A special section to ASSEMBLY

Horizontal wire harness braiding machines are available in several sizes. Photo courtesy Steeger USA Inc.

Semiautomated equipment puts a twist on wire harness protection.

Braiding Machines Protect

Wire Harnesses

Austin Weber // Senior Editor // webera@bnpmedia.com

Twisting long strands of hair is often associated with bored or disinterested teenagers. But, in the wire processing industry, braiding is a way to give thin, fragile wires extraordinary flexibility, super strength and a protective sheath.

Harness braiding is a process that involves covering wire bundles with protective sleeves made of woven materials. It’s used for a variety of applications, including everything from large aerospace and automotive harnesses to tiny microelectronics and medical devices.

Advantages of braided wire harnesses include abrasion resistance, electrical insulation, impact resistance and temperature resistance. It provides an extra layer of insulation and protection from chemicals, electromagnetic interference, fluids, heat, moisture, moving parts, squeaks, rattles and vibration. Wire harnesses with braided sleeves can withstand harsh environments and ensure the uninterrupted flow of electrical signals.

See us at The ASSEMBLY Show South, Booth 1023.

“Wire harness protection is essential to safeguard electrical systems from environmental factors, mechanical wear and electrical interference,” says John Tomaz, vice president of Wardwell Braiding Co. “The various methods in use today, including braiding, taping, split loom and heat-shrink tubing, offer distinct advantages and limitations.

“Braiding offers a number of advantages over the other processes, which clearly outnumber the disadvantages,” explains Tomaz, who will be speaking on the topic next month at the Electrical Wire Processing Technology Expo in Milwaukee. “Unlike the other processes, braiding conforms to the harness shape and size, offers [a customizable] degree of stiffness or flexibility, allows for multiple layers of protection when necessary and provides excellent termination, as it adds tensile strength.

“Because braid is applied directly on the harness, it offers maximum protection while adding the least amount of weight and bulk,” notes Tomaz. “Braiding, naturally, allows the harness to breathe and eliminates the possibility of moisture build-up. It remains more flexible at all temperatures, which is especially beneficial at lower temperatures.

“Braiding allows manufacturers to provide traceability and application identification using trace strands of different colors and sizes,” adds Tomaz. “Lastly, braiding simply outperforms and outlasts all the other protection options. The main criticism leveled against braiding is that it’s a slow process.”

Braiding covers wire bundles with protective sleeves made of woven materials. Photo courtesy Wardwell Braiding Co.

According to Tomaz, braiding is used in diverse applications, because it can serve multiple functions. “The most promising emerging application is the use of shielded cables in both traditional and electric vehicles, due to the increasing need for signal and communication transmissions,” he points out.

However, braiding machines are also widely used to produce a variety of medical devices and microelectronic components. Catheters, stents, leads and data cables are some typical applications.

“Our niche is being able to braid tiny wires and fibers, which are especially in demand for minimally invasive medical devices,” says Sean Hargett, president of Steeger USA Inc., which has been making braiding equipment for more than 150 years. “Our machines process wires as small as 0.0005-inch and 5-denier single filament fibers.” (Denier is a unit of measurement for the linear mass density of fibers. A 1-denier polyester fiber has a diameter of about 1 micron).

The basic technology behind wire harness braiding is similar to age-old techniques used to make products such as rope and textiles. Like yarn-spinning machines, multiple strands of material on spools twist around each other, creating a braided pattern on wire harnesses and branches.

Typically, one single wire alternately passes under, then over another single wire. The wires rotate in opposite directions. Herringbone patterns are commonly used. Braid density, also known as programmable picks per inch (PPI), also plays a role in mechanical properties and performance.

Traditional materials used to braid wire harnesses range from continuous filament fibers to monofilament fibers made out of polyethylene terephthalate or polyetheretherketone. However, there’s growing demand for different types of materials, such as more use of polyvinyl chloride-coated nylon.

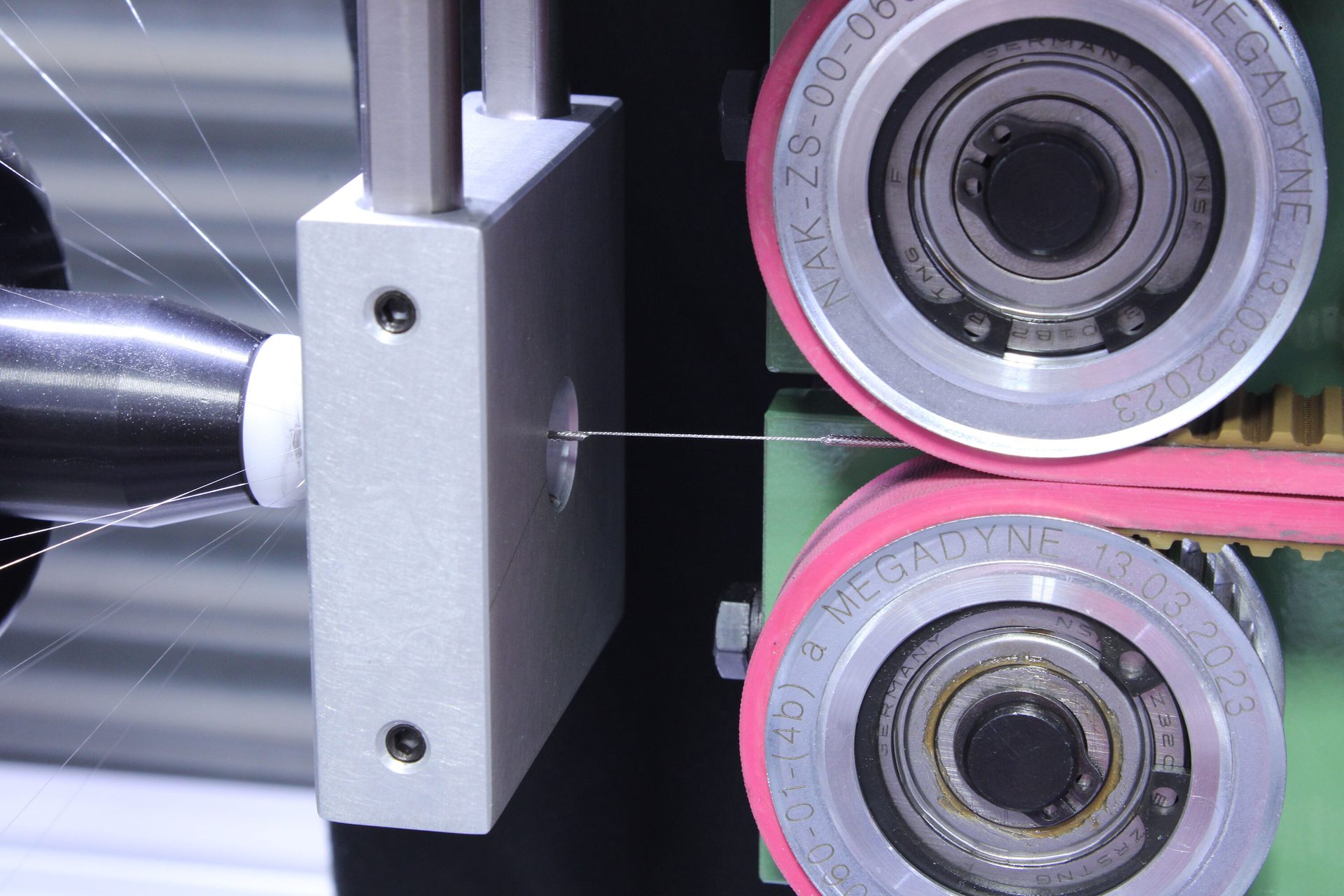

This mandrel feeder is designed to ensure tension and precise placement of wire braiding material. Photo courtesy Steeger USA Inc.

Automation Alternatives

Semiautomated braiding machines operate in either a horizontal or a vertical configuration. Vertical braiders are used for reel-to-reel production, which minimizes floor space and maximizes production volumes.

“Horizontal braiders have the ability to over-braid rigid or solid mandrels, which enables processing of discrete length pieces,” explains Hargett. “However, these type of machines can also be used in reel-to-reel applications.”

Most braiding machines are available with a variety of bobbin and carrier sizes to meet different production volumes and applications. They also feature manual, mechanical or electrical feeding options.

But, changes in braiding equipment design have traditionally come slowly. Over the past decade, there have been gradual advances in electrical components, electronics and machine construction materials.

“Recent trends in wire harness braiding machines focus on enhancing efficiency, flexibility and adaptability to meet the evolving demands of the industry,” says Tomaz. “[Our] Cobra 450 has evolved to increase production speeds and accommodate larger yarn or wire packages. This design reduces material wastage and minimizes downtime, leading to improved productivity and profitability.

“Safety and ergonomics are in everyone’s mind these days,” notes Tomaz. “The Wardwell Model B10 features interlocking switches, minimal gaps for the material to pass through, [which prevent] operator access to rotating parts, and clear protection panels. These enhancements allow operators to monitor the braiding process easily, contributing to a better working environment.

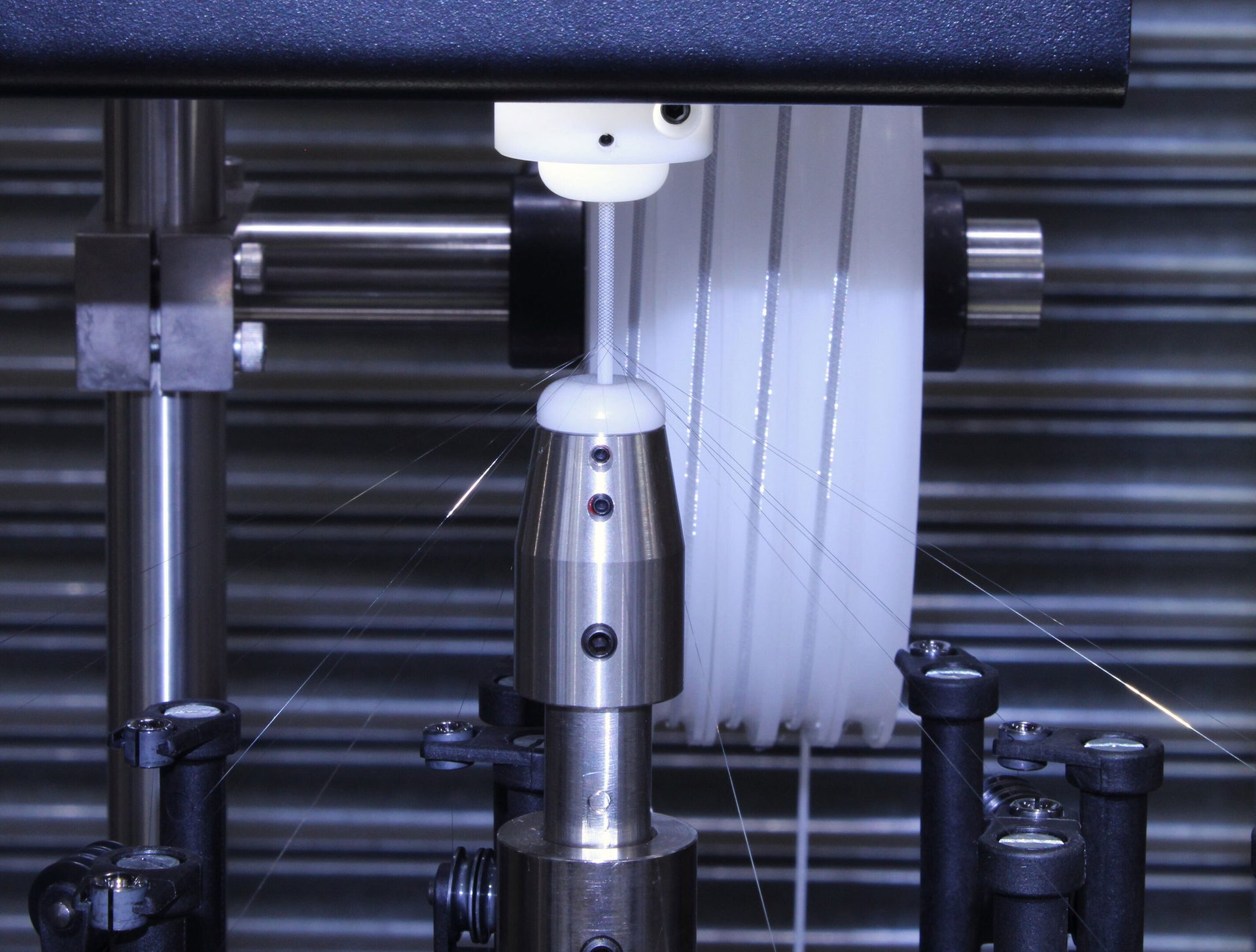

This visual inspection system identifies braiding defects and ensures uniformity. Photo courtesy Steeger USA Inc.

“The term ‘automation’ is often overused, but incorporation of digital controls and a group of sensors in braiding machines have greatly improved consistency, precision and safety,” claims Tomaz. “Features such as programmable settings for speed and braiding angles result in improved product quality and operator performance.

"Most of our regular customers continue to ask for higher speed, greater bobbin capacity, more efficient electrical components and enhanced human-machine interfaces,” says Tomaz. “There is another customer segment for whom liability concerns drive equipment sourcing requirements.

“For these customers, we are increasingly providing UL-approved electrical panels [rated to Performance Level E, the highest in the ISO 13849-1 standard for machine safety],” explains Tomaz. “Another frequent request centers on remote access and data collection capabilities.”

Although braiding is a loud, labor-intensive process, Tomaz says full automation and the use of cutting-edge technology, such as artificial intelligence, has remained elusive. Several years ago, however, JobFlow unveiled a device called BraiderBot that can be used with machines such as the Cobra 450. It features belt-driven robotic arms and sensors that pull wire harnesses through a braiding machine, eliminating a time-consuming process. One operator can run multiple braiders at once. But, the device is limited to a single application—braiding continuous lengths of a single harness.

“There’s a very manual nature to the manufacturing of braided harnesses,” says Steeger’s Hargett, “For instance, there’s a lot of operator manipulation with branches that involves moving pieces back and forth. But, today, a lot of manufacturers are faced with various types of ergonomic issues and concerns.

This braiding machine is designed to reduce material waste and minimize downtime. Photo courtesy Wardwell Braiding Co.

“Many customers are looking for new ways to limit the amount of operator interface that’s required,” explains Hargett. “To address that, we recently unveiled an autofeeder that enables manufacturers to boost efficiency and achieve consistent, high quality results with their harness braiding applications.

“The automated mandrel feeding system minimizes operator interaction while maximizing accuracy, efficiency and quality,” claims Hargett, “Designed for seamless integration with horizontal braiding machines, this semiautomatic [system] eliminates up to 95 percent of manual intervention in the braiding process. From loading unbraided mandrels to precise cutting and collection, this system is engineered to optimize production workflows while maintaining superior quality.”

Steeger also recently partnered with Taymer International Inc. on an automated visual inspection system. The BX1100 can be integrated in-line with horizontal or vertical braiders, automating the inspection process. It can also be utilized offline as a tabletop unit where operators can view surface images and defect dimensions.

“Our cutting-edge braid inspection system can be mounted on or within any [of our] machines, revolutionizing the way that braided products are inspected during production,” says Hargett. This innovative technology inspects braided materials in real-time as they are being crafted around the mandrel.

“By automating the braid inspection process, we eliminate the need for manual checks, significantly reducing scrap and labor hours,” explains Hargett. “This means manufacturers can produce top-of-the-line braided medical devices, like catheters, with enhanced efficiency and quality, identifying any issues early in the process.”