Jim Camillo // Senior Editor // camilloj@bnpmedia.com

Welding

This manufacturer uses a custom 16-gun machine to spot weld hat-section stiffeners used in hollow metal prison doors. Photo courtesy T.J. Snow Co.

Optimizing the Spot Welding Process

Spot welding can be improved in many ways, starting with selecting the right machine, maintaining heat balance and using advanced controls.

Kaizen, or continuous improvement, is a basic tenet of lean manufacturing. It says, in effect, that less-than-optimal is never acceptable. The concept can be applied to every major assembly process, including resistance spot welding.

Spot welding involves generating heat at the interface of the parts to be joined by passing an electrical current through the parts for a set amount of time and pressure. Engineers obtain a strong weld by carefully determining the best combination of time, force and current.

The technology is widely used in the automotive, aerospace, white goods and electric-vehicle battery industries. It’s fast, cost-effective and flexible enough to use on both aluminum-to-aluminum and steel-to-steel joints.

“Despite being the fastest way to join sheet metal, and producing the strongest bonds of this type of metal, resistance spot welding does present a challenge,” explains Tom Snow, chairman of the board of the T.J. Snow Co. “Unlike with an arc weld, machine operators can’t simply look at the part and know for sure it has a good welded joint. It may look fine, but only by using the proper amount of heat, force and duration, and then testing the joint, can an end-user be sure the weld has the required strength.”

T.J. Snow has been making and repairing standard and custom resistance spot welders since 1963. The company’s pedestal-type SlimLine machines come in horn and platen styles, and use one or multiple weld heads. Standard features include a rigid heavy-duty frame, a fixture-type transformer and an easily adjustable electrode gap.

Last year, T.J. Snow supplied a custom SlimLine machine to a Tier 1 aerospace manufacturer to spot weld exhaust components for jet engines. The parts are made of a high-temperature alloy. A robot picks up each part and places it inside the throat of the machine, where the part is welded within 1 second. After this, the robot places the assembly on a conveyor.

Popular and Powerful

Spot welding is actually undergoing a kind of renaissance. After being accidentally invented by engineer Elihu Thomson in 1885, spot welding slowly grew in usage until the late 20th century. Then, technologies like laser welding, friction stir welding and advanced arc welding were considered the future of the technology. Now, however, advanced machine controls are helping spot welding recapture its place as a leading type of welding—by fully optimizing its process.

Spot welding is the most common type of resistance welding used in assembly. Other types include butt, projection, seam, percussion and upset welding. These methods primarily differ by the type and shape of electrodes that apply the pressure and conduct the current.

A typical resistance spot welding setup consists of a power supply (also known as a welding controller), a transformer, one or more weld heads, positive and negative electrodes, and, optionally, an external monitor. The power supply uses either closed-loop or open-loop technology, according to Marty Mewborne, sales engineering manager at Amada Weld Tech Inc.

Closed-loop technologies include linear DC and a high frequency (HF) inverter. Both types respond well to changing resistance values every 10 to 250 microseconds, thereby keeping the programmed parameter (current, voltage or power) constant for more consistent welds.

Mewborne says that open-loop technologies have been around longer and include capacitor discharge (CD) and direct energy (AC). They offer little or no feedback and are more susceptible to electrode wear and part positioning challenges.

“Years ago, AC-type transformers were very popular,” notes Don DeCorte, vice president of resistance welding products at RoMan Manufacturing Inc. “But now, because electricity is much more expensive, manufacturers have a greater need for more-efficient MFDC (medium frequency direct current) transformers.”

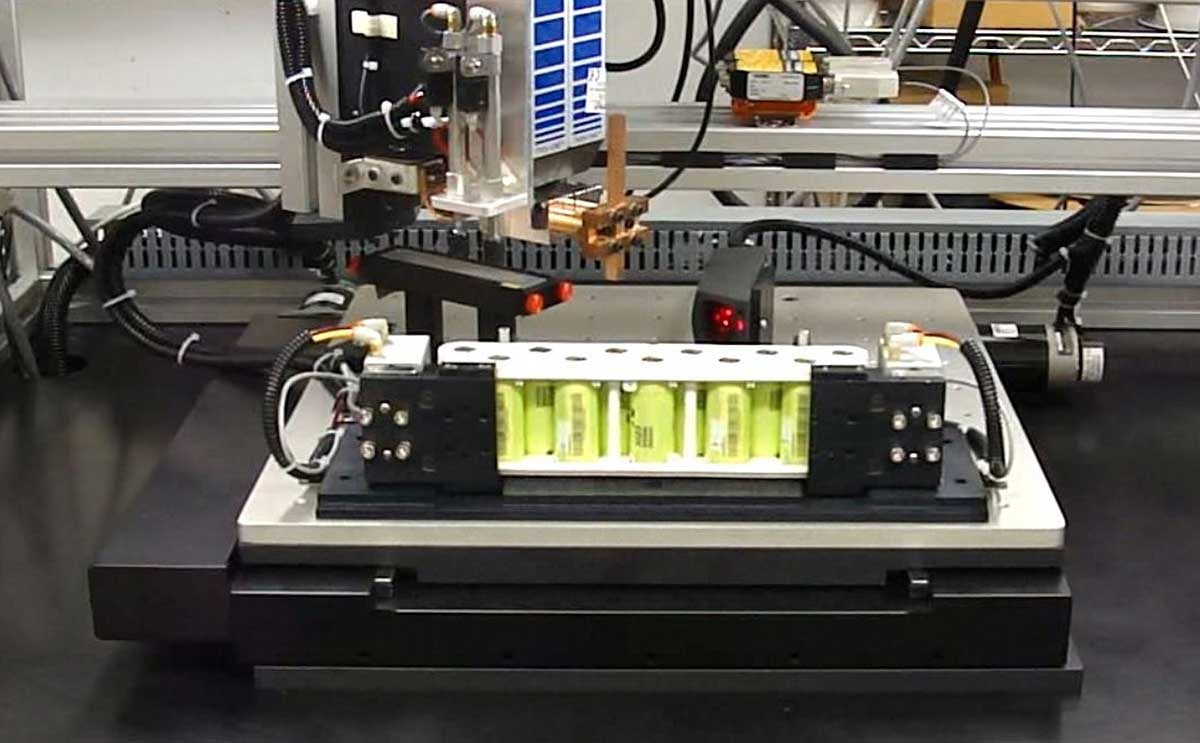

Resistance spot welding is widely used in the automotive, aerospace, white goods and electric-vehicle battery (shown) industries. Photo courtesy Amada Weld Tech Inc.

RoMan is the largest manufacturer of standard and custom transformers for resistance welders in the world, according to DeCorte. He estimates that 85 percent of all such welders in the United States work with a RoMan transformer. The transformer weighs from as little as 12 kilograms, to as much as 5 tons, depending on the welding machine.

“Some time ago, we were contacted by a long-time customer that makes lawn tractors, mowers and other lawn-and-garden equipment about changing its resistance spot welding system from one with a single-phase AC transformer to our MFDC model,” says DeCorte. “The company plant had recently added some new AC equipment to several older AC welding machines.”

Unfortunately, the plant engineers had not taken the additional loads into consideration and were now overloading the power system of both their plant and that of neighboring plants. The local power company got involved and forced RoMan’s customer to only operate during its second and third shifts to spread out the power demand. This caused several production problems.

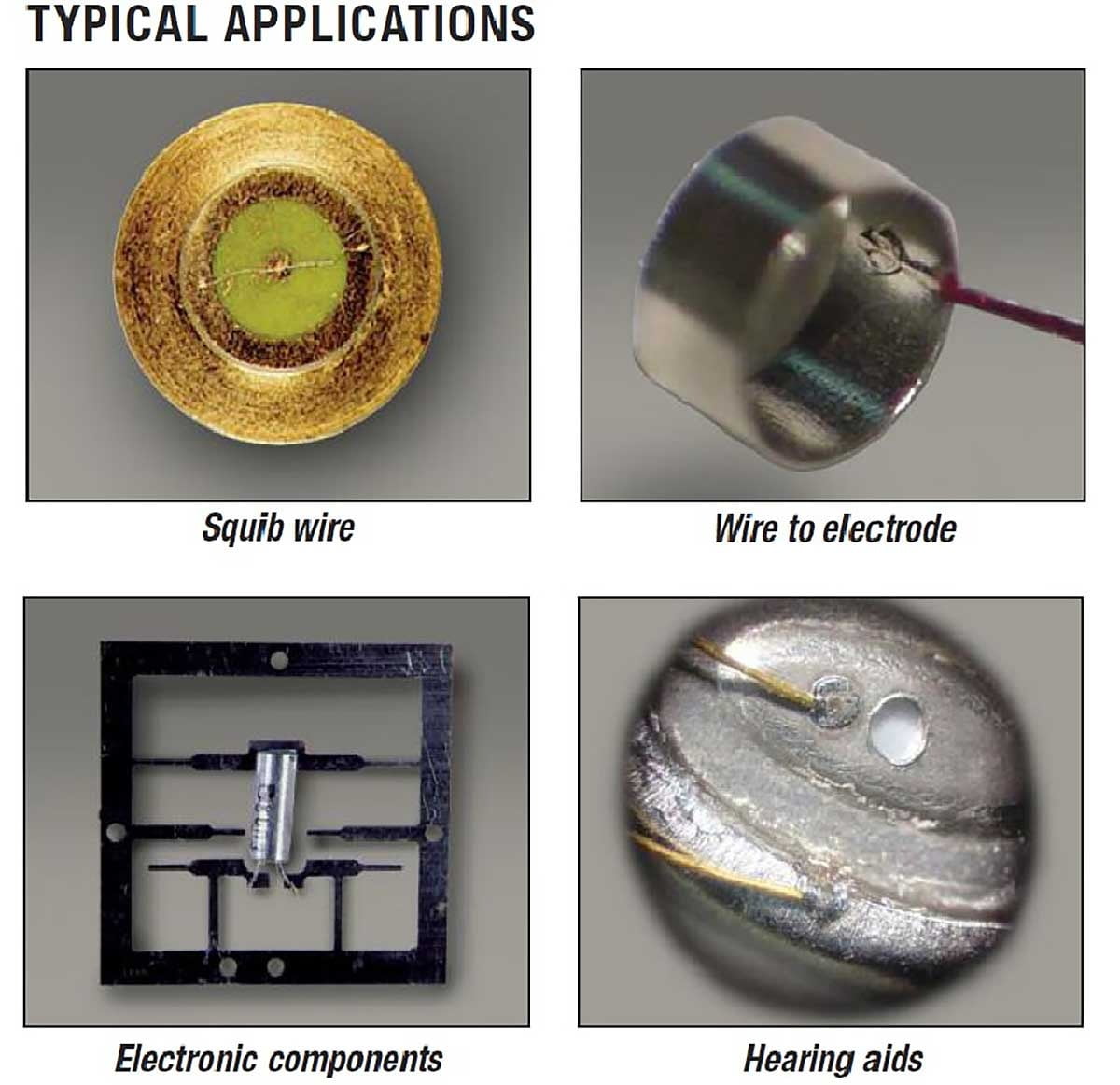

Spot welding is used to join many types of parts. This is just a small sample. Photo courtesy Amada Weld Tech Inc.

“We showed the company that changing to the MFDC process would lower the overall power consumption to about 70 percent of what it was,” says DeCorte. “This allowed them to go to daytime-shift operation and still have some room for future growth. It also saved them from having to upgrade expensive primary transformers on the plant roof, wire feeders and other related power equipment.”

Spot welding weld head types include manual, pneumatic, motorized servo and electromagnetic. Weld head dynamics refers to the way the head moves and interacts with the parts during each phase of spot welding: approach, impact force, squeeze, fire (triggering the power supply to weld), follow-up and hold for solidification.

Electrodes are configured directly, indirectly, in parallel or in series. Tip materials include copper chromium alloy, aluminum oxide, copper cobalt beryllium alloy, molybdenum, tungsten and copper tungsten alloy.

The spot welding process can be semiautomatic, fully automated or integrated into an assembly line. In a semiautomatic workstation setup, an operator loads parts into a fixture, presses dual buttons or uses a foot switch to activate welding, and then unloads finished parts.

A fully automated station typically has a six-axis robot picking up parts and moving them to the machine for welding before placement on a conveyor. The inline approach involves automatically placing each part into a machine at a dedicated workstation, activating welding and then removing the part.

Many Ways to One Goal

Ideally, spot welding optimization begins with machine selection. Snow says manufacturers need to focus on a few key factors during the selection process.

The first is to find a machine that can make optimum-strength welds with about 25 percent of its available amperage and force range left in reserve. Engineers also need to be aware that a too-large machine can cause just as many problems as one that’s too small.

This is especially important when the air-cylinder diameter is so oversized that it must be run on an air-line pressure below 40 pounds to achieve the desired weld force. Unacceptable weld strength can result from inadequate air-cylinder follow-up at the instant the sheet metal reaches the molten state, the point at which the metals need to be properly forged.

“All spot welding equipment should be sized and specified from the electrodes back, but end-users can only properly do this after knowing exactly what the work is, what they are welding,” explains DeCorte. “Having a safety margin is good, but too big means waste and not optimization, so don’t oversize. And don’t buy equipment strictly based on its KVA (kilovolt-ampere) rating.”

For manufacturers already using spot welding, Snow recommends they immediately purchase a resistance-welding amp meter and a direct-reading force gauge, if they don’t already own them. The meter accurately measures the secondary root mean square (RMS) welding current that is delivered to the electrode tips. And the gauge measures the actual weld force between the tips.

“Testing spot welds should be more scientific than dropping welded parts on the floor,” notes Snow. “The best quality-assurance tool is a tensile tester designed to pull small welded sample coupons to failure. The shear strength of a good spot weld should exceed that of the parent material.”

Next, carefully determine the weld window (or lobe) for the application. Within this window are all combinations of current, force and time settings that produce acceptable welding results.

Starting in the middle of this range, rather than on the ragged edge, allows the spot welding process to be the most stable and reliable, according to Snow. The operator needs to confirm the optimum weld recipe and use those parameters as a starting point for the production run.

Highly conductive materials usually require electrodes of high resistance. Similarly, hard materials require softer copper-based electrodes. If stored energy or half-cycle equipment is used to weld dissimilar materials, place the more resistive material against the negative electrode. Likewise, if similar materials with thickness ratios greater than four-to-one are welded, place the thinner material against the negative electrode.

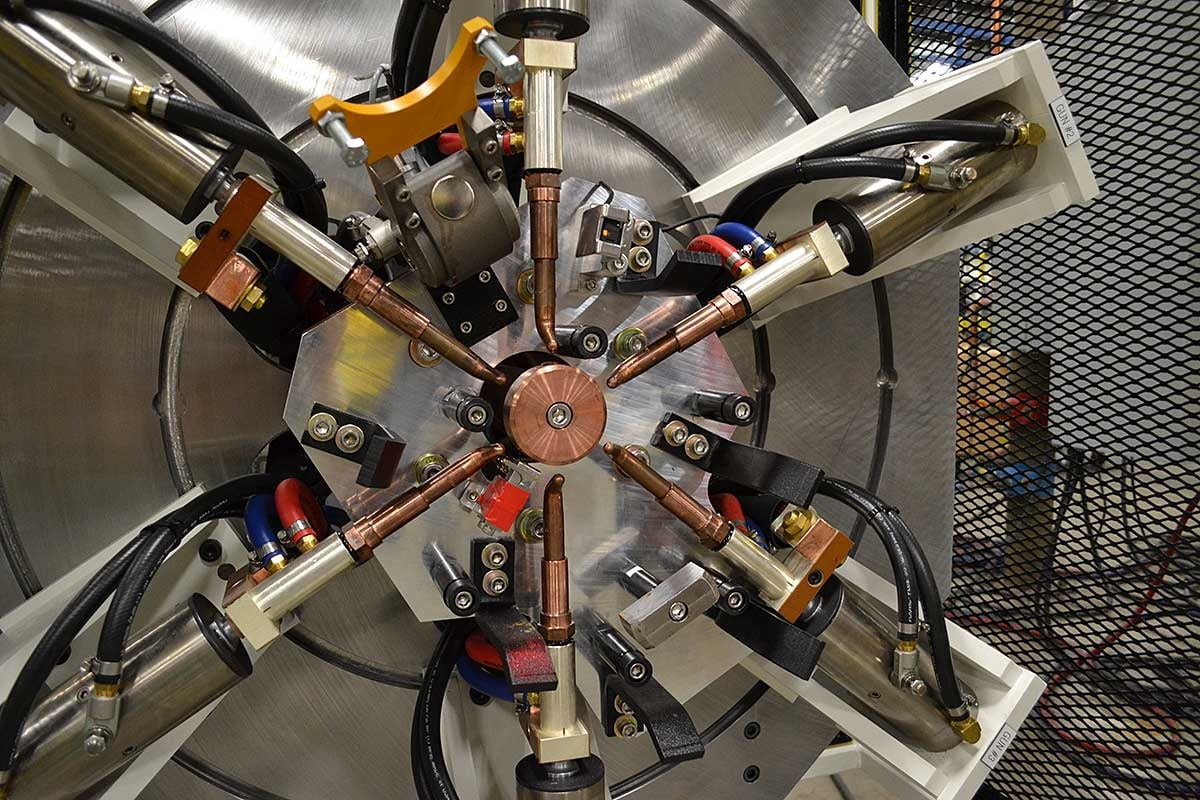

Automotive mufflers are often spot welded. This six-gun radial machine was custom-made to weld mufflers. Photo courtesy T.J. Snow Co.

DeCorte also recommends engineers study Joule’s Law to gain a better understanding of all input elements and variables related to the spot welding process. This law says that heat required to make the weld is proportional to the resistance of the work, the time the current is applied and to the square of the welding current applied. DeCorte cites welding time, work resistance and secondary current as the most important factors to fully understand relative to this law.

During production, heat balancing is necessary to form the weld nugget at the right location between parts. Achieving this can be challenging, says Mark L. Boyle, Ph.D., product manager at Amada Weld Tech Inc., because materials can be of a different conductivity or thickness, and the heat sink could be drawing heat away, creating a weld nugget in the wrong place.

Suggested remedies include increasing electrode force or upslope time to shift heat away from contact areas. Manufacturers can also increase electrode face size to shift heat away from the electrode, or use a more resistive electrode to draw heat toward it.

Spot welding systems require a transformer, such as the MFDC (medium frequency direct current) model. Photo courtesy RoMan Manufacturing Inc.

“Troubleshooting spot welding should always begin by referring to the process audit worksheet (PAW) to verify all of the process settings, like power supply schedule, menu, head force and speed,” says Boyle. “The materials being welded should also match what’s on the PAW.”

Mewborne cites weak welds, insufficient nuggets and sparking as being among the most common symptoms of less-than-optimum spot welding. The latter problem can occur as a result of insufficient force, no squeeze and poor follow-up.

Further troubleshooting may involve checking things related to the materials, machine and operator, according to Mewborne. For example, if a new lot of materials is causing problems, look for some parts from a previous lot to see if they will still weld normally.

“Check the power supply, and make sure it is connected to the correct line voltage and that all of the electrical connectors are secure,” suggests Mewborne. “Also check the tooling that holds the parts in alignment with the electrodes to ensure it has not been modified or damaged.”

Regarding veteran operators, find out if they are doing anything differently, including electrode maintenance, part handling and initiation procedure. If new operators are using the equipment, make sure they have been properly trained on the full operation of spot welding.

“Ninety percent of resistance spot welding problems occur at the business end,” says Boyle. “That encompasses material control, part-to-part positioning and electrode-to-part positioning.”

“Weld quality must always meet the end-user’s specific application requirements,” adds DeCorte. “The best way to do this is to create and implement a weld verification process for all equipment, along with a detailed process for preventative maintenance of the equipment.”

Also be sure to properly size the plant’s water supply to meet equipment requirements. DeCorte says this is one of the main reasons for spot welding failure. The same risk applies to plant power and air supplies.

Finally, DeCorte emphasizes the need for each operator to receive high-quality, complete and ongoing training in resistance spot welding. He recommends the Resistance Welding Manufacturing Alliance as a great source for this level of training.

“Spot welding is the most robust of all welding processes because it has the fewest variables to deal with and the least amount of operator input,” concludes DeCorte. “Not understanding the process can result in wasted time and money. Proper training is a cheap way to assure success.”

ASSEMBLY ONLINE

For more information on resistance spot welding, visit www.assemblymag.com to read these articles: