Hyundai Opens EV Assembly Plant in Georgia

NEWS

Hyundai’s new assembly plant near Savannah, GA, will produce a variety of electric and hybrid vehicles. Photo courtesy Hyundai Motor Group

ELLABELL, GA—Hyundai Motor Group opened a new assembly plant here that will produce a variety of electric and hybrid vehicles under the Hyundai, Genesis and Kia nameplates. The $7.6 billion facility is located 20 miles west of Savannah.

“Hyundai Motor Group Metaplant America (HMGMA) represents [our] advanced manufacturing capabilities and commitment to innovation…” says Euisun Chung, executive chair of Hyundai Motor Group. “With the rich history of craftsmanship and manufacturing in this community, together with the talented workforce at HMGMA, we are building the future of mobility with America, in America.

“HMGMA’s architecture blends advanced technology with design elements that reflect [our] brand identity and the natural beauty of the Savannah area,” explains Chung. “The 3,050-foot-long front of the building’s exterior is lit in two parallel lines, inspired by a stream, and outlines an area where interstate travelers [on I-16) can view vehicles as they travel by conveyor from paint to general assembly.”

HMGMA has integrated a variety of manufacturing technologies and systems from Hyundai Motor Group Innovation Center Singapore, scaling them to accommodate the larger production volume at the Georgia facility.

For example, all HMGMA’s processes, including order collection, procurement, logistics and production, are optimized using artificial intelligence and real-time data. The assembly plant also features cutting-edge robotics and vision systems that ensure high-quality vehicle production.

“These innovative manufacturing systems help create a human-centered work environment, with robots assisting human workers, improving efficiency,” claims Chung. “HMGMA expands its mixed-model production capability and integrates various robot processes to enhance automation, including automated guided vehicles for an optimized logistics system…. Automation in HMGMA’s assembly shop is nearly double that of [our] existing facilities.”

“It is as important for us to create a comfortable and welcoming work environment for our Metaplant employees, also known as Meta Pros, as it is for us to create an energy-efficient and technologically advanced plant,” adds Oscar Kwon, CEO of HMGMA. “It is essential for our Meta Pros to be happy, comfortable and safe in their work environment for long-lasting careers at HMGMA.

“All the work zones, from office to production areas, have been designed to encourage communication and build team collaboration,” says Kwon. “The designs feature open layouts with ample daylight and indoor landscaping. Production areas, such as those in the assembly building, have team centers with skylights delivering natural light at the center of the building; they can be used for employee breaks and meetings.”

HMGMA has also deployed Hyundai’s Xcient heavy-duty hydrogen fuel-cell electric trucks for logistics. More than 20 vehicles are currently in operation, transporting parts from suppliers across the region to the 2,906-acre assembly plant.

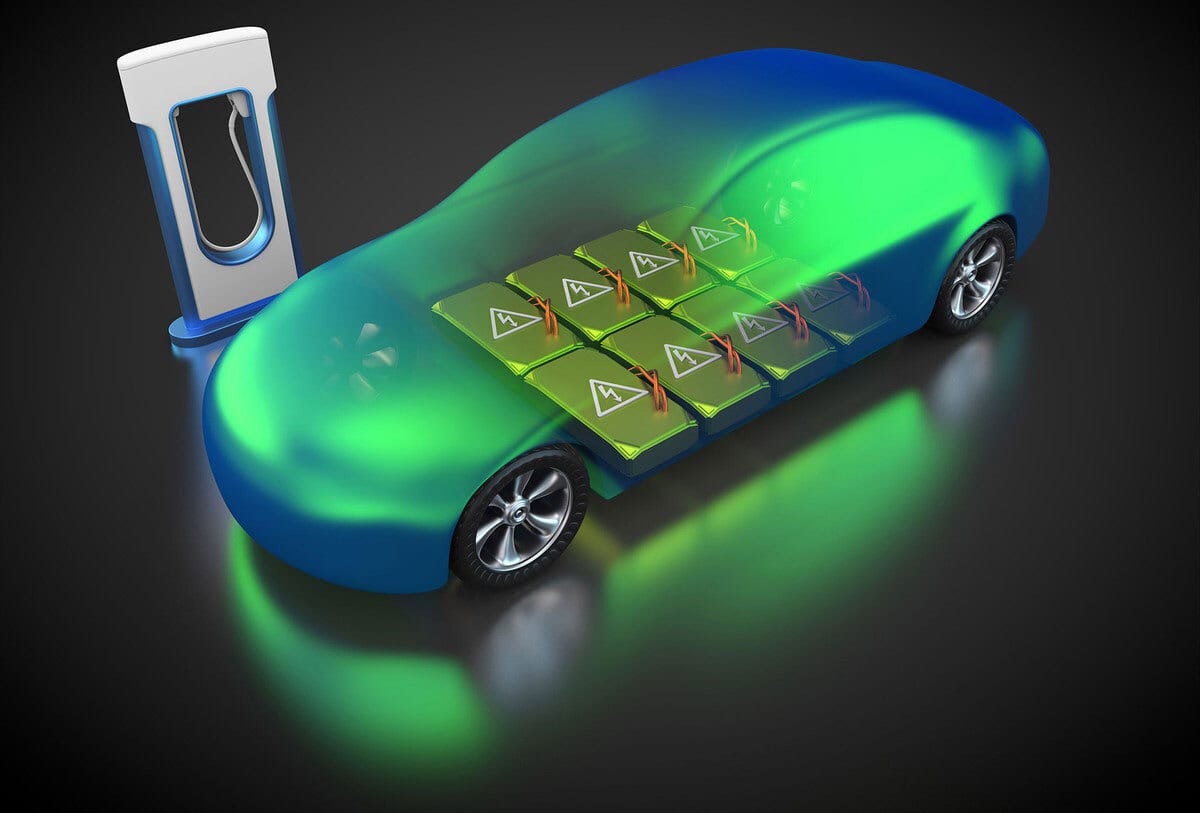

New Battery Manufacturing Process Addresses Cold Weather Issues

A new process for manufacturing electrodes enables electric vehicle batteries to operate more reliably in colder climates. Photo courtesy University of Michigan

ANN ARBOR, MI—As electric vehicle owners in the Midwest and Northeast know, cold weather can play havoc on batteries. Engineers at the University of Michigan have addressed the issue by developing a new process for manufacturing electrodes.

Traditionally, EV batteries store and release power through the movement of lithium ions back and forth between electrodes via a liquid electrolyte. In cold temperatures, this movement slows, reducing both battery power and charging rates.

To extend range, automakers have increased the thickness of the electrodes they use in battery cells. While that has allowed them to promise longer drives between charges, it makes some of the lithium hard to access, resulting in slower charging and less power for a given battery weight.

“Charging an EV battery takes 30 to 40 minutes, even for aggressive fast charging, and that time increases to over an hour in the winter,” says Neil Dasgupta, Ph.D., an associate professor of mechanical engineering and materials science at the University of Michigan. “This is the pain point we want to address.

“For the first time, we’ve shown a pathway to simultaneously achieve extreme fast charging at low temperatures, without sacrificing the energy density of the lithium-ion battery,” claims Dasgupta. “Lithium-ion EV batteries made this way can charge 500 percent faster at temperatures as low as 14 F.”

The structure and coating developed by Dasgupta and his colleagues prevents the formation of performance-hindering lithium plating on the battery’s electrodes. As a result, batteries with these modifications keep 97 percent of their capacity, even after being fast-charged 100 times at very cold temperatures.

The devices were built in the U-M Battery Lab and studied at the Michigan Center for Materials Characterization.

“We envision this approach as something that EV battery manufacturers could adopt without major changes to existing factories,” says Dasgupta.

Previously, the engineers improved battery charging capability by creating pathways—roughly 40 microns in size—in the anode. Drilling through the graphite by blasting it with lasers enabled the lithium ions to find places to lodge faster, even deep within the electrode, ensuring more uniform charging.

This sped up room-temperature charging significantly, but cold charging was still inefficient. The engineers identified the problem: the chemical layer that forms on the surface of the electrode prevents it from reacting with the electrolyte.

Dasgupta compares this behavior to butter: you can get a knife through it whether it’s warm or cold, but it’s a lot harder when it’s cold. If you try to fast charge through that layer, lithium metal will build up on the anode like a traffic jam. That plating prevents the entire electrode from being charged, which reduces the battery’s energy capacity.

To prevent that surface layer from forming, Dasgupta and his colleagues coated the battery with a glassy material made of lithium borate-carbonate, approximately 20 nanometers thick. The addition of this coating sped up cold charging significantly, and when combined with the channels, the test cells were 500 percent faster to charge in subfreezing temperatures.

BMW’s New EV Factory Features Unique Layout

BMW’s new assembly plant in Hungary is designed to improve production efficiency. Photo courtesy BMW AG

DEBRECEN, Hungary—BMW AG is ramping up its new state-of-the-art assembly plant located 155 miles east of Budapest. It has been designed specifically for the production of electric vehicles, such as the new BMW iX3 SUV, which will be built on the automaker’s Neue Klasse platform. The facility also holds the distinction of being the first BMW factory to operate entirely without the use of fossil fuels.

“Our highly efficient and ergonomic assembly line immediately started running without any issues,” claims Hans-Peter Kemser, managing director of BMW Group Plant Debrecen. “We achieved this thanks to virtual planning and tests, as well as the outstanding collaboration between our new, highly motivated employees in Debrecen and our experts within the BMW Group’s global production network.

“The innovative vehicle architecture of the Neue Klasse opens totally new possibilities with regard to assembly: greater efficiency thanks to modularization, fewer different connecting elements and a simplified installation of the wiring harness,” explains Kemser. “An innovative cockpit assembly also accelerates the process.

“Some components are modularized when one module is formed from many small individual parts,” says Kemser. “The variation of connecting elements has also been radically reduced for the Neue Klasse. This in turn reduces the number of different plugs, screws and clips. All of this makes assembly significantly more simple.”

According to Kemser, a wide range of quality checks can be performed digitally while vehicles are still on the assembly line. A flexible cockpit assembly process also accelerates production at the Debrecen plant.

“Cockpit pre-assembly is located right next to the main line,” explains Kemser. “Once the cockpit has been pre-assembled, it is then installed directly in the vehicle just a few meters ahead.”

Another unique feature of the Debrecen plant is its layout. It uses what BMW calls a “finger structure” or “comb structure,” because it resembles the fingers on a hand or the teeth of a hair comb. The design improves material flow in the factory, enabling components and preassembled modules to be transported directly to the assembly line.

“A record proportion of parts—up to 80 percent—can be delivered directly in Debrecen, as the fingers will enjoy logistics supply from both sides for the first time,” says Kemser. “This is the highest ratio in [our entire] production network. The finger structure allows subsequent extension and the integration of further assembly steps [for greater] flexibility.”

Tesla Cybertuck Recalled Over Structural Adhesive Issue

Tesla’s Cybertruck has experienced a problem with the structural adhesive used to attach an exterior trim component. Photo courtesy Tesla Inc.

WASHINGTON—The National Highway Transportation Safety Administration (NHTSA) has recalled Tesla Inc.’s controversial Cybertruck over a faulty body panel that can potentially fall off. The “cant rail” is a 9-foot-long stainless steel exterior trim component located above the driver’s side door. It is attached to the battery-powered pickup truck with a structural adhesive at the automaker’s assembly plant in Austin, TX.

According to Reuters, the cosmetic applique “has been found to be susceptible to environmental issues. The new version will use a different adhesive that will be reinforced with a stud welded to the stainless panel, with a nut that clamps the steel panel to the vehicle structure.”

In its description of the defect, the NHTSA says “The Cybertruck is equipped with a cosmetic applique along the exterior of the vehicle, known as the cant rail, which is an assembly comprised of an electrocoated steel stamping joined to a stainless steel panel with structural adhesive. The cant rail assembly is affixed to the vehicle with fasteners.”

Automakers use a variety of adhesive tapes and structural adhesives, such as acrylics and epoxies, to join lightweight aluminum parts. They replace or augment rivets, bolts, welding and other traditional fastening methods in their assembly processes. There are a number of reasons for doing so, including improved product performance, improved aesthetics, lower production costs, reduced overall assembly time and weight reduction.

MAY 2025 | ASSEMBLYMAG.com