AUGUST 2023

SCREWDRIVING AND RIVETING

High-Tech Tools Ensure Quality at Battery Manufacturer

CATL uses advanced fastening tools to error-proof assembly of EV batteries.

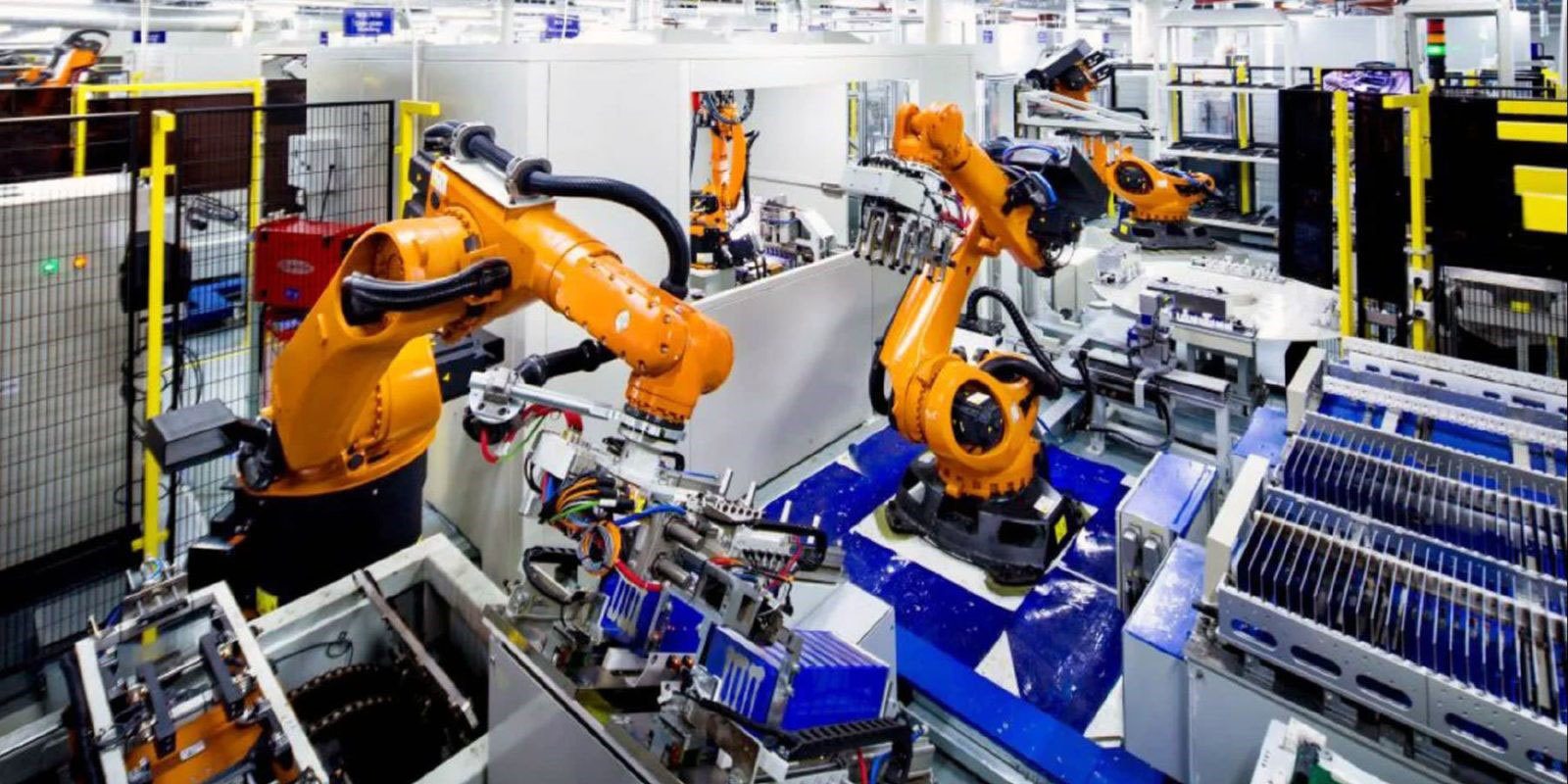

With a market share of 37 percent in 2022, CATL is the largest manufacturer of EV batteries in the world. Photo courtesy Contemporary Amperex Technology Co. Ltd.

John Sprovieri // Chief Editor

Founded in 2011, Contemporary Amperex Technology Co. Ltd. (CATL) is a Chinese manufacturer of lithium-ion batteries for electric vehicles and energy storage systems, as well as battery management systems. With a market share of 37 percent in 2022, CATL is the largest manufacturer of EV batteries in the world. The company has set a manufacturing capacity target of more than 500 gigawatt-hours (GWh) by 2025 and more than 800 GWh by 2030.

Earlier this year, CATL began series production of the Qilin, its third-generation cell-to-pack battery system. This new battery embraces recent advances in battery materials, packaging technology improvements, weight reduction and reliability. Qilin’s groundbreaking design can achieve 72 percent volume efficiency and an energy density of 255 watt-hours per kilogram.

Headquartered in Ningde, China, CATL operates five R&D centers (four in China and one in Munich, Germany) and 13 assembly plants (11 in China, one in Erfurt, Germany, and one in Debrecen, Hungary). Two of those facilities—the plants in Yibin and Ningde, China—were recently chosen to be part of the Global Lighthouse Network of exemplary, state-of-the-art factories by the World Economic Forum.

For example, the Yibin plant has been certified as the world’s first zero-carbon battery factory. After deploying AI, IIoT and flexible automation, the plant increased line speed by 17 percent and reduced yield loss by 14 percent.

It’s not for nothing that CATL is investing in state-of-the-art assembly technology. Beyond the need to meet skyrocketing demand, the battery pack is critical for the security and overall performance of an EV. It’s also the most expensive component of the vehicle. Efficient production and minimal wastage are therefore essential to drive down costs.

CATL’s emphasis on state-of-the-art technology extends even to the fastening tools on its assembly lines. From a fastening standpoint, EV batteries pose several challenges. One is high-mix production. Tools must be able to quickly switch between assembly lines. Tools must accommodate a relatively large torque range and be adaptable to diverse tightening requirements.

One more challenge is maintaining accuracy and repeatability. Assembly tools must prevent fasteners from being tightened to the wrong torque or in the wrong sequence. Since EV manufacturing is a relatively new industry, experienced assemblers are few and far between. Often, an operator’s capabilities cannot keep pace with developments in battery design. Error-proofing technology is therefore critical to ensure quality and safety.

TOP TOOL TECH

Desoutter has worked with CATL from the early stages of its development, helping the company to establish robust tightening standards and improve existing tightening processes. Desoutter supplied CATL with a variety of fastening technologies, including the CONNECT platform, Nexonar positioning system, ERS electric screwdrivers, CVI3 controller, and automatic screw feeders.

CONNECT is a modular, wireless communication hub for cordless fastening tools. The device provides a single point of connection for communications between a factory network and up to 20 tools, reducing cost of ownership and simplifying installation for easier line rebalancing. It takes just 10 seconds to pair a tool to CONNECT using RFID technology, so tools can be added or moved on a line without disruption. This enables CATL to respond quickly to changes in production. The hub can also connect with error-proofing accessories, such as stack lights, smart socket trays, operator controls, and remote user interfaces.

Two versions are available. CONNECT-W has an embedded wireless access point and can communicate with up to 10 fastening tools. CONNECT-X requires an external wireless access point, but can communicate with up to 20 tools.

This compact device—it occupies just 0.13 cubic feet of space—can be installed anywhere in an assembly plant: at a workstation, at the end of the line, on a manager’s desk, or even in the server room. Powerful diagnostics make it easy to spot operator performance trends, causes of faults, and areas for improving efficiency.

With feature management, engineers can fine-tune each tool according to the requirements for each workstation. A feature can be activated for one tool, but not on another. Software is available for tightening strategies, assembly process management, key performance indicators, and traceability. Tools linked to CONNECT can be set up to automatically change their tightening parameters depending on the fastener being installed.

Desoutter’s Nexonar 3D spatial positioning system uses infrared sensors to accurately monitor and locate fastening tools or the position of an operator’s hands in critical assembly processes to within 1 millimeter. Nexonar ensures that all screws are tightened in the right place, in the intended sequence, and with the appropriate parameters. The system can be retrofit to existing tools. It is able to detect pitch, roll and yaw of the tool. Several hundred trackers can be monitored simultaneously in real-time and with no latency. It can also be used to ensure as accurate part picking, placement and fulfillment in kitting operations.

Nexonar leads assemblers through each step and eliminates the possibility of errors, helping them complete each task efficiently and with optimal quality. It also registers the position of each part during assembly to guarantee total traceability.

The ERS transducerized electric screwdriver features headlights; a programmable reverse button; lever start or push start; and four reporting LEDs, two of which are programmable. A tapered, durable soft rubber grip accommodates all operators comfortably.

The tool comes in straight, angle-head and fixed-spindle versions. Three models are available: Model ERS2 with a torque range of 0.6 to 2.5 newton-meters; Model ERS6 with a torque range of 1 to 6 newton-meters; and Model ERS12 with a torque range of 1.5 to 12 newton-meters. Depending on the model, maximum speed ranges from 280 to 3,000 rpm. Tool weight ranges from 1.54 to 2.7 pounds.

Designed to meet the demands of the automotive industry, the CVI3 tool controller ensures traceability of all safety-critical fastening processes. The controller accommodates a wide range of tools, and various error-proofing modules are available. Built-in error prevention measures include re-hit and seating-point detection.

Four versions are available: the CVI3 Essential for handheld fastening of Class B joints; the CVI3 Function, which has a keypad interface; the CVI3 Vision, which has a touch-screen interface and can be extended to work with cordless tools; and the Twin CVI3 Vision, which has two tool channels.

All versions can be networked with standard fieldbus and advanced customer protocols. Engineers can monitor and control multiple fastening parameters, including speed, torque and angle. Torque and angle curves can be displayed on the controller screen or a remote HMI.

Engineers can import, export and analyze fastening data with results, curves, filters and profiles. The controller collects and stores 100 percent of tightening data in a real-time database with advanced analytics via web-based software.

ASSEMBLY ONLINE

For more information on fastening tools, visit www.assemblymag.com to read these articles: