product spotlight

Products

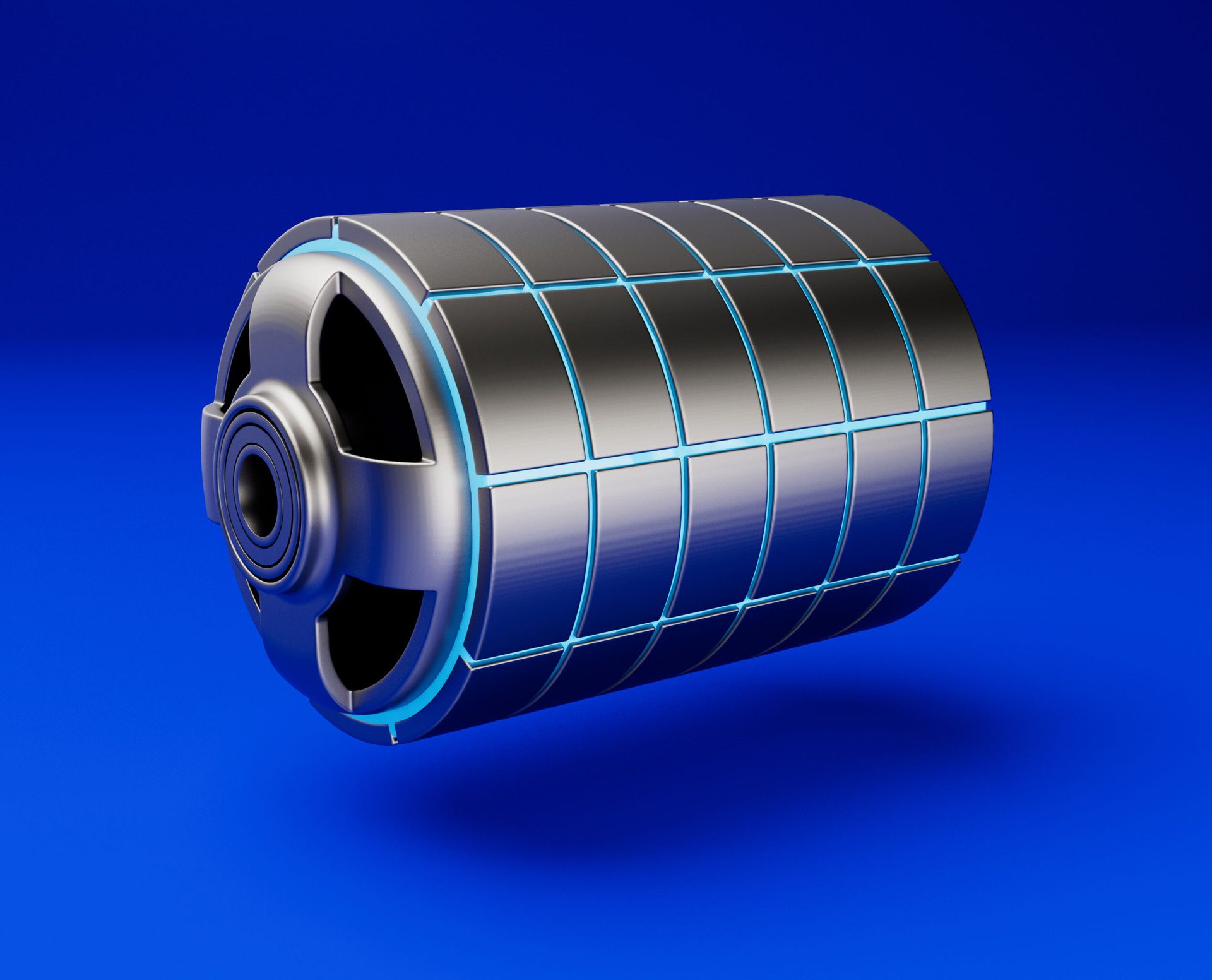

Epoxy Adhesive Bonds E-Motor Magnets

Structalit 5859 is a structural adhesive developed specifically for electric motor magnet assembly applications. It can be used for magnet-rotor bonding and for joining magnets in pole housings. The one-component epoxy cures at temperatures as low as 100 C. At 150 C, the curing time can be reduced to as little as 5 minutes. Due to its high glass transition temperature of 143 C, the adhesive has a tensile shear strength of 17 megapascals on steel, even at temperatures of 150 C. In addition, the adhesive is characterized by high impact strength and good elongation at break, which makes it possible to use it with material pairings that have different coefficients of thermal expansion.

Panacol

Automated High-Voltage EV Cable Processing Machine

The Lambda 141 is a compact, versatile machine for processing high-voltage EV cables. It features three configurable processing stations for shield cutting, shield folding and rotary stripping, all within a 20-second cycle time. The machine can process cables with a minimum length of over 400 millimeters and a stripping length of less than 100 millimeters for outer insulation. Its 10-inch touch screen ensures intuitive operation and seamlessly integrates into manufacturing systems. The machine is designed to minimize downtime and maximize throughput.

Komax Group

Structural Adhesive Is Thermally Conductive

CoolTherm TC-2002 is a two-component adhesive for structural bonding applications that require thermal conductivity with high bond strength. It can be used on parts that experience operating temperatures from -65 C to 100 C. Low coefficient of thermal expansion minimizes the possibility of cracking during wide temperature cycling. The adhesive is UL 94 V-0 certified for flame retardancy. It cures at room temperature (25 C). Handling strength is achieved in 20 to 25 minutes, and the adhesive will cure to full strength in 2 to 3 hours.

Parker Lord Engineered Materials Group

Laser Cutter Processes EV Battery Cell Foils

A new laser cutting system enables high-speed processing of foils for lithium-ion battery cells. It is more cost-effective than traditional mechanical cutting or punching methods. The machine uses a contactless roll-to-roll cutting process called notching, where the edges of foils are trimmed on the fly. The automated machine delivers higher quality, reduces operating costs and offers greater flexibility than alternatives. The process operates at web speeds of up to 4 meters per second, ensuring that electrodes remain free from particle contamination. It can also handle different geometries without requiring any modifications.

Sonplas GmbH

MAY 2025 | ASSEMBLYMAG.com