CORPORATE

PROFILES

Create economical, flexible reliable structures and AGVs

Creform, the original adaptive material handling system is the tool for continuous improvement, 5-S organization and lean manufacturing programs. The company helps analyze, plan and install material handling systems that can include plant wide or point-to-point AGV systems, warehouse kitting operations and multi-station assembly work cells.

The Creform System consists of over 700 cataloged components including unique 42mm pipe & joints and Placon® wide roller conveyors. In addition, Creform sales engineers can help you with a custom design or an existing solution from our database of thousands of designs to assist you in providing solutions to material handling problems.

Examples of these structures and vehicles include: Automated Guided Vehicles (AGVs) from simple bolt-on units to sophisticated low-profile towing units that manage entire fleets of carts; workstations, from simple one-person units to multi-person assembly cells; flow racks, from single lane parts-feeders to large supermarket systems; and carts, from small general purpose push carts to part specific custom kitting carts.

For detailed examples of these and other structures visit www.creform.com for a detailed review of the types of applications we can develop for you. We can show you how you can build your own Creform structures or we can build them for you.

ZIMMER GROUP - SUCCESS since 1980

ZIMMER Group is based in Rheinau – Freistett, Germany and is a family-owned and operated company.

In 1980, the company was founded in an old converted barn by Guenther Zimmer, his father and his brother Martin. They were tinkering with a standardized gripper that facilitates manufacturing processes in industry and can be used in many different ways. This idea led to the breakthrough and laid the foundation for the international success of the later Zimmer Group.

In 1992, the PowerStop shock absorbers were launched, which outshined all competitor products in terms of low-vibration damping of moving masses and maximum energy absorption in the smallest installation space by the patented spiral groove technology.

In 1994, the first clamping elements for profiled rail guides were launched. Today, Zimmer Group is the market and technology leader in clamping and braking elements with the widest range for all linear rail manufacturers.

Under the slogan “The Know How Factory”, Zimmer Group combines 6 technologies: Handling-, Damping-, Linear-, Process-, Machine Tooling- and System Technology.

Today, the company is among the leading manufactures in the automation industry and both our standardized and bespoke solutions for mechanical and plant engineering have become globally recognized as quality products.

Ellsworth Adhesives

877-454-9224

W129 N10825 Washington Drive

Germantown, WI 53022

The Adhesive Experts

Ellsworth Adhesives is a global distributor of adhesive products, specialty chemicals, and equipment. They are a value-added supplier of adhesives, sealants, coatings, encapsulants, tapes, releases, and lubricants from leading manufacturers including 3M, Bostik, Dow, Dymax, Fisnar, Henkel LOCTITE®, HumiSeal, Parker LORD, Permabond, Techcon, and many others.

The Glue Doctor® represents the technical expertise and unique capabilities of more than 70 Engineering Sales Representatives (ESRs) in North America, and more than 130 globally. With over 800 combined years of experience, ESRs specialize in working with customers on engineered assembly processes and implementing adhesive solutions in the manufacturing environment.

Through a wide variety of services, Ellsworth Adhesives aims to fulfill all specialty chemical needs. From custom adhesive formulation and custom packaging, to automated and meter mix dispensing, as well as low-pressure molding, Ellsworth Adhesives strives to help customers achieve maximum productivity.

Ellsworth Adhesives operates sales offices and warehouses all over the globe. The company is ISO 9001:2015 and AS9120B certified. Ellsworth Adhesives can be contacted directly at 1-877-454-9224 or by visiting ellsworth.com.

TOOLS you can TRUST

Save time! No matter what wire processing needs you have, Phoenix Contact has a solution. Looking for UL-listed, durable, ergonomic hand tools that will strip or crimp consistently every time? The TOOLfox can introduce you to our complete line of industrial and electrical hand tools, all covered by Phoenix Contact’s Limited Lifetime Warranty.

Need to speed things up? Phoenix Contact’s range of bench-mounted cut, strip, and crimp semi-automatic machines will increase your wire processing productivity to get the bigger jobs done quickly and efficiently. When you purchase Phoenix Contact tools, you are not only getting TOOLS you can TRUST, but you are also getting the support of a dedicated sales team, tech service, and the expert advice of the TOOLfox. Check out our website at www.phoenixcontact.com/us-TOOLfox to request a brochure, schedule an onsite demo, and earn a free gift!

Fisnar®: Precision Fluid Dispensing

Fisnar® is a leading manufacturer and supplier of precision fluid dispensing and fluid handling solutions. Whether it’s for benchtop assembly operations or for integration in a larger in-line process, Fisnar provides fluid dispensing systems that meet the needs and requirements of their customers.

With over 45 years of knowledge in the dispensing industry and its global requirements, Fisnar offers a range of dispensing products including robotics, valves, liquid dispensers, reservoirs, pumps, and a complete selection of consumables. By choosing Fisnar fluid dispensing products, customers can be confident in the precise application of assembly fluids, ensuring reduced waste and high product quality. Common assembly fluids include adhesives, epoxies, silicones, solvents, solder pastes, lubricants, and more.

Armed with technical expertise and a diverse portfolio of dispensing products, Fisnar can supply a system to suit every budget, application, and industry.

Fisnar can be contacted directly at 866-634-7627 or by visiting fisnar.com.

Elite Robots

10521 Research Dr., Ste 104

Knoxville, TN 37932 USA

865-392-1215

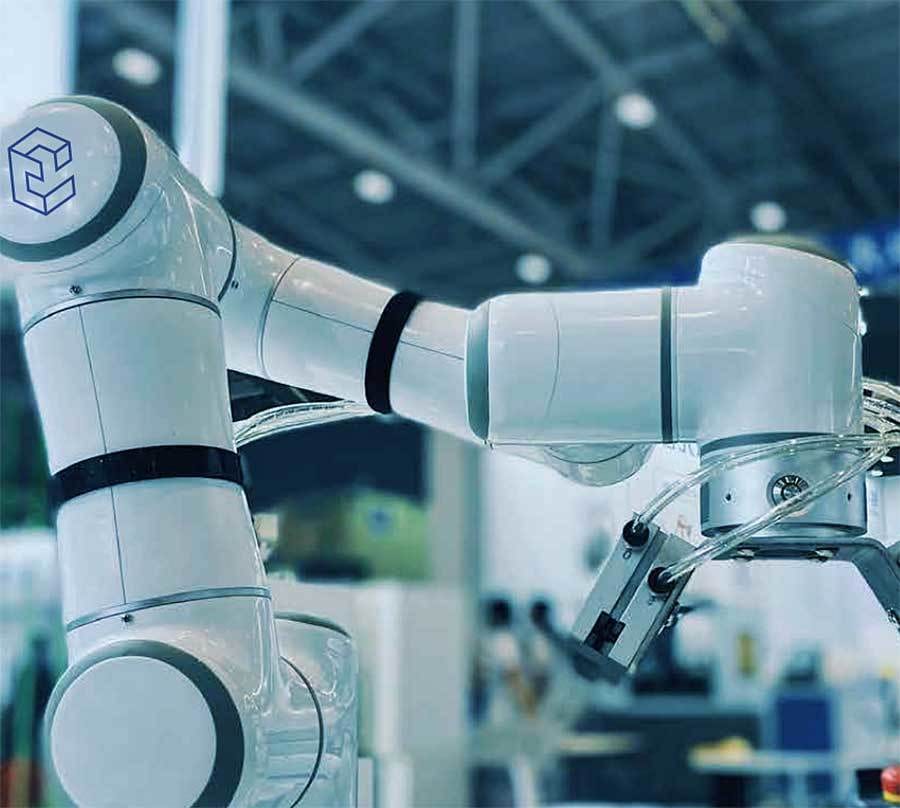

Collaborative robots for industrial solutions

Elite Robots was established in 2016 by technical experts who have developed and manufactured lightweight 6-axis collaborative robots with a range of (3kg, 6kg, and 12kg). The current offing is the EC Series; later in the fourth quarter, a new Cobot CS Series will be available in North and South America. These cobots help companies maximize productivity across industries worldwide.

Elite cobots have gained a positive reputation among users in the:

- Automotive

- Metal Processing

- Electronics

- Packaging Logistics

- Rubber

- Plastics

- Chemicals, and other industries.

See the Elite Robots YouTube channel for more applications: https://www.youtube.com/channel/UCM6M7_iFyKDKwlKQYtf1baA/videos

The new office in Knoxville, TN, will help North and South American companies be more productive without the huge capital expense of automating production lines. This local coverage also gives our customers confidence in creating robotic solutions to meet their needs.

Visit us at www.elite-robotics.com to see our collaborative robots that can meet your needs.

Starline Flexible Power Distribution Systems

Starline, a brand of Legrand, is a global leader in power distribution equipment. For over 30 years, Starline products have provided data center, retail, health care, higher education, and manufacturing facilities with the most flexible, reliable, and reconfigurable power distribution systems on the market. By continuing to promote the concepts of innovation and smart yet simple design strategy, the Starline brand has evolved to include three main product lines: Track Busway, Plug-In Raceway, and Critical Power Monitor (CPM).

Starline’s overhead distribution system, Track Busway, has revolutionized the way power is distributed to manufacturing environments of all sorts. The simple, maintenance-free and compact busway design incorporates a continuous access slot that runs along the system. This allows customizable plug-in units to be repositioned and re-inserted wherever power is required along the access slot, in a matter of minutes. This ability to access power anywhere along the busway provides endless flexibility to your operations, allowing ease of use to change or add to operational layouts without losing any uptime.

Headquartered just outside of Pittsburgh, PA, Starline provides innovative, customizable power distribution and monitoring solutions that are particular to each customer’s critical requirements.

ABOUT PRO-LINE

Founded in 1978, Pro-Line, headquartered in Haverhill, Massachusetts, is the recognized leader in ergonomic workbench design. The company is credited with producing one of the first hand-crank, height-adjustable tables in 1987: the model EL, still available today. Pro-Line ensures that all of its products are not only high quality but ergonomically sound, making workers less fatigued and more productive.

Pro-Line offers two workbench product groups. The Pro-Line Series products are typical of general industrial and business operations. Pro-Line workstations and workbenches offer enhanced modularity to maximize production line and packaging flexibilities and accommodate future needs. Applications include production assembly of piece goods at individual or conveyorized workstations; diagnostic repair at ECN stations; packaging and mailroom workstations and workbenches; computer LAN stations; wire harness fabrication; ergonomic material handling equipment to lift, slide or orient heavy components; ergonomic seating; and more. Many models are in stock and ready to ship in five days or less.

The company’s Pro-Lab Series workbenches add extensive casework (cabinets and pedestal units with drawers, doors) as well as modular laboratory bench options for biotechnology businesses, schools and laboratories. Clean-room workbenches are also part of the Pro-Lab series and provide controlled environments for the most sensitive tasks.

Motion Index Drives Cam Indexer Manufacturer

Motion Index Drives has been a manufacturer of cam and servo indexing devices for over 45 years. We have been continually perfecting the automation process through engineering the highest precision rotary index tables and indexing machines through your customized specifications. Our devices are free of backlash allowing for smooth, continuous and maintenance free operation, eliminating the need for shot pins to get high accuracy and repeatability. Our products include fixed and programmable rotary index tables, precision link conveyors, lift and rotate units, weld positioning systems, tool tray shuttles, robot transfer units and much more.

We are dedicated to customizing and engineering equipment to meet our customer’s application needs. We offer additional options such as dial plates, machine bases, slip rings, backbones, tooling frames and VFD controllers. We design every product we make with special attention to safety, quality, versatility and value to ensure longevity and worry free operation for many years to come.

Our indexers have operated in various industries due to our unmatched reliability and flawless operation. Those include automotive, aerospace, medical, packaging, and consumer goods who all benefit from our 24/7 service and customer support.

IPR Robotics, LLC

50775 Wing Drive

Shelby Township

MI 48315, USA

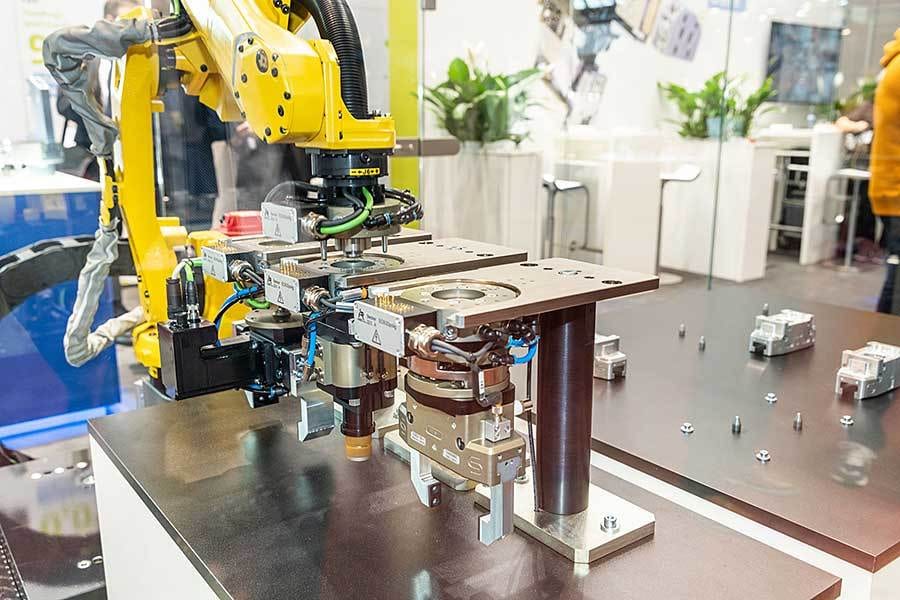

IPR Robotics, LLC

Everything robots need to do their job.

The whole world of assembly and handling technology.

IPR offers an extensive range of products with innovative systems and components for assembly and handling technology. Our parallel and angular grippers, tool changers, alignment devices and load limiters, 7th axes, force-and-torque-sensors and customized solutions are used by customers in many countries worldwide. Companies across all sectors place their trust in our products. Quality, technical expertise and industry knowledge are our most important factors for success.

Factory Proven Electric Fastening and Servo Press Systems

Formed in 1983, FEC Inc. installed the first electric torque-controlled fastening system in North America into a major automobile manufacturer changing the way automated fastening would be performed moving forward. Today, our fastening and servo press systems have evolved with cutting-edge technology while increasing system reliability and durability. Since today’s assembly applications continue to demand higher levels of quality, precision and functionality than ever before, FEC is continuously developing and applying new technologies to our products.

Through years of global factory-proven experience, FEC fastening and press products have developed to meet your specific demands, with a diverse line of fastening and press systems to handle multiple form factors and market segments. Whether you’re in the automotive, aerospace, off-road equipment, appliance, medical or other industries, our products and solutions address each customer’s specific standards and requirements. FEC can provide everything from stand-alone fastening / press system components to full turn-key assembly systems.

We have achieved our stellar reputation in the industry by providing unprecedented support to our customers and continue with that philosophy today. FEC offers a line of performance driven, price competitive products designed around the latest motor and servo technologies.

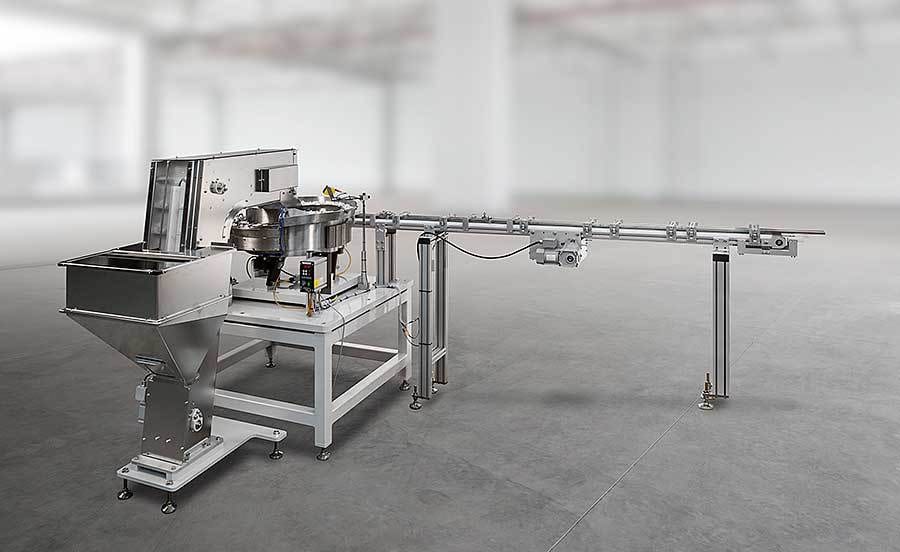

Advanced Manufacturing for Part Feeding Solutions

Manufacturing solutions in automation are achieved through continuous innovation and technological advancements. Performance Feeders is continuously working to advance our manufacturing processes and machining technologies to expand parts feeding solutions for a variety of industries.

Specializing in the design and manufacture of quality parts feeding equipment since 1973, our knowledgeable sales team evaluates each application and works with our manufacturing team to engineer and construct each quality system to seamlessly integrate into automation operations.

Consistent collaboration with our customers to achieve the most efficient feeding method for each individual application is an element of our manufacturing process that creates success in the design of sustainable feeding solutions. Advancements in our design process using solid modeling and CAM software, CNC machinery, and 3D printed prototypes enable our team to create customized and repeatable solutions.

Our extensive feeding product line includes Vibratory Feeder bowls, Centrifugal (high speed) Feeder bowls, Step Feeders, Drum Feeders, Flex Feeders, Conveyors, Spring Feeders, Prefeeders, Elevators and Protective System Enclosures with Visual inspection, Part Isolation, and Controls packages available.

ViscoTec America Inc.

770 422-4281

770 422-0265

sales@viscotec-america.com

www.viscotec-america.com

Dosing technology for fluids & pastes

In addition to the high-quality workmanship of the dispensing pumps and components, ViscoTec’s customers appreciate the excellent service. And this distinguishes ViscoTec from its competitors: Customers are accompanied from the planning phase to commissioning and even after.

ViscoTec is a specialist for “challenging” dispensing applications – not only defined by high viscosities. Rather, they include additional challenges such as abrasive materials (such as thermal conductive pastes in e-mobility), compressible media (such as sealants in the aerospace sector) or chemically aggressive liquids and pastes (such as methyl methacrylates in the automotive sector).

ViscoTec has more than 20 years of experience in the field of adhesive and fluid application in automatic production lines and in solving complex dispensing tasks. The technology is based on a well-known pump principle and has been optimized to meet the requirements of the dispensing sector. Integrated into semi- or fully automated production systems, the products ensure reliable production processes.

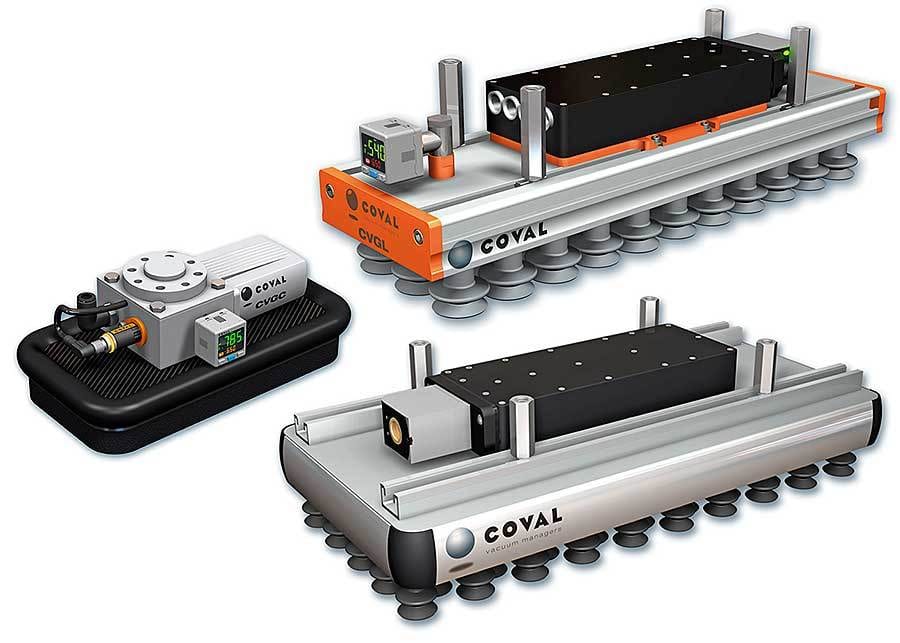

COVAL Vacuum Technology Inc.

901-100 Jones Franklin Rd

Raleigh, NC 27606

Tél. : 919-233-4855

Fax : 919-233-4854

YOU DESERVE MORE THAN JUST VACUUM

At COVAL, we set out to provide our clients and users with vacuum handling solutions that meet their goals in terms of profitability, productivity, quality, safety, and environmental conservation. To achieve this, COVAL is rallying its efforts to predict, plan, innovate, and manufacture with one aim in mind: offering the right products and services at the right time.

Benefitting from high-performance products for the vacuum handling of workpieces, products, and packages is the main objective, but that’s not enough by itself: solutions should be thorough, performing, and perfectly suited for the industry. In order to bring more than just vacuum, we are committed to a comprehensive development approach:

SOLUTIONS that account for every concern, KNOWLEDGE that meets customer needs, PRODUCTS that customers can trust, and TEAMS focused on specific industries.

Our goal is to be present wherever vacuum handling and automation is useful for the performance of the business. What distinguishes us is our capacity to provide you with a complete solution above and beyond just our products. We are always able to analyze, propose, develop, manufacture and provide THE perfectly adapted solution for every need. This means we are Vacuum Managers, every day.

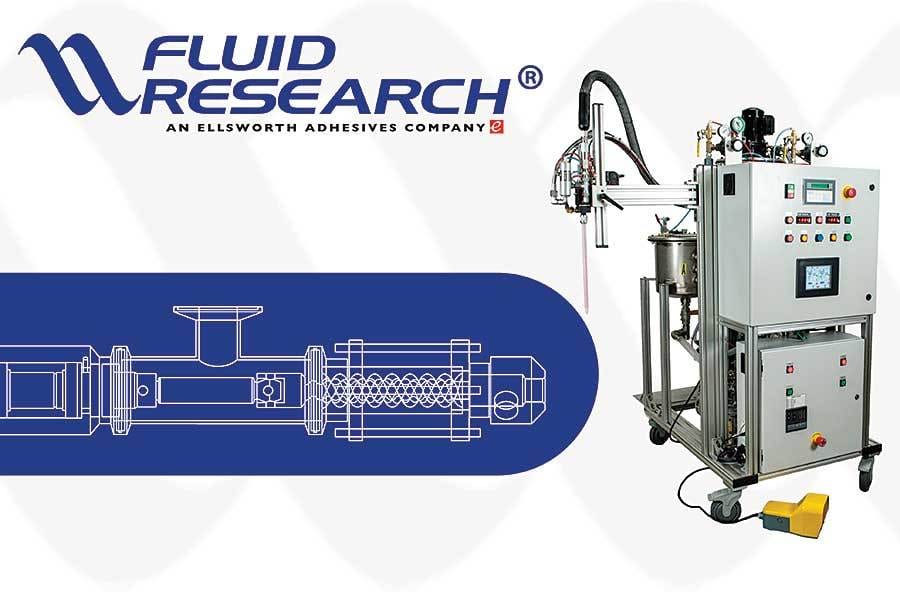

Meter/Mix Dispense Systems

Fluid Research® develops technology and proprietary system controls for accurate, durable, and reliable metering mix systems and dispensing equipment designed for benchtop, cart mount, or free-standing workstations. These systems can easily mix and dispense materials including abrasives, adhesives, sealants, and polymers.

Fluid Research has launched a new product: the VersaMix® 2K meter mix dispensing system. The VersaMix has a variable flow rate and offers a dispense ratio range from 1:1 to 20:1 for potting or beading applications.

Expert Manufacturing & Engineering

The Fluid Research engineering staff integrates proprietary controls and components to customize machines for unique formulations and applications in various industries throughout the world. Service technicians offer training for customer manufacturing engineers and maintenance personnel to ensure success and quality.

Custom Solutions

Fluid Research understands the need to build systems that work for unique operation requirements. For this reason, a variety of add-ons are available to modify or enhance meter mix and dispensing equipment for compatibility with a specific application. System add-ons include speed agitators, automated refilling, filtration, mounted dispense valves, heating packages, programmable vacuum degassing, and more. Reduce operational costs through decreased labor and repairs, improved safety, waste reduction, and more.

Visit fluidresearch.com to learn more.

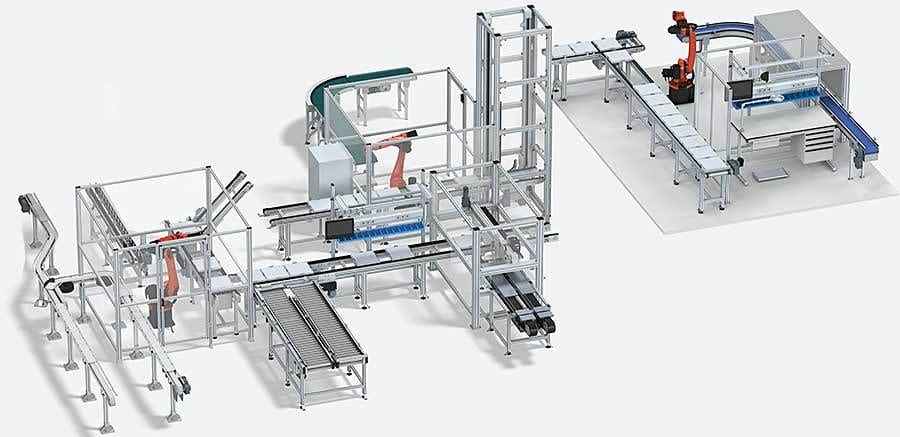

About Bosch Rexroth

Bosch Rexroth is one of the world’s leading suppliers of drive and control technologies, including industrial hydraulics, electric drives and controls, linear motion and assembly technology. Our broad product portfolio, innovative data solutions and application expertise are trusted across the globe.

Bosch Rexroth provides versatile solutions for your Factory of the Future. Our customizable aluminum structural framing is lightweight and durable for easy design and precision assembly. As the world’s largest modular profile system, it gives you everything to build anything. For your assembly processes, Bosch’s EXACT ION series cordless screwdrivers offer you greater reliability and lower production costs.

When it’s time to move parts or goods, our full range of conveyor and transfer solutions, such as ActiveMover, VarioFlow plus and the TS 5 modular conveyor, helps raise your process quality, productivity and profitability. Some TS modules are available with a four-week lead time through our TS Express program, plus we offer expert transport system field service, including complete on-site system assembly, parts replacement, conveyor tune-up and more.

From ergonomic assembly workstations to innovative automation platforms, Bosch Rexroth brings an extensive range of intelligent components, customized solutions and real-world expertise to your most demanding manufacturing applications. Learn more at www.boschrexroth-us.com/assemblytechnology.

Michigan Based – Global Assembly Expertise

Promess was formed as a Michigan Corporation in 1984 to provide the manufacturing industry with in-process monitoring systems. Specializing in force and torque monitoring applications. Promess quickly developed a worldwide reputation for supplying state-of-the-art, turnkey sensing and test systems.

In 1989 Promess entered the motion control arena developing a fully electric, ball screw assembly press with built in force monitoring. This was a first step in using process data measured in real time to close the loop on motion control. Additional developments followed in both the pressing and torque testing areas.

While still specializing in force and torque measuring systems Promess continued to develop systems that utilize various sensors including; pressure, flow, laser and temperature transducers to measure and react to process variables, adjusting the process in real time to produce good parts each and every cycle.

Today Promess is known as the manufacturer of complete turnkey monitoring and motion systems used in a wide variety of Assembly and Test applications around the world. Promess delivers the complete system including the mechanics, control electronics, all the sensors, amplifiers, and software. Promess also provides pre-project application engineering assistance, installation support and training services.

Joining is our business worldwide!

With its headquarters in Switzerland, the BalTec Group sees its core competence in the manufacturing of joining technology machinery, with a special focus on radial riveting technology, but also orbital riveting, roller forming and pressing. As early as 1968, BalTec (then still known as Bräcker) had already made radial riveting technology a familiar process in a variety of different sectors. With over 40,000 machines installed, we are the global leader in riveting technology, encompassing six companies at five different locations with over 60 direct employees and 40 sales partners on every continent.

BalTec Corporation manufactures work cells which include riveting machines and press systems. To assure a high level of quality and customer satisfaction we support manufacturers and customers in our trials and testing lab when it comes to determining the best joining technology as well as during the integration of machines. Over 20 sales representatives located in strategic regions of the US, Canada and Mexico provide a close personal support.

DEPRAG, Inc.

640 Hembry St.

Lewisville, TX 75057

800-433-7724

972-221-8731

DEPRAG – Your Worldwide Partner

DEPRAG has production facilities in Germany, the Czech Republic, China and engineering, sales, and service subsidiaries in France, Mexico, Sweden, the USA, and the United Kingdom.

Products

Screwdriving Technology: Our screwdriving technology solutions benefit from our shut-off clutch's extreme torque accuracy and the renowned robust and reliable design of all our screwdrivers. Screwdriving perfection is our guiding principle, and we command undisputed market leadership in many applications.

Automation: Our experience in assembly technology has enabled us to develop first-class solutions. Our measuring instruments, controllers, and successful feeding technology are utilized in our customers' applications. In conjunction with our project engineers' long-standing experience, we produce assembly machines for a wide variety of client requirements.

Air motors: Air Motors are of utmost importance as a drive element for machines and equipment. As a market leader in this field, we provide an extremely versatile program for the most varied applications from the food industry to medical technology.

Air tools: Classic industrial devices such as grinding machines, drills, and sheet metal tools are our company's roots. High performance, reliability, and outstanding ergonomic design are the distinguishing characteristics of DEPRAG tools.

DEPRAG – your partner worldwide!

mk North America

105 Highland Park Drive

Bloomfield, CT 06002

860-769-5500

better products. better solutions

Since 1988 mk North America, Inc. has been providing products and solutions for assembly and factory automation needs for companies across North America.

mk offers the widest variety of conveyor systems in the industry, as well as a complete line of compatible t-slot aluminum extrusion. mk’s conveyor line includes belt conveyors, plastic modular belt conveyors, timing belt indexing conveyors, incline and curve conveyors, roller conveyors, as well as accumulating chain and flexible flat top chain conveyors.

mk’s t-slot aluminum extrusion line features four different base sizes and includes all the necessary hardware, mounting angles and brackets, floor mounts and accessories needed to build guards, workstations, carts and so much more.

When you work with mk; you work with a design, engineering and manufacturing company that is committed to providing not only a better product, but also a better solution.

WEISS North America Inspires Automation

An integral part of the Weiss global network and leaders in rotary and linear motion automation solutions, WEISS North America, Inc. (ISO-9001 Certified) manufacturers high-quality cam-, servo-, and linear motor-driven automation components and solutions. WEISS supplies rotary indexing tables, palletized conveyors, linear motor-driven pick-and-place units, cam- and servo-driven assembly chassis, ring index tables, machine bases and tool plates.

WEISS leverages over 50 years of reliable global expertise to comprise an integrative, customer-specific approach to deliver innovative solutions that enable our customers to be more efficient, effective, and competitive. WEISS specializes in the highest quality craftsmanship and offers an industry leading four-year warranty.

Whether you need to rotate 100 tons or very precisely pick and place a 1 oz. part, WEISS manufactures the world-class automation and assembly solutions to help you achieve your goals. As the world leader in indexing and positioning tables, we have the most robust and innovative designs, and newest products available.

ASG, Division of Jergens, Inc.

15700 S. Waterloo Road

Cleveland, Ohio 44110

216-486-6163

ASG: Products & Solutions for Assembly

ASG, Division of Jergens, Inc. has been offering products and solutions for assembly since 1976 and offers a full range of power tools and specializes in providing world class quality torque control and error-proofing products, including a vast array of premium solutions such as the X-PAQ precision fastening system for your assembly needs. The ASG Express ecommerce platform is home of electric and pneumatic screwdrivers, Gedore manual torque tools, torque testers, and production aides. ASG Automation offers pre-engineered and custom automated assembly systems solutions underpinned by world-class knowledge of threaded fastening. Experience the market leading precision and consistent threaded fastening results ASG customers depend on.

With headquarters in Cleveland, Ohio (USA) subsidiaries in Shanghai (China) and Mumbai (India), and sales offices in Mexico and Europe, the ASG footprint covers the globe. Learn more today!

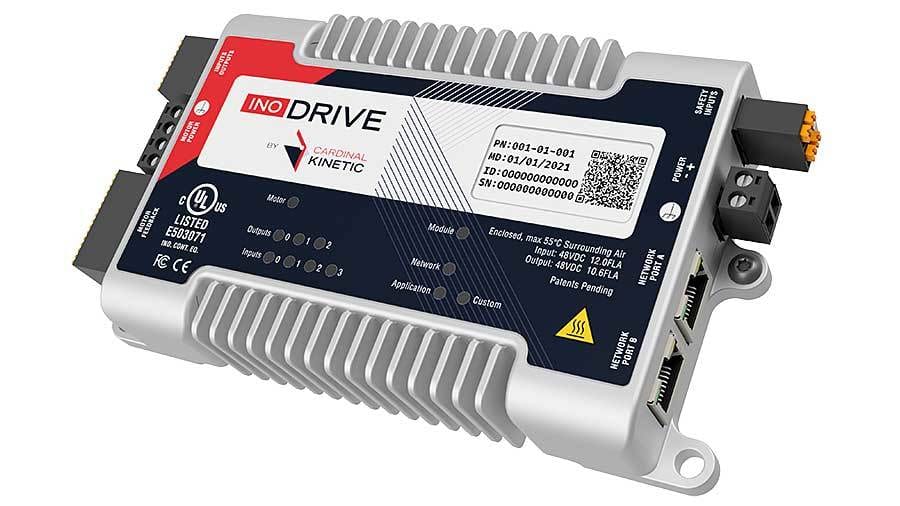

Introducing The Future of Motion Control

Cardinal Kinetic is the developer of the innovative new InoDrive™ + InoWorx™ system introduced for thefirst time at Assembly 2021. InoDrive is a networked, integrated motion system built for modern engineerswho require highly reliable, accurate, and precise control of servo motors. It combines all the capabilities ofa servo amplifier, motion controller, and fully functional logic engine into a single, flexible, and powerfulcontrol unit.

InoDrive is powered by InoWorx™, a powerful web IDE, code-free platform that provides all the critica ldesign elements needed to solve the most demanding motion applications. The system allows users to program and control one or more brushless DC servomotors over an Ethernet network with the highest degree of accuracy and precision.

InoDrive + InoWorx is poised to transform the way businesses control motion. Our unique approach to programming in a web-based integrated environment is simple to use, easy to understand, and continuously updated, offering a new level of freedom to the developer to focus on better suited aspects of the motion system.

The Cardinal Kinetic team consists of experts in motion control, material handling, and general automation.

Our origins are traced to Insight Automation, a leading material handling company founded in 2000.

GAGE BILT Inc.

44766 Centre Ct.

Clinton Twp. MI 48038 USA

586-226-1500

GAGE BILT – Committed to Quality, Innovation and Service

Gage Bilt celebrates 66 years manufacturing robust blind rivet, lockbolt and new blind rivet-nut tooling and nose assemblies. Gage Bilt serves the global markets of aerospace, defense, truck/trailer, rail, automotive and many other industries. We have tools and nose assemblies to install anything from small nonstructural 3/32” blind rivets to 1” diameter lockbolts. Our product line includes: Tools, Nose Assemblies, Power Units, Accessories, Spare parts and now Battery Operated Installation Tools.

Gage Bilt’s wide-range of products is a result of our continued dedication to create innovative designs focused on quality, safety, productivity, ergonomics and FOD control. One of our newly patented innovations, the Feed-N-Swage, is a lockbolt collar auto-feeder eliminating the need to hand load collars. Another revolutionary innovation is our GB756SH Split-Handle Tool, capable of installing 3/8” lockbolts. The hand-held weight of the GB756SH is just 4.3 lbs, that’s 250% lighter than any other 3/8” lockbolt tool in the market! Check out our website for full product details.

Gage Bilt is committed to providing quality solutions, manufacturing innovative and robust, standard and custom products, competitive prices, and best in class lead-times. Contact our technical support and customer service teams to choose the best product solutions for your needs.

Technology that delivers Zero Defect Manufacturing

Born and bred on the plant floor with over 20 years in the manufacturing business, Ujigami PDMS is a comprehensive suite of software solutions that deliver the highest quality active controls and mistake-proofing. Our capabilities expand dock-to-dock with a goal of ensuring all of our customers achieve zero defect manufacturing and eliminate or reduce entire cost categories such as warranty, expedited shipping, training, and more.

Ujigami PDMS: More than just an MES. The Ujigami Product Directed Manufacturing System (PDMS) delivers active control of the assembly process to ensure parts are built to the highest standard at the lowest cost. Ujigami is a configurable Industry 4.0 platform that provides interactive work instructions, scheduling, complete control + sequencing, birth certificate traceability, advanced KPI reporting, label printing and packout, MRP/ERP integration, and more.

We are manufacturing people first and foremost – and we created Ujigami for the people that want to assemble the best quality products in the world.

Contact us to schedule a demo and find out more.

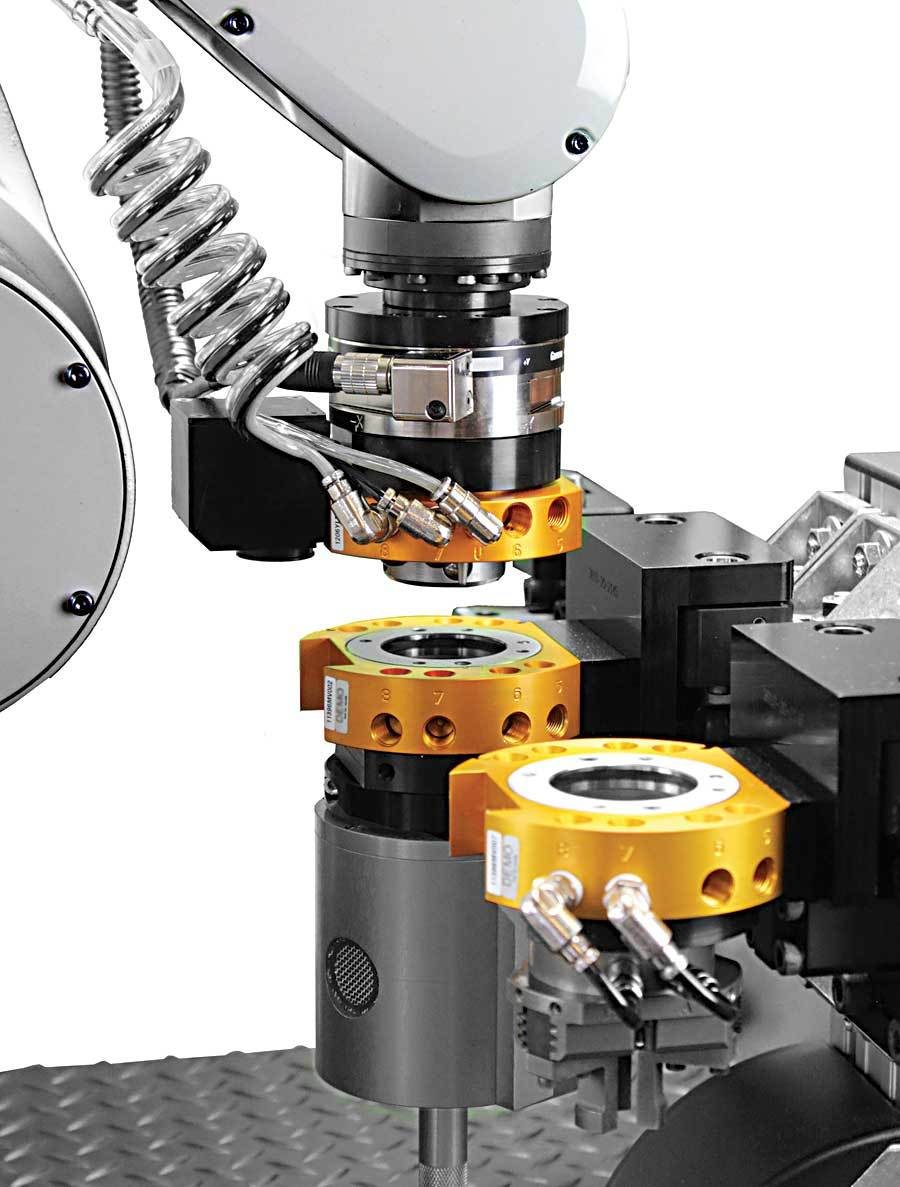

ATI Industrial Automation

ATI Industrial Automation is the world-leading engineering-based developer of robotic accessories and robot arm tooling, including Automatic Tool Changers, Multi-Axis Force/Torque Sensing Systems, Material Removal Tools, Utility Couplers, Robotic Collision Sensors, Manual Tool Changers, and Compliance Devices. Their products are found in thousands of successful applications around the world.

Since 1989, their team of mechanical, electrical, and software engineers has been developing cost-effective, state-of-the-art end-effector products and solutions that improve robotic productivity.

Their Mission is to provide customers around the world with high-quality robotic peripheral devices, tooling and sensors that enhance customer profitability by increasing the effectiveness, flexibility, safety and productivity of their automation applications. They accomplish this through continuous improvement of existing products, product customization and new product innovation. Their engineering-centric staff focuses on providing customer solutions to robotic, automation and sensing applications.

Afag Automation North America

820 Fesslers Parkway Suite 210

Nashville, TN 37210

615-730-7515

North American Operations Continue Growth

As a global supplier of high-quality feeding, handling, and transport soutions, Afag’s operations in North America are on pace for record growth. The Nashville, TN location is poised to grow not only with additional personnel in 2022, but the company is looking for additional space to house the growing concern. “We are very pleased with how this market is responding to our technology.” Said Helmut Niederer, president of the company in Nashville.

Afag has a global reputation for precise, innovative engineering, and responsive sales and service. A leading provider for vibratory feeding solutions across multiple markets, the company has seen great success in the medical, pharmaceutical, and automotive markets. Much of the success lies in the products themselves and how they benefit their customers. Milled bowls and patented drives create solutions that are quiet, precise, and easily reproduced. Couple this with local stock and service, and you get a winning combination.

Swiss precision, German Engineering and American determination. This is Afag!

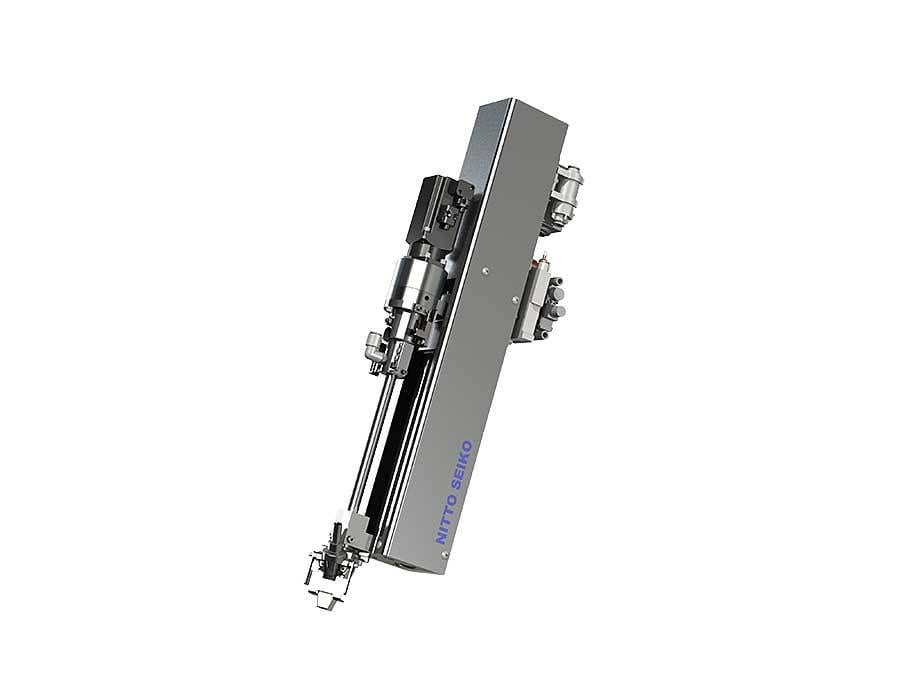

Total Fastening Solutions Provider

Nitto Seiko America is the North American branch of Nitto Seiko, Ltd. and a provider of industry leading screw driving equipment. We offer the full range of screw driving equipment – our own motors and controllers, hand-held drivers, single-spindle drivers, multi-spindle drivers, feeders and robots. This allows us to provide any and all of the equipment you need from a single source, from stand-alone motors and controllers, all the way up to turn-key robotic screw driving systems.

SCHUNK is a German family-owned company and global player in one. The company was founded in 1945 by Friedrich Schunk as a mechanical workshop and has developed under the leadership of Heinz-Dieter Schunk to a competence and world market leader for gripping systems and clamping technology. Today, the company is run by third generation siblings Henrik A. Schunk and Kristina I. Schunk. More than 3,500 employees in 9 plants and 34 directly owned subsidiaries and distribution partners in more than 50 countries throughout the world ensure an intensive market presence.

With 11,000 standard components SCHUNK offers the world’s largest assortment of gripping systems and clamping technology from one source, and 2,550 SCHUNK grippers makes it the largest product range of standard gripping components on the market. The complete program of gripping systems comprises more than 4,000 components. SCHUNK has pushed digitalization of its portfolio forward for years now, ensuring that customers can plan their processes efficiently, clearly, and economically. Customers also benefit from SCHUNK’s comprehensive application knowledge which is constantly growing and making progress in many innovative fields of application where automation can be applied.

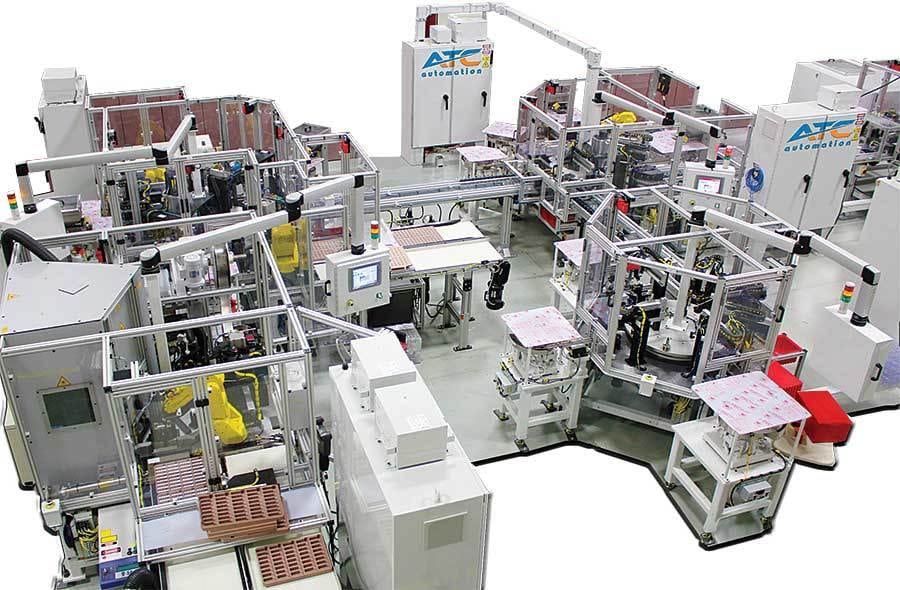

ATC Automation designs, engineers, and builds custom automated assembly and test automation for industries including automotive, energy storage, life science, and consumer products. With over 40 years of experience our innovative design and build teams embrace today’s every changing global manufacturing environment. The size of ATC’s automated systems ranges from complete “factories in a box” to hybrid systems and lean systems that can be integrated into a current manufacturing process. The manufacturing facility located in Cookeville, TN has 200,000 sq feet of manufacturing space, including a Life Science Division with dedicated manufacturing space and privacy walls. ATC Automation Mexico facility has 16,000 sq feet of manufacturing space. ATC has the resources to produce systems that range from very robust manufacturing lines for the automotive and consumer product industries to equipment that will be used in clean rooms for the life science and energy industries. ATC’s business structure revolves around a team concept. ATC’s team structure is unique in the way it is designed to provide synergy and cohesiveness throughout the team and provide the customer with the best solution and experience. ATC is an ISO 9001:2015 certified company.

Schleuniger, Inc.

603-668-8117

Toll Free Technical Support: 877-902-1470

About Schleuniger

As a global technology company and leading supplier to the wire processing and testing industry, Schleuniger offers an expansive range of innovative solutions for virtually all applications to meet the evolving demands of the wiring harness industry.

From simple to complex applications, Schleuniger’s automatic and semiautomatic machines process wires and cables reliably, economically, and precisely. And with an extensive array of global service products that is unmatched in the industry, Schleuniger will assist you in achieving precision results throughout the entire life cycle of your equipment, helping you reduce costs, increase machine uptime, and improve overall productivity.

Innovative product design, long-term experience, and open communication with our customers has enabled Schleuniger to consistently refine and expand our product portfolio since 1975. At Schleuniger we claim “To Be Precise.“ with good reason. It is our passion and the standard we set for ourselves. We maintain control over the elements critical to our success, from product development to production, sales, and service. This allows us to quickly respond to the needs of our customers and to assist them in finding the right solutions for their specific applications.

Headquartered in Thun, Switzerland, Schleuniger and its subsidiaries DiIT, adaptronic, and Cirris serve customers spanning a broad range of industries.