ASSEMBLY HOW TO

ASSEMBLY HOW TO

MOTION CONTROL

HOW TO pick the right damper for your application

Sizing a damper

When beginning to size a damper, one needs to first calculate the kinetic energy at impact is generated by the load.

This calculation depends upon a number of factors such as mass, impact speed, gravity, whether it’s free moving or driven, translational (linear) or rotational, and stroke of the shock.

This yields energy per stroke, which when considered with cycles per hour, gives energy per hour.

Using energy per hour we can pick a shock or shocks appropriately.

Hardness of the shock based on the impact speed.

Zimmer Group offers a convenient online sizing tool that can guide a user through the selection process for a wide variety of application examples.

Dampers and shock absorbers are integral parts of almost every automation application. From simple damping of sliding doors on CNC mills, to end stops on linear slides, to dampers on conveyor pallets preventing impacts, to PET blow molding machines, selecting the right damper for your application can be of the most important choices when designing a machine.

Proper sizing of a damper that can handle the demands of your application can be the difference between a smoothly operating, long lasting machine and a machine that breaks down due to harsh impacts, vibrations, and crashes.

In today’s highly productive, high yield manufacturing environments, improperly sized dampers can lead to costly machine downtime due to errors and emergency stops.

Different types of dampers

Before sizing a damper that is right for your application, let’s take a quick look at different kinds of dampers.

The most basic dampers are springs or rubber bumpers. These usually offer little damping as they usually rebound the energy directly back following impact with little control.

Profile dampers are a further improvement to the standard rubber bumpers. They are usually made from co-polyester elastomer and with shapes engineered to absorb energy and dissipate rather than rebound, they are a better choice than springs or rubber bump stops. They are usually highly resistant to harsh conditions without the swelling, becoming brittle, or decomposing that may occur with a standard rubber bumper.

Industrial shock absorbers are the most reliable way to decelerate load, while still providing smooth damping and being able to stop to a fixed repeatable point.

Most industrial shock absorbers are hydraulic cylinders with a piston assembly. When a load is put on the cylinder’s piston rod, the piston pressurizes the fluid and force it to travel past the piston via some sort of restricted path. These pathways act as throttles, slowing the fluid’s movement, and in turn decelerate the load. The fluid also heats up due to its viscosity, converting the load’s kinetic energy to heat and transferring that out of the shock through its body.

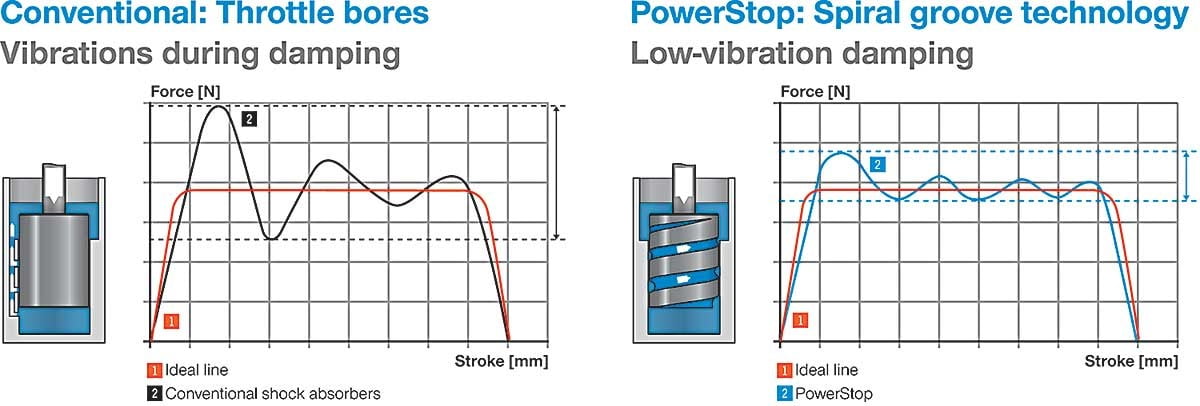

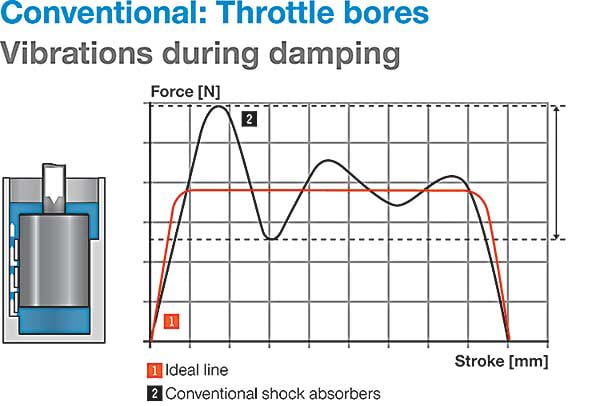

The most common shock absorber uses a series of restricting orifices or throttle bores to provide a pathway for the fluid. Depending on piston position and stroke of the piston, different amounts of throttle bores will be active. A problem with this is that the damping curve can be inconsistent through the stroke range. Additionally, the throttle bore method can introduce vibrations and excess heat as each throttle bore become active. Excess heat can cause the fluid to lose its viscosity and reduce its damping effectiveness.

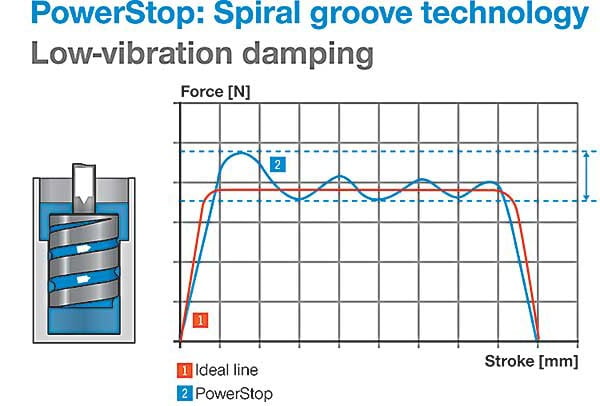

A more refined method of moving the fluid past the piston is the use of a continuous, consistent pathway such as the decreasing diameter spiral groove machined into the piston on Zimmer Group’s new PowerStop 2.0 shock absorbers. The spiral groove ensures consistent damping rate throughout the stroke of the shock, whether just a few millimeters into the movement, or near the end. This also reduces vibrations, and keeps the fluid cooler, allowing it to absorb more energy over time and extend its lifespan.

Other considerations

Other factors to be considered in selection would be environmental concerns, such as installation in a corrosive environment, or extreme temperatures. An all stainless steel shock may be necessary.

If the shock absorber will be subjected to a wide range of impact speeds, an adjustable shock absorber may be needed.

If there are dust/dirt/coolants present, the shock absorber may need to be protected to prevent ingress of contaminants.

Shock absorbers used in food handling applications may require to be filled with foodsafe/biosafe hydraulic fluid.

Zimmer Group offers a wide variety of innovative dampers, from the industry leading “PowerStop 2.0” shock absorbers to “BasicStop” profile dampers and all associated accessories.

If you need assistance in selecting the proper damper for your application, please do not hesitate to get in touch with any of our sales engineers at Zimmer Group.

Figure 1 – Conventional Throttle bores vs. Spiral groove method

Figure 2 – Zimmer Group Industrial Shock Absorbers PowerStop

Figure 3 – Adjustable Shock Absorber PowerStop 2.0

April 2021

HOW TO GUIDE