By Austin Weber, Senior Editor // webera@bnpmedia.com

Power Inverters Create Longer Range for Electric Cars

AV/EV tech trends

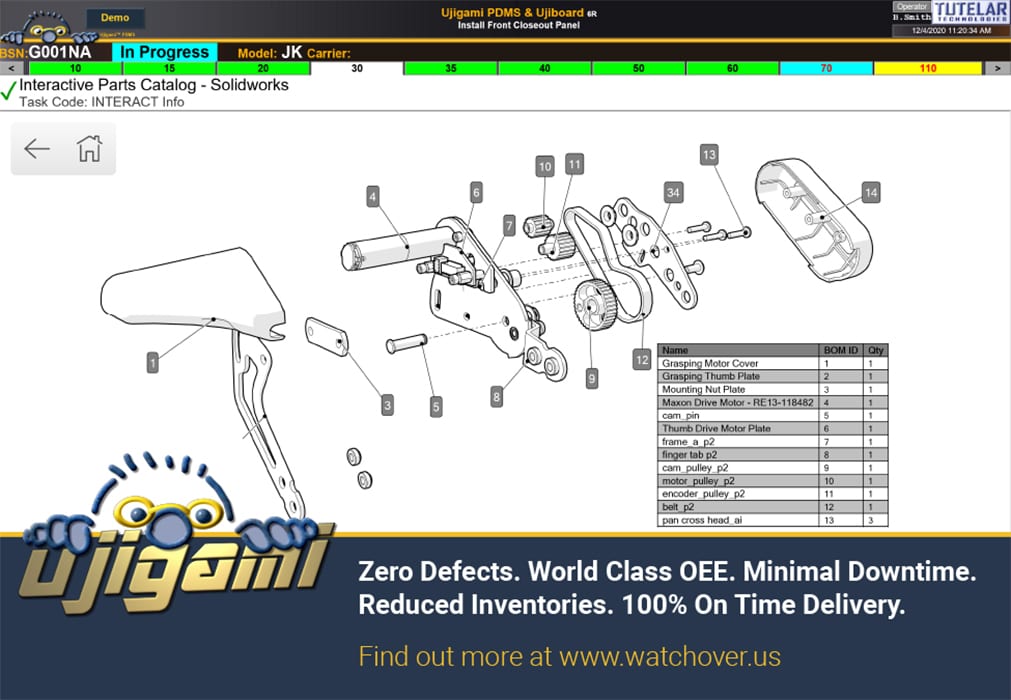

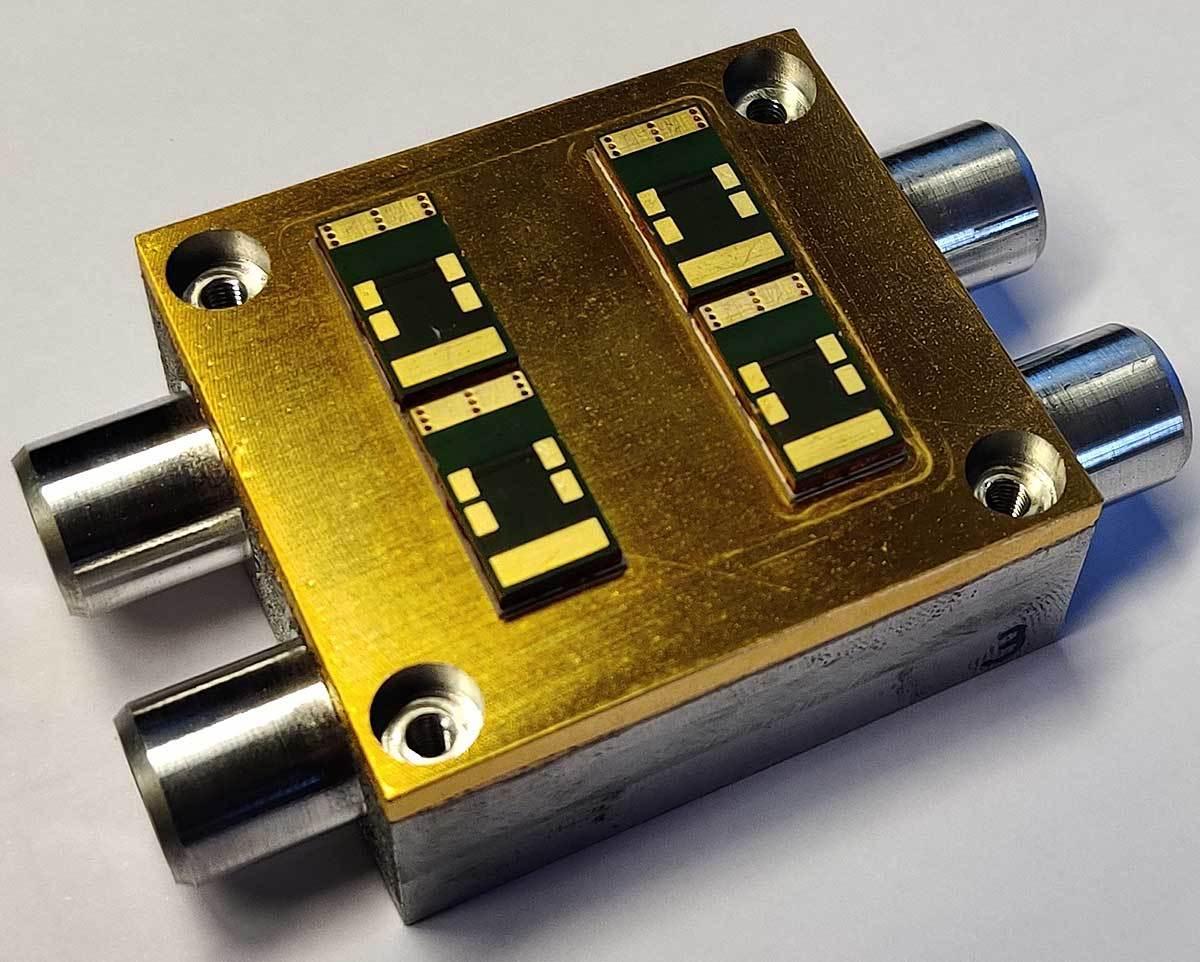

Silicon carbide semiconductors dissipate less power as electric current flows through them. Photo courtesy Fraunhofer

Electronic control units optimize energy flow between batteries and electric motors. A large amount of current flows through the power inverter and its transistors. To prevent the device from heating up like a toaster, the heat has to be discharged through cooling elements.

Engineers at the Fraunhofer Institute for Reliability and Microintegration (IZM) believe silicon carbide (SiC) semiconductors can solve this challenge. They are using the technology to develop transistors that dissipate less power as current flows through them. The goal of the SiCeffizient project is to redesign the cooling elements of the power inverters to keep semiconductor cooler while maintaining the same dissipation rate.

“Particularly when a vehicle is accelerating, braking and traveling at high speeds, power is lost from the inverter as large quantities of current flow back and forth between motor, power inverter and battery,” says Eugen Erhardt, head of the SiCeffizient project at Fraunhofer IZM. “SiC semiconductors reduce these losses.

“By optimizing the drivetrain this way, the range of electric cars [could] be extended by up to 6 percent,” explains Erhardt. “Six percent may not sound like much. But, when it comes to electric car batteries, this kind of performance boost can only be achieved by increasing the number of batteries or through considerable research effort.”

To cool the SiC transistors, Erhardt and his colleagues created a thin-walled cooling element with additive manufacturing technology. The transistors sit on a metal plate that is just a few millimeters thick. As a result, the transistors move closer to the cooling water, and this intensifies the cooling effect.

To prevent the thin metal plate from deforming under load, the cooling fins are modeled in a 3D printer in such a way that they support the metal plates just like the columns in a dome. This structure is so stable that the cooling element can withstand both the pressure of the cooling water and the forces occurring when the transistors are sintered onto the cooling element.

Traditionally, power modules are composed of dissimilar materials. When heated, they expand at such different rates that stresses occur in the structure. This can cause the power inverter to crack and fail.

The new Fraunhofer IZM cooling element solves this problem. Because the metal plates are kept extremely thin, they are able to compensate for the stresses occurring as they are heated or cooled by deforming slightly. As a result, the entire thermoelectrical structure is very flexible. This spares the expensive SiC semiconductors and extends their service life.

And, the new power inverter modules are not connected to other electronic components in the usual way by solid, copper conductor tracks. Instead, the structure comprising the cooling element and the SiC transistors is linked to the rest of the electronic system by stranded, flexible, fine copper wires.

The power inverter will be tested at project partner Robert Bosch over the next few months. Then, Porsche plans to install the device in a newly designed drivetrain that is precisely matched to the SiC structure.

Ultra-Sensitive Light Detector Gives Self-Driving Tech a Jolt

Autonomous cars require technology that can quickly sense and react to obstacles and other vehicles in real time. To address the issue, engineers from the University of Texas at Austin and the University of Virginia recently created a new light-detecting device.

It can more accurately amplify weak signals bouncing off of faraway objects than current technology allows, giving autonomous vehicles a fuller picture of what’s happening on the road. The device is more sensitive than other light detectors, because it also eliminates inconsistency, or noise, associated with the detection process. Such noise can cause systems to miss signals and increase the risk of accidents.

“Autonomous vehicles send out laser signals that bounce off objects to tell you how far away you are,” says Joe Campbell, Ph.D., a professor of electrical and computer engineering at the University of Virginia. “Not much light comes back, so if your detector is putting out more noise than the signal coming in, you get nothing.

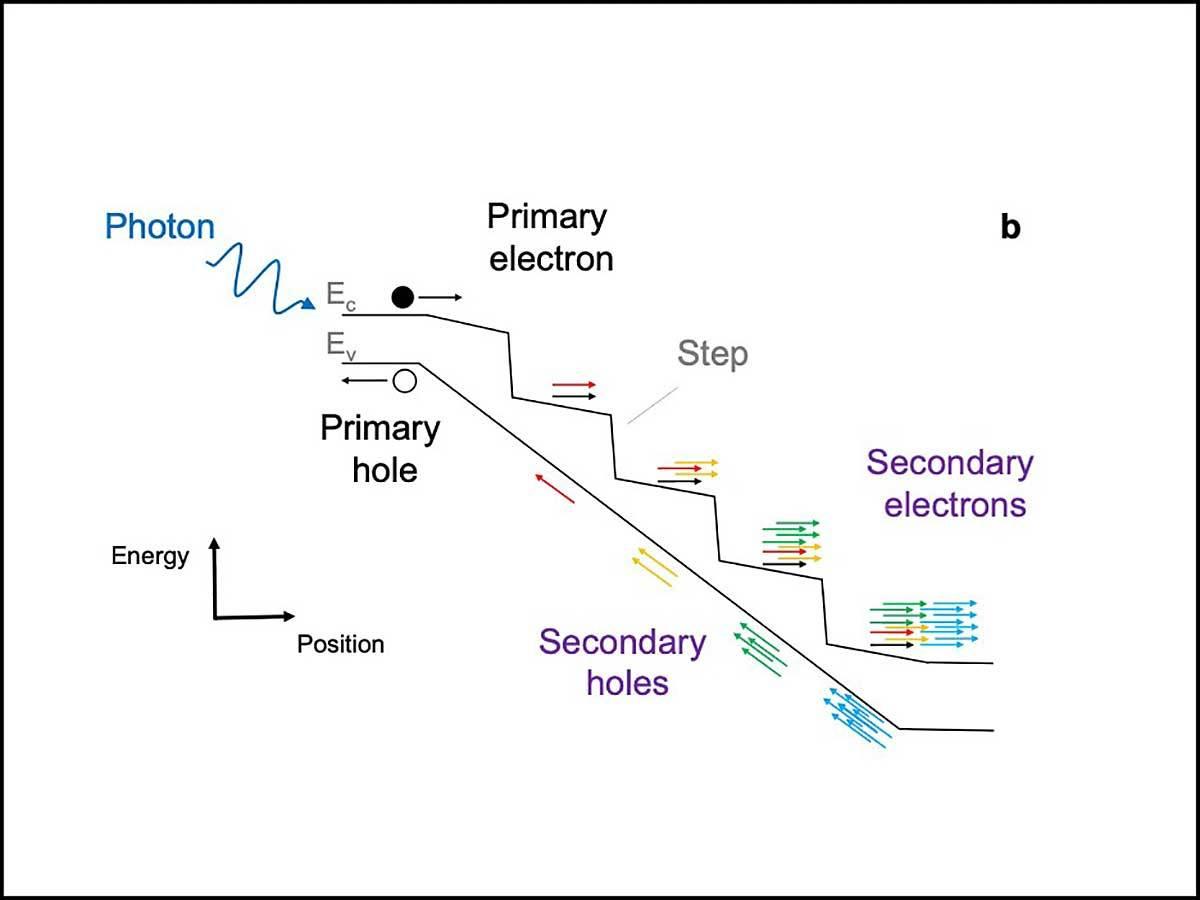

Physical steps in energy that electrons roll down, multiply along the way and create a stronger electrical current for light detection as they go. Illustration courtesy University of Texas/University of Virginia

“What makes [our] new device stand out is its staircase-like alignment,” claims Campbell. “It includes physical steps in energy that electrons roll down, multiplying along the way and creating a stronger electrical current for light detection as they go.”

“The electron is like a marble rolling down a flight of stairs,” adds Seth Bank, Ph.D., a professor of electrical and computer engineering at the University of Texas. “Each time the marble rolls off a step, it drops and crashes into the next one.

“In our case, the electron does the same thing, but each collision releases enough energy to actually free another electron,” explains Bank. “We may start with one electron, but falling off each step doubles the number of electrons.”

According to Bank, the new pixel-sized device is ideal for lidar receivers, which require high-resolution sensors that detect optical signals reflected from distant objects. Adding steps increases the sensitivity and consistency of the device. And, the consistent multiplication of electrons with each step makes the electrical signals from the detector more dependable, even in low-light conditions.

"The less random the multiplication is, the weaker the signals you can pick out from the background,” Bank points out. “The science behind this breakthrough comes in a new way of growing materials.

“Instead of growing materials with randomly distributed atoms, [we] created layered alloys composed of binary compounds—those made up of two elements—stacked on top of each other,” says Bank. “This allows [us] to change the electron’s energy landscape in a very simple way.”

The device can operate at room temperature. Today, the most sensitive light detectors need to be kept at temperatures hundreds of degrees below zero, making them too expensive and impractical for applications such as lidar.

The engineers also plan to marry their multistep staircase device with an avalanche photodiode they built last year that is sensitive to near-infrared light, which opens up new applications such as fiber-optic communications and thermal imaging.

“This should give us the best of both worlds: response to a wider range of colors and greater sensitivity to weak signals because of the lower noise amplification that comes naturally from the staircase architecture,” claims Bank.

See us at The ASSEMBLY Show Booth 331

Solid-State Lithium Battery Is Long-Lasting and Stable

For decades, engineers have tried to harness the potential of solid-state, lithium-metal batteries, which hold substantially more energy in the same volume and charge in a fraction of the time compared to traditional lithium-ion batteries.

“A lithium-metal battery is considered the holy grail for battery chemistry because of its high capacity and energy density,” says Xin Li, Ph.D., an associate professor of materials science at Harvard University. “But, the stability of these batteries has always been poor.”

Li and his colleagues believe they have solved this challenge. They recently designed a stable lithium-metal, solid-state battery that can be charged and discharged at least 10,000 times at a high current density. They paired their new design with a commercial high-energy-density cathode material.

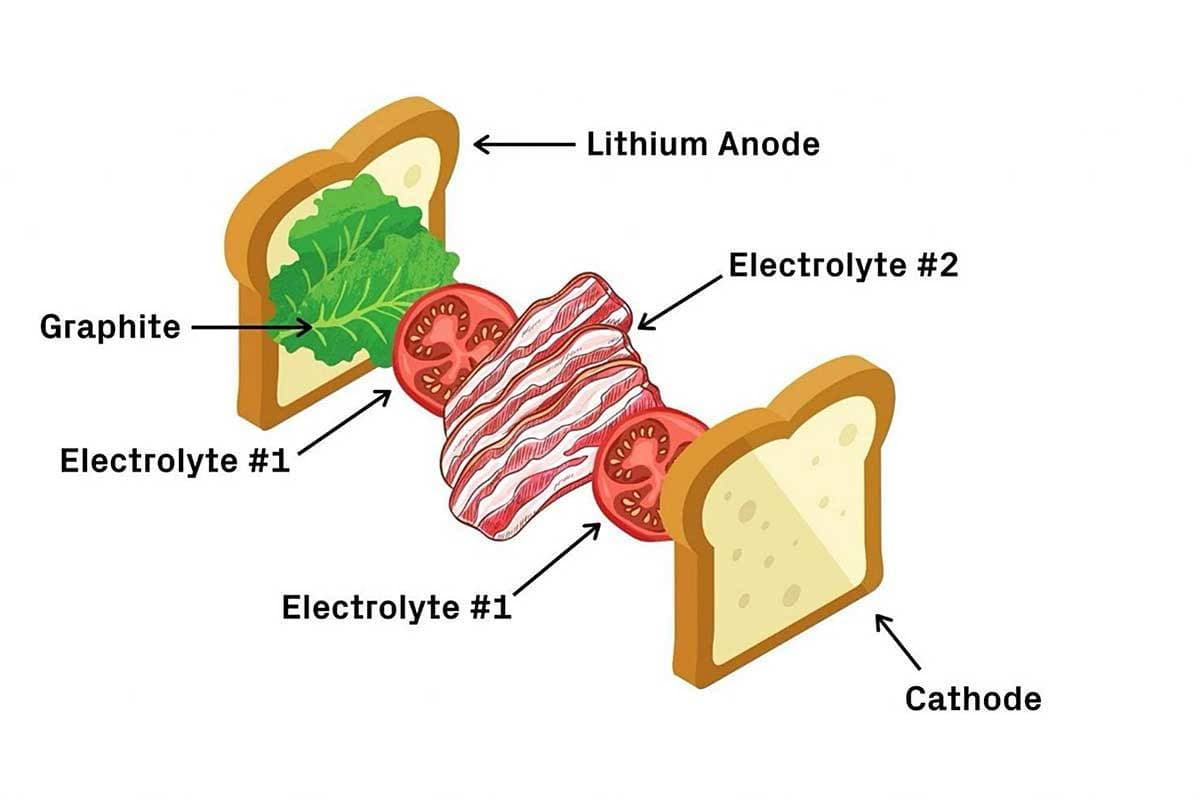

A new solid-state, lithium battery sandwiches different materials of varying stabilities between the anode and cathode. Illustration courtesy Harvard University

According to Li, this battery technology could increase the lifetime of electric vehicles to that of the gasoline cars—10 to 15 years—without the need to replace batteries. With its high current density, the battery could also pave the way for EVs that can fully charge within 10 to 20 minutes.

“Our research shows that the solid-state battery could be fundamentally different from the commercial liquid electrolyte lithium-ion battery,” explains Li. “By studying their fundamental thermodynamics, we can unlock superior performance and harness their abundant opportunities.”

The big challenge with lithium-metal batteries has always been chemistry. Lithium batteries move lithium ions from the cathode to the anode during charging. When the anode is made of lithium metal, needle-like structures called dendrites form on the surface. These structures grow like roots into the electrolyte and pierce the barrier separating the anode and cathode, causing the battery to short or even catch fire.

To overcome this challenge, Li and his colleagues designed a multilayer battery that sandwiches different materials of varying stabilities between the anode and cathode. This multilayer, multimaterial battery prevents the penetration of lithium dendrites not by stopping them altogether, but rather by controlling and containing them.

“Think of the battery like a BLT sandwich,” says Li. “First comes the bread (the lithium metal anode), followed by lettuce (a coating of graphite). Next, a layer of tomatoes (the first electrolyte) and a layer of bacon (the second electrolyte). Then, you finish it off with another layer of tomatoes and the last piece of bread (the cathode).”

The first electrolyte is more stable with lithium, but prone to dendrite penetration. The second electrolyte is less stable with lithium, but appears immune to dendrites. In this design, dendrites are allowed to grow through the graphite and first electrolyte, but are stopped when they reach the second. In other words, the dendrites grow through the “lettuce and tomato,” but stop at the “bacon,” which prevents the dendrites from pushing through and shorting the battery.

“This proof-of-concept design shows that lithium-metal, solid-state batteries could be competitive with commercial lithium-ion batteries,” claims Li. “And, the flexibility and versatility of our multilayer design makes it potentially compatible with mass-production procedures in the battery industry. Scaling it up to a commercial battery won’t be easy and there are still some practical challenges. But, we believe they will be overcome.”

september 2021 | ASSEMBLYMAG.com

Scroll to

read full article