ASSEMBLY HOW TO

ASSEMBLY HOW TO

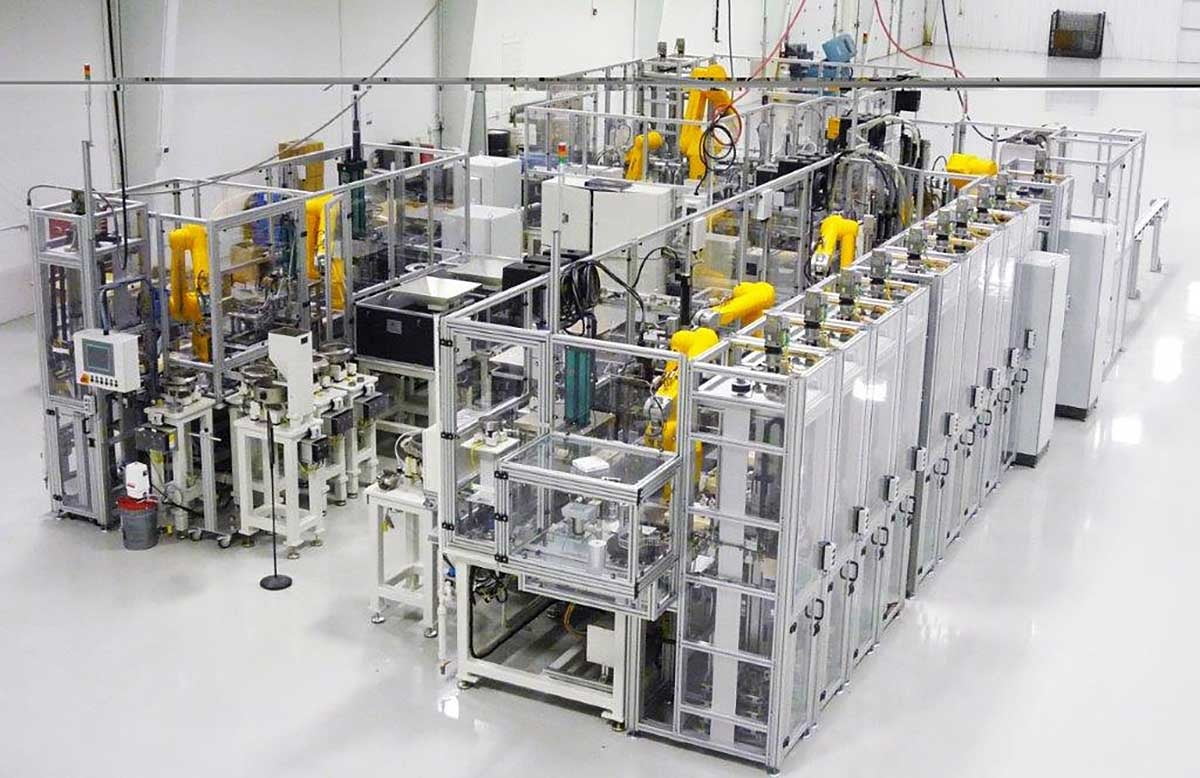

AUTOMATED ASSEMBLY

How to Manage a Capital Spending Project

Capital Project Mastery is achieved by executing at every phase of the project. Communication coupled with the tools of the trade will help ensure the project is on time and in the budget. The stakeholders will be delighted because the recognition of revenue justifies the capital investment. The implementation team will be motivated because they were a part of a successful project to add to their resume. The customer is receiving quality parts on time. Everybody wins!

Have a capital project you would like to discuss? Contact ATC Automation at query@atcautomation.com or 931.528.5417.

For more information about how to become a Certified Capital Project Manager, visit www.certifiedcpm.com. Email feedback to the author @ russ@ownyourcategory.com. Also, reach out to receive a copy of the book Capital Disaster to learn about the top mistakes companies make in executing capital projects.

Capital Project Basic Project Steps

There are five phases of a typical capital project – vision, selection, execution, implementation, and production. In this article, we discuss the vision phase of the capital project process. For more detail on all phases send a request to russ@certifiedcpm.com.

Vision Phase – As you would suspect, this is the time to clarify what the project will look like when completed and the desired output defined. In this phase, you will create the vision for the project and determine the success criteria.

The vision phase involves:

- Determining financial justification.

- Creating the executive summary.

- Defining the ideal partner.

- Completing the Request for Quote.

- Team member role definition.

- Team member selection.

- Defining acceptance criteria.

- Determining communication cadence with the team and management.

- Vision: The most successful projects are defined in the mind and on paper before being built. Imagine building a skyscraper without a plan. The skyscraper would be a disaster, yet every day, customers ask for an equipment quote without a vision for what the finished project will look like or how its success is determined.

- Success Criteria: These are performance-based metrics that you can be measure. Below is a list of typical success criteria for capital equipment:

Return on Investment (ROI): What is the target ROI for a world-class organization?

Overall Equipment Effectiveness (OEE): OEE is a formula that considers the main aspects of manufacturing equipment, including machine availability, performance, and product quality.

Budget Targets: Identify the available budget and the necessary resources to achieve the vision of the project.

Timing Milestones: Factory Acceptance Test & Site Acceptance Test plus Start Of Production (SOP), Date of Occupancy, etc.

Hours Per Unit (HPU): Utilizing this calculation helps understand the real cost per unit built

- Executive Summary: The Executive Summary (ES) is a tool used to confirm management’s commitment to the project. The intent of the ES is to help your management gain a high-level understanding of the project before it officially begins. It is also a reference document when confusion on the intent or objectives of the project arises. In other words, when management asks, “why are we doing this project?” the project manager shares the executive summary to remind them. The goal of the executive summary is stakeholder buy-in and project support.

- Defining the Ideal Partner: Just as you took the time to create a vision for a successful project, you will also want to determine what the right partner looks like for this project and your company. The most common mistake I have witnessed in my 24-year career is customers choosing with the wrong vendor.

- Request for Quote (RFQ): This document will capture and clearly articulate the expectations of the vendor. It will allow them accurately and efficiently quote the project. This document will also become the document of record if issues arise regarding vendor performance or content disputes. You will want to make a special effort to create a document that is comprehensive and an accurate representation of what a successful project looks like including the success criteria early reviewed (less the financials).

- Create Vendor Selection Criteria: Now that the successful project has been defined and the ideal vendor has been defined; we can develop a selection matrix to help us select the best vendor for the project.

About the author: Russ Sorrells owns Capex Sales and is an account manager for ATC Automation. Russ has 25 years experience in the automation industry.

My career in capital equipment began in 1994 as a manufacturing engineer. Within the first two weeks of my career, my manager turned me loose to buy a new wash system! The supplier search began by flipping through the Thomas Register (the encyclopedia of suppliers - no internet back then). I settled on three companies and shared my two-page request for quote with each of them. After receiving the quotes, we selected our supplier. I made every mistake in the book, including violating the two rules of project management – don’t be late and over budget. Capital equipment, it turns out, is justified based on payback. When the project is late, it delays the savings of implementation. When the project is over budget, the cost justification is no longer valid. I went to a great university, but they did not teach about managing capital projects. Below is a guide to help you benefit from my failures.

Having a well-defined selection matrix makes the vendor selection process much clearer and eliminates any potential jury tampering.

- Team Member Roles Defined: High-performance project managers clearly define expectations for each project team member role. The reason is that team members will come to the project with their own objectives that might not align with the PM›s objectives. Defining the expectations upfront can eliminate confusion about what is expected from the team member filling a specific role.

This role definition process is defined in later chapters of the CPM book.

- Team Member Selection: This step for ensuring success may or may not be within the project manager›s control. In the creation of the executive summary, we encouraged the project manager to note the ideal team members within the organization to help bolster the chances of a successful project. Some of those team members will be available, and some will not be available due to limited time and other commitments. Ask for what you want but be prepared to accept what is available.

- Acceptance Criteria: This includes the project success criteria previously described but then goes more in-depth. The acceptance criteria will be checklists provided by various departments. These typically include a quality checklist, safety checklist, maintenance checklist, facilities checklist, and machine spec compliance checklist. These are usually predetermined and do not require additional work to create. Visit www.certifiedcpm.com/

checklists for sample checklists.

- Determine Communication Plan: The best strategy for ensuring world-class communication is to schedule it and do it. Put the communication plan on the calendar and stick to it. Even if you have nothing new to report, it is a good idea to send a message out to the team and stakeholders to let them know you have nothing to report. Over-communicate.

April 2021

HOW TO GUIDE