ASSEMBLY ESSENTIALS

Meter/Mix Dispense Systems

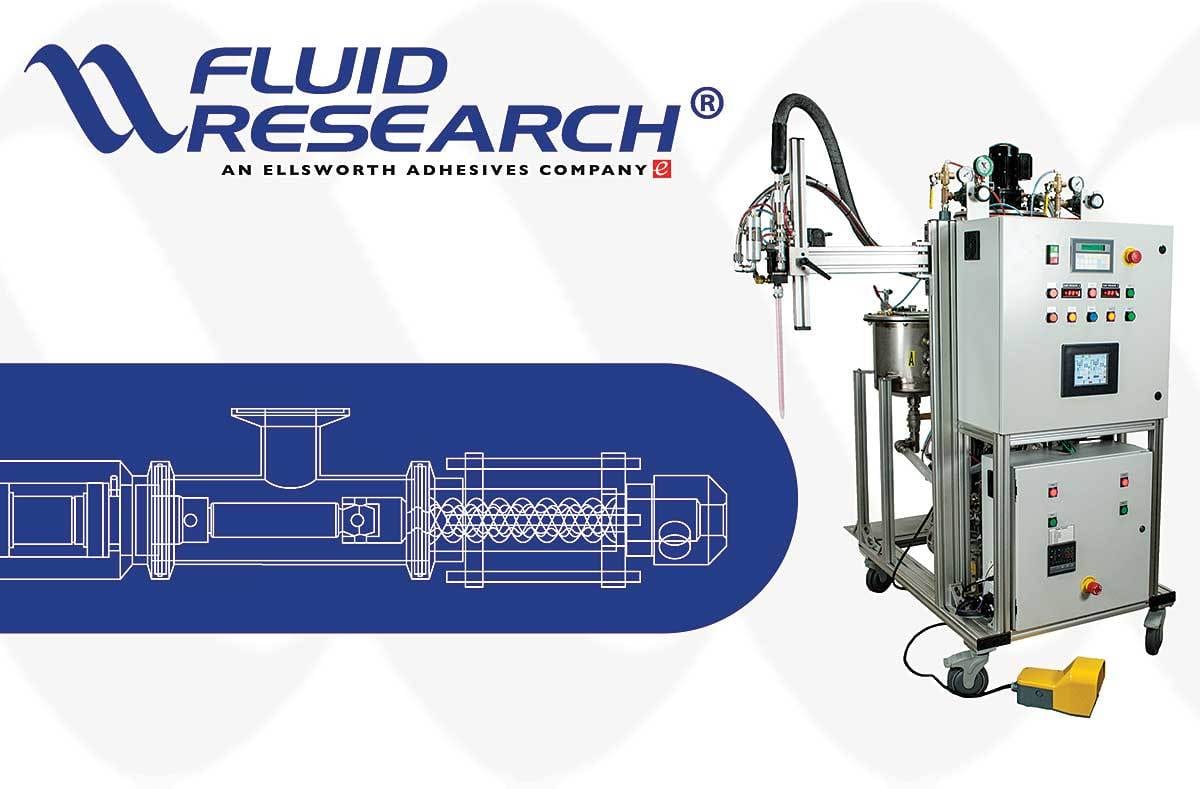

Fluid Research® develops technology and proprietary system controls for accurate, durable, and reliable metering mix systems and dispensing equipment designed for benchtop, cart mount, or free-standing workstations. These systems can easily mix and dispense numerous materials including abrasives, adhesives, sealants, and polymers. Compatible in a wide variety of industries, Fluid Research systems deliver consistent control and uniform results all while meeting environmental standards. This enables companies to recoup considerable operation costs after the initial investment through improved safety, decreased labor and repairs, and waste reduction.

Leaders in Liquid Control

Servicing the industry’s widest range of fluid viscosities, the Fluid Research® portfolio offers superior performance with even the most abrasive fillers and chemically aggressive materials. Advanced system controls allow users to benefit from leak and drip free operation with low maintenance.

- Meter Mix Dispense Systems: Mechanical meter mix dispense systems ensure that the dispensed material will perform at the manufacturer’s specification and to the specifications needed in the final design of the component. Fluid Research designs customized fluid management and dispensing systems based on customers’ unique materials and application requirements. Choose from single and multi-component systems with options for nearly any assembly process.

- Pump Technology: Progressive cavity pump and more traditional piston pump technologies are offered to accommodate a wide variety of shot sizes and frequencies. Fluid Research progressive cavity pumps ensure the amount of material delivered per complete rotation, or portion of a rotation, is exact and repeatable. This can be adjusted to any amount of material delivered singly, repeatedly, or continuously.

- Material Management: Temperature, agitation, gas absorption, and isolation must be closely controlled at constant values to ensure predictable results. Material management systems are designed specifically to handle common dispensing problems that occur due to poor material handling. This includes Standard Material Management Units™, NeverEmpty Material Management Units™, and pail and drum ram emptying systems.

- Accessories: Fluid dispensing accessories are designed for even, accurate mixing of two-part materials such as luer lock adapters and retaining nuts, completing your meter mix dispense system.

A new addition to Fluid Research, the VersaMix® multi-component meter mix dispense system powered by Sentinel Logic™ software is a unique, dual servo-driven, variable ratio machine created for encapsulation, formed-in-place gaskets (FIPGs), cured-in-place-gaskets (CIPGs), and other applications that require consistent, repeatable meter mixing. This unique system simplifies the meter mix process without sacrificing performance, fitting seamlessly into any assembly line.

Expert Manufacturing & Engineering

Utilizing a combined 60 years of experience, Fluid Research engineering staff integrates proprietary controls and components to customize machines for unique formulations and applications in various industries throughout the world. Service technicians offer training for customer manufacturing engineers and maintenance personnel to ensure success and quality. Customers benefit from:

- Expert dispensing equipment and automation support, including customized pre-installation inspection, data maintenance, and in-house training.

- Non-standard equipment offerings like versatile gear and piston pump systems.

- Customized edge-fill solutions through a partnership with ResinLab®, a custom formulator of adhesives and encapsulants.

By engaging with customers beyond the build with ongoing support, the Fluid Research team ensures successful implementation and long-term maintenance of a liquid control investment.

Custom Solutions

Fluid Research understands the need to build a final product that works for unique operations and offers a variety of add-ons to enhance the abilities of industry-leading products. System add-ons include speed agitators, automated refilling, filtration, mounted dispense valves, heating packages, material management units, programmable vacuum degassing, and more. Reduce operational costs through decreased labor and repairs, improved safety, waste reduction, and more.

If testing is preferred before making an investment, the Fluid Research team of experienced factory application engineers is equipped to provide design assistance and coordinate a demo at one of our locations, or a nearby factory installation. After investment, customer manufacturing engineers are invited to take advantage of training for proper operation and maintenance.

To learn more about liquid dispensing solutions from Fluid Research and connect with the engineering team, visit fluidresearch.com.