product spotlight

Products

AGV Features Powered Conveyor

The HA-A50060 automated guided vehicle is equipped with a powered conveyor to increase productivity. It features a single-direction drive unit with 90- and 180-degree spin-turn capability. The unit can travel at speeds up to 164 feet per minute and can carry a load of up to 1,320 pounds.

Creform Corp.

Torque Screwdriver Is Designed for Precise Control

Torque screwdrivers are designed to provide precise control over both the electrical current (torque control) and the angle or orientation of the tool during assembly tasks. They ensure seamless operation, guaranteeing optimal performance and reliability in critical production processes.

Sumake North America

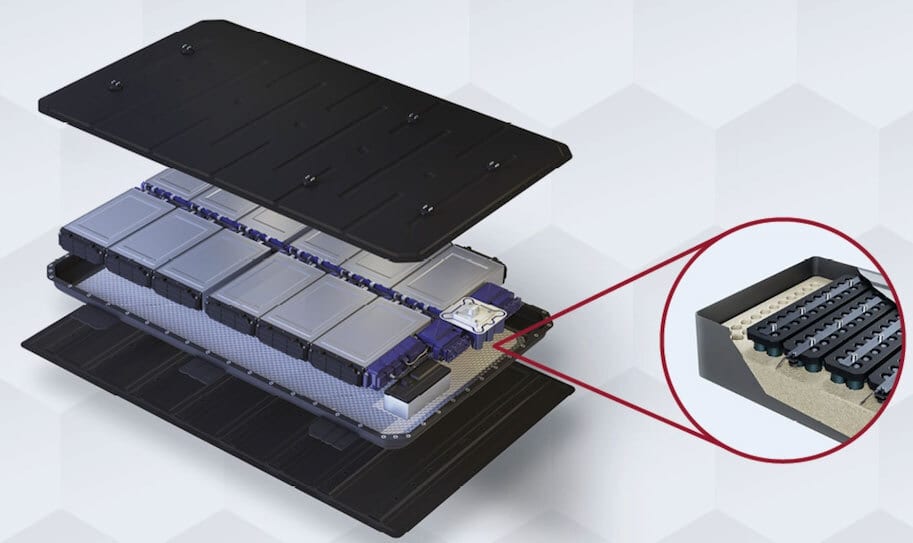

Polyurethane Foam Protects Electric Vehicle Batteries

Shokless foam systems feature lightweight, durable polyurethane that has been developed for the potting and fixation of cells mounted in EV batteries. The new range also includes products that can be used as a moldable encapsulant in battery modules or packs. They safeguard the structural integrity of EV batteries in case of impact or a thermal event.

Huntsman Corp.

Leak Tester Measures Tightness of Battery Cells

The ELT Vmax tests the tightness of battery cells filled with liquid electrolyte—whether lithium-ion or sodium-ion cells, prismatic, round and button cells with a rigid housing, or pouch cells with a soft, bag-like housing. Designed for installation in 19-inch racks, the device detects electrolyte leaking from filled cells in a vacuum chamber. It is designed for flexibility and easy integration into test systems on mass-production lines.

Inficon

Automated Rotor Assembly Line Is Compact

The PM compact rotor assembly line features multiple stations that handle a variety of production processes, including dispensing, magnet insertion, light fixation, heat curing, shaft fitting, cooling, ball bearing fitting and balancing, as well as magnetizing. It is designed to work as efficiently as possible, optimized for minimal adhesive use and quick curing. The compact machine can be easily integrated into most production lines and can process rotors up to 150 millimeters in diameter.

Grob-Werke GmbH

Sealants Enable Immersion Cooling of EV Batteries

Polyurethane-based potting compounds and sealants are designed for safe and reliable immersion cooling applications. They enable faster charging times than with conventional indirect cooling methods. They permanently seal the 0.1 to 0.2 millimeter gaps that arise when battery cells are inserted into a housing. Their thixotropy has been adjusted so that they do not flow into gaps during production of battery stacks.

Wevo-Chemie GmbH

High-Current Ring Terminals Secure Wire Attachments

BT-Series heavy-duty battery terminals are made from 0.060-inch thick brass or copper for maximum conductivity. They are designed to be ultrasonically welded for use in any high-current application. Featuring four teeth that extend 0.065-inch from the terminal surface of the ring, sharp wedges bite into metal and anchor the terminal to help prevent unwanted rotation. The terminals are ideal for any high-voltage wiring application, including EV batteries.

ETCO Inc.

Mobile Robotic Cell Provides Flexible Automation

ZiMo is a mobile robotic workcell that can be easily positioned at various locations without the need for complex integration into existing systems. An intuitive set up allows for operation without programming knowledge. A flexible configuration with quick adaptation enables ease of use, even for small-batch sizes. The mobile robotic cell also offers versatility due to its compact size.

Zimmer Group US, Inc.

September 2024 | ASSEMBLYMAG.com