By Austin Weber, Senior Editor // webera@bnpmedia.com

Automation Enables High Throughput Battery Cell Production

E-ssembly in Action

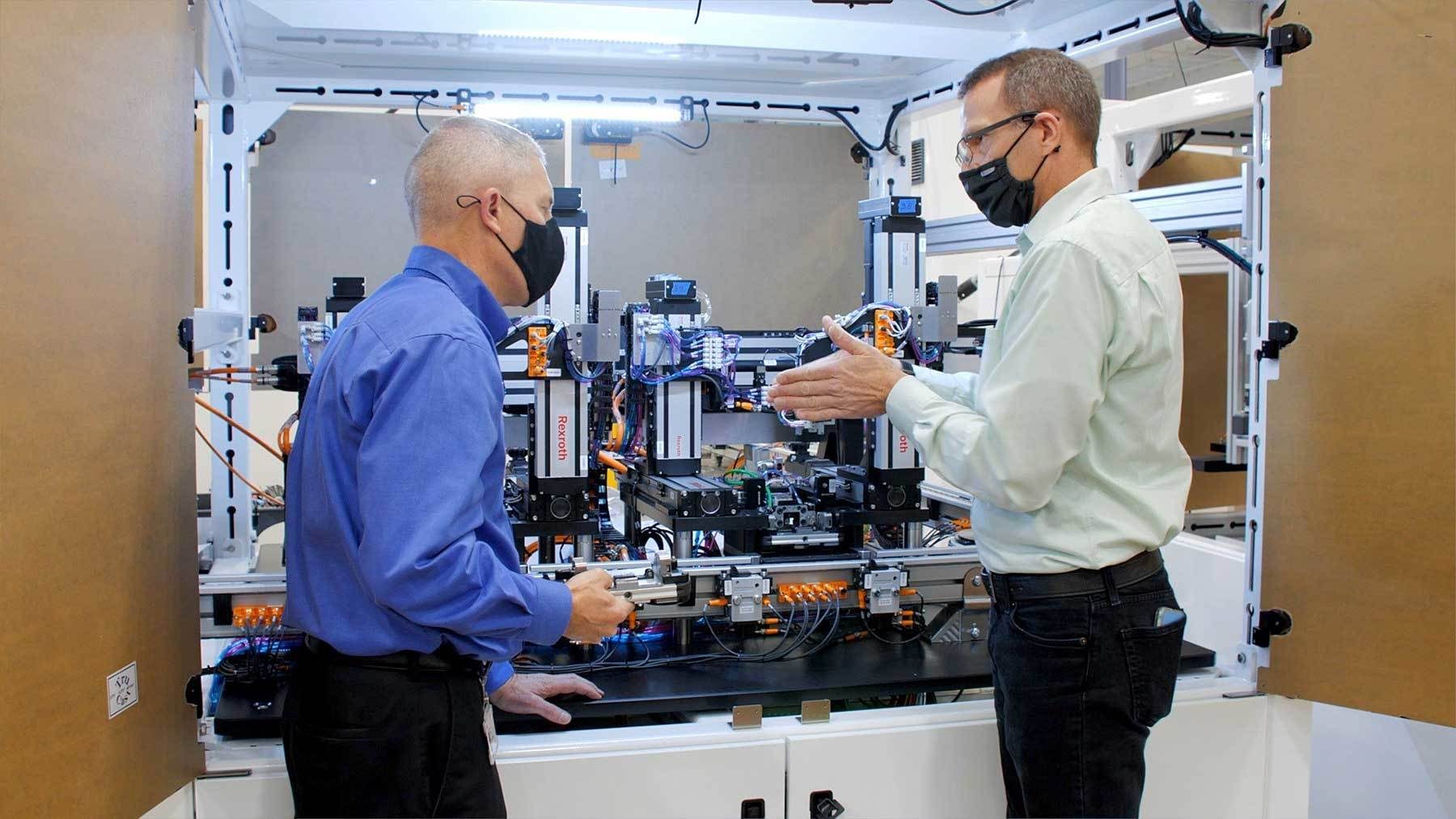

Automated battery production lines require extremely tight assembly tolerances, high rates of throughput and real-time inspection, data capture and communication with machine and plant-level control systems. Photo courtesy Bosch Rexroth Corp.

Unprecedented demand is prompting many battery manufacturers to rapidly add new production capacity. However, highly automated battery assembly lines traditionally take months to develop.

Battery manufacturing is a complex, multistep process that brings together dissimilar materials to form a cathode and anode, then combines them with a conductor into a finished package. Batteries today are becoming smaller with higher energy densities, which presents additional complexity.

DWFritz Automation Inc., a systems integrator based in Wilsonville, OR, recently tackled the challenge when it delivered a new, flexible, high-throughput assembly line to a leading North American battery manufacturer in record time.

Extremely tight assembly tolerances, higher rates of throughput and real-time inspection, data capture and communication with machine and plant-level control systems were all key requirements of the project.

Because of the complexity and short development time, DWFritz sought a strategic partner that could provide expertise in multiple technologies while operating in a concurrent engineering environment. It decided to partner with Bosch Rexroth Corp. to enable rapid design iteration and accelerated project execution. Several key operating requirements helped drive that decision.

“The line had to operate at very high speeds,” says Chris Povich, vice president of sales at DWFritz Automation. “Space was also a challenge. Even though the line is more than 100 feet long, it had to be designed to fit into a very tight footprint. And, the motion platform had to handle very robust motion control demands. One system alone had in excess of 50 axes of motion.”

One of the biggest challenges that Povich and his colleagues faced was time.

“In the past, we would have used several different suppliers,” explains Mukesh Dulani, president of DWFritz Automation. “But, just to start the collaboration between different suppliers in this case would have taken us at least 10 to 15 weeks.

“For this project, we only had 12 weeks of design and engineering time and eight weeks for procurement,” says Dulani. “So, we had to work with a partner [that] could supply the technology and the engineering support for us to be successful.”

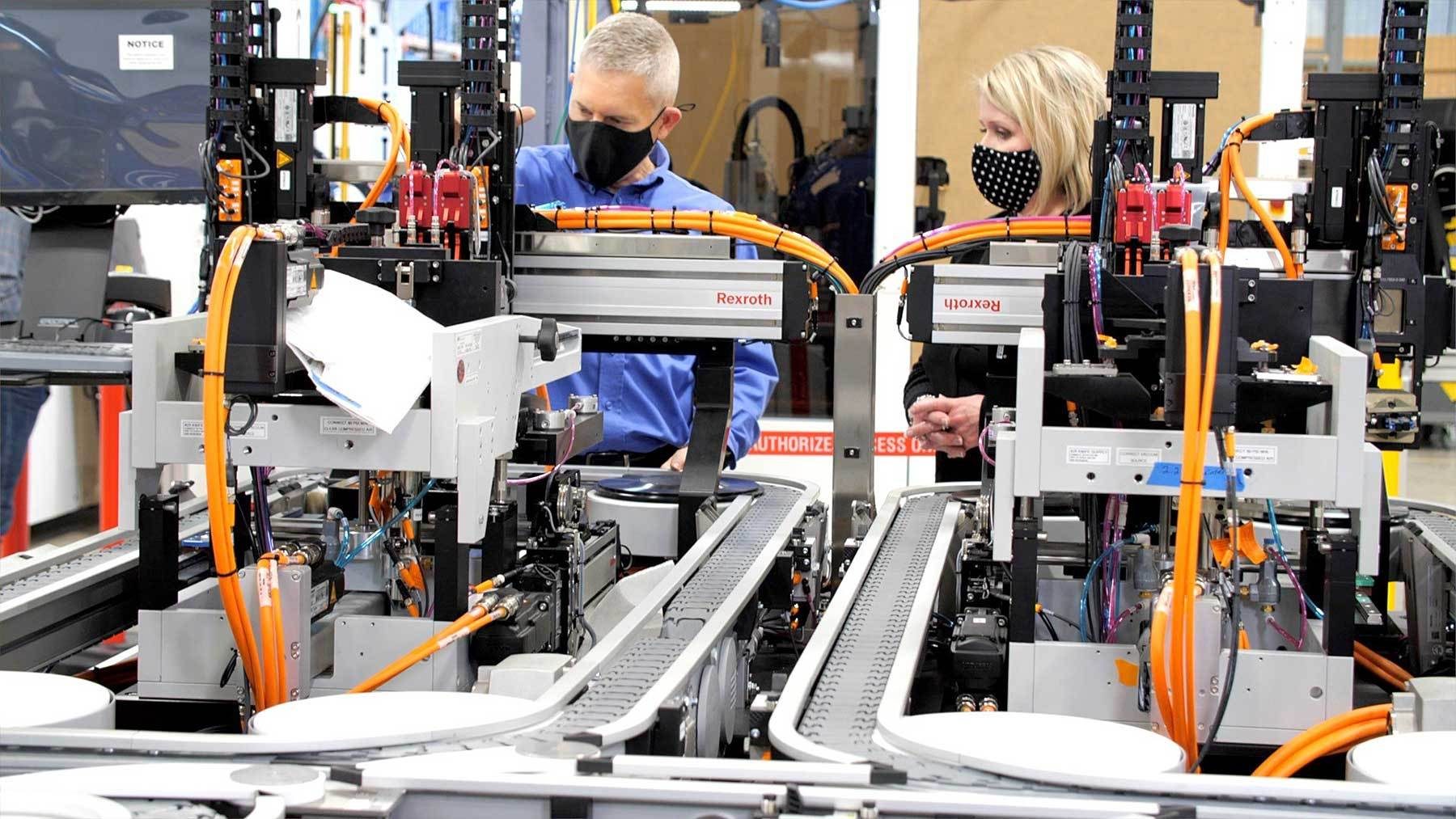

Using a concurrent engineering process, DWFritz Automation and Bosch Rexroth Corp. worked together to design and install a flexible, high-throughput and fully automated battery production line in record time. Photo courtesy Bosch Rexroth Corp.

State-of-the-Art Technology

“[Today], customers want better results, with more open and innovative systems that move real-time machine information from the shop floor to where it can be used more effectively,” says Matthias Aberle, senior vice president for manufacturing, engineering and factory automation at Bosch Rexroth North America. “To do that, we’re developing key partnerships with technology stakeholders like DWFritz so that the combined strengths of our organizations will drive major transformations in the automation industry.”

Bosch Rexroth provided a variety of state-of-the-art technology to create the new battery production line, including:

- Multiple conveyor systems to transport batteries within and between production cells.

- Precision linear motion modules used in gantry-style handling systems.

- Aluminum structural framing.

- A full suite of advanced motion control and drive systems, including one of the first implementations of the new Rexroth ctrlX AUTOMATION control platform.

The Rexroth VarioFlow plus flexible chain conveyor system, configured with workpiece pallets, was ideal for the size of the product being manufactured, its weight and the throughput speeds and stopping accuracy required. Photo courtesy Bosch Rexroth Corp.

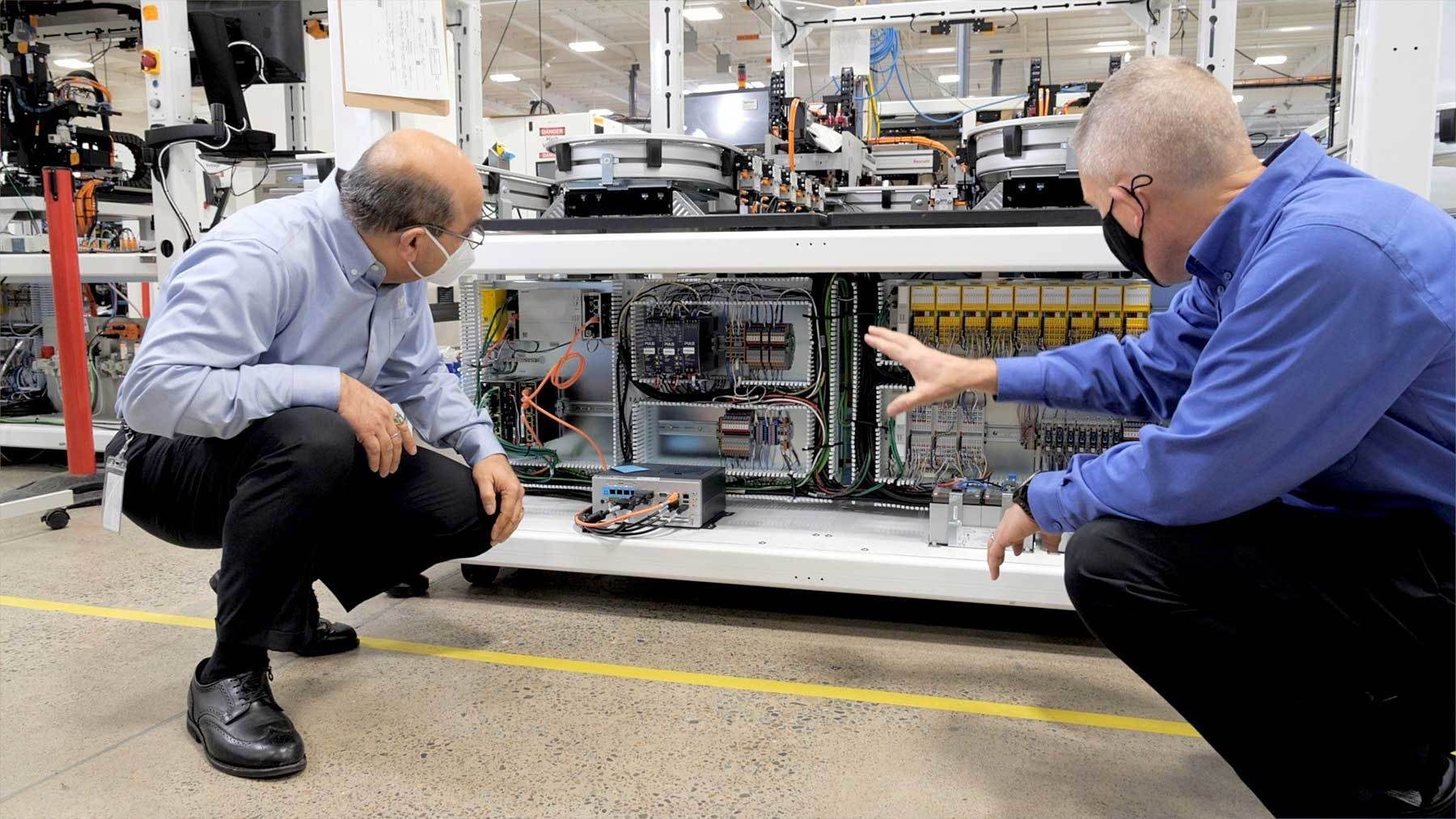

“One of our most important goals was to have an open machine control architecture so that our customer’s servers could directly query the machine and get real-time data,” explains Dulani. “Using the Rexroth ctrlX AUTOMATION platform and its ctrlX CORE controller not only made this project successful, but it enables our customer to build future production lines using the same platform.”

The platform encompasses both hardware and software. With a Linux-based real-time operating system, consistently open architecture and web-based engineering, it enables engineers to create, add or share automation functions via an app, making automation as easy as using a smartphone.

In addition, the controllers can manage third-party field devices through a deterministic real-time communication platform, enabling support of advanced camming systems and synchronizing the production modules on the same real-time control clock.

The ease of use and openness of the platform were vital for the DWFritz team to complete this complex project within the short time frame. It supports the free choice of programming languages instead of being limited to proprietary platforms.

Web-based system configuration also allows fast, simple start-up without the need to install software. And, a completely virtual development environment enabled the team to create a digital twin of the communication platform between MES and automation controllers, saving an enormous amount of time.

“The ability to use a digital twin gave the DWFritz engineers a software platform they could work on immediately,” says Dave Hull, regional vice president of Bosch Rexroth. “Months before they got the hardware, they were testing all of its systems, how it was going to work and how it would interface with the battery manufacturer’s MES system. It gave us a great head start.”

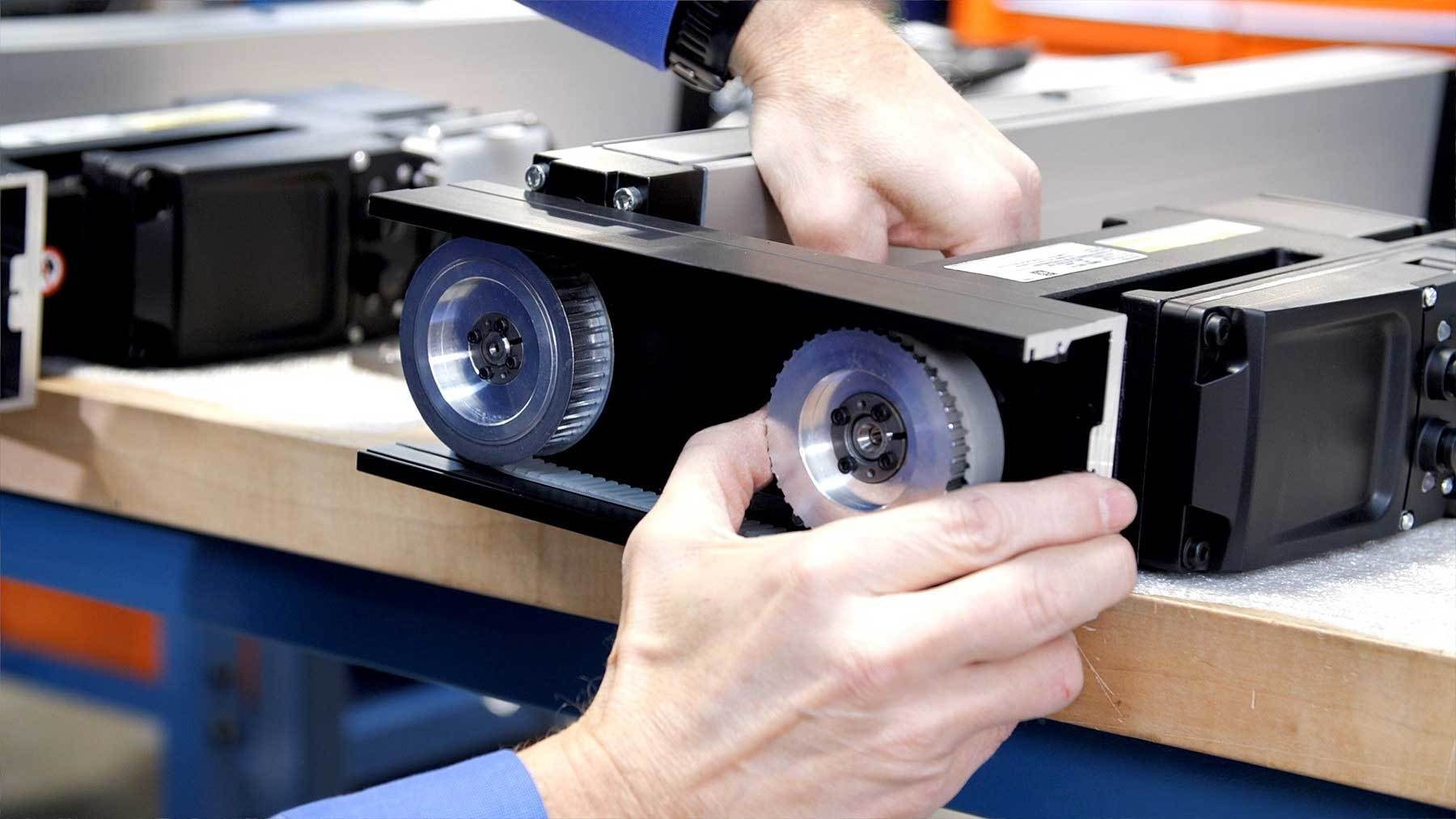

Bosch Rexroth linear modules are very compact and feature high accuracy, with repeatability in the 5-micron range. Photo courtesy Bosch Rexroth Corp.

Precise Motion and High Throughput

DWFritz Automation built the production cells for the battery line around its Flexible Platform DFP5000 assembly cell. The modular platform can be custom-configured with controls, servo drives and transport in-feeds for specific processes.

Precision kinematic tools were essential elements for multiple production cells to carry out a wide range of assembly and inspection tasks. “Correctly aligning all the components with tolerances between 20 to 50 microns in a battery, as it is assembled and processed at high throughput rates, requires precision components,” explains Martin Bamberger, staff engineer at DWFritz Automation.

To provide the required precision and functional efficiency for these kinematics, Rexroth CKK colinear modules were selected.

“Our modules are very compact and feature high accuracy with repeatability in the 5-micron range,” says Mike Ziencina, sales manager at Bosch Rexroth. “The modules were combined to create a variety of kinematic solutions, such as Cartesian robot pick-and-place systems, incorporated into the DFP5000 cell.”

The Rexroth ctrlX AUTOMATION platform and its ctrlX CORE controller made the battery assembly line project successful. Photo courtesy Bosch Rexroth Corp.

Another key technology contribution from Bosch Rexroth was the compact IndraDrive Mi motor-integrated servo system, which was used on web handling stations where the initial battery production phase takes place. The cabinet-free system combines the servo drive and motor in a single package and offers connectivity flexibility based on the application requirements. This enabled the engineers to integrate all electrical drive components directly into the machine, saving floor space and setup time.

With the speed and complexity of this production line, safety was also a critical consideration. Bosch Rexroth provided a full suite of state-of-the-art machine safety systems, including integrated Safety PLC with automation controllers, built-in advanced SafeMotion safety technology in the servo drives and Safety I/O, and integrated safety communications support with PROFIsafe.

For product handling, conveyors were key to the project’s success. To determine which conveyor offerings were the most suitable to use, engineers considered the size of the product being manufactured, its weight, the throughput speeds and stopping accuracy required, among other criteria.

In the end, the Rexroth VarioFlow plus conveyor, configured as a pallet-based system, provided the best platform. It is a flexible, modular plastic chain conveyor with the design versatility to move high-volume products horizontally, vertically, around obstacles or in other configurations. Workpiece pallets can be used to convey products in applications where positioning or higher precision is needed.

Because the assembly cells are so tightly packed with automation components, the VarioFlow plus system allowed for many processes to occur, while still maintaining the pallet position on the conveyor system through each of the tools. In addition, the conveyor made it easier to create a recirculating system to return the empty pallets back to the beginning and start the process over again, saving valuable floor space.

For more information on engineered-to-order precision automation, metrology and inspection systems, visit www.dwfritz.com.

For more information on complex machine automation technology, visit www.boschrexroth-us.com.