INVErTERS

Component Corner

Inverters play a key role in the performance and efficiency of electric vehicles. The devices take power from batteries and convert DC power to AC power, which is then delivered to traction motors. The faster and more efficient the inverter is, the more efficient the vehicle is as a whole, and the greater the amount of driving range that can be extracted from the battery.

Traditionally, EVs have used inverters with insulated-gate bipolar transistors (IGBTs), which switch current at up to 20kHz. However, silicon carbide (SiC) delivers significant advances, offering higher power levels, lower power losses and improved overall efficiency.Here’s a brief look at several recently unveiled products.

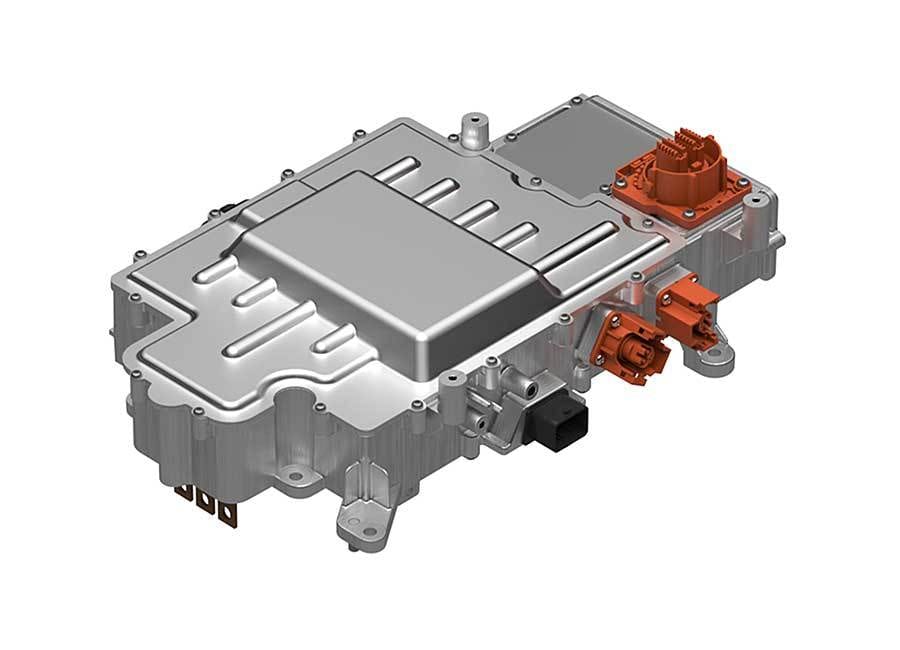

800-Volt Silicon Carbide Inverter

IPG5 is an 800-volt inverter that supports the next generation of EVs, featuring lighter electric cabling and ultra-fast charging. SiC technology enables a significant increase in switching frequency, which allows the use of a faster, more efficient and lightweight drivetrain, including inverter, motor and battery systems. It also switches more efficiently than conventional inverters, producing less heat and enabling a smaller cooling system, which reduces the weight and cost of drivetrains. Increased drivetrain efficiency enables a reduction in battery size.

McLaren Applied Ltd.

400-Volt Silicon Carbide Inverter

A 400-volt SiC inverter features dual-sided cooled power switches, providing improved switching efficiency and increased junction temperature capabilities. It provides enhanced driving performance, longer range, greater power density and reduced switching losses. The system features greater durability through its wire-bondless power switch design. The silicon-isolated gate bipolar transistor power switches have been replaced by SiC metal-oxide-semiconductor field-effect transistor power switches. This delivers up to a 70 percent reduction in switching losses.

BorgWarner Inc.

Next-Gen Inverter Is Compact and Lightweight

The HPI-800 inverter leverages the power of silicon carbide to reduce weight and simplify packaging. It can reduce the size of an EV battery by 10 percent, while switching frequencies of up to 40kHz, or double that of traditional IGBT-based inverters. The compact device is 494 millimeters long, 287 millimeters wide and 94 millimeters tall. It weighs 12.7 kilograms and delivers a maximum continuous output power of up to 400 kilowattts, depending on the type of motor used.

Equipmake Ltd.

Inverter Features Scalable Architecture

A scalable and modular e-motor inverter architecture allows OEMs maximum flexibility from 400 to 800 volts. It features next-generation power semiconductors and highly intelligent software algorithms. The modular platform is not dependent on predefined semiconductors and is designed to help bridge the transition to SiC technology. Benefits include faster power semiconductor switching times and better short circuit protection.

ZF Friedrichshafen AG

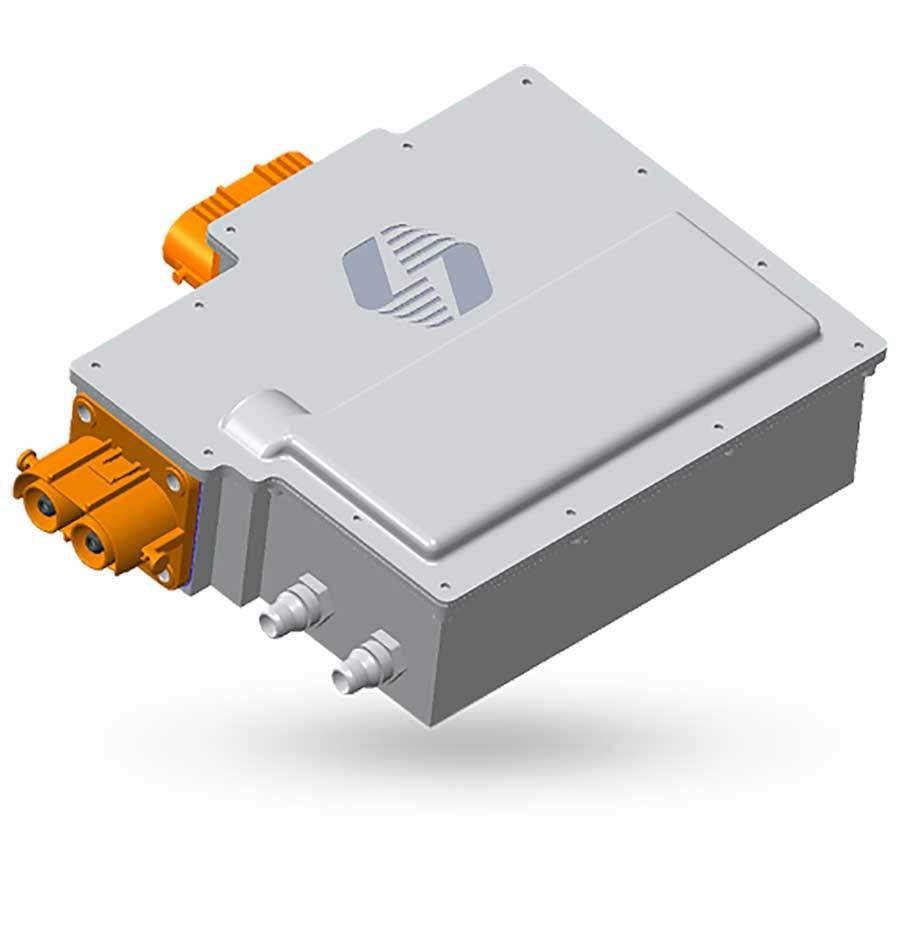

SiC Inverter Reduces Heat Production and Loss

The High Efficiency Inverter (HEI) addresses many common challenges faced by today’s EV power trains. It is lighter, more compact and more efficient than current inverters. It enables reduced overall vehicle weight, increased payload and range capability, and reduced heat production and loss to optimize battery performance and reliability. By materially eliminating switching losses, the inverter achieves higher switching frequencies without increasing semiconductor losses and temperatures. The device is scalable across a wide range of power levels and can be customized to deliver SiC inverter advancements that make it possible for EV manufacturers to deliver more power.

Hillcrest Energy Technologies