By Austin Weber // Senior Editor // webera@bnpmedia.com

Water-Based Batteries May Be Key to Bigger Storage Capacity

AV/EV tech trends

Water-based batteries can prevent fires, because they don’t contain cobalt. Illustration courtesy Texas University

Water is the source of life on Earth. It also may hold the key to increasing the storage capacity of electric vehicle batteries.

Engineers at Texas A&M University have discovered a 1,000 percent difference in the storage capacity of metal-free, water-based battery electrodes. The devices would also prevent fires, because they are different than traditional lithium-ion batteries that contain cobalt.

“In the future, if material shortages are projected, the price of lithium-ion batteries will go way up,” says Jodie Lutkenhaus, Ph.D., a chemical engineering professor at Texas A&M. “If we have this alternative battery, we can turn to this chemistry, where the supply is much more stable because we can manufacture them here in the United States, and materials to make them are here.”

Aqueous batteries consist of a cathode, electrolyte and an anode. The cathode and anode are polymers that can store energy, and the electrolyte is water mixed with organic salts. The electrolyte is key to ion conduction and energy storage through its interactions with the electrode.

“If an electrode swells too much during cycling, then it can’t conduct electrons very well, and you lose all the performance,” explains Lutkenhaus. “There is a [huge] difference in energy storage capacity, depending on the electrolyte choice, because of swelling effects.”

According Lutkenhaus, redox-active, nonconjugated radical polymers (electrodes) are promising candidates for metal-free aqueous batteries because of the polymers’ high discharge voltage and fast redox kinetics. The reaction is complex and difficult to resolve because of the simultaneous transfer of electrons, ions and water molecules.

Lutkenhaus and her colleagues complemented their experiments with computational simulation and analysis to gain insights into the microscopic molecular-scale picture of the structure and its dynamics.

“Theory and experiment often work closely together to understand these materials,” explains Daniel Tabor, Ph.D, an assistant professor of chemistry at Texas A&M. “We charged up the electrode to multiple states of charge to see how the surroundings respond to this charging.

The engineers macroscopically observed if the battery cathode was working better in the presence of certain kinds of salts by measuring exactly how much water and salt was going into the battery as it was operating.

“With this new energy storage technology, this is a push forward to lithium-free batteries,” says Tabor. “We have a better molecular level picture of what makes some battery electrodes work better than others, and this gives us strong evidence of where to go forward in materials design."

A Fourth Traffic Light Could Make Autonomous Vehicles Safer

Installing a fourth light at busy intersections could enable autonomous vehicles to operate safely in the future. Photo courtesy North Carolina State University/Siyuan

Green, red and yellow lights have been used for decades to control the flow of traffic at busy intersections. However, a fourth light could enable autonomous vehicles to operate safely in the future.

Engineers at North Carolina State University believe a white light would benefit humans and reduce accidents. In computational simulations, the new approach significantly improves travel time through intersections and reduces fuel consumption.

“This concept we’re proposing for traffic intersections, which we call a ‘white phase,’ taps into the computing power of autonomous vehicles themselves,” says Ali Hajbabaie, Ph.D., associate professor of civil, construction and environmental engineering at NC State. “The white phase concept also incorporates a new traffic signal, so that human drivers know what they are supposed to do.

“Red lights will still mean stop,” explains Hajbabaie. “Green lights will still mean go. White lights will tell human drivers to simply follow the car in front of them.”

The white phase concept rests on the fact that it is possible for AVs to communicate wirelessly with both each other and the computer controlling the traffic signal. When enough AVs are approaching an intersection, this would activate the white light. The white light is a signal that AVs are coordinating their movement to facilitate traffic through the intersection more efficiently.

Any traditional, nonautomated vehicles would be required to follow the vehicle in front of them. If the car in front of them stops, they stop; if the car in front of them goes through the intersection, they go through the intersection.

When the majority of vehicles approaching an intersection are controlled by drivers, rather than AVs, the traffic light would revert to the conventional green-yellow-red signal pattern.

“Granting some of the traffic flow control to the AVs is a relatively new idea, called the mobile control paradigm,” says Hajbabaie. “It can be used to coordinate traffic in any scenario involving AVs. But, we think it is important to incorporate the white light concept at intersections because it tells human drivers what’s going on, so that they know what they are supposed to do as they approach the intersection.”

According to Hajbabaie, the actual color of the “white light” doesn’t matter. What’s important is that there be a signal that is clearly identifiable by human drivers.

The concept relies on distributed computing—using the computing resources of all AVs to dictate traffic flow.

“This is both more efficient, and less likely to fall prey to communication failures,” Hajbabaie points out. “For example, if there’s an interruption or time lag in communication with the traffic light, the distributed computing approach would still be able to handle traffic flow smoothly.”

Hajbabaie says that AVs are not ready to adopt the new distributed computing approach tomorrow, nor are governments going to install brand new traffic lights at every intersection in the immediate future.

“However, there are various elements of the white phase concept that could be adopted with only minor modifications to both intersections and existing AVs,” claims Hajbabaie. “There are opportunities to test drive this approach at specific locations, such as ports that use autonomous vehicles.”

Controlling Speed Dynamics Could Improve All-Solid-State Batteries

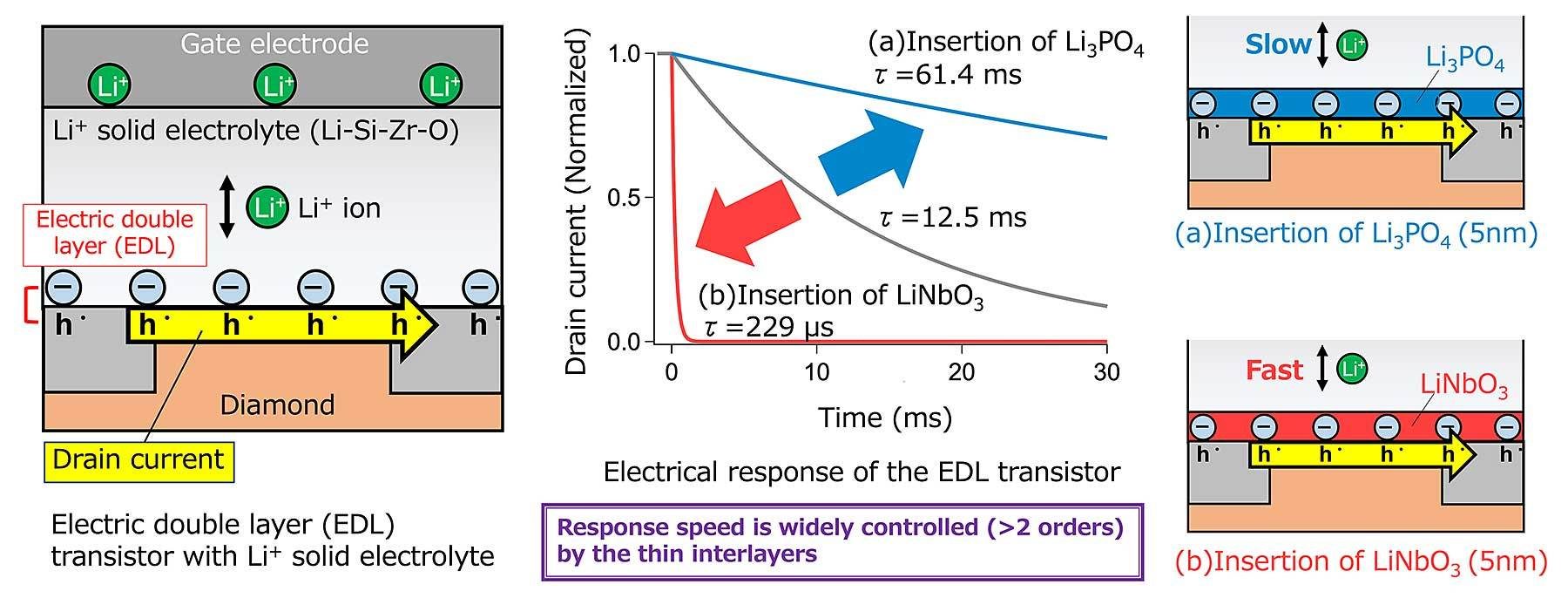

Engineers have developed a way to modulate electric double layer dynamics at the solid-solid electrolyte interface. Illustration courtesy Tokyo University of Science

All-solid-state batteries hold big potential for next-generation electric vehicles, because they offer greater energy storage density, faster charging and better safety than current batteries. However, their high surface resistance causes these batteries to have low output, limiting their applications.

To overcome this challenge, engineers at the Tokyo University of Science have developed a way to modulate electric double layer dynamics at the solid-solid electrolyte interface.

“The electric double layer (EDL) effect occurs when colloidal particles gain negative electric charge by adsorbing the negatively charged ions of the dispersion medium on their surface,” says Tohru Higuchi, Ph.D., associate professor of physics and material science at Tokyo University of Science. “This occurs at the solid-solid electrolyte interface, posing a problem in all-solid-state lithium batteries.”

Higuchi and his colleagues recently developed a way to quantitatively evaluate the EDL effect. They used an all-solid-state hydrogen-terminated diamond (H-diamond)-based EDL transistor (EDLT) to conduct Hall measurements and pulse response measurements that determined EDL charging characteristics.

By inserting a nanometer-thick lithium niobate or lithium phosphate interlayer between the H-diamond and lithium solid electrolyte, the engineers could investigate the electrical response of the EDL effect at the interface between these two layers.

“The electrolyte’s composition did, indeed, influence the EDL effect in a small region around the electrode interface,” explains Higuchi. “The EDL effect was reduced when a certain electrolyte was introduced as an interlayer between the electrode-solid electrolyte interface. EDL capacitance for the lithium phosphate/H-diamond interface was much higher compared to the lithium niobate/H-diamond interface.”

The engineers also improved the switching response time for charging all-solid-state electric double layers (ASS-EDLs).

“The EDL has been shown to influence switching properties, so we considered that the switching response time for charging ASS-EDLs could be greatly improved by controlling the capacitance of the EDL,” says Higuchi. “We used the non-ion-permeable property of diamond in the electron layer of the field-effect transistor and combined it with various lithium conductors.

“The interlayer accelerated and decelerated the EDL charging speed,” Higuchi points out. “The electrical response time of the EDLT was highly variable. It ranged from about 60 milliseconds (low-speed switching for lithium phosphate/H-diamond interface) to about 230 microseconds (high-speed switching for lithium niobate/H-diamond interface). However, we controlled the EDL charging speed for over two orders of magnitude.

“These results are important for improving the interface resistance and may lead to the realization of all solid-state batteries with excellent charge-discharge characteristics in the future,” claims Higuchi.

MAY 2023 | ASSEMBLYMAG.com