A special section to ASSEMBLY

Machine Automatically Cuts, Strips Wire

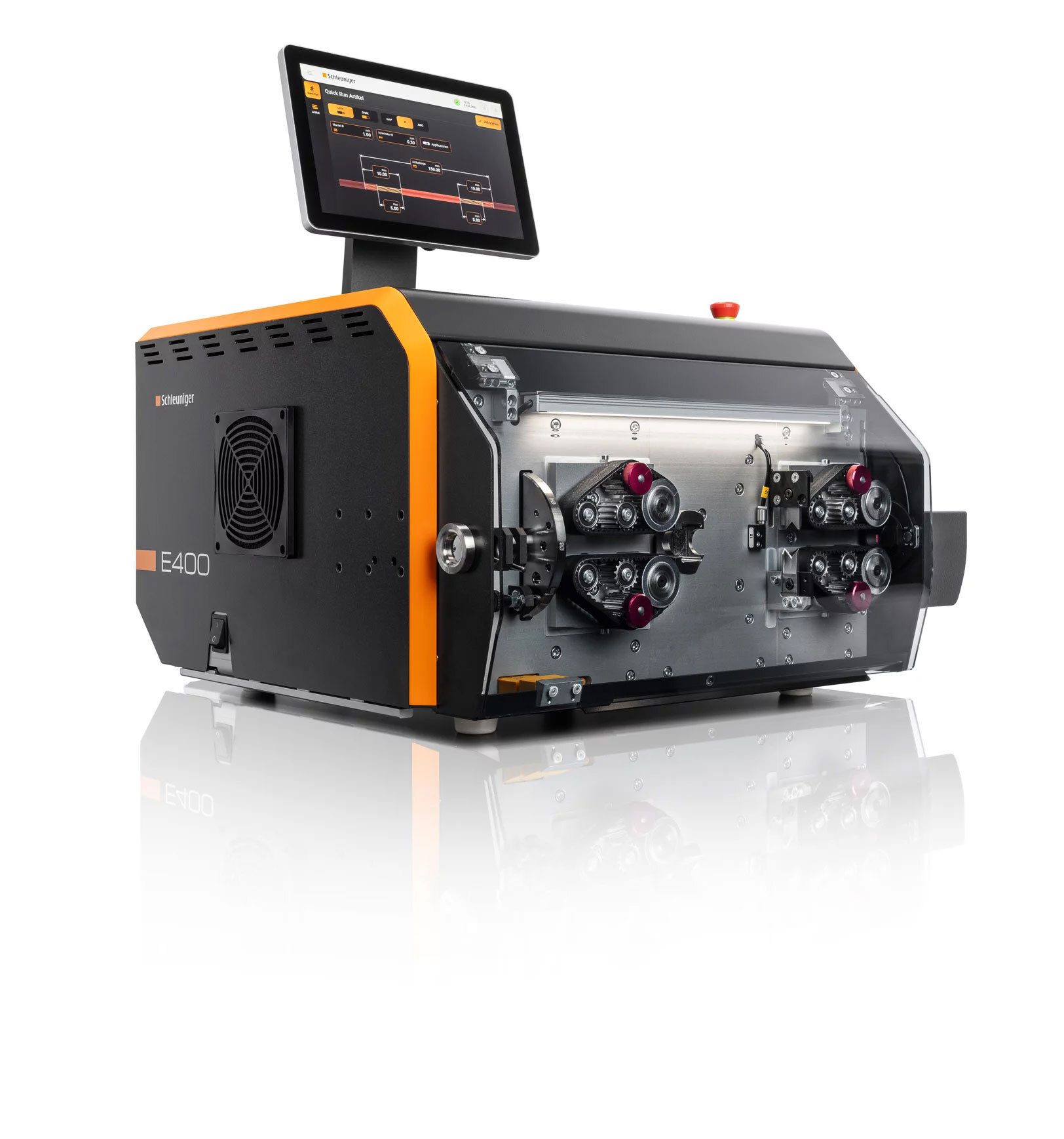

The E400 automatically cuts and strips wire ranging from 26 to 6 AWG and cable ranging from 0.8 to 12.5 millimeters in diameter. It can also process tubing, ribbon and multiconductor cables. It can cut a variety of insulation materials, including PVC, PUR and Teflon. It can strip the outer jacket in several steps. It can do full and partial strips on one or both ends of a wire. Blades, belts and guides of the predecessor model, the MultiStrip 9480, are compatible with the new machine.

The contact pressure on the feeding unit is programmable. This allows for fine and targeted adjustments. The E400 is equipped with a belt drive system with an integrated short piece kit. The gripping axis is programmable and ensures accurate transport of the cable.

An intuitive interface with a 10-inch color touch screen facilitates the creation of jobs and article programs. Predefined and verified default parameters support quick creation of processing jobs. “Quick-Run Mode” allows immediate production with just a few clicks.

Options include a cable jam detector, various radius blade sets, and a tool bar with magnetic holder for accessories.

Schleuniger Inc.

Side-Entry Terminal Blocks

Klippon Connect side-entry terminal blocks feature lateral Push In technology for fast and reliable connections. Push In technology reduces connection times for terminal blocks by up to 50 percent. Conductors can be connected quickly without a bending radius and without tools. This reduces the installation height and increases clarity, as markings and functional areas remain clearly visible even when wired.

Measuring just 3.9 inches long and 0.2 inch wide, the terminal block makes wiring more convenient even for compact terminals. An extensive range of accessories and various cross-connection options are available for any application.

“Our Push In connection technology is designed according to the compression spring principle, which means that the spring for the wire connection is held separately in the housing,” says Carlus Hicks, director of the cabinet products division at Weidmuller. “This design feature ensures a separation of mechanical and electrical functions, resulting in high conductor extraction forces to ensure maximum conductor connection.”

Weidmuller

Connectors and Terminals for Alarm, Security Applications

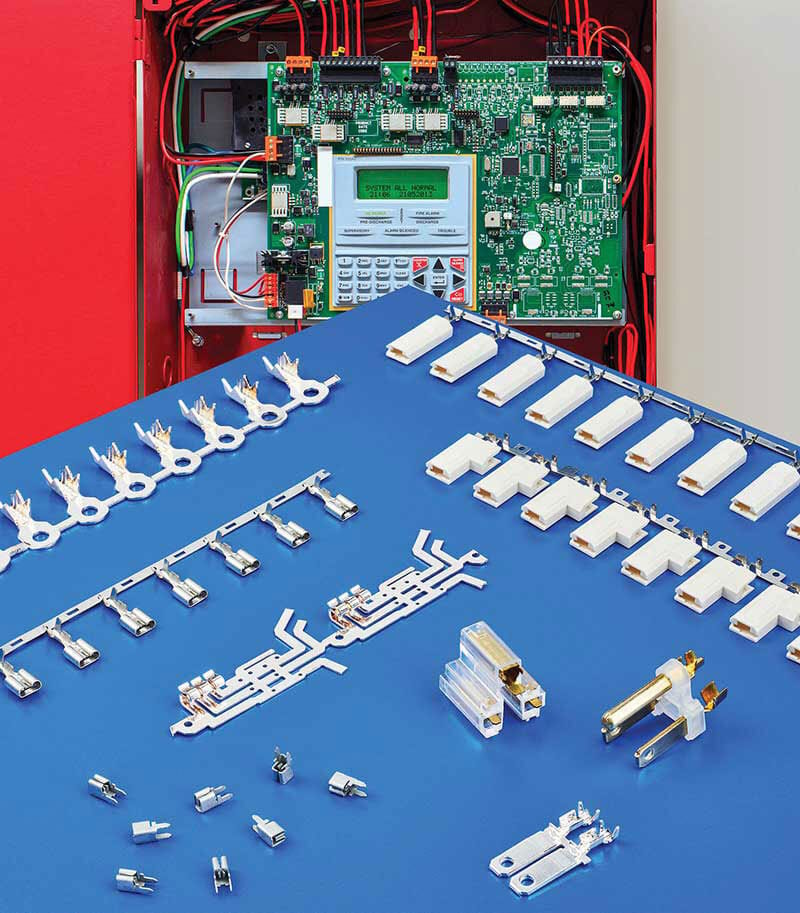

ETCO produces a wide range of electrical connectors and terminals for every requirement in an alarm and security system, including PCB and Wi-Fi components. The company’s product line includes insulated terminals that are constructed from a high-temperature alloy and provide an F-crimp connection inside fire-retardant insulators that can withstand 150 C temperatures. They are offered in straight and flag styles. Other components include circuit board terminals in numerous shapes, materials and stock thicknesses.

Designed for application by automated wire processing equipment, all ETCO connectors and terminals are offered in strip or loose form and meet ISO, IATF, UL and NEMA specifications. A wide range of standard parts are available, and custom parts can be manufactured from virtually any material in various wire and insulation sizes and stock thickness.

ETCO Inc.

Tester Measures Leakage at Low Voltage

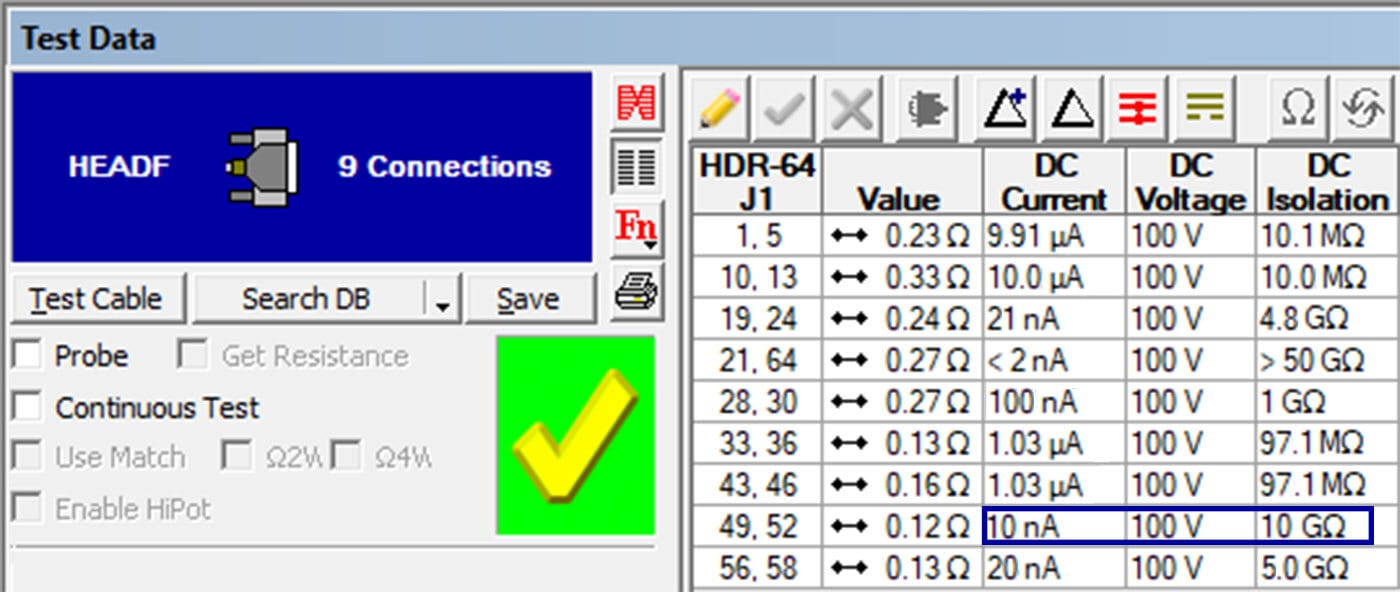

A new option for the HVX line of harness and cable testers permits leakage measurements of 10-gigaohm isolation at a test voltage of 100 VDC. This capability will be of interest to manufacturers requiring extremely high isolation resistance measurements at very low voltages. The option can be ordered with new testers or added as an upgrade to previously purchased systems.

The option comprises custom software and a hardware upgrade that allows an external measurement instrument to be used in combination with the HVX’s internal relay-switching matrix and reporting software. It uses the built-in external terminals of an HVX tester to accept stimulus signals from the external source, and that source’s USB or serial channel to control it and read measurement data.

CableEye internal software presents the acquired data in the standard report format used for all CableEye wiring reports. The customer will need to purchase a third party instrument, the Keithley Model 2410 SourceMeter, to obtain the new function.

Applications for such high isolation measurements include mission-critical devices with densely packed pins that would arc at higher voltages, potentially causing damage—for example, the testing of military or aerospace cables with nano connectors.

CAMI Research Inc.

Bulkhead Routes Cables at 90 Degrees

The bulkhead range from Icotek is being expanded to include a new product variant in two versions. With the new bulkhead, cables can be routed at 90 degrees over a very large bending radius.

The new KEL-FW B is suited for cables with plugs (maximum diameter of 35 millimeters). Rigid cables with larger diameters can also be easily inserted. Smaller cables that require a large minimum bending radius, as well as fiber optic cables, are also a typical application.

The installation is simple: The KEL-FW B is fixed using the two rear drill holes on the housing in advance and then fitted with the desired cable grommets. The cover is then folded down, locked and screwed to the housing through the two front drill holes. The cover of the new KEL-FW B bulkhead is firmly connected to the mounting housing by a hinge and is therefore unattachable. The system is easy and quick to assemble.

With its integrated seal, the bulkhead achieves protection class IP65, has a high stability and is vibration-proof. The strain relief is carried out in accordance with DIN EN 62444. Thanks to the use of polyamide as a material and a fire class of UL94-V0, the KEL-FW B is self-extinguishing. It is also silicone- and halogen-free.

Icotek

Sleeves Bundle Automotive Wire Harnesses

SuperSleeveplus 51036 PV6 and PV78 sleeves feature both a layer of cloth and a layer of fleece to bundle wires together in a car body. The sleeves enable the wires to bend and stay firmly together and protected. Adhesive tapes lack this flexibility and leave wires rigid. The sleeves also provide abrasion and temperature resistance, along with noise dampening and protection from dirt and grit kicked up from the road or from extensive disuse. SuperSleeveplus products resist temperatures of up to 300 F for 3,000 hours.

Sleeves can be applied in a fraction of the time that it takes for wires to be wrapped with tape in a spiral. Plus, under-wrapping and spot taping are removed from the process entirely. Precision is increased and inconsistencies are reduced because “lengthwise wrapping” is easier to perfect than spiral wrapping.

Tesa Tape