ASSEMBLY ESSENTIALS

The Versatile, Flexible and Efficient WEISS LS Hybrid

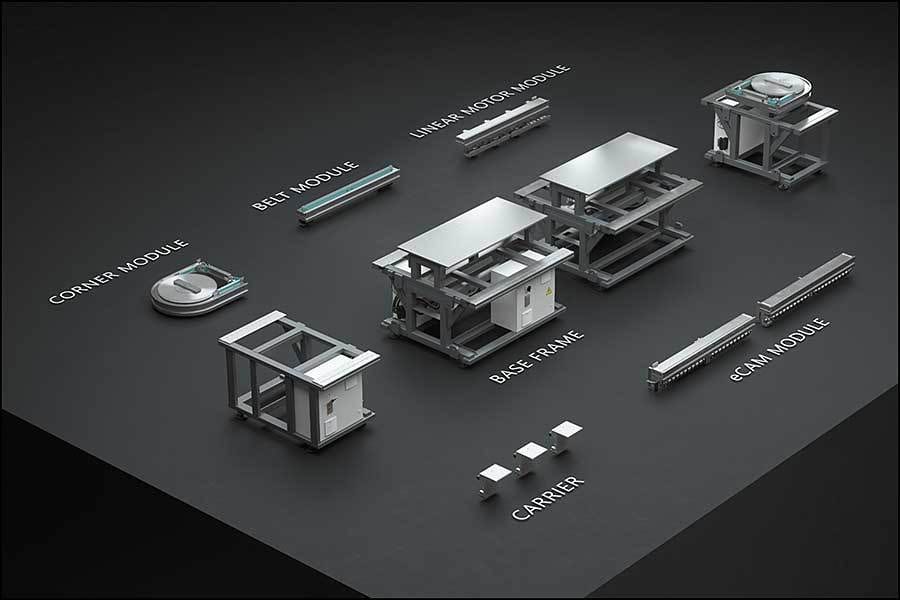

WEISS North America recently introduced the NEW LS Hybrid Linear Transfer System at the 2021 Assembly Show. An alternative to rotary indexing tables, linear transfer systems allow for faster and easier scaling of production. This is particularly true with the highly configurable and modular LS Hybrid Linear Transfer System from WEISS.

Whether a cam drive, direct drive, freely programmable redirection or belt drive – the LS Hybrid Transfer System is based on a modular design principle that allows the customer to adapt the system to precisely fit the needs of their specific application. This flexibility allows each module to be implemented with the most appropriate drive technology for maximum precision or dynamics to fit each particular process step.

Developed with this “hybrid drive” concept in mind, the LS Hybrid offers integrated eCam, linear and belt drive options and is particularly effective where fast and efficient tooling carriage transport is required. With the highly customizable WEISS LS Hybrid, customers can achieve up to 40% shorter cycle times and perform more processes in less space in either a horizontal or vertical orientation. In addition, the patented eCam Module supports absolute locking without the need and added expense of a locking unit, providing an optimized motion profile and up to 60 cycles per minute, while the highly dynamic linear motion module is freely programmable, allowing for any stop position.

Compared with a classic pallet transfer system, the LS Hybrid is quick and easy to place into operation via WEISS Application Software (W.A.S.) and has distinctive characteristics that position this system for flexible and economical production. The flexible design permits faster assembly stations to be served sequentially, while slower stations can be supplied with components in parallel, providing a significant reduction in transport times. For production environments that involve a very nonuniform distribution of processing times between the individual stations, the LS Hybrid can easily compensate for these time differences.

With a load capacity of up to 10 kg and a tooling carrier size of up to 500 mm, the LS Hybrid provides for a wide component spectrum, further expanding the scope of its processing capabilities. Due to the mechanical interlock, very high process forces of up to 1000 N can be applied directly to the tooling carrier without additional support, making it ideal for a press-fit process, for example.

With the integrated control system and WEISS Application Software (W.A.S.), the drives can be commissioned very quickly and without any specialized expertise. Format changes and changeover times are also reduced in terms of effort, due to the fact that the parameters can be directly adjusted with the WEISS Application Software. This allows smaller batch sizes to be implemented with significantly shorter product throughput times.

Productivity is further increased by enabling simultaneous processing of parts without disrupting the overall production flow, thus reducing downtime. The individual decoupling of stations and modules is significantly increased and offers the customer a wide range of mechanical vertical integration. Versatile, flexible and efficient - the LS Hybrid elevates manufacturing to greater heights of profitability and productivity.

WEISS North America, Inc.

3860 Ben Hur Ave.

Willoughby, OH 44094

888-WEISSNA (888-934-7762)

info.us@weiss-world.com

https://www.weiss-world.com