By Austin Weber // Senior Editor // webera@bnpmedia.com

Air Taxi Batteries Demand Unique Power Densities for Safe Operation

AV/EV tech trends

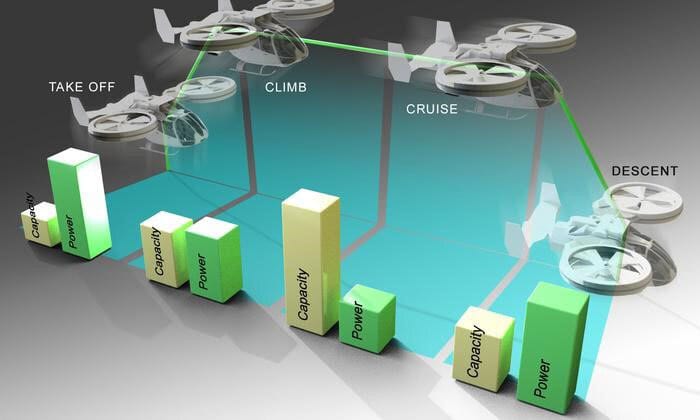

The operating phases of an eVTOL need varying amounts of power. Some require the battery to discharge high amounts of current rapidly, reducing the distance an aircraft can travel before its battery must be recharged. Illustration courtesy Oak Ridge National Laboratory

Electric vertical takeoff and landing (eVTOL) aircraft are one of the hottest segments of the aerospace industry, with legacy manufacturers and startups scrambling to develop a variety of urban air taxis and delivery drones. The new breed of vehicles are designed to rise into the air like a helicopter and fly using wing-borne lift like an airplane.

Compared with helicopters, eVTOLs generally use more rotors spinning at a lower speed, making them both safer and quieter. However, developing lightweight, yet powerful batteries is a big challenge.

According to engineers tackling the issue at Oak Ridge National Laboratory (ORNL), eVTOL batteries can’t just be adapted from electric car batteries, as some people think. So, they are evaluating how lithium-ion batteries fare under extremely high power draw, and developing new energy-dense materials and control systems.

“eVTOLs present a unique opportunity for creating a brand new type of battery with very different requirements and capabilities than what we have seen before," says Ilias Belharouak, Ph.D., head of the electrification section at ORNL. “This requires us to answer questions about the interplay of battery safety, cycle life and stability at high temperatures, while balancing the need for short bursts of high power with energy reserves for longer-range flight.”

According to Belharouak, the power and performance demands for eVTOL batteries can significantly reduce their longevity and durability. Unlike electric car batteries, which typically drain at a steady rate, eVTOL batteries need varying amounts of power for flight stages such as climbing, hovering and descent, with some phases requiring high bursts of power.

Belharouak and his colleagues recently made lithium-ion batteries at ORNL’s Battery Manufacturing Facility and ran them through simulated climb stages of eVTOL aircraft. They studied what happens inside the battery during cycling, including how much energy is rapidly accessible during the demanding takeoff phase. Afterwards, they tested the battery materials for corrosion and other chemical or structural changes.

As they push the limits for battery power, payload and safety, the engineers are also working on further improvements to the electrolyte and other battery components. Recent experiments involved collecting real-world data from drone flights over the lab’s campus, then using that information to develop a customized profile of the load and draw on the battery. Batteries made at ORNL were then run through the same cycles.

DC Power Converter Features High-Boost and High-Efficiency

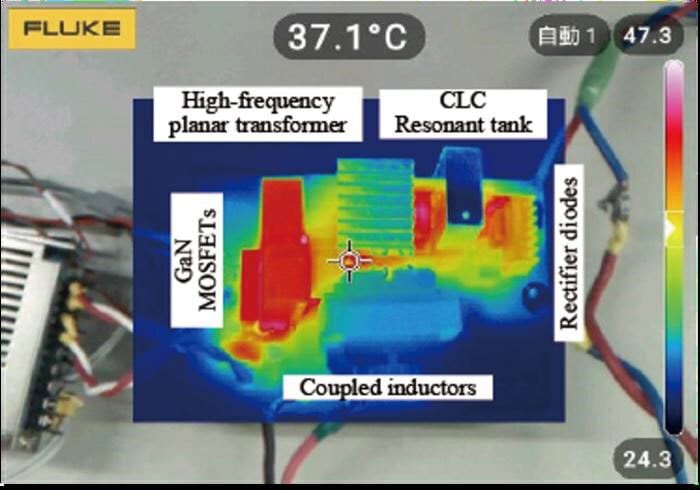

A new direct-current voltage boost converter has reduced electromagnetic noise while achieving a high energy efficiency of more than 91 percent. Illustration courtesy Kobe University

A new electrical power converter developed by engineers at Kobe University achieves a much higher efficiency at lower cost and maintenance than conventional devices.

They managed to combine high-frequency switching (about 10 times higher than before) with a technique that reduces electromagnetic noise and power losses due to heat dissipation, called “soft switching,” while also reducing the number of components. The direct-current voltage boost converter could lead to next-generation power electronics for electric vehicles.

“When the circuit changes between two states, there is a brief period when the switch is not completely closed, and at that point there is both a voltage and a current across the switch,” says Mishima Tomokazu, Ph.D., an associate professor at Kobe University and head of the Advanced Power Electronics Research Laboratory. “This means that during this time, the switch acts like a resistor and thus dissipates heat.

“The more often a switch state changes, the more this dissipation occurs,” explains Tomokazu. “Soft switching is a technique that guarantees that the switch transitions happen at zero voltage, thus minimizing the heat loss.”

Traditionally, this has been achieved by “snubbers”—components that offer alternative energy sinks during the transition period, which subsequently leads to energy losses.

Tomokazu and his colleagues use “resonant tank” circuits that can store energy during the switching period and therefore have much lower losses. In addition, they use a component-saving design with flat components printed onto a circuit board, called a “planar transformer,” which is very compact and has both good efficiency and thermal performance. The engineers also built a prototype of the circuit and measured its performance

“We confirmed that our snubberless design has reduced electromagnetic noise and a high energy efficiency of up to 91.3 percent, which is unprecedented for a MHz drive with high-voltage conversion ratio,” claims Tomokazu. “This ratio is also more than 1.5 times higher than existing designs.”

“The current development is a 100W-class small-capacity prototype, but we aim to expand the power capacity to a larger capacity in the future by improving the electronic circuit board and other components,” adds Tomokazu.

LiDAR Flaws May Make Autonomous Vehicles Vulnerable

Engineers fooled the sensing systems that enable autonomous vehicles to navigate into perceiving objects in the roadway or missing them entirely. Their custom-designed experimental apparatus included a laser, lens and advanced electronics. Photo courtesy Keio University

Autonomous vehicles depend on a variety of sensors to safely navigate streets, roads and highways. One of the most important is light detection and ranging (LiDAR) technology.

A recent research study conducted by engineers at the University of California, Irvine (UCI) and Keio University discovered that LiDAR may be prone to potentially hazardous vulnerabilities. They used lasers to fool LiDAR devices into “seeing” objects that are not present and missing those that are. Nine commercially available LiDAR systems were used in the study, including both first-generation and next-generation devices.

“This is to date the most extensive investigation of LiDAR vulnerabilities ever conducted,” claims Takami Sato, a Ph.D. candidate in computer science at UCI who conducted the study. “Through a combination of real-world testing and computer modeling, we were able to come up with 15 new findings to inform the design and manufacture of future autonomous vehicle systems.”

Testing first-generation LiDAR systems, Sato and his colleagues perpetrated an attack identified as “fake object injection” in which sensors are tricked into perceiving a pedestrian or the front of another car when nothing is there. In this situation, the sensors communicate the false hazard to the autonomous vehicle’s computer, triggering an unsafe behavior such as emergency braking.

“This chosen-pattern injection scenario works only on first-generation LiDAR systems,” says Sato. “Newer-generation versions employ timing randomization and pulse fingerprinting to combat this line of attack.”

However, the engineers found another way to confuse next-generation LiDAR systems. Using a custom-designed laser and lens apparatus, they could conceal five existing cars from the sensors.

“These findings unveil unprecedentedly strong attack capabilities on LiDAR sensors, which can allow direct spoofing of fake cars and pedestrians and the vanishing of real cars in the AV’s eye,” notes Qi Alfred Chen, Ph.D., an assistant professor of computer science at UCI. “These can be used to directly trigger various unsafe autonomous vehicle driving behaviors, such as emergency brakes and front collisions.”

May 2024 | ASSEMBLYMAG.com