ADVERTISEMENT

Flagship of Modern Assembly Automation

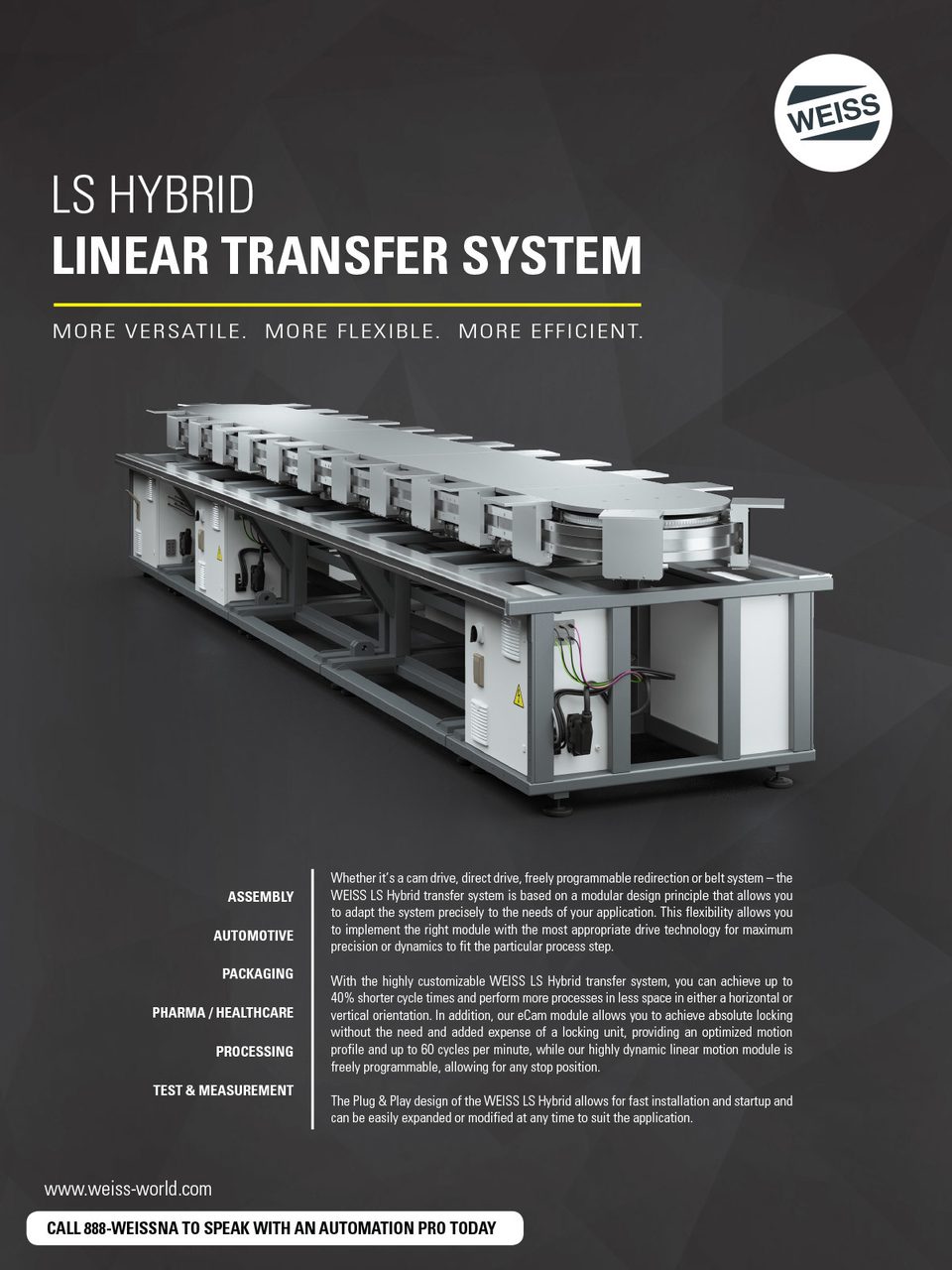

Developed with a “hybrid drive” concept in mind, the WEISS LS Hybrid linear transfer system offers integrated eCam, linear and belt drive options and is particularly effective where fast and efficient tooling carriage transport is required. An alternative to rotary indexing tables, linear transfer systems allow for faster and easier scaling of production, particularly true with the highly configurable and modular LS Hybrid from WEISS. With up to 60 parts/min and 40% shorter transport times, the LS Hybrid enables more processes to be performed in less space - resulting in a significantly smaller footprint and cycle time reductions.

The LS Hybrid optimizes a classic pallet transfer system with mechatronic and highly dynamic properties. This optimization provides a production line with more flexibility and efficiency since both the hybrid drive technology and “Plug & Produce” characteristics offer increased design freedom. In addition, the system allows the linear flow of the assembly process to have more processing capacity & capability due to the “hybrid productivity” of the fast, high-precision tooling carriages. Superior to conventional linear transfer systems with rigid flow and one-dimensional drive systems, the LS Hybrid enables more advanced machine concepts to become a reality.

Installation and configuration are quick and straightforward with the W.A.S. (Weiss Application Software) control package, eliminating the need for special expertise or experience. The LS Hybrid is a true flagship of modern assembly automation that delivers outstanding value in terms of economic, flexible & reliable performance.

WEISS North America, Inc.

888-WEISSNA (888-934-7762)