Material Handling

What's New

With Conveyors

John Sprovieri // Chief Editor // sprovierij@bnpmedia.com

Conveyors remain essential for getting parts to the right spot at the right time. Here’s a look at the state of the art.

Transportation—moving parts or assemblies from place to place in a factory—is one of the seven wastes specified in the principles of lean manufacturing. Transportation does not add value.

That does not obviate the need for conveyors, however. These machines remain essential for getting the right parts to the right spot at the right time. Indeed, according to our annual Capital Equipment Spending Survey, one-third of U.S. assembly plants will purchase conveyors this year, marking the fourth straight year in which that percentage has exceeded 30 percent. All totaled, assemblers will spend $97 million on conveyors and material handling equipment in 2021, only slightly less than the $100 million they spent on the technology last year.

Here’s a look at the latest offerings.

Modular Pallet-Transfer Conveyor

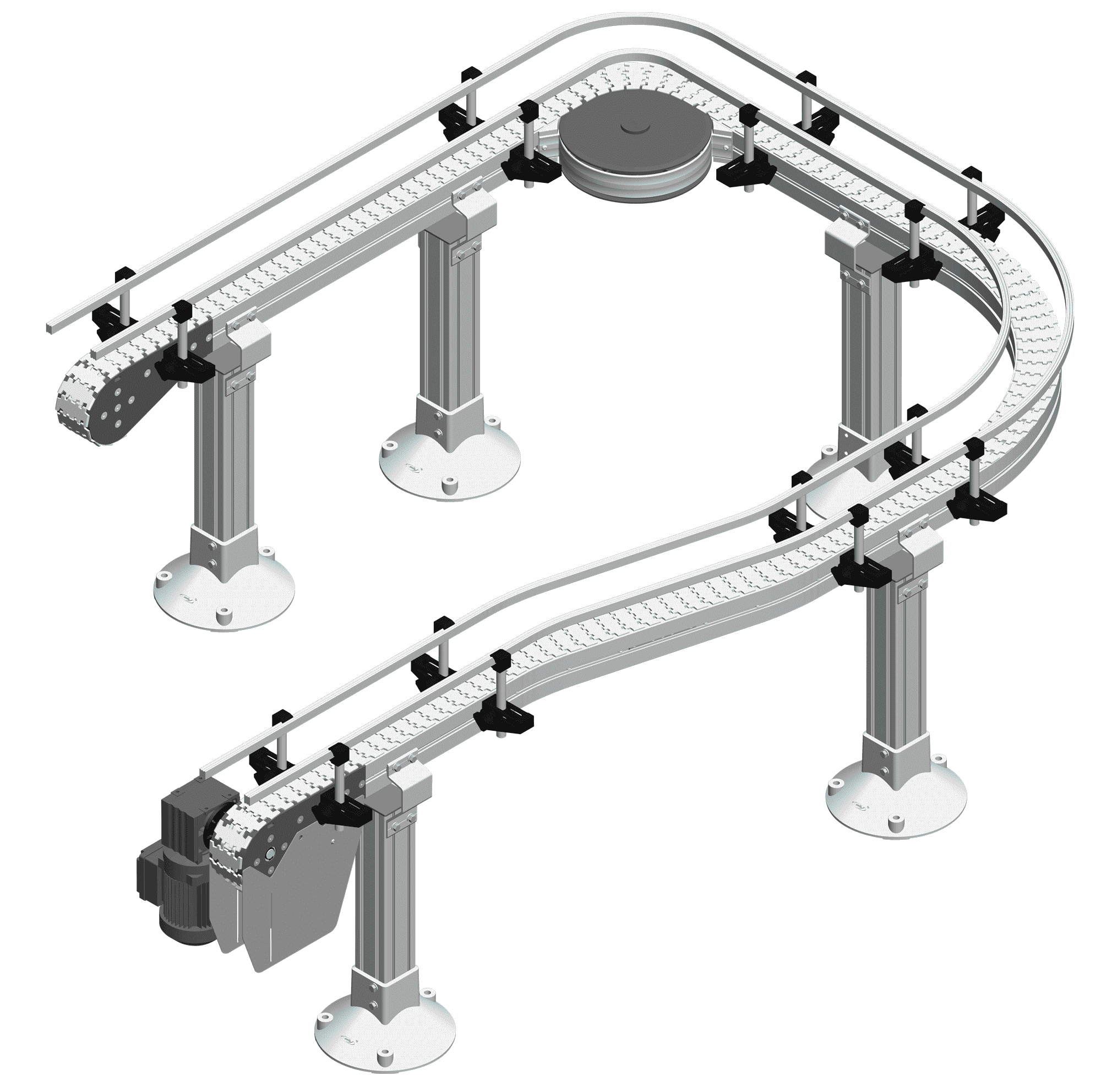

The TS 2plus pallet-transfer conveyor is available with three conveying media (belt, flat-top chain or roller chain), 26 pallet sizes, and a range of positioning and transfer modules.

All components of the TS 2plus system are pre-engineered and modular, so engineers can mix belt, flat-top chain or roller chain and accessory modules as needs require. The system can be easily expanded, reconfigured or relocated as needs change. Assemblers can phase in their investment as time and budget permit. Start with a simple conveyor for basic assembly and grow into a fully automated, progressive assembly system. As production requirements change, TS 2plus provides the flexibility to add manual or automatic workstations.

The conveyor transports parts on pallets, which range in size from 160 by 160 millimeters to 1,040 by 1,040 millimeters.

Pallets can be positioned at workstations with an accuracy of ± 0.05 millimeter when used with a Rexroth lift-position unit. Pallets can be tooled with fixtures to secure parts for manual or automated operations. Identification and data-carrying devices can be mounted to pallets to coordinate assembly sequences, identify model types, and store production data.

Pallets can be stopped on the leading or trailing edge, regardless of pallet orientation on the conveyor. Pallets can also be accumulated in queue and released one at a time. Exciter plates on the pallet bottom and sides work with conveyor-mounted proximity switches to detect presence of a pallet at a station. Pallet orientation and routing can be controlled using Rexroth ID/10, ID/15 or ID/40 identification systems.

The TS 2plus also provides an abundance of components for curves, transverse conveyors, positioning units and drive units.

The conveyor is designed to carry loads of up to 240 kilograms.

For more information, click www.boschrexroth-us.com.

This hybrid conveyor system combines a traditional TS 2plus pallet-transfer conveyor with a high-speed section powered by linear motors for payloads up to 40 kilograms. The TS 2 Booster features a maximum speed of 180 meters per minute, a maximum acceleration of 3g, and positioning accuracy up to up to ±10 microns.

Photo courtesy Bosch Rexroth

Modular Transfer System

Engineers can use the modular Linear Transfer System from Afag Automation to create a variety of rectilinear assembly line layouts.

Photo courtesy Afag Automation

Engineers can use the modular Linear Transfer System from Afag Automation to create a variety of rectilinear assembly line layouts. Manual or automated workstations can be located along both longitudinal and transverse tracks. Processes can even be completed from below the workpiece.

Modular transport tracks are available in five widths and three belt speeds. Maximum track length is 6 meters. Pallets come in widths of 160, 200, 250, 320 and 400 millimeters. Support plates can be made from steel or aluminum. Maximum weight per pallet is 20 kilograms.

To accommodate product variants, manual tasks or automated operations with longer cycle times, pallets can be transferred from the main assembly line to parallel tracks or cycle-independent workstations. Pallets can be moved from one line to another by lift-and-transfer or lift-and-turn mechanisms. Fixed deflection units are also available for 90- and 180-degree turns without changing the orientation of the pallet.

For more information, click www.afag.com/en.

Chain Conveyor for Small, Light Products

The X45 conveyor is a compact plastic-chain conveyor for handling small, lightweight products from 10 to 100 millimeters wide.

Photo courtesy FlexLink Systems Inc.

The X45 conveyor from FlexLink Systems Inc. is a compact plastic-chain conveyor for handling small, lightweight products from 10 to 100 millimeters wide. Typical products transported directly on the conveyor are pharmaceutical bottles, perfume bottles and small packages. The conveyor can also transport pucks for handling small assemblies, such as batteries.

The flexible plastic chain, 43 millimeters wide, permits horizontal and vertical transport of products, as well as multiple bends. On the horizontal plain, the chain can bend 30 to 180 degrees. The chain is available in five versions: plain, conductive, friction top, conductive friction top, and cleat.

Support beams can be made from aluminum or stainless steel. The beams are designed for rigidity, smooth running and low noise. T-slots ensure easy but rigid attachment of accessories, such as guide rail brackets.

Divert and merge devices are used to route products by dividing or combining product flows. Lines typically consist of a main conveyor, or “highway” (Model X45H), and separate subordinate conveyors, or “satellites” (Model X45C). On the satellites, products can be subjected to various operations, such as turning, grinding, assembly or testing, without disturbing the main flow. After the operations, the products return to the highway.

Model X45C is available with a maximum length of 6 meters and can carry a maximum total weight of 30 kilograms. Conveyor speed can be varied from 5 to 20 meters per minute. Model X45H is available with a maximum length of 25 meters and can carry a maximum total weight of 125 kilograms. Conveyor speed is fixed, ranging from 5 to 60 meters per minute.

RFID is available for controlling puck handling functions.

For more information, click www.flexlink.com.

Conveyor Tops Mobile Robot

Autonomous mobile robots can be topped with a short section of conveyor to transfer pallets from one assembly line to another.

Photo courtesy Glide-Line LLC

Autonomous mobile robots (AMRs) are increasingly being used to deliver parts throughout an assembly plant. Now, engineers can top AMRs with a short section of conveyor to transfer pallets from one assembly line to another.

Conveyor toppers from Glide-Line LLC are built from lightweight aluminum extrusions to maximize the robot’s payload and extend battery life. The strength and performance of the conveyor belt is enhanced with the use of T5 teeth around the drive pulley. Compact, lightweight DC motors drive the conveyor without overtaxing the battery. Less than 3 inches tall, the conveyor can handle loads up to 200 pounds.

Conveyor toppers can be customized to suit any application. For example, conveyor toppers can designed to lift, rotate or tilt the payload. If there’s a gap between the AMR conveyor and the destination conveyor, the gap can be closed by creating an overlap between strands. If the AMR is serving a robotic pick station, the topper can be designed with a gap to accommodate gripper tooling.

For more information, click www.glide-line.com.

Pallet Stop Prevents Bounce Back

The DRE anti-bounce stop prevents the rebound of a pallet from the stopping position, especially in combination with undamped stoppers. This ensures that the pallet stops immediately at the desired position.

Photo courtesy Woerner GmbH

The DRE anti-bounce stop from Woerner GmbH is an accessory for pallet-transfer conveyors with a low coefficient of friction. It prevents the rebound of a pallet from the stopping position, especially in combination with undamped stoppers. This ensures that the pallet stops immediately at the desired position.

As a second function, the DRE can be lowered electrically to allow the pallet to move backwards during reverse operation. In addition, the DRE can be used as an undamped stopper for lightweight applications, enabling the pallet to move backwards in reverse mode without further control.

The DRE can be equipped with sensors to detect open and closed positions of the stop plate, regardless of the position of the lowering system.

For more information, click www.woerner-gmbh.com.

Flexible Plastic Chain Conveyor

QC Conveyors is now the exclusive North American distributor for Modu flexible conveyors from Malaysian supplier Modu Systems.

Photo courtesy QC Conveyors

QC Conveyors is now the exclusive North American distributor for Modu flexible conveyors from Malaysian supplier Modu Systems. These modular conveyors feature plastic chain belts, enabling them to move product around curves and up or down to differing elevations. The conveyors are available with an aluminum or stainless steel frame. In addition to curves, inclines and declines, the conveyors can be configured for alpines and gripper elevators.

Modu products will be stocked at QC Conveyors’ facility in Cincinnati, where conveyor systems will be designed, assembled and tested before shipment. For integrators, machine builders and those who prefer to assemble their own systems, conveyor components will also be available.

For more information, click www.qcconveyors.com.

Motorized Carts Move Assemblies

With the eCart transfer system, assemblies are moved from station to station on self-driven intelligent carts riding on a passive track.

Photo courtesy Logomat Automation Systems Inc.

Most conveyors transfer unpowered pallets from station to station with belts, chains or rollers driven by a central electric motor.

The new eCart transfer system from Logomat Automation Systems Inc. reverses that concept: Assemblies are moved from station to station on self-driven intelligent carts riding on a passive track. The cart actively brakes and powers off its drive motor if an e-stop is activated, if the cart’s front or rear bumper is actuated, if intelligent tooling on the cart sends a stop signal, or if excess speed is detected.

The power-off-functionality can be tailored to specific sections of the line thanks to predetermined splice points in the power rail. The cart’s active braking system can also be enabled via optional additional devices, such as manual stop buttons on the cart’s tooling or a laser scanner located above the line.

Carts queue up without contact. An approaching cart won’t bump into a stopped cart in front of it. If the cart’s tooling extends beyond the length of the cart, a bumper can be mounted onto the tooling. All bumpers initiate the cart’s active braking with minimal stopping distance. Contact-free accumulation avoids a buildup of impact forces.

The track has no moving parts, so there are no pinch or shear points. The power rail is securely tucked underneath and protected by the conveyor track. The carts are powered by a harmlessly low DC voltage. Each cart also provides 48 VDC to power smart tooling, even when the system is in motion. The track is 220 millimeters tall, so workers can step over it when necessary.

Carts come in three sizes. The eCart 600 measures 900 long by 600 millimeters wide and can carry 1,300 pounds. The eCart 700 measures 1,000 by 700 millimeters and can carry 3,000 pounds. And, the eCart 900 measures 1,200 by 900 millimeters and can carry 4,400 pounds. For oversized parts, the overall cart length can be adjusted with extended front and rear bumper assemblies.

Cart speed ranges from 2 to 24 meters per minute, though speed limitations based on the weight and size of the assembly may be required for safety.

Electrical stop units are used for touchless stopping and accumulating. When a cart approaches a stop unit or another cart, it gently decelerates and stops without any impact. Because there is no pressure buildup when accumulating carts, a single stop unit can be used to hold an unlimited number of carts. If a more precise location is required at specific stop points, the carts can be indexed from below with a locating pin.

In case of a failure, the affected cart can easily be pushed forward manually or removed from the track. The functionality of the conveyor track and the other carts on the line remains unaffected. Via self-diagnostics, each cart can proactively detect when maintenance is required and automatically direct itself to a designated maintenance area on the line.

Options include a lift gate; a turntable to rotate carts; a shuttle to move carts from one section of track to another; and a docking cart to add or remove carts from the line.

For more information, click www.logomat-online.com.

Conveyor With Electric Stops

The stoppers, transfer units and centering devices of the 300e conveyor are controlled via electric drives rather than pneumatics.

Photo courtesy STEIN Automation

STEIN Automation has introduced a variant of its STEIN 300 pallet-transfer conveyor, the STEIN 300e. Instead of pneumatics, the conveyor’s stoppers, transfer units and centering devices are controlled via electric drives. This makes the conveyor more energy-efficient and enables the machine to be used in ISO 6 and 7 clean rooms. Electric drives also enable engineers to query the status of stoppers, centering devices and other mechanisms.

With Softmove control software, the conveyor gently moves pallets from station to station. Pallets do not collide with each other, even in high-speed, high-volume operations. This reduces wear, dirt and operating noise.

When equipped with electronically commutated motors, the conveyor lets engineers switch off motors as soon as they are not needed. This saves energy, decreases wear and reduces noise.

Pallets can be equipped with RFID chips to transmit the identity of the workpiece to each assembly station and track the progress of production. The conveyor’s control software can interface with factory ERP systems to guide individual pallets through the assembly line, enabling high-mix production.

Options include display screens; lift and turn units; a folding gate section to enable personnel to access the interior of a line; and height adjustable manual workstations.

For more information, click www.stein-automation.de.

Roller Conveyor Features Zone Control

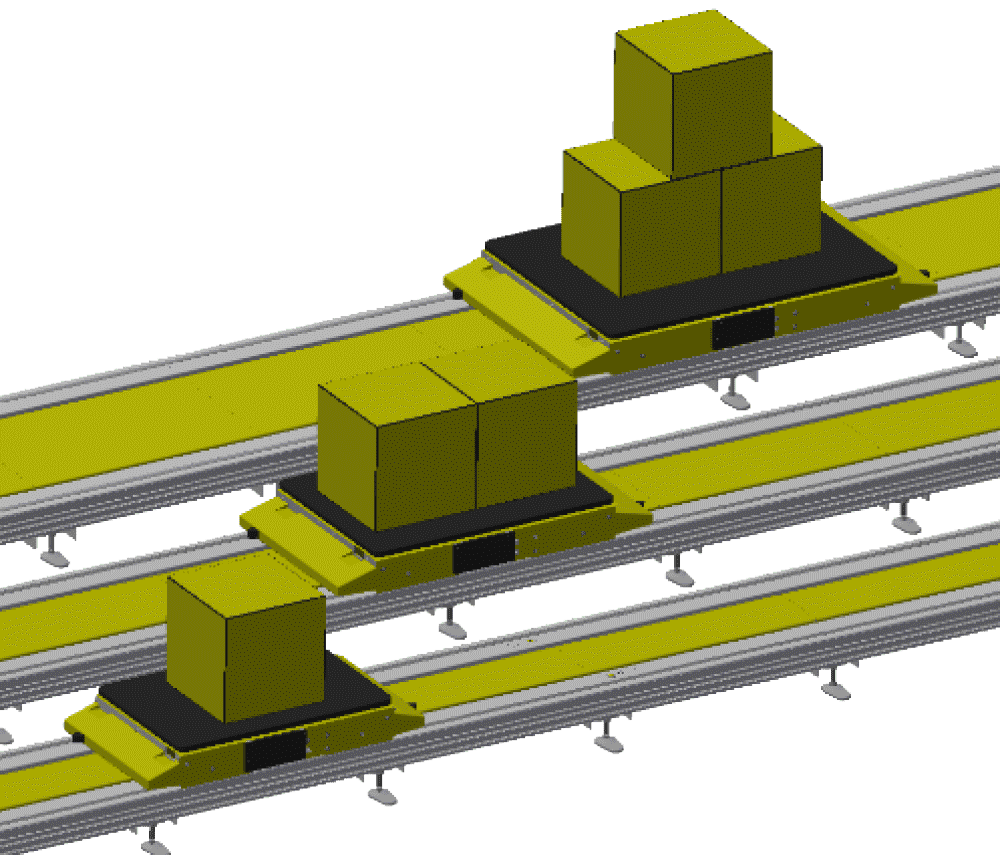

The Powered Zone Roller conveyor is arranged in a series of zones. Each zone is driven by a bidirectional motor. Parts are driven out of a zone only when the next zone is vacant.

Photo courtesy Automation & Modular Components

The Powered Zone Roller (PZR) modular conveyor from Automation & Modular Components allows parts to accumulate without contacting one another. The conveyor is arranged in a series of zones. Each zone is driven by a bidirectional motor. Parts are driven out of a zone only when the next zone is vacant, so parts can accumulate without the need for pallets. And, since the conveyor runs only when a part or pallet is present, the system is energy efficient.

The conveyor comes in standard lengths, allowing a floor layout to be assembled more quickly. Engineers can place modules into layouts without lengthening and shortening every unit. To simplify integration, the conveyor’s tread and drive concepts are duplicated by other members of the PZR family, such as turntables, shuttles, rail-guided vehicles. It’s also possible for two conveyor lines to merge.

For more information, click www.amcautomation.com.

ASSEMBLY ONLINE

For more information on assembly conveyors, visit www.assemblymag.com to read these articles:

Animation courtesy selamiozalp, Creatas Video

Scroll to

read full story