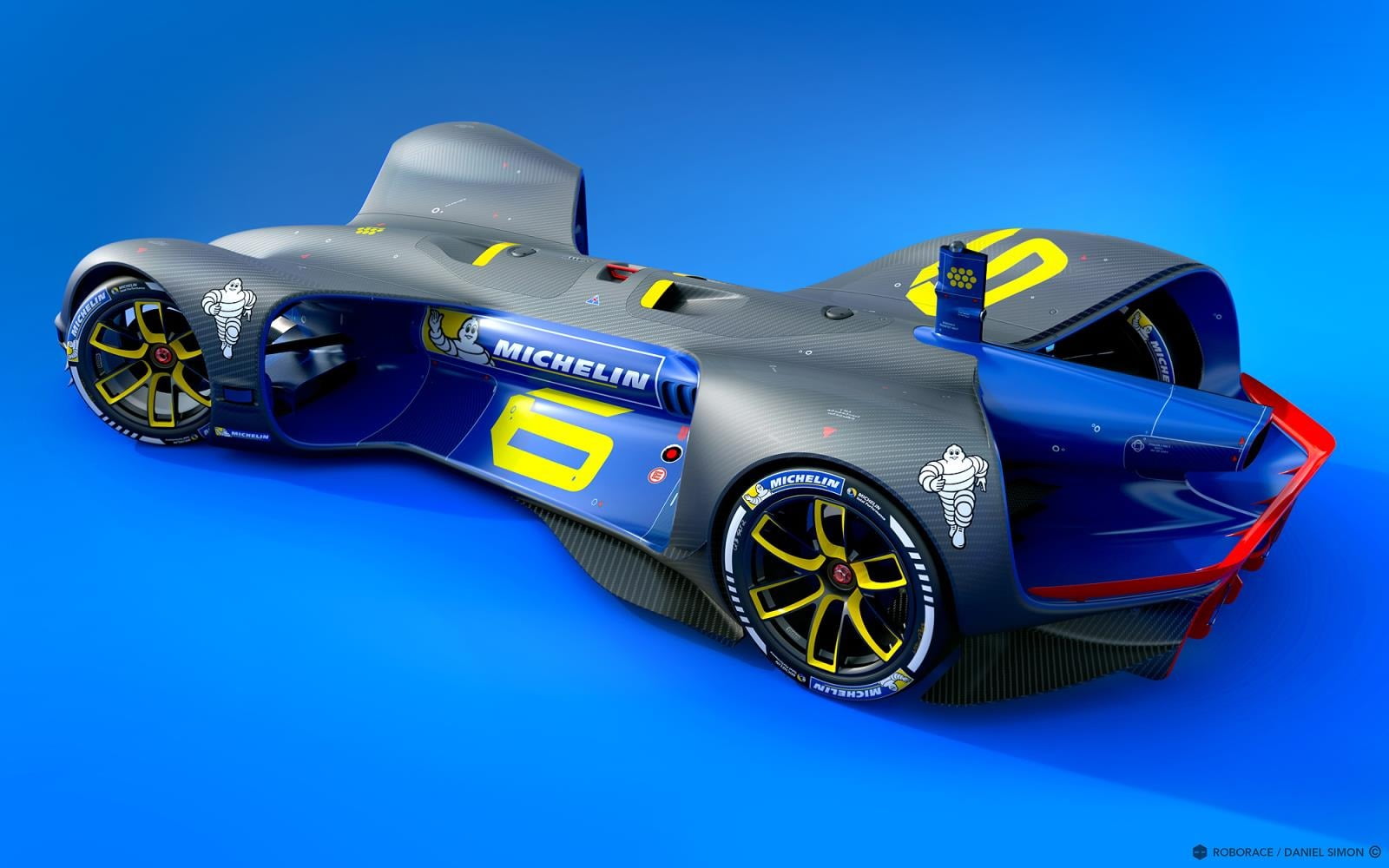

Autonomous car racing competitions such as Roborace pose a number of hardware- and software-based challenges for engineers. Photo courtesy Michelin

Roborace

Another autonomous competition is called Roborace. However, unlike the Autonomous Indy Challenge, it involves a series of races on European road courses. In addition, RoboRace is open to nonuniversity teams

“Roborace was created to accelerate the development of autonomous software by pushing the technology to its limits in a range of controlled environments, as well as educate and inform the world about autonomous driving,” says Chip Pankow, chief championship officer. “In 2019, the Alpha series held six events. Next, we commenced a Beta series with six competing teams featuring 12 races.” The next Roborace season is scheduled to begin in September.

“The technology in our cars and competition structure has been created to expose teams to a variety of edge-case scenarios that are relevant to real-world problems facing the industry today,” explains Pankow.

Teams compete using standardized cars powered by their own artificial intelligence algorithms in a series of races that test capabilities such as speed and object detection.

“Autonomous auto racing is an enabler for solving several of the challenges associated with the so-called ‘edge-cases’ in the autonomous vehicle development,” says Alexander Wischnewski, a professor of mechanical engineering at the Technical University of Munich who runs a student team that has competed in Roborace and also plans to participate in the Autonomous Indy Challenge. “If you can drive in this highly uncertain environment of multivehicle racing, you learn a lot about the design of algorithms required to handle unforeseen situations in everyday traffic, even though these might have completely different characteristics.

“The control of vehicles at the limits of the physical capabilities in every corner helps us to understand what is needed to build the next generation of vehicle safety systems, including features such as autonomous evasion maneuvers in situations where an emergency brake might not be feasible anymore,” explains Wischnewski.

According to Wischnewski, autonomous car racing poses a number of hardware- and software-based challenges. “[It forces us to] develop algorithms that are capable of operating in an environment which is inherently difficult to predict, as only very few rules for interaction between the vehicles are defined,” he points out.

“[We also have to] identify the right balance between the computational resources and algorithm fidelity required,” says Wischnewski. “To race an autonomous vehicle at high speeds, [we have to] deliver reliable software within short timeframes and development cycles.”

High-tech eSkootrs will be capable of unbelievable acceleration and extremely high cornering speeds. Illustration courtesy Electric Scooter Championship

MotoE

Two-wheeled electric vehicles participate in the MotoE World Cup, which began in 2019. Riders compete in 15-minute sprints onboard high-powered machines supplied by Energica Motor Co.

Energica is based in Modena, Italy, the hometown of Ferrari and Maserati. The bikes accelerate from 0 to 60 mph in 3 seconds and reach a top speed of more than 150 mph.

“We have convinced even the most skeptical motorcycle racing enthusiasts and we aim at continuing to ensure them with an exciting and thrilling show,” says Livia Cevolini, CEO of Energica. “Our Ego Corsa machines have been highly praised by the riders taking part in this innovative series, and MotoE has proven to be an invaluable platform for [our] business strategies and technological advancements.

“The first two seasons have helped build a tremendous amount of experience, which is constantly transferred to our road models,” notes Cevolini. “We are writing a new chapter in the history of motor sport and motorcycle racing.”

The 2021 MotoE season will consist of six races on European road circuits. The first event is scheduled for May 2 in Spain, followed by other races throughout the summer in Austria, Holland, France and Italy.

ESkootr

Electric scooter enthusiasts are also getting in on the racing action. Electric Scooter Championship (eSC) machines will feature carbon-fiber chassis eSkootrs that will enable competitors to reach speeds of more than 60 mph.

“The Electric Scooter Championship is an international race series that promotes the cost, convenience and sustainability benefits of micromobility in our cities,” says Hrag Sarkissian, CEO of eSC. “[Our machines] will be capable of unbelievable acceleration and extremely high cornering speeds.

“It’s clear that micromobility will play an increased role in the urban lives of millions of people, and the eSC provides a fantastic opportunity for manufacturers to develop and showcase new technology before it’s brought to market,” notes Sarkissian.

Williams Advanced Engineering will supply the S1-X, which will be powered by 1.5-kWh lithium-ion batteries and two 6-kW motors—one housed in each wheel.

The high-speed scooter will also feature a torque vectoring system to distribute power to the front and rear wheels. During races, this system will be able to be overridden by competitors to provide a boost in acceleration.

“The opportunity to further explore the sector with the eSkootr provides an opportunity for us to refine the packaging, ergonomics and systems required for deployment on a micromobility scale,” says Iain Wight, business development director at Williams Advanced Engineering. “Capable of cornering angles of 50 degrees on specially designed circuits between 400 and 1,000 meters long, it is an example of how racing technology can transform an everyday vehicle, and develop and accelerate pioneering future technologies for the road.”

The 2021 competition is scheduled to begin this year, but a calendar of events has not yet been released.

E1 Series

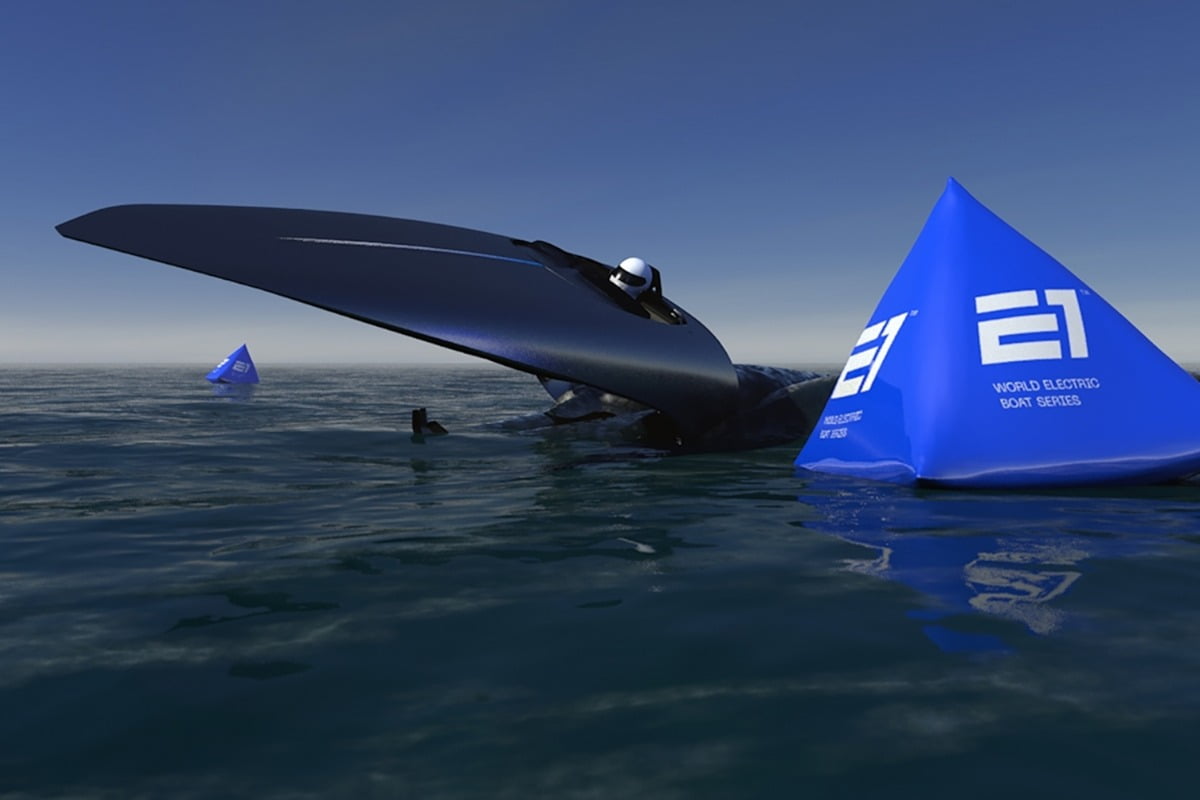

The E1 World Electric Powerboat Series will feature electric craft skimming across lakes, rivers and seas around the world. The hydrofoil-equipped boats will have a top speed of 70 mph.

“E1 will act as a technology test bed for marine electric technology,” says Rodi Basso, CEO, a former aerospace engineer who has worked at NASA and Ferrari. “The advances achieved in E1 will be used to improve all kinds of electric watercraft, supporting the transition to cleaner water mobility for the global industry. It will also showcase electric boat performance in a sporting environment.”

Potential race locations include Detroit, London, Monaco, New York City, San Francisco and Sydney. While there’s no set timeframe yet for the first event, Basso anticipates it will take place in late 2022.

Competitors will pilot identical Racebird O1s designed by SeaBird Technologies Ltd. The sleek boats are being built in Italy by Victory Marine. They will be equipped with batteries that produce 30-kWh of usable capacity and a peak power of 150-kW. Each race will last 40 minutes and include multiple heats.

“The courses will be tight and technical, so it will look much faster than it sounds,” claims Sam Mallinson, head of communications for the E1 Series. “The powerboats will progressively get faster and more efficient each season as the technology develops.”

The goal of Airspeeder is to develop electric vertical take-off and landing aircraft technology. Photo courtesy Airspeeder

The E1 series will feature hydrofoil-equipped electric power boats. Illustration courtesy E1 Series

Air Race E

Next year, the world’s first all-electric airplane competition will take to the skies with Air Race E. Eight planes at a time will fly wingtip to wingtip at speeds up to 250 mph around a tight 1.5-kilometer oval circuit marked by large pylons.

Organizations such as Airbus and Ansys Inc. are involved in Air Race E, which poses a number of aerospace engineering challenges. The goal is to help drive the development and adoption of cleaner, faster and more technologically advanced electric engines that can be applied to urban air mobility vehicles and commercial aircraft.

“The power electronics and battery management system must safely and optimally handle the rapid discharge of significant battery energy during a race,” says Jeff Zaltman, founder and CEO of Air Race Events. “This presents considerable thermal management issues, requiring extensive external and internal aerodynamic and aerothermal configuration redesign. Additionally, the electric power train must be integrated and optimized to deliver a race-winning performance.

“Lacking historical design precedent for these highly sophisticated electric aircraft, simulation [is] the only way to safely develop innovative technologies under incredibly tight deadlines,” claims Zaltman. “[Aerospace engineers] are developing cleaner, faster and highly advanced electric aircraft using Ansys simulation tools. These advances will help usher in the next chapter of electric aviation.”

“[Our software] will help engineers significantly improve batteries and battery management systems to deliver more power with less weight penalty, create small electric machines that are reliable and efficient, design electric power trains equipped with power electronics to overcome thermal and high-voltage challenges, and perform safe system-wide integration,” explains Shane Emswiler, senior vice president of Ansys. “[We] are accelerating the journey to sustainable aviation, empowering Air Race E teams to cost-effectively develop new aircraft that will shape the future of electric flight.”

During Air Race E events, eight planes at a time will fly wingtip to wingtip around a tight oval circuit. Photo courtesy Air Race E

Airspeeder

One of the newest electric racing series is also the most futuristic. Airspeeder features full-sized flying electric racing cars and claims to be the “most exciting and progressive motor sport on the planet.”

This year, teams will compete with a remotely operated electric vertical take-off and landing (eVTOL) vehicle dubbed the Mk3. It will act as a technical test bed for a manned racing series in 2022 featuring more advanced Mk4 vehicles.

The initial aircraft will fly at speeds of more than 74 mph with a 96-kW electric power train. The carbon-fiber fuselages are being designed and built by Alauda Aeronautics in Adelaide, Australia.

“Racing will play a vital role in hastening the arrival of eVTOL technologies, which promise to revolutionize urban passenger mobility, logistics and even remote medical transport,” says Matt Pearson, CEO of Airspeeder. “Airspeeder is built on the philosophy that nothing accelerates technical progress like sporting competition.

“The next-generation sport plays the same role the pioneers of Formula 1 did nearly a century ago in driving technical development and building public acceptance for a new mobility revolution,” explains Pearson.

Electric Car Racing Is Nothing New

Despite all the recent buzz about electric car racing, it’s nothing new. Indeed, when the first auto race in America took place 126 years ago, it featured several battery-powered machines.

In 1895, the Chicago Times-Herald newspaper sponsored a contest for “motocycles” and “motor carriages.” The race was held on Thanksgiving Day and attracted 90 entries from around the United States. Only six vehicles started the race in Jackson Park on the South Side of Chicago. But, the event included two electric models.

One was the Electrobat from mechanical engineer Henry Morris and chemist Pedro Salom of Philadelphia, which featured a 1,600-pound lead battery. The other electric vehicle was built by William Morrison of Des Moines, IA. It was driven by Harold Sturgis, an executive at the American Battery Co. in Chicago. Unfortunately, both electric vehicles broke down and did not finish the 52-mile race.

Although the race wound through many neighborhoods in the Windy City, stretching as far north as Evanston, few people witnessed the historic event due to an early winter storm that dumped almost a foot of snow on Chicago the night before. Slippery, slushy streets and cold, blustery air made driving conditions atrocious. As a result, only two vehicles managed to finish the grueling event.

J. Frank Duryea won the race (and received $2,000) in a gasoline-powered contraption that he designed and built with his brother, Charles. The vehicle consisted of a wood buckboard wagon mounted on top of a metal frame. It featured a 2-cylinder internal combustion engine and pneumatic tires.

It took Duryea and his intrepid passenger more than 10 hours to navigate the course. The runner up was a machine built in Germany by Karl Benz and imported by the H. Mueller Manufacturing Co. of Decatur, IL (a manufacturer of plumbing fixtures and water distribution products).

The world’s first auto race, the Paris-Bordeaux event of June 1895, also featured an electric vehicle: a Jeantaud.

may 2021 | ASSEMBLYMAG.com

ASB-AEM // May 2021