Motion Control

Video: OKIOKI / Creatas Video+ / Getty Images Plus via Getty Images.

Conveyors

New Technology for

These five new conveyors position parts quickly and efficiently.

John Sprovieri // Chief Editor

Conveyors remain essential for getting the right parts to the right spot at the right time. Here’s a look at the latest offerings.

High-Speed Transport and Positioning

In connected factories, everything must interact seamlessly and quickly. This also applies to the transport and positioning of products and materials. The linear motion system ctrlX Flow HS achieves this through flexibility and high speed, in less space. The compact system can be configured flexibly to suit various topologies and applications.

The linear motion system is 100 percent integrated into Bosch’s automation toolkit ctrlX Automation, and it benefits from the openness and safety of the entire product family. It gives engineers access to all features, including interfaces for interoperability with other systems and communication and security standards thanks to ctrlX IOT. Using the embedded software ctrlX Motion, it is also possible to operate robots and other axes in a synchronized manner with ctrlX Flow HS.

The ELX6233 terminal meshes the advantages of the EtherCAT industrial Ethernet system with the emerging possibilities of Ethernet-APL. When connecting corresponding field devices, the new I/O terminal offers a modular approach along with numerous associated advantages, including a compact footprint and high channel density; easy expandability and an adaptable number of channels to suit each application; simplified integration; faster cycle times than field switch systems; and compatibility with all EtherCAT terminals, couplers and other devices.

The ELX6233 connects to sensors according to the SPAA (TS10186) port profile and integrates them into the system via Profinet. Two APL ports are available for this purpose in the space-saving 24-millimeter terminal housing. This allows data from connected sensors to be transmitted to the controller and to the higher-level process control system (DCS) via ultra-fast EtherCAT communication.

Bosch Rexroth Corp.

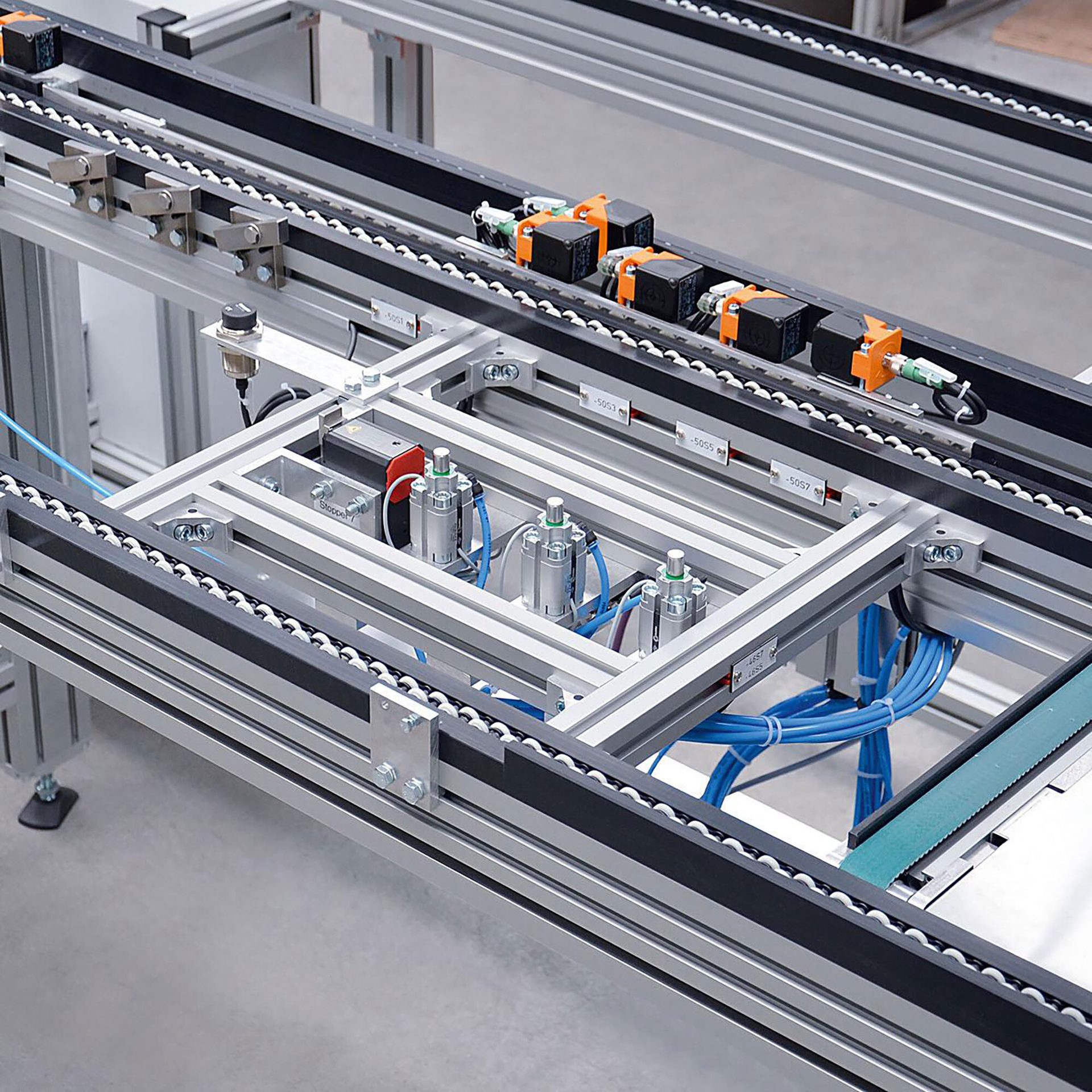

Conveyor Carries Battery Packs

The VersaMove line of pallet-handling conveyors has been expanded to accommodate the demands of manufacturing and testing EV battery packs. The weight limit, per pallet, has been increased from 800 pounds to 1,200 pounds. Additionally, the maximum width has increased to 1,500 millimeters, and the conveyor can transport the battery packs directly, without the use of a pallet. Higher loads and widths are available upon request.

VersaMove conveyors allow for product to be stopped on the conveyor and precisely located. Product can also be rotated and diverted off the main line. Product can also easily change elevation via vertical transfer units.

mk North America

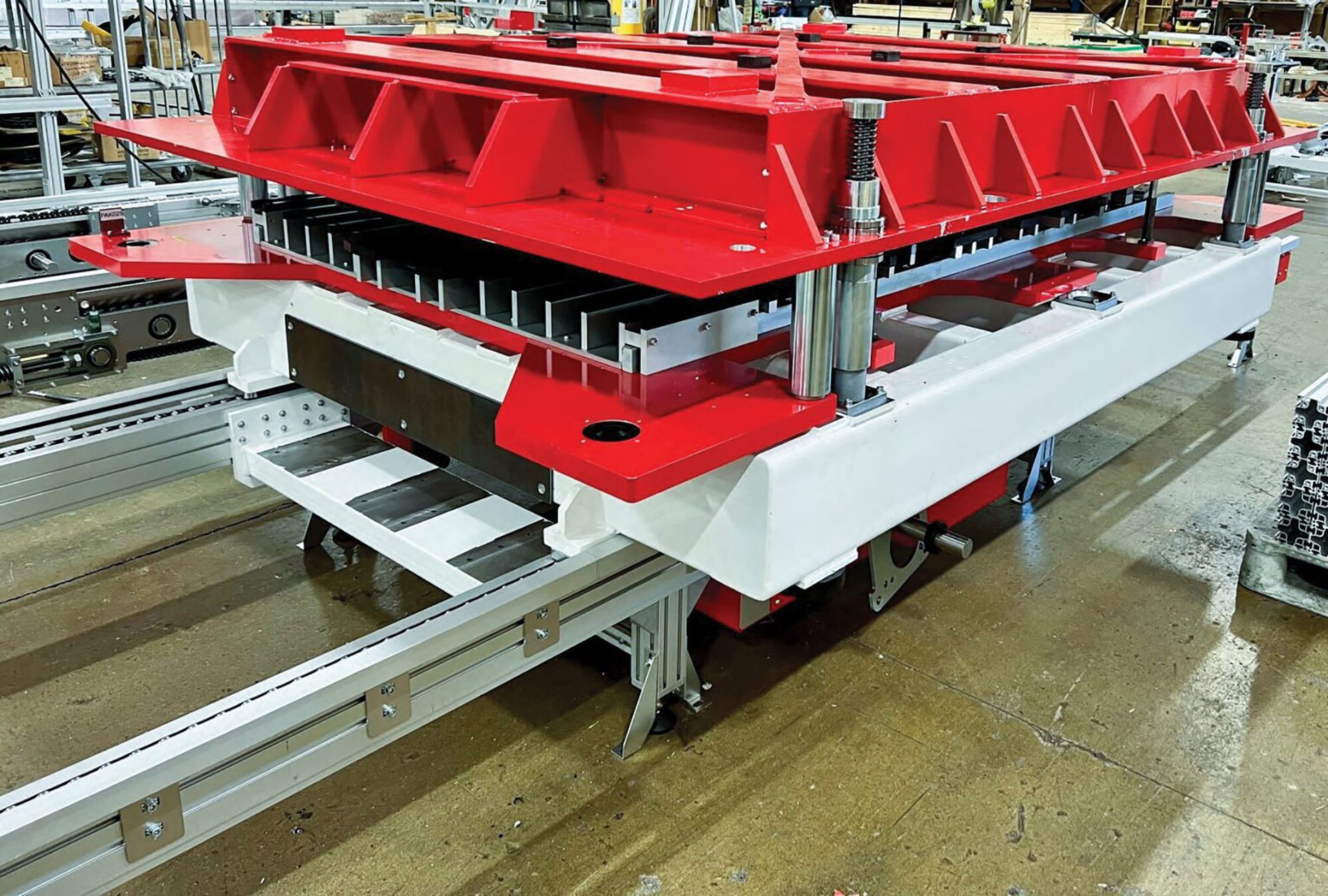

Twin-Strand Conveyor for EV Batteries

Automation and Modular Components (AMC) recently designed and built a conveyor for a manufacturer of EV batteries. AMC provided its Mod 4 conveyor as a turnkey system, including controls, PLC design and programming. The company also installed the system at the customer’s assembly plant.

The system comprises 138 feet of conveyor in a loop structure that provides seamless transportation of pallets within the battery curing loop, optimizing the production process. The system was designed to handle loads exceeding 8,000 pounds.

To further enhance functionality, the system incorporates four rotation stations and nine individual center-drive conveyors. This configuration provides flexibility in the production line, accommodating various stages of battery manufacturing with precision and efficiency.

The installation posed unique challenges, especially considering it was set up on a mezzanine. The weight distribution on the mezzanine’s I-beams required meticulous planning and engineering expertise to ensure structural integrity and safety.

Automation and Modular Components

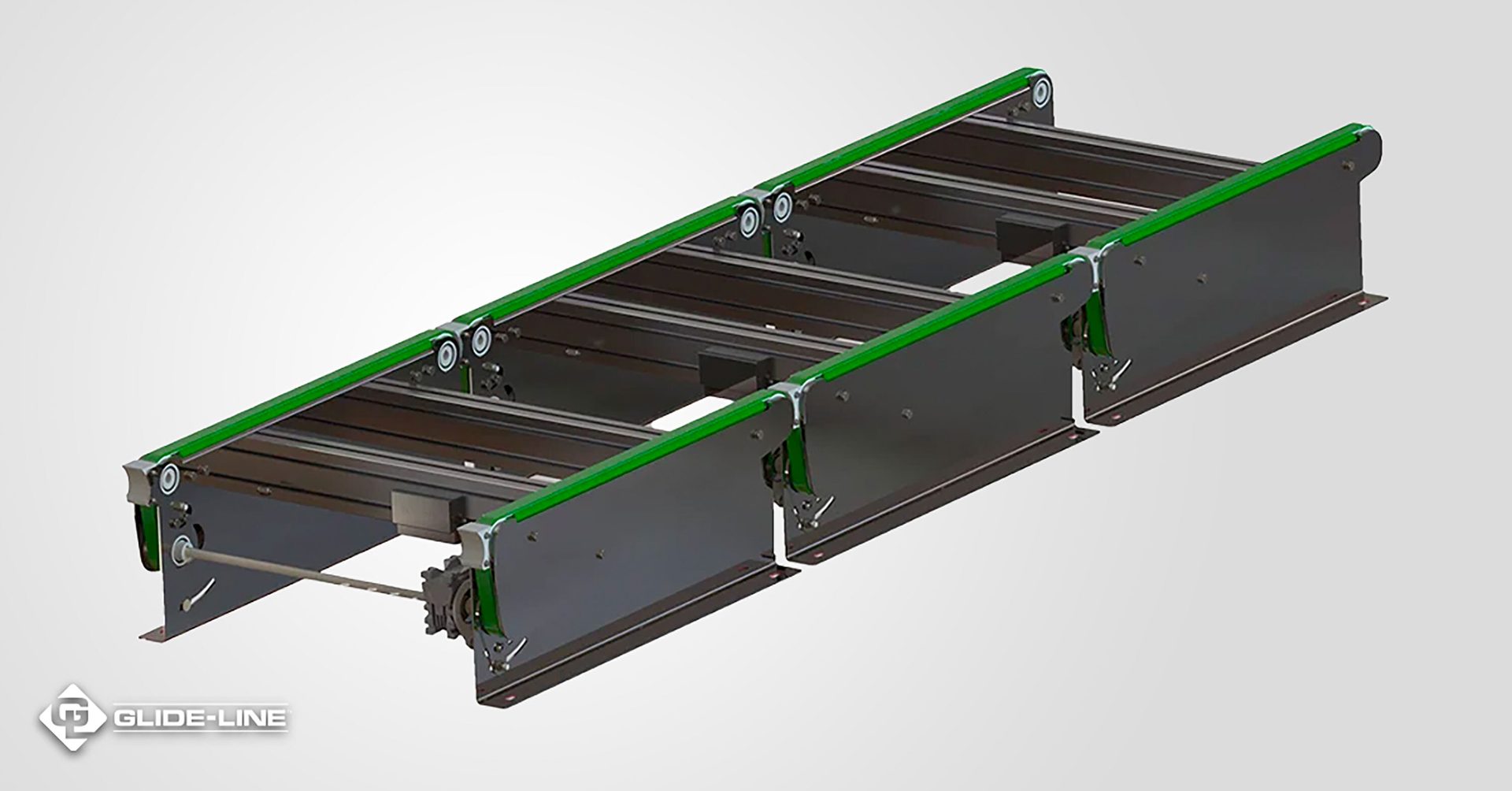

Zero-Contact Zoned Conveyor for Direct Product Handling

Glide-Line’s zero-contact zoned conveyors offer flexibility and control when handling products directly on the line. Whether the conveyor is moving rugged assemblies or delicate items, such as electronics, appliances, musical instruments or photovoltaic cells, each individually controlled zone guarantees zero contact or collisions between products. Transporting products directly on the conveyor saves the cost of pallets, totes or trays.

The high-friction, soft durometer belt protects products from scratches, while DC drives with precise control ensure smooth stops and starts at every stage in the assembly process. Linear segments can be combined with vertical transfers, shuttles, merges and rotating units to meet a variety of transport needs.

The units enable engineers to take control of assembly operations with individually controlled zones that accumulate, orient, and manipulate products exactly how they are needed.

Glide Line

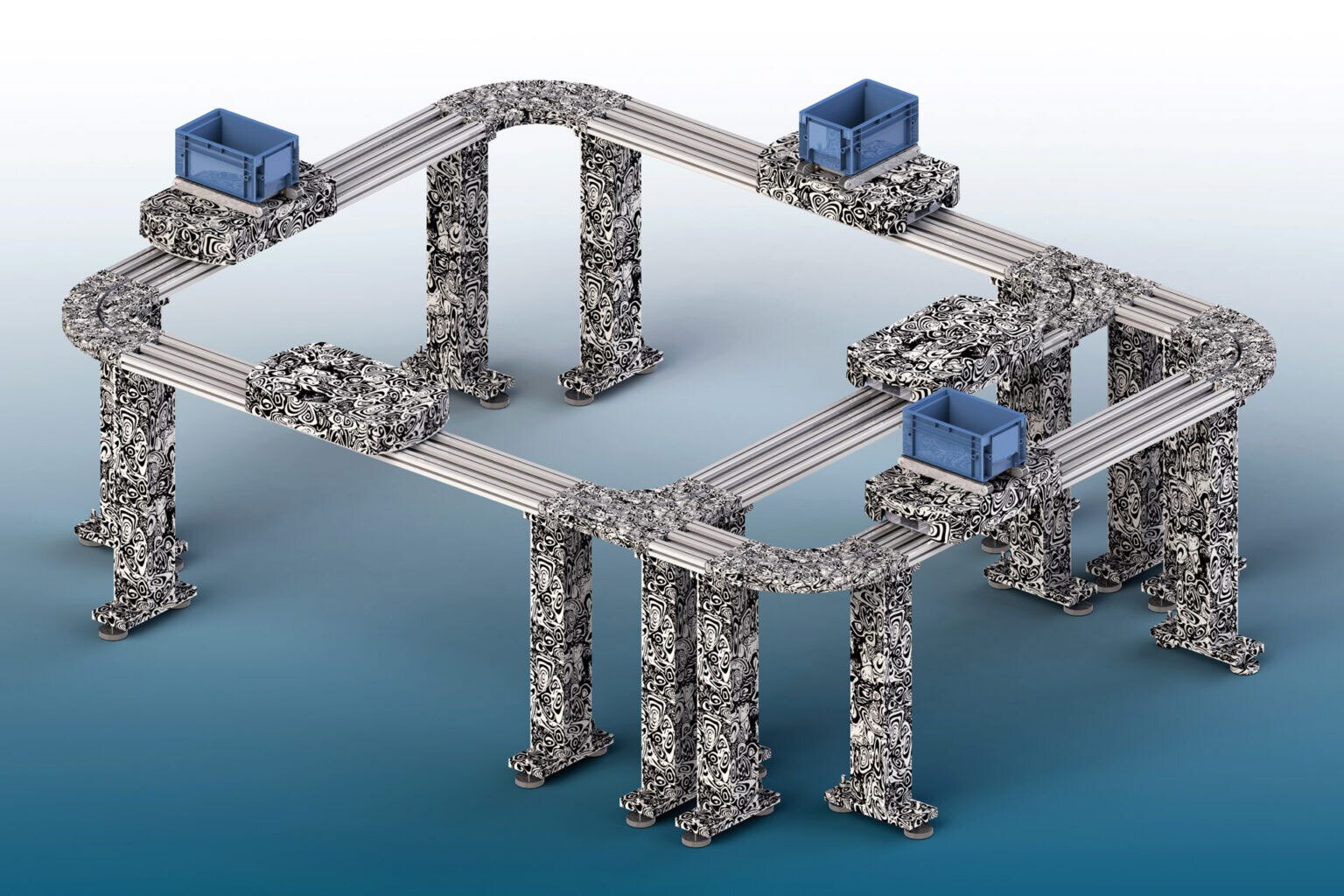

Conveyor With Intelligent Shuttles

The Stein link intralogistics system transports products via intelligent, battery-powered shuttles. The system can transport payloads of up to 80 kilograms at speeds of up to 50 meters per minute. The shuttles provide shock-free transport of products. Shuttles can be equipped with RFID technology to communicate with individual stations and higher level systems. Batteries can be changed manually or automatically within a few seconds.

Stein Automation