A special section to ASSEMBLY

Machine Cuts, Strips Wire

The E300 automatically cuts and strips wire, tubing, ribbon and multiconductor cable. It can process a variety of insulation materials, including PVC, PUR and Teflon. Standard applications include stripping of the outer jacket in several steps, as well as full and partial strips—on both ends of the wire—with conductor cross sections from 36 to 8 AWG and cable diameters from 0.3 to 8.0 millimeters. Different belt materials and a kit for processing short pieces enable the machine to handle a wide range of applications.

The contact pressure on the feeding unit is programmable. This allows for fine and targeted adjustments. The machine is equipped with a two-in-one quick-change feeding unit suitable for roller drives. The gripping axis is programmable and ensures accurate transport of the cable.

An intuitive interface facilitates the creation of jobs. Predefined and verified default parameters support quick creation of processing jobs.

Blades and guides from the previous model, the EcoStrip 9380, are compatible with the E300.

Schleuniger

Tool Installs EMI Shielding

These manual two-step banding tools are qualified to SAE AS81306/2 specifications.

The DBS-1200 is designed to install 0.25-inch M85049/128 welded buckle bands. These tools tension and cut the band leaving an extended cut off tab. The DBS-R05 roll-over tool is then used to fold the tab 180 degrees to prevent slippage. It also installs M85049/128-5 flat bands and M85049/128-6 coiled bands. The tool weighs just 1.4 pounds.

The tools apply tension ranging from 70 to 90 pounds, and they are sold with banding calibration certificate traceable to NIST standards. DMC’s The tools can be adjusted and verified to ensure correct band tension. (An optional verification gauge is available to measure the tool tension.) The cut-off blades are replaceable.

For improved ergonomics in high-volume production environments, the PBT1200 pneumatic banding tool is also available.

Daniels Manufacturing Corp.

Technology Welds Flexible Bus Bars

Flexible bus bars are used in electric vehicles for power distribution. The purpose of these connectors is to compensate for possible tolerances in the high-voltage network of the vehicle.

Depending on the desired flexibility, flexible bus bars can be produced from stacks of thin copper foils or from thin, braided copper wire. Either way, the ends are welded over large areas—up to 1,000 square millimeters.

Strunk’s new three-phase resistance welding machine can weld the foil layers or compact the strands completely in one operation. These systems are characterized by optimal current distribution over large surface areas. Direct cooling of the components using water is unnecessary. This prevents oxidation of the connectors and eliminates the time-consuming drying of the finished components.

The system produces reliable connections at high speeds. As a result, the surfaces do not tarnish, so the function and service life of the connectors are not impaired.

Semiautomatic and fully automatic systems are available. Optional downstream punching and smoothing processes can be integrated to create the required surface quality.

Strunk Connect GmbH & Co. KG

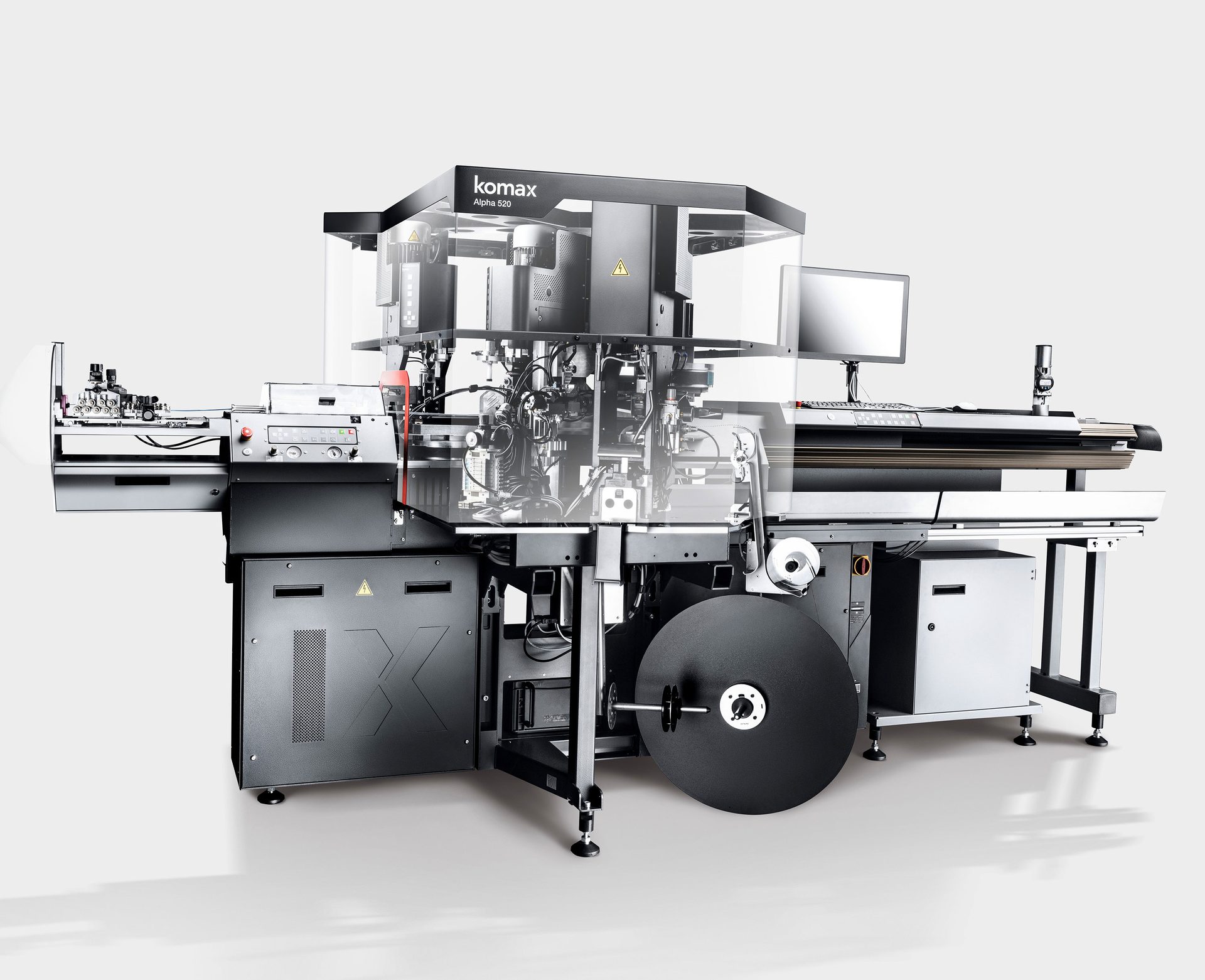

Cut, Strip and Crimp System Has Programmable Z-Axis

The Alpha 520 automatically cuts, strips and crimps wire and cable. Its fully programmable Z-axis optimizes the crimping process by automatically adjusting the vertical height of the crimping module. This reduces changeover times. The machine stores the optimal position of the crimping module for each article, which eliminates the need for manual adjustments.

For open barrel “F-style crimp” terminals, the Z-axis positions the crimping unit below the wire line, allowing the wire to swing over the crimping ears of the terminal. During the process, the wire is lowered into the terminal in conjunction with the crimping tool, ensuring accurate wrapping of the terminal ears around the conductor to form the crimp.

For closed barrel applications, the wire must be inserted into the terminal’s cavity before crimping. In this case, the Z-axis automatically raises the crimping module, ensuring the correct insertion of the wire into the terminal.

For wires less than 22 AWG, the Z-axis improves the quality of crimping by raising the crimping module and reducing the vertical movement of the wire as it is lowered into the F-style crimp. By reducing the wire movement, the crimping process is more stable.

Komax Group

Semiaumatic Benchtop Crimper

The PowerCrimper Vario is a semiautomatic benchtop crimping machine with a purely electric drive for high process flexibility and security. No foot switch required. The compact machine can crimp insulated connectors from 20 to 10 AWG or ferrules from 10 to 6 AWG. Cycle time is approximately 1 second. An LED display provides simple, intuitive and user-friendly operation. For safety, the machine will only cycle when the protective cover is closed.

Weidmuller

Software Monitors Ultrasonic Welding Process

The Telso Assist control system for ultrasonic metal and plastic welding systems enables engineers to visualize and monitor the joining process and log any deviations. Workflows are designed in such a way that they reduce familiarization time with the machine and assist with specific recommendations where necessary.

Based on the acoustic parameters, which are recorded digitally and compared with operating data as required, anomalies can be detected and rectified at an early stage.

The software enables welding process data to be exchanged quickly, securely and in line with requirements. Thanks to the cloud-based infrastructure and the use of asymmetric encryption standards, companies can be sure that their data is protected and available at all times.

Telsonic AG

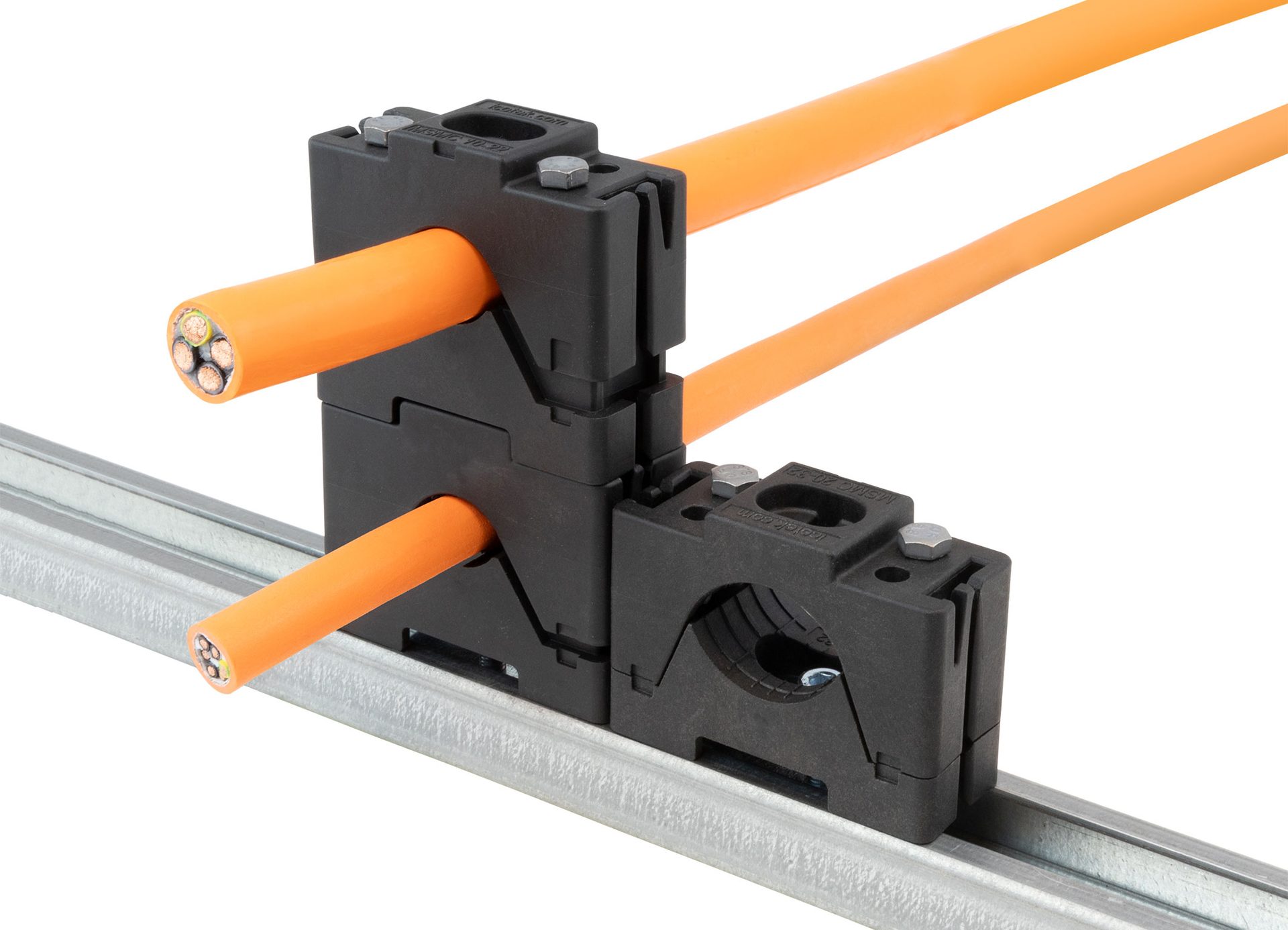

Modular Stackable Cable Clamp

The MSMC modular stackable cable clamp is a flexible fastening system for cables, pipes and cylindrical components with a diameter of 10 to 55 millimeters. Thanks to its modular design, it enables a simple and quick expansion by connecting or stacking several clamps.

The stacking or connecting principle allows several clamps to be combined. The CMC30 connector can also be used to connect clamps with different clamping areas of the same size. The clamps and the screws, made of zinc-nickel-passivated material for protection against corrosion.

Longitudinal and cross ribs on the support surface ensure high stability and reduce torsion. A slotted hole as a central tightening point enables flexible fastening options on different surfaces.

The clamp consists of an upper and lower part, as well as hexagon screws. The connector allows several clamps to be connected in a row. To increase stability and torsion resistance, two long screws can be used for fastening.

Icotek