Vision Systems

New Tech for

Machine Vision

John Sprovieri // Chief Editor

A host of new products offer higher resolutions, faster speeds and more user-friendly programming.

Vision systems play a vital role in automated assembly systems. They can check for the presence or absence of parts or materials. They can measure key dimensions of assemblies. They can tell robots the precise location of parts. They can even read 1D and 2D codes. Here’s a look at some of the latest developments.

A Proven Process

The new BVS SL Smart Camera Lite provides a cost-effective option for manufacturers wanting a machine vision system, but not requiring all the image analysis features of full-size smart camera models. Photo courtesy Balluff Inc.

The new BVS SL Smart Camera Lite from Balluff Inc. is a simplified version of the company’s existing smart camera. The new lite model provides a cost-effective option for manufacturers wanting a machine vision system, but not requiring all the image analysis features of full-size smart camera models. But, like Balluff’s other smart cameras, it allows engineers to detect production defects early in the manufacturing process. It can also be used for reading codes and text, and for guiding robots.

All of the camera’s inspection routines can be implemented with its built-in Cockpit software. All that is needed to configure the camera is a web browser.

Engineers can generate inspection programs and transfer the results to the controller or file servers. Engineers can adjust the amount and format of the data as needed. This reduces the amount of data sent over the process network. Integration into an existing system is easy using the camera’s six programmable I/O. IT and OT communication are delivered via Ethernet TCP/UDP.

For more information, visit www.balluff.com.

Flowchart-Based Vision Software

The latest version of Matrox Design Assistant X flowchart-based vision software includes new tools for 3D imaging and inspection. Photo courtesy Matrox Imaging

Matrox Imaging has released the latest version of its flowchart-based vision software, Matrox Design Assistant X.

Version 2109 includes a range of new 3D steps and functionality; supports Matrox Iris GTX smart cameras; offers OPC UA communication to manufacturing systems; features a new step for enhancing image contrast; and simplifies project troubleshooting and optimization.

The software interfaces to a wide range of 3D cameras and sensors, including Matrox AltiZ 3D profile sensors, as well as third-party 3D cameras and sensors through their SDK or the interface standard they support.

The new version adds the ability to visualize point clouds—optionally color-coded, meshed and filled—in addition to depth maps and profiles.

Also new to Design Assistant X are steps to crop 3D data and calculate volume. The former allows engineers to pull out a portion of a point cloud for closer analysis, while the latter computes the volume of a depth map or a point cloud.

Iris GTX smart cameras are edge IoT devices that deliver complete on-device image acquisition and processing for real-time, optimized response and action. Design Assistant X provides Iris users with a suite of tools for developing both traditional vision operations, as well as deep-learning inference in the form of image classification and segmentation.

The software comes ready for the demands of Industry 4.0, supporting communication using the OPC Unified Architecture (OPC UA) for interaction with manufacturing systems.

Design Assistant X also includes a new high dynamic range step. This step works to generate images with enhanced contrast by combining images of an identical scene, taken at different camera exposure levels, into a single image with a greater range of luminance.

To enhance operator insight, the development environment incorporates new charts into the operator interface to graphically show results, including trends.

Finally, the software simplifies project troubleshooting and optimization with run-time execution monitoring and reporting capabilities.

For more information, visit www.matrox.com/imaging.

Ultra-High-Resolution Cameras

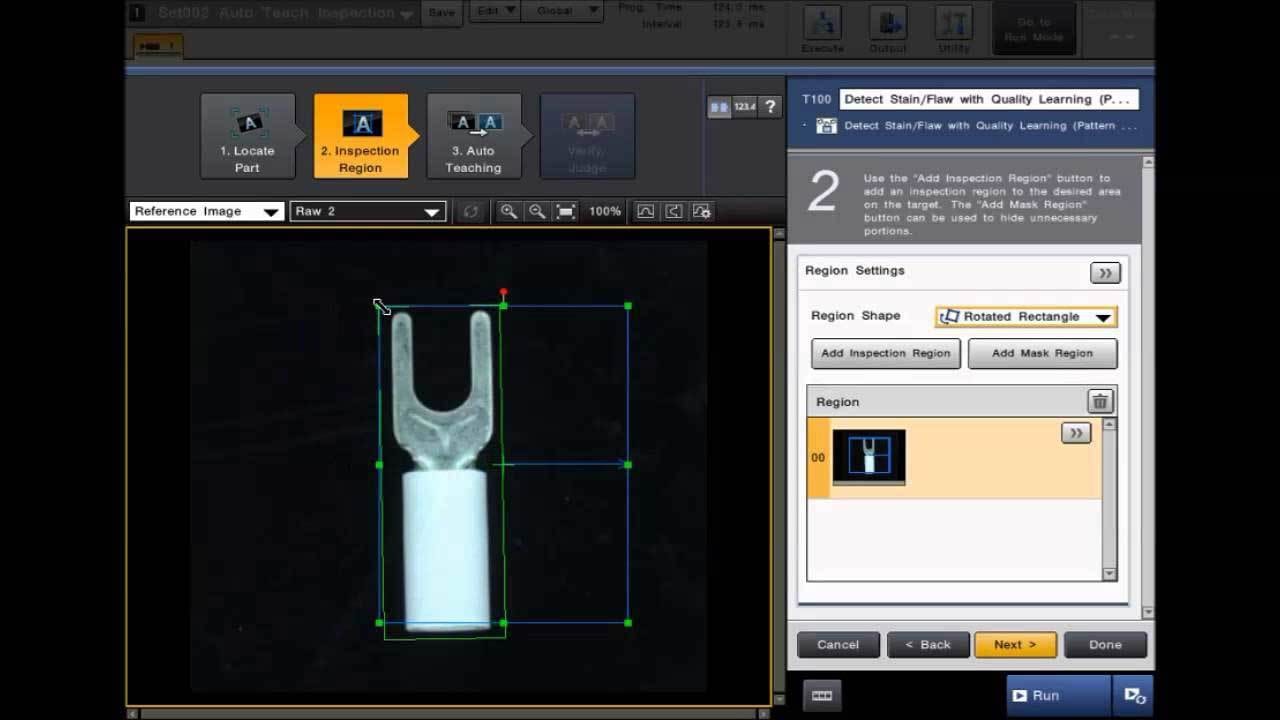

The CV-X and XG-X line of machine vision cameras provide ultra-high resolution and a wide field of view. Photo courtesy Keyence Corp. of America

The CV-X and XG-X line of machine vision cameras from Keyence Corp. of America provide ultra-high resolution and a wide field of view.

The most powerful camera in the lineup is a 64 megapixel camera for detailed inspection over a wide field of view. The camera has 12.8 times more pixels than a 5 megapixel camera. Global shutter technology allows inspection even on production lines with moving targets.

Ultra-high resolution and a wide field of view are advantageous for several reasons. Typically, when inspecting large targets, either the camera or the target must be moved to ensure accuracy, resulting in longer inspection times.

For dimensional inspections of small parts, such as multi-pin connectors, insufficient resolution can have a negative impact on accuracy. With the new camera, the entire target can be imaged with a single capture, without sacrificing accuracy, and inspection can be performed with the shortest possible time. This also helps simplify equipment installation.

The CV-X and XG-X cameras are also fast, with an image transfer time of 57.6 milliseconds. The cameras provide an image-transfer frequency of 1.1 gigahertz—more than five times that of conventional systems. This opens the door to high-speed, ultra-resolution inspections that were not possible before.

Despite the high pixel count, the camera retains the same physical size as conventional models: 50 by 50 millimeters. This allows the use of general-purpose lenses. The built-in angle sensor allows stable camera installation with alerts if misalignment from the original setup occurs. As a result, operation is stable at the best possible resolution even for larger targets.

For more information, visit www.keyence.com.

JAI Expands Go-X Series With Rolling Shutter Cameras

JAI has expanded its Go-X Series of small industrial cameras with three new models built around Sony’s popular STARVIS sensor platform featuring CMOS rolling shutter technology. Photo courtesy JAI

JAI has expanded its Go-X Series of small industrial cameras with three additional models. The new models are built around Sony´s popular STARVIS sensor platform featuring CMOS rolling shutter technology and includes 6.3-megapixel (IMX178), 12.2-megapixel (IMX226) and 20-megapixel (IMX183) resolutions, all available in monochrome and color versions.

The sensor design utilizes back-side illumination technology featuring a simpler and more compact pixel architecture leading to

excellent light sensitivity and high quantum efficiency. The new cameras include a global reset function that lets engineers combine the advantages of global and rolling shutters in applications where flash illumination can be used. The cameras are ideal in vision systems where cost-efficiency is a key system design parameter.

The cameras feature high shock and vibration ratings of 80G and 10G, respectively, and are designed to optimally dissipate heat to avoid breakdowns in industrial environments and under nonstop operating conditions. The cameras are backed by a six-year warranty.

The cameras are designed to provide high image quality, thanks to a rigorous dust prevention and screening process. The special dust prevention measures include clean room assembly, internal seals around the sensor compartment, and a rigorous inspection process.

The cameras share many of the same features as the rest of the Go-X Series including, standard C-mount, region-of-interest settings, image flipping and mirroring, blemish compensation and shading correction. An automatic level control function lets engineers define the interactions between auto-gain and auto-shutter operation to minimize noise and optimize apertures

in dynamic lighting conditions. Power can be provided over the GigE Vision interface or via a separate 6-pin I/O connector.

For more information, visit https://insights.jai.com/go-x-series.

Cameras for Challenging Lighting Conditions

The Genie Nano-1G and Lumenera Lt machine vision cameras provide high levels of detail in low-light environments. Photo courtesy Teledyne Imaging

Teledyne Imaging has extended its Teledyne DALSA Genie Nano-1G Camera Series and Teledyne Lumenera Lt Series USB3 cameras based on third-generation Sony Pregius Global Shutter CMOS sensors. Available in both color and monochrome models, the latest cameras are capable of large, full-well capacity and bring increased dynamic range to the Genie Nano-1G and Lt Series camera portfolio. This, in combination with larger pixel sizes, allows for high levels of detail in low-light environments.

Ranging in resolution from 0.5 to 7.1 million pixels, the cameras take full advantage of the unique high conversion gain provided by these new Sony Pregius sensors. This allows the cameras to obtain clear images by capturing more light without introducing high levels of noise.

Both series are engineered to deliver high dynamic range with low read noise for a variety of demanding applications ranging from traditional machine vision to high-speed industrial automation.

For more information, visit www.teledynedalsa.com.

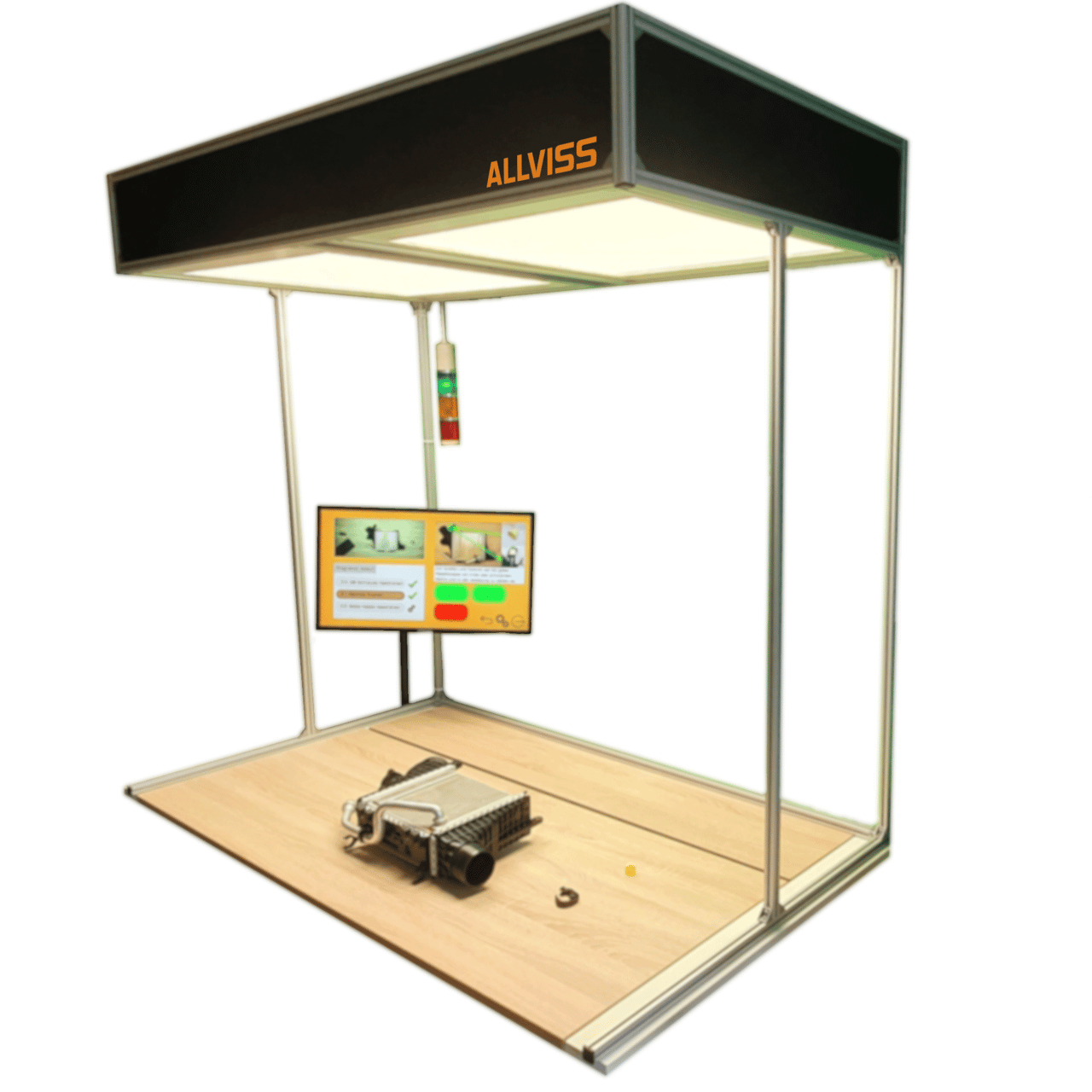

Vision Sensors Error-Proof Manual Assembly

The Allviss system uses vision sensors and work-instruction software to error-proof manual assembly tasks at a workstation. Photo courtesy Eye Vision Technology

Allviss from Eye Vision Technology uses vision sensors and work-instruction software to error-proof manual assembly tasks at a workstation.

The systems shows step by step on a display how the work is to be carried out and which components are to be attached. Sensors above the work surface recognize which components need to be assembled and shows them to the worker. In this way, the system supports the employee and provides information at an early stage if the wrong components have been used or installed in the wrong place. Allviss thus ensures that all assembly steps are carried out in the correct order with the correct components.

Tools and equipment, such as torque wrenches and bar code scanners, can also be connected to the intelligent assistance system through various interfaces.

After all work steps have been carried out correctly, Allviss alerts the operator visibly and audibly that the job has been completed successfully.

All the data that Allviss generates can be integrated into a SCADA system for traceability and analysis.

Assemblers interact with the system via an intuitive touch screen, which is also used to configure the system. All processes and steps are configured graphically using a drag and drop system. New parts are trained simply by showing them to the camera.

For more information, visit www.evt-web.com.

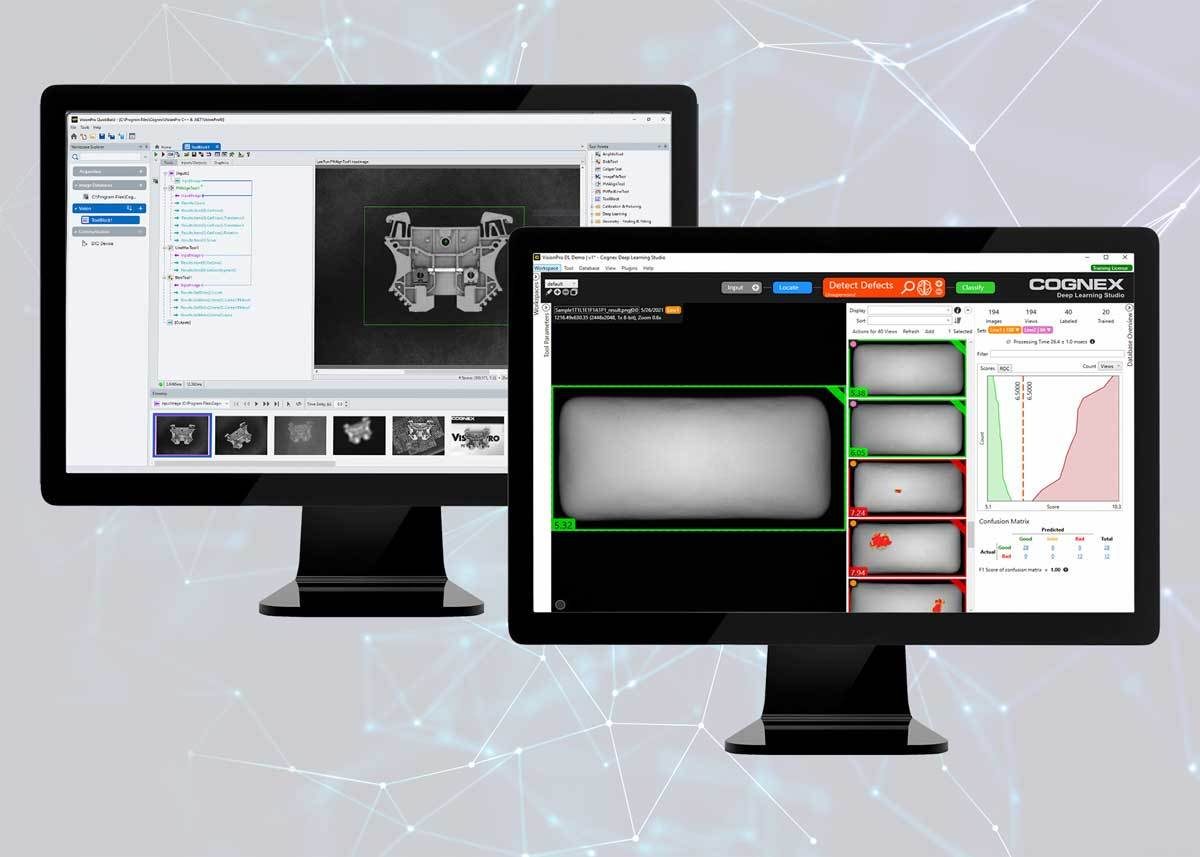

Software Breaks Barriers Between Deep Learning, Traditional Vision

VisionPro Deep Learning 2.0 integrates tightly with VisionPro 10.0, enabling engineers to combine deep learning and traditional vision tools in the same application. Photo courtesy Cognex Corp.

Cognex Corp. has released two updates to its line of vision software products. VisionPro 10.0 is a major update of the company’s PC-based vision software that delivers faster application performance and simpler application setup. VisionPro Deep Learning 2.0 integrates tightly with VisionPro 10.0, enabling engineers to combine deep learning and traditional vision tools in the same application.

The software programs also introduce advanced vision tools for precision gauging and inspection applications. SmartLine is a hybrid smart tool. It combines deep learning enhanced line finding for complex scenes with precise positional data from traditional vision algorithms. The new VisionPro Deep Learning high-detail segmenter is for demanding medical and electronics applications that require precise measurement of scratches, contamination and other defects.

“As deep learning gains a foothold in the factory, we are seeing that many applications require more than just traditional vision or deep learning alone—they need both,” says Joerg Kuechen, senior vice president of vision products at Cognex.

For more information, visit www.cognex.com/visionpro-10.

ASSEMBLY ONLINE

For more information on vision systems, visit www.assemblymag.com to read these articles: