ASSEMBLY HOW TO

ASSEMBLY HOW TO

AUTOMATED ASSEMBLY

Evaluate Your Screw Driving Application

Cycle time is an important requirement. It takes about 3 seconds per screw for a system to move to point, feed and drive. If you need 400mm in the Z-axis and using a pneumatic axis, you have to add a couple seconds. A servo axis is much faster and takes less time. If you only need 100mm (or less) and are using servo axis, you can subtract a second. Using pick and drive, you need to add a couple seconds. But using 3 seconds to start is safe and allows you to explore your options.

Your equipment provider will size your motor, based on the torque requirement. Generally, this will be around the 50% of the max torque of the motor, insuring the motor is not overworked or oversized. But electric motors generate heat and need to cool down. A fast duty cycle may not allow the motor enough time to cool down. For example, you drive 17 screws per part, with 15 seconds between the last drive and the first drive of the next part, with no problems. If that same application only has 3 seconds between the last screw and the first screw of the next part, it may not adequately cool. If the equipment provider has this information, they will size the motor larger, around 25% of the max torque. This larger motor will not heat as quickly in the higher duty cycle applicaiton.

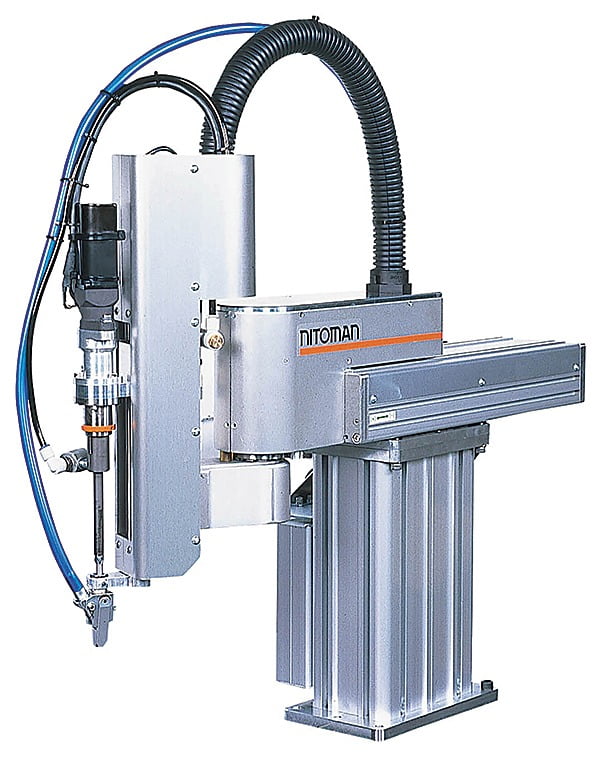

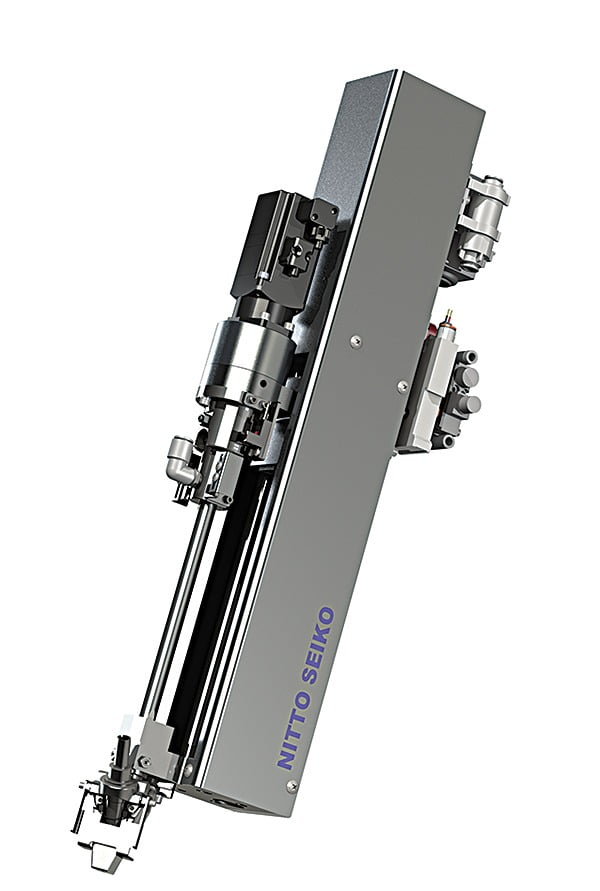

The geometry of the part is going to determine the type of spindle, chuck, stroke and options needed. If all the screws are in one plane, a pneuatic axis should be sufficient. If they are in multiple planes, you will need a servo axis for programmable heights. If there are no obstructions near the screw, then a chuck-style driver may be best. Chuck style drivers need clearance around the hole for the chucks to open up. If there are obstructions, a vacuum driver is best. With a vacuum driver, the chuck is stationary and a vacuum tube sucks the screw to the bit, then advances through the chucks to the part. This type only needs a clearance 1mm greater then the head diameter of the screw, allowing access to tight spaces and deep recesses.

Stroke is next. You want to be as close as possible to the part to decrease cycle time, but you also need to move around the part safely. Calculate the distance between the lowest screw and highest feature. Thie driver will be as close as possibly, with no crash conditions.

Preparing this info is going to lessen chances something gets overlooked in your application.

Next comes the fastener. There are two ways to handle the fastener in automated fastening. First is blow feeding, second is pick and drive. Blow feeding the screw is always desired, if possible. Blow feeding is fast and the feed time can be buried by various methods, such as a high-speed chuck that allows you to feed while you are driving. For pick and drive, seconds are added to each cycle in order to move to the feeder, pick the screw, return and drive.

The geometry of the screw will determine the method to be used. If the ratio of the head diameter to length of screw is too small, the screw will tumble in the tube, or chuck, and can’t be orientated to the bit. A rule of thumb is anything larger than a 1.5 ratio (head diameter 10mm with length of 15mm, for instance) can be reliably fed. Under that, there are other factors that need to be considered. With an anti-tumble chuck, you can go down to 1.2, or even lower. Your equipment provider can evaluate the fastener for you.

Automating your screw driving processes can be a quick way to get a return on your investment and improve your manufacturing operations. There are many factors your equipment provider will need to know, in order to provide you your best solution. Evaluating this information ahead of time will let you understand your application better and make working with your equipment provider a smoother and more accurate process.

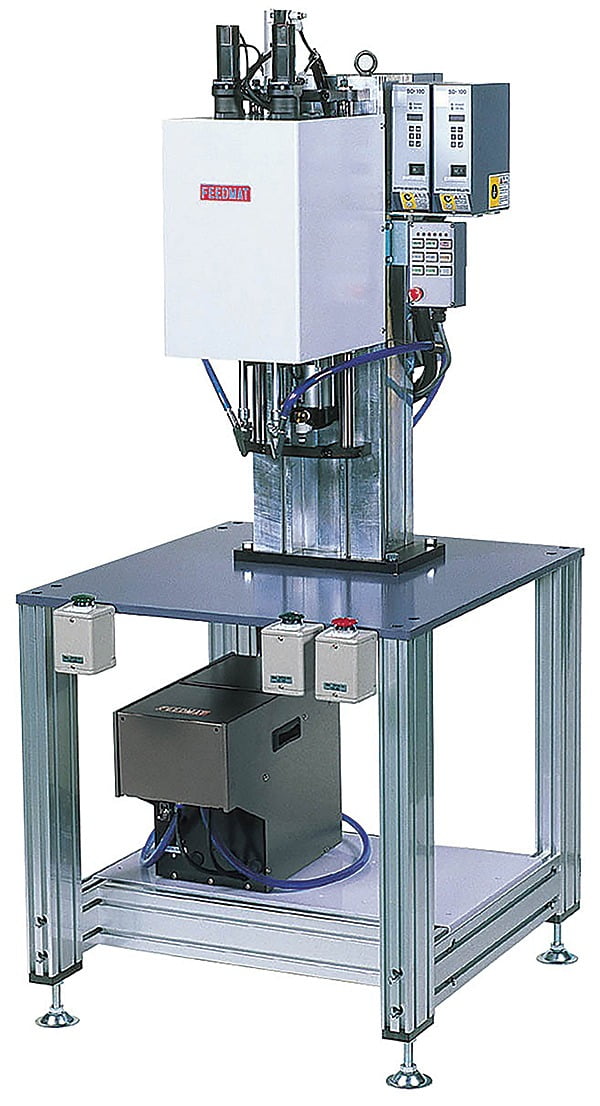

The first question to ask yourself is “Why do I want to automate this process?” The answer will steer you towards the equipment you will need. If you are looking for ergonomic benefits, you may just need a self-fed handheld driver. If you are looking to remove an operator from the process, a single spindle or robot might be your answer. If speed is the concern, a multi-spindle driver would deliver the highest rates. If you are looking for flexibility for many different products or models, a robot is your best bet. All of these can be coupled with a motor, from a pneumatic, up to an AC Servo motor with a transducer and waveform analysis, to match the level of quality needed.

April 2021

HOW TO GUIDE