VinFast Breaks Ground on North Carolina Assembly Plant

NEWS

VinFast is building an EV assembly plant in Raleigh, NC. Photo courtesy VinFast

RALEIGH, NC—VinFast recently held a groundbreaking ceremony here for its new EV assembly plant. The Vietnam-based automaker’s factory will produce the VF 7, VF 8 and VF 9 models, with an expected production capacity of 150,000 vehicles per year. Production is slated to begin in 2025.

“Today’s event marks a new milestone for VinFast, affirming our commitment to the North American market,” says Le Thi Thu Thuy, CEO of VinFast. “Not only will this project create thousands of jobs and contribute to North Carolina’s economic development, but electric vehicles produced here will also bring additional economic benefits to consumers. We look forward to contributing to the development of the North Carolina community—our second home—during the production and business operation here.”

Electric Vehicles Take top honors in enlighten Awards

The 2024 Polestar 2 recently received the Altair Enlighten Award for sustainability and lightweighting advancements. Photo courtesy Polestar

TROY, MI—The 2024 Polestar 2 sedan recently received the Altair Enlighten Award for sustainability and lightweighting advancements. The annual awards program, sponsored by Altair and the Center for Automotive Research (CAR), also honored the Nikola Tre FCEV truck and the Lucid Air sedan.

The Polestar 2 features next-generation electric motors, quicker charging, greater efficiency and a range of up to 654 kilometers. Despite the significant increases to performance, range and efficiency, the vehicle also boasts a reduced carbon footprint, with some versions now producing up to 3 tons less carbon dioxide compared to the launch version released in 2020. In addition, Polestar uses blockchain technology within its supply chain to expand raw material traceability and address social and environmental issues.

When developing the fuel cell powered Tre FCEV Class-8 truck, Nikola engineers emphasized recycling—100 percent of scrap produced in the production of pre-consumer batteries was recycled or reused. In addition, 100 percent of hazardous waste produced during production was safely recycled. Nikola also implemented a circular reuse program for all battery pallets, and the vehicle manufacturing process consumes no water.

Lucid Motors received a runner-up award for its Lucid Air sedan, which has set records for range, charging speeds, aerodynamics and performance. The vehicle features in-house developed technology that can add 300 miles of range in just 22 minutes of charge. It also boasts an industry-leading aerodynamic drag coefficient of 0.197, and includes trims with an EPA-estimated range of up to 516 miles and mileage efficiency of 4.6 miles per kilowatt-hour.

“The Altair Enlighten Award…showcases how the automotive industry’s leading minds—from the biggest names to its newest startups—are applying advanced technologies and responsible AI to create a better, greener industry,” says James Scapa, CEO of Altair. “Lightweighting, optimization and sustainability are more important than ever in the modern automotive industry. Altair is proud to honor the innovations that will drive the future of a sustainable industry.”

“As always, we’re honored to be presenting the Enlighten Award together with Altair, and we look forward to seeing what innovations this year’s submissions bring as we work toward a more sustainable automotive ecosystem,” adds Alan Amici, president and CEO of CAR.

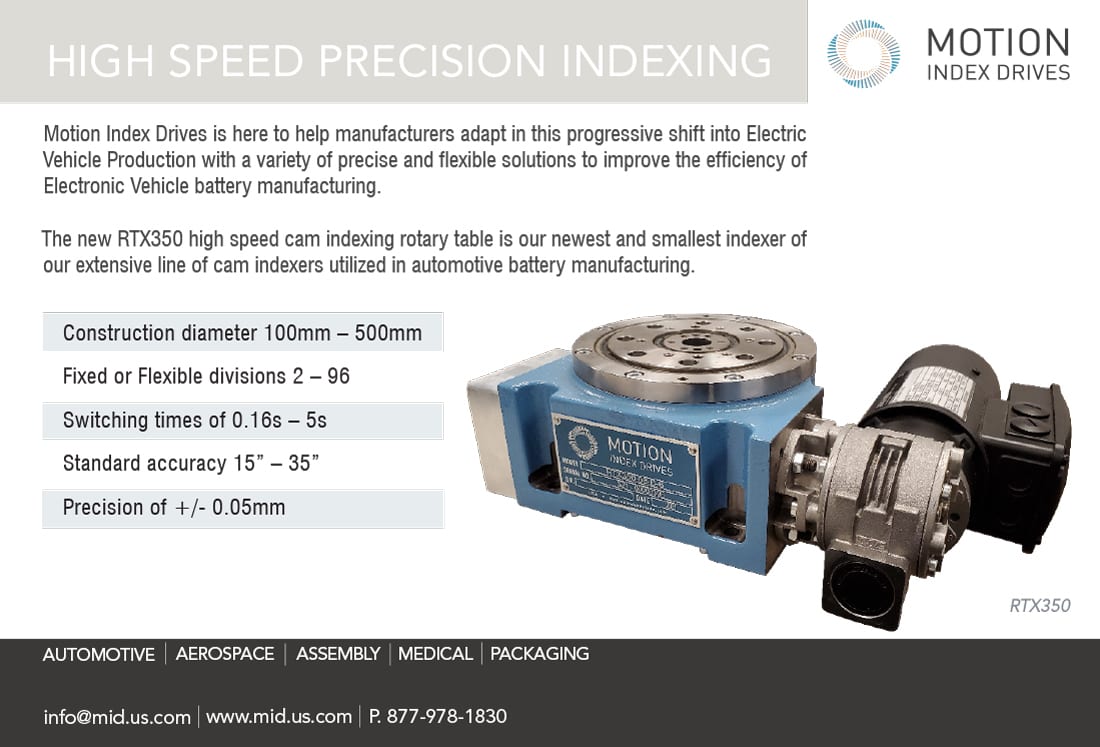

See us at at The ASSEMBLY Show, Booth 305.

Bosch Starts Assembling Fuel Cell Modules for Nikola

Bosch is producing fuel cell modules for Nikola Corp.’s much-anticipated Class 8 truck. Photo courtesy Robert Bosch GmbH

STUTTGART, Germany—Assemblers at Bosch’s Feuerbach factory have begun producing fuel cell modules for Nikola Corp.’s much-anticipated Class 8 truck, which will finally become available later year. Other local Bosch facilities are supplying components, such as fuel cell stacks, electric air compressors and recirculation blowers.

After several years of delays and setbacks, Nikola’s Tre FCEV truck will be assembled at a state-of-the-art facility in Coolidge, AZ. The heavy-duty vehicle is expected to have a range of up to 500 miles and an estimated fueling time of approximately 20 minutes.

“A hydrogen engine can do everything a diesel engine does, but on top of that, it is carbon neutral,” says Markus Heyn, chairman of Bosch Mobility. “It also allows a fast and cost-effective entry into hydrogen-based mobility. One major advantage is that more than 90 percent of the development and manufacturing technologies needed for it already exist.”

By 2030, Bosch plans to generate sales of roughly $5.3 billion with hydrogen technology. In addition to the German plant, the company is currently producing fuel cell modules at a facility in Chongqing, China.

Heyn claims that more than 3,000 Bosch employees are working on projects related to hydrogen technology. Earlier this year, the company started constructing prototypes for electrolysis using proton exchange membranes, which is the reverse of the energy conversion method used in mobile fuel cells. Starting in the fall, the company intends to make 1.25-megawatt prototypes available for pilot applications and is on track to start volume production in 2025.

Bosch is exploring several options for the future use of hydrogen, such as stationary solid-oxide fuel cells that can be used for the distributed supply of power and heat.

In addition to fuel cell power trains, Bosch engineers are working on hydrogen engines, developing systems for both port and direct injection of hydrogen. The H2 engine for heavy-duty vehicle applications will be launched in 2024.

BMW to Use Molex Electrical Interface on Next-Generation EVs

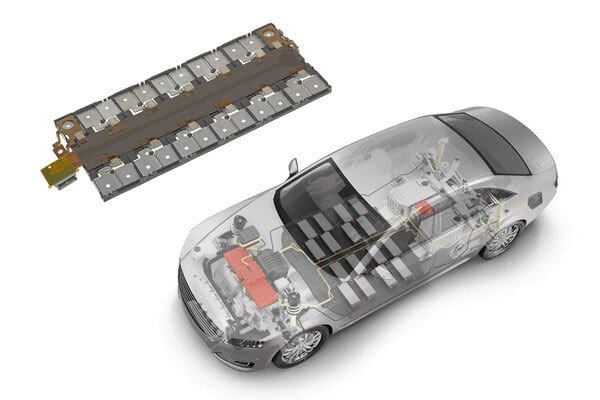

BMW Group has selected Molex’s Volfinity Cell Contacting System (CCS) for use in next-generation electric vehicles.

Illustration courtesy Molex

LISLE, IL—BMW Group has selected Molex’s Volfinity Cell Contacting System (CCS) for use in next-generation electric vehicles.

In development since 2018, Volfinity delivers a reliable and easy-to-implement interface that connects cells to the control board in an EV battery module, eliminating the need for daisy-chained wires. It enables integrated cell sensing features, cell monitoring and balancing, and temperature measurement functions, all designed to meet functional safety requirements.

“[Our] cell contacting system award is a testament to BMW Group’s commitment to driving comparative advantage through engineering innovation in the EV space,” says Steve Drysdale, vice president and general manager of the Micro Solutions Business Unit at Molex.

“Our global teams located in Singapore, China and Germany served as an extension of the BMW Group’s engineering teams, collaborating around-the-clock to provide rapid design iteration and problem resolution to innovate Volfinity to meet BMW’s unique requirements,” adds Drysdale. “Our dedication to the innovation process resulted in a transformational interconnect solution for the BMW Group, and we are thrilled to be chosen.”

Lion Electric Inaugurates Electric School Bus Factory in Illinois

Lion Electric recently opened a new factory in Joliet, IL, that will produce school buses and trucks. Photo courtesy Lion Electric

JOLIET, IL—This blue-collar city 40 miles southwest of Chicago was once famous for steelmaking and its imposing prison. Today, Joliet is home to the largest all-electric U.S. manufacturing facility dedicated to assembling medium- and heavy-duty commercial vehicles.

The 900,000-square-foot facility recently celebrated its official opening with a diesel fuel hose “ribbon” cutting ceremony attended by Illinois Governor J.B. Pritzker and U.S. Senators Dick Durbin and Tammy Duckworth.

The facility is expected to have a manufacturing capacity of 2,500 electric school buses by the end of this year. Once production fully ramps up, it will be capable of producing 20,000 buses and trucks annually.

Lion Electric chose Illinois for the state’s resources, its central proximity to customers and the domestic supply base, and for its vision that aligns with the state’s common goals for a more sustainable future.

“We are at the forefront of a manufacturing rebirth in the United States, and…we are creating the next era of transportation in the Midwest, with a critical need to reduce carbon emissions, strengthen the region’s economic vitality, and support sustainability,” says Marc Bédard, CEO of Lion Electric.

Stellantis Unveils Flexible EV Platform

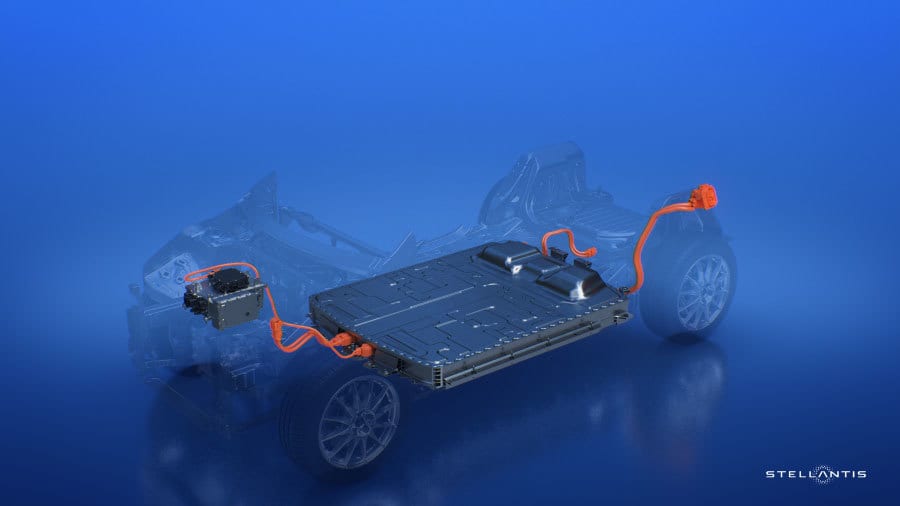

Stellantis has unveiled a new flexible EV platform dubbed STLA Medium. Illustration courtesy Stellantis

AMSTERDAM—Stellantis has unveiled a new flexible EV platform dubbed STLA Medium. It features long range (up to 435 miles) combined with flexibility that will enable the automaker to produce a variety of vehicles and propulsion configurations in the C and D market segments.

Stellantis brands currently offer 26 vehicle nameplates in those two segments, which accounted for nearly half of the 78.5 million vehicles sold globally last year. The automaker plans to produce up to 2 million vehicles per year based on the STLA Medium platform, with a variety of body styles, such as passenger cars, crossovers and SUVs. It is the first of four global EV platforms that will underpin the company’s future products as part of its Dare Forward 2030 initiative.

“What we see today is the product of just over two years of no-compromise innovation to deliver clean, safe and affordable mobility, supported by our €30 billion investment in electrification and software through 2025,” says Carlos Tavares, CEO of Stellantis. “The STLA Medium platform demonstrates the power of [our] global technical community, delivering products that are hyper-focused on our customers and rewriting long-held assumptions of transportation as we drive for carbon net zero by 2038.

“STLA Medium, which uses a 400-volt electric architecture, will deliver best-in-class energy efficiency and charging time and connectivity to a charging and services ecosystem that enhances every journey,” claims Tavares. “Depending on the application, consumption can be less than 14 kWh per 100 kilometers, which is best in class in energy efficiency. Owners will be able to take their battery from 20 percent to 80 percent charge in 27 minutes, a rate of 2.4 kWh per minute.”

Vehicles based on STLA Medium will be sold globally and be available with front-drive propulsion or all-wheel drive—with the addition of a second electric drive module at the rear—with BEV power output range from 160 to 285 kW.

According to Tavares, the flexibility of STLA Medium will provide Stellantis engineers the freedom to create vehicles with a wheelbase that can range between 2,700 to 2,900 millimeters; an overall length range of 4.3 to 4.9 meters; ground clearance of more than 220 millimeters; and wheels of up to 750 millimeters in diameter.

The STLA Medium platform can accommodate front-drive, rear-drive, all-wheel drive and multi-energy propulsion systems covered by a family of three, scalable electric drive modules. It also includes provisions for future battery chemistries, such as nickel- and cobalt-free and solid-state batteries.

“STLA Medium will deliver best-in-class battery packaging cost that also enhances production volumes,” explains Tavares. “The perimeter dimensions of the battery pack are constant among the stored energy options, with common tray and cooling designs.

“Platform components, such as the cabin heating and cooling system, steering, braking assist and propulsion are designed to minimize energy consumption,” adds Tavares. “Those efforts combine with extensive use of lightweight, rigid materials to optimize vehicle range and deliver exemplary ride and handling performance.”

september 2023 | ASSEMBLYMAG.com