ASSEMBLY HOW TO

ASSEMBLY HOW TO

SCREWDRIVING AND TORQUE CONTROL

How To Select a Screw Presenter, Pick an Air Motor & Test Torque

HOW TO SELECT A SCREW PRESENTER:

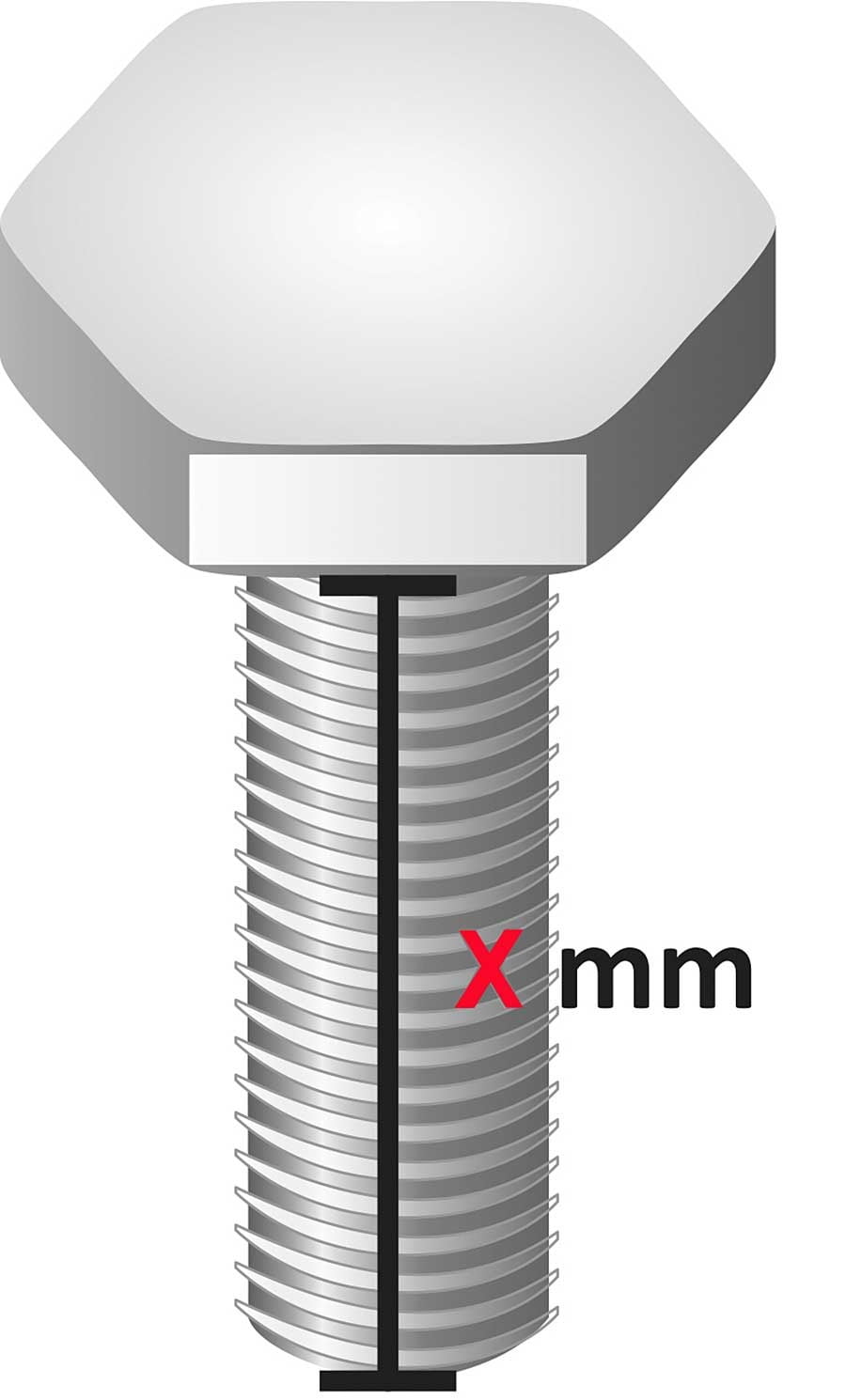

1. Determine the length of the screw under the screw head.

NOTE: ASG screw presenters cover a maximum length of 25mm. If the screw is longer than 25mm, contact the ASG service department for additional help.

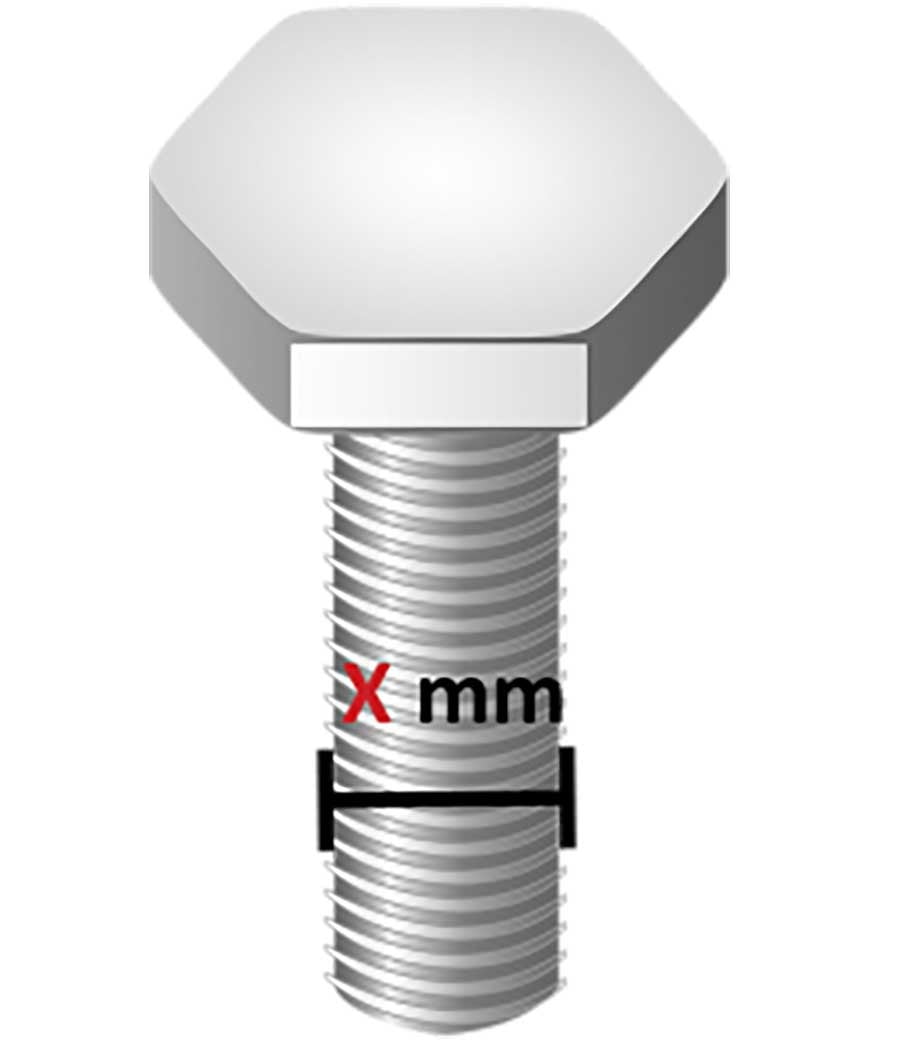

2. Determine the screw diameter by measuring the diameter of the threads.

3. Determine if the screw is ferrous or non-ferrous.

NOTE: The OM Series screw presenters can only be used with ferrous screws. Other screw presenters can be used with both ferrous and non-ferrous screws.

4. Determine if the application is manual or robotic.

Manual models include: OM-M, NSB, NSBI, NJ, and NJL series

Robotic models include: OM-R, NSR, NSRI, and NJR series

ASG offers additional presenter options for fasteners that do not fit within the specifications of the screw presenter series listed above. Please contact ASG for additional information if needed.

5. Determine the length of the screw under the screw head.

Visit asg-express.com or look in the ASG Production Aids Catalog to determine the correct screw presenter for the application. asg-express.com has filters to easily narrow down your options!

Screw presenters improve production efficiency. ASG offers a wide variety of screw presenters accommodating multiple screw sizes and types. Screw presenters are easy to set-up and use. ASG offers interchangeable rail presenters making it easy to use one unit with multiple rails for different screw sizes. The ability to change rails makes it a cost-effective option on your assembly process. Learn how to select a screw presenter that meets the requirements for your application by following these steps:

By Tim Haper, Product Manager at ASG, Division of Jergens, Inc.

tim.haper@asg-jergens.com

The Advantages of Air Motors and How to Size One

Air motors have found widespread success in both the hand-held and stationary tool industry. An air motor does the mechanical work by expanding compressed air. The motor converts the compressed air energy to mechanical work through the rotary motion. The power that an air motor produces is the end product of torque and speed. Air motors are compact, reliable, and light weight, making them an ideal solution for many applications.

Air motors are extremely versatile and can be used for mixing liquid substances, moving, drilling, milling, grinding, sawing, amongst other things. Therefore, air motors can be used with conveyor belts, machine tools, automatic feed devices, and on bottling machines. Some air motors come with ATEX certification allowing operation in an explosive environment.

In comparison to electric motors, air motors are small and light weight, easy to control, and robust in design. It is a safer solution with no risk of over-heating, sparking, or generating short circuits. Speed, power, torque, and air consumption can be easily controlled by changing the input air pressure. Air motors operate in all orientations and are reversible. If you have a space constraint, air motors could be the solution. Air motors are available with a variety of drive shaft options.

Additionally, air motors are easy to maintain and repair. Air motors can stall without damage. They can be used in humid environments and do not suffer overheating – the more the motor runs, the cooler it becomes.

HOW TO SIZE AN AIR MOTOR:

1. Determine the product performance requirement.

• Example: Need approximately 500 RPM at 2.5 N.m load

2. Calculate the size of the air motor needed using this formula:

• (π x L x S) 30 = P

• L: Torque in N.m

• S: Speed in RPM

• P: Power in Watts

• Example: Need approximately 500 RPM at 2.5 N.m load

• (3.14 x 2.5 x 500) 30 = 130.8 Watts

3. Determine if a non-reversible or reversible motor is needed.

4. Find the reversible or non-reversible air motor that has a power rating closest to the calculated power in watts.

5. Determine the type of spindle needed.

6. Determine if a mounting flange is needed.

Torque Testing & Calibration Explained

Regardless of what you’re manufacturing, implementing a torque measurement program to ensure your tools are applying the correct amount of torque is necessary.

A proper measurement program can help you avoid free fall (not tightened enough), and/or damage to either the fastener or substrate (too tight), all while extending the life of your tool.

Torque testers are a vital production component to ensure assembly tools and torque wrenches are providing accurate and repeatable results, so let’s quickly jump into their use, and highlight the process by which this testing and calibration is conducted.

Overall, the operation of torque testers is a pretty standard across the board with the exception of what some of the buttons are called between brands/models.

- First up is identifying and selecting the measuring mode for your test within the torque tester’s menu system. Peak torque, first torque, track mode, etc.

- Adjust the torque of the tool, aiming for the target torque. This might take some trial and error to align the torque output of the tool and reading on the tester.

- Apply torque to the sensor by using the tool until the tool shuts off or the torque wrench or driver hits torque.

- At this point the preliminary results should be displayed. Most companies will require a certain number of rundowns - 25 or more.

- Record the results. Many torque testers will allow you to save these for future reference.

- If the tool is not able to come into calibration, service is recommended.

ASG offers a variety of torque testing models including the DTT Series, DDT-L Series, and ST Series Smart Transducers. ASG also carries a variety of HIOS torque testers which can be used for testing or auditing depending on the needs of the operator. All testers come with a certificate traceable to N.I.S.T. Various rundown adapters are also available.

You can also Recycle your used torque tester and receive a new ASG DTT Torque Tester at a deep discounted price with our current trade in event promotion while supplies last!

April 2021

HOW TO GUIDE