ADVERTISEMENT

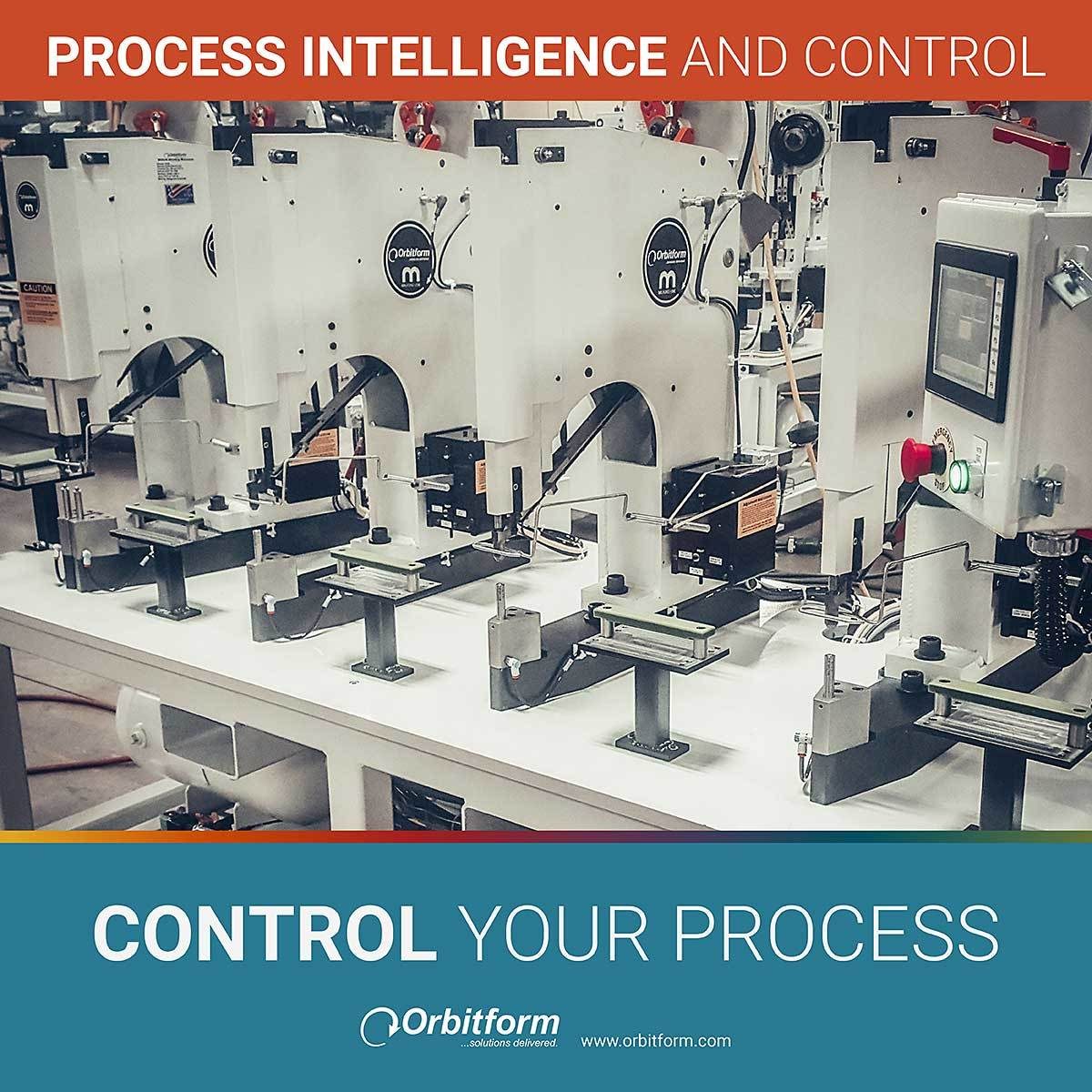

Gain Control Over Your Manufacturing Process

Including Orbitform’s Process Intelligence Packages will improve quality and reduce scrap on forming, riveting, and assembly equipment.

Monitoring Packages

Force – Internal mounted load cell package provides force monitoring of the process as the head advances to process the workpiece.

Distance – Internal mounted LVDT package provides stroke monitoring of the head as it advances to process the workpiece.

Pre-Form Stack up Height Verification – Internal mounted LVDT and load cell packages, along with a programmable height sensing pressure pad, are used in conjunction to validate the pre-form stick-out height of the workpiece.

Detecting Workpiece Presence – Using the same machine set-up as “force monitoring” or “pre-form stack-up height” condition as described above, the presence of the workpiece can be detected every cycle.

Multiple Z-Axis Forming Positions – Orbitform’s Servo Z-axis control package and our Servo Riveters provide the capability to process workpieces at different height positions.

Control Packages

Form to a Force – Internal mounted load cell package, this feature can complete the process cycle upon achieving a set process force.

Form to a Distance - Internal mounted LVDT package, this feature provides the capability to complete the process cycle upon achieving a set advanced position of the head.

Form to a “Form Collapse” – Internal mounted load cell and LVDT packages, along with our programmable height sensing pressure pad and motor clutch/brake package; upon tooling contact of the workpiece during low pressure or low-speed head advancement, this position becomes “0”, and then the head advances to the set “form collapse” position and then retracts.

More information included in our blog article.