Produce More with Less Labor

Today’s labor market is tight, making recruitment difficult. High training costs, absenteeism and low retention rates can cause expensive production shortfalls and quality issues. Here’s a lighted hearted look on how to navigate through the challenge of this labor pool. It is a step-by-step analysis of how to capture the low hanging fruit as well as the fractions of percents. The combination of these improvements can result in dramatic increases in productivity with less labor. Worksmart Systems, a leader in Lean Assembly implementation, produced this video to assist in continuous improvement.

Meeting Market Deadlines with Scalable Automation

A leading medical device manufacturer faced a critical challenge: their initial automation supplier was falling behind schedule, jeopardizing a key product launch. Delays threatened substantial market share and revenue losses. Turning to Arthur G. Russell Co. (AGR) for a solution, the manufacturer required swift, effective action.

AGR responded with unparalleled speed and precision, delivering a 30 PPM (parts per minute) machine in under four months. This rapid solution ensured the product launched on time, safeguarding the manufacturer’s market position. Following this success, the customer quickly commissioned a second 30 PPM machine to meet growing demand.

AGR’s strategic approach also minimized risk. By validating automation concepts on the first two lines, AGR set the foundation for future high-volume production with proven technology and processes.

“Our unprecedented collaboration showcased the true power of teamwork and innovation,” said Jason Ensminger, President of AGR.

AGR’s scalable solutions not only addressed immediate challenges but positioned the customer for long-term success. With expertise spanning proof of principle to full-scale automation, AGR ensures timely market entry and the flexibility to scale efficiently as demand grows, making them a trusted partner in the competitive medical device industry.

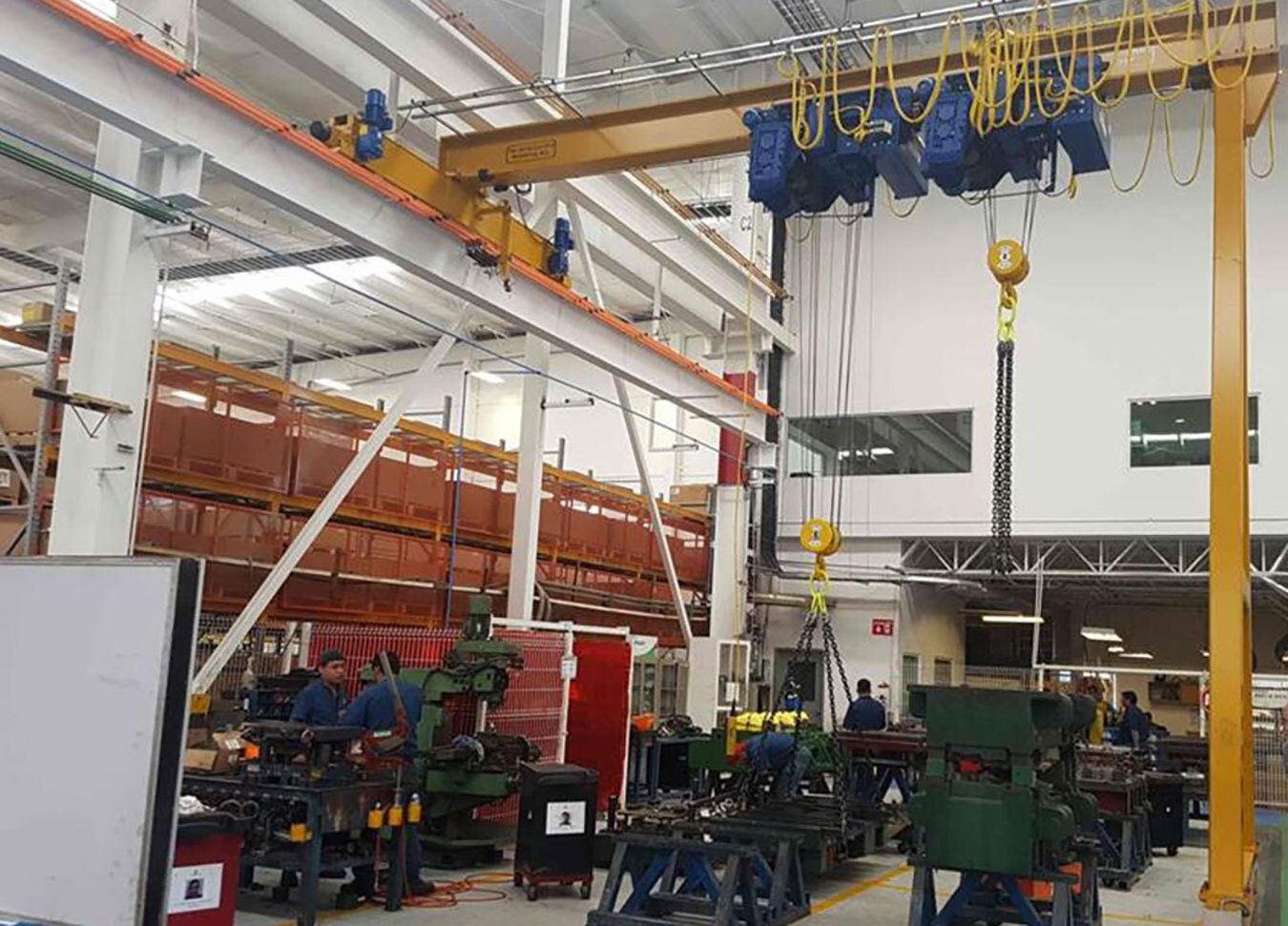

Semi-Gantry Crane Provides

Complete Solution

Pridgeon & Clay (P&C), Nuevo Leon, Mexico; offers progressive and transfer metal stamping processes with presses up to 2,000 tons. One routine process procedure required the rotation of large dies. P&C’s system incorporated one hoist. Damage to the equipment was always a potential problem. Worker safety was also an issue.

American Crane Systems (ACS), an Engineered Material Handling (EMH) Mexican distributor and crane builder offered a better solution. The company recommended the EMH Single-Leg Semi-Gantry Crane. By integrating two ten-ton hoists that work in tandem, the crane enabled Pridgeon & Clay to rotate and turn large dies up to 90 degrees safely, efficiently, and with precision accuracy, while dramatically reducing the chances of damage to the stamping dies. The EMH Crane was also selected because the span was too large and unsuitable for a standard overhead crane installation.

With installation under the main overhead crane, the EMH Single Leg Semi-Gantry Crane made it easy to transfer loads between workstations, freeing up P&C’s overhead crane to handle other tasks. With its 10-ton capacity, shop floor productivity was multiplied. With exclusive wear-resistant poly wheel design, the need to install built-in floor rails was eliminated, which reduced costs while improving floor safety.

Promess Inc.

810-229-9334

promess@promessinc.com

Safe & Precise Pressing of Explosive Materials with Promess Hazardous Location Press

Challenge:

A manufacturer needed to press an explosive material into a housing at high force while ensuring complete safety in a hazardous environment where combustible dust was always present. Standard electric presses posed a risk of ignition, making a specialized solution essential.

Solution:

Promess provided a C2D1-certified Hazardous Location Press, engineered for operation in explosive environments. Featuring intrinsically safe controls and a motor protection system where the servo motor is pressurized and its pressure is continuously monitored, the system eliminated ignition risks while delivering the precision and force required. The press maintained all the benefits of Promess’s Electro-Mechanical Assembly Press (EMAP) technology, including force and position control for a repeatable, high-quality assembly process.

Results:

Eliminated ignition risk with C2D1 certification and safe control architecture.

Achieved precise, high-force pressing without compromising safety. Ensured continuous operation in a hazardous environment without downtime or safety concerns.

By leveraging Promess’s expertise in controlled pressing solutions, the customer successfully integrated a safe and reliable process for handling explosive materials.

Have a similar challenge? Contact Promess today to discuss a solution tailored to your needs.

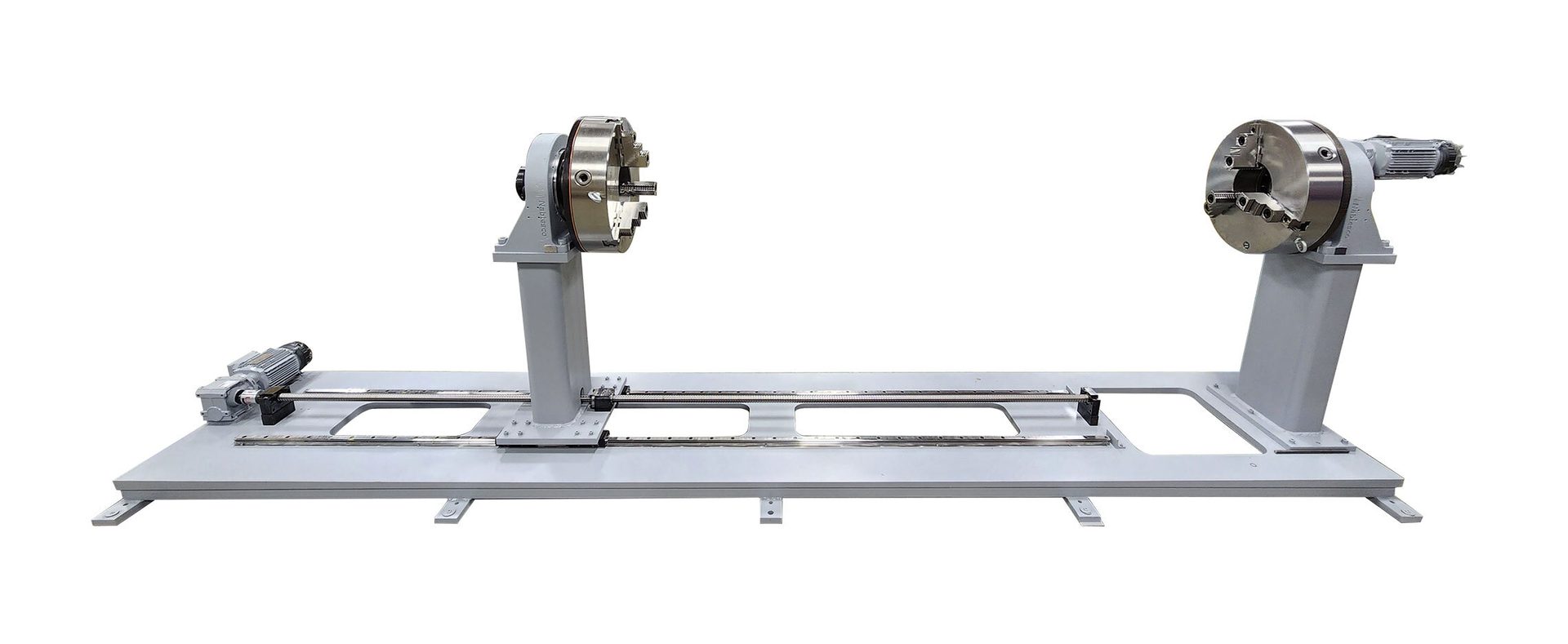

Custom Single Axis Weld Positioning System

Our customer asked us to design, engineer and fabricate an automated welding application. This Single Axis Weld Positioner was specially crafted to effortlessly handle heavy workpieces for welding. The customer needed it to be versatile, featuring a motorized adjustment of 130 inches to easily adapt to different workpieces, along with gator chucks, capable of managing parts up to 20 inches in diameter. To accommodate these specifications, Motion Index Drives equipped this positioner with a large ball screw to facilitate the flexible motion and NSK linear bearings that are self-lubricated and equipped with scrapers to clean weld splatter. The customer also required weld isolation and a grounding kit which comes through the headstock.

This machine can be optimized to adapt to varying customer requirements by incorporating an auxiliary axis motor or a full servo motor for precise positioning, making it fully automated.

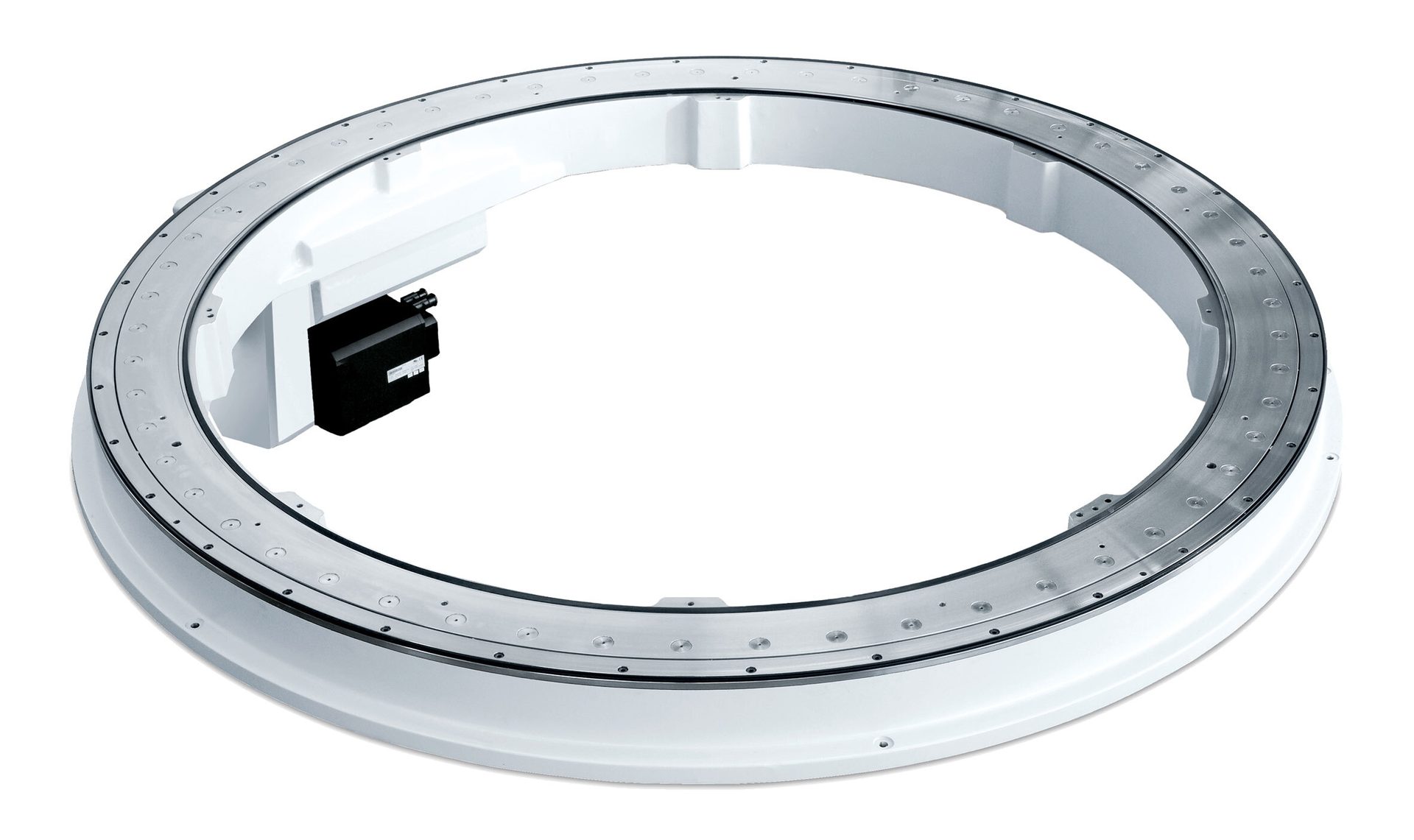

WEISS North America, Inc.

888-WEISSNA (888-934-7762)

info.us@weiss-world.com

Rotary Ring Technology Provides Solution

A customer in the medical industry reached out to WEISS North America regarding the assembly of a new product. The application involved the assembly of a cassette and MicroClave for an IV valve. Due to the accuracy requirements of the application, the customer believed that a PLC was required but the high cost was prohibitive when it came to the project’s budget. It was up to WEISS to help them develop a solution that would overcome the high cost of a PLC and still meet the required accuracy.

After reviewing the requirements of the application, WEISS was able to develop and deliver a custom solution based upon the proven WEISS TR1100 rotary indexing ring technology. The completed system is utilized to automate precise movement and positioning of the various IV valve components during the assembly process, such as part feeding, leak testing, unloading good/bad parts and final assembly.

The system includes a 24 station TR1100 with aluminum base plate, aluminum table riser, static steel riser plate, aluminum dial plate, aluminum stationary plate and a variable frequency drive and brake resistor kit.

Learn how a WEISS custom automation solution can help you stay on time and on budget.