A special section to ASSEMBLY

Assembling a Wire Harness for Deep Space

NASA’s Europa Clipper spacecraft poses unique challenges for wire harness design.

NASA’s Europa Clipper will conduct 44 flybys of Europa, Jupiter’s fourth largest moon, beginning in April 2030. Photo courtesy NASA

John Sprovieri // Chief Editor

What is the origin of life on Earth? Is there life on other planets?

These age-old questions may finally be answered when NASA’s Europa Clipper conducts 44 flybys of Europa, Jupiter’s fourth largest moon, beginning in April 2030. The spacecraft will perform a detailed reconnaissance of Europa and investigate whether the icy moon could harbor conditions suitable for life.

Slightly smaller than Earth’s Moon, Europa is primarily made of silicate rock. It has a water-ice crust and probably an iron-nickel core. It has a very thin atmosphere, composed primarily of oxygen. Its surface is striated by cracks and streaks, but craters are relatively few.

Europa has the smoothest surface of any solid object in the Solar System. The apparent youth and smoothness of the surface have led to the hypothesis that a water ocean exists beneath the surface, which could conceivably harbor extraterrestrial life.

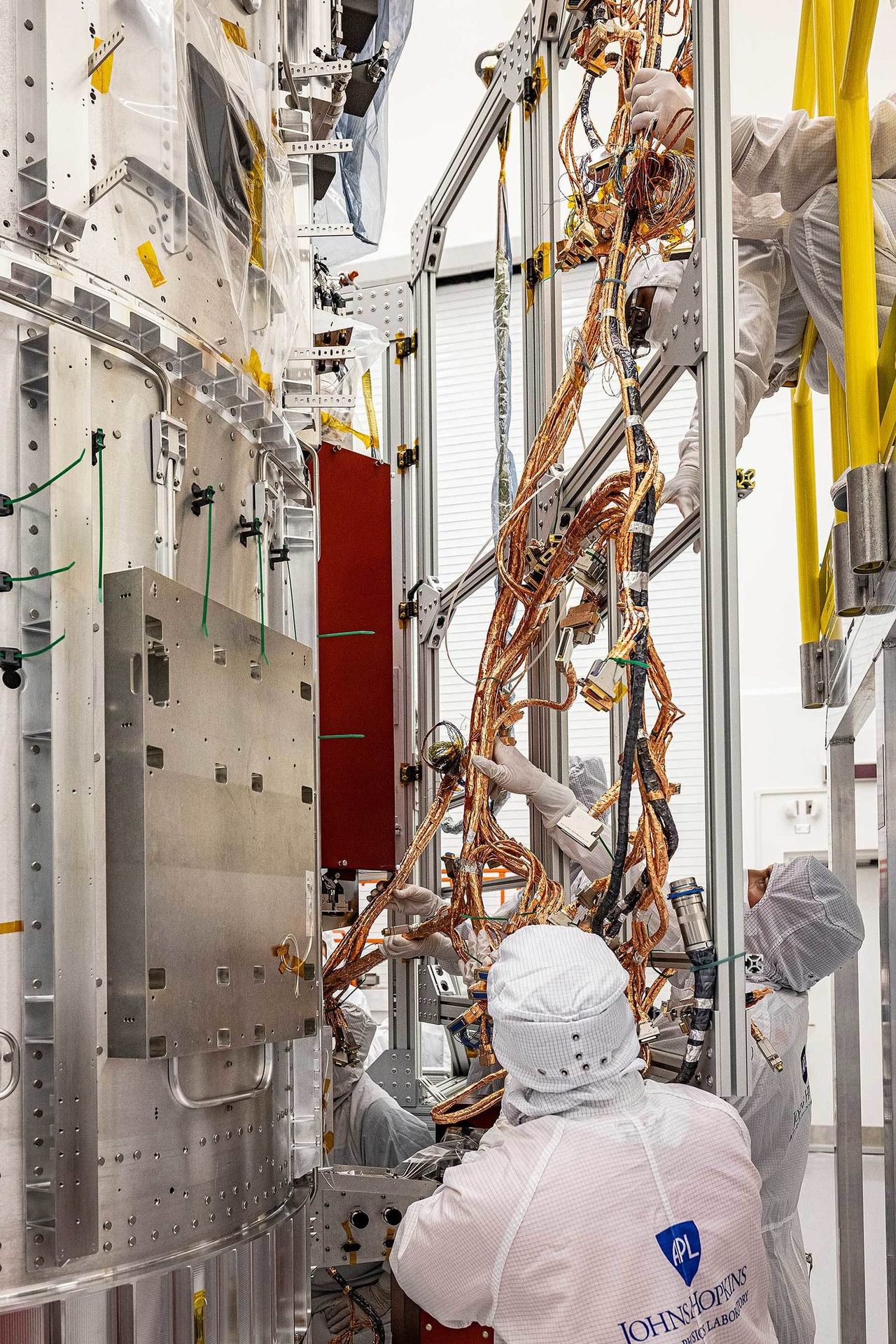

The Europa Clipper’s wire harness consists of some 2,600 conductors and weighs 150 pounds.Photo courtesy NASA

The Europa Clipper’s mission is to find out if that’s the case. The Johns Hopkins Applied Physics Laboratory (APL) in Laurel, MD, designed Europa Clipper’s body in collaboration with NASA’s Jet Propulsion Laboratory (JPL) in Pasadena, CA, and Goddard Space Flight Center in Greenbelt, MD.

Standing 10 feet tall and 5 feet wide, the spacecraft is an aluminum cylinder packed with electronics, radios, thermal loop tubing, cabling and the propulsion system. With its solar arrays and other deployable equipment stowed for launch, Europa Clipper will be as large as an SUV; when extended, the solar arrays make the craft the size of a basketball court. It is the largest NASA spacecraft ever developed for a planetary mission.

Set to launch in October 2024, the Europa Clipper is equipped with nine instruments to study Europa’s interior and ocean, geology, chemistry and habitability. The instruments will be protected from radiation by a 150-kilogram titanium and aluminum shield. The instruments are:

A thermal emission imaging system to detect geologically active areas, such as vents erupting plumes of water into space.

A mapping imaging spectrometer, a near-infrared spectrometer to analyze the surface, identifying and mapping the distributions of organics, salts, acid hydrates, water ice phases, and other materials.

A visible spectrum camera that will map most of Europa at a 50-meter resolution. The camera will also provide images of selected surface areas at a resolution of up to 0.5 meter.

An ultraviolet spectrograph to detect small plumes and measure the composition and dynamics of the moon’s exosphere.

A dual-frequency, ice-penetrating radar to characterize and sound Europa’s ice crust from the near-surface to the ocean, revealing the hidden structure of Europa’s ice shell and potential water pockets within.

A magnetometer.

An instrument for measuring the plasma surrounding Europa to characterize the magnetic fields generated by plasma currents. In conjunction with the magnetometer, this instrument will measure Europa’s ice shell thickness, ocean depth and salinity.

A mass spectrometer to determine the composition of the surface and subsurface ocean by measuring Europa’s atmosphere and any surface materials ejected into space.

A surface dust analyzer, a mass spectrometer to measure the composition of small solid particles ejected from Europa. The instrument can identify traces of organic and inorganic compounds in the ice of ejecta.

Wiring Up a Spacecraft

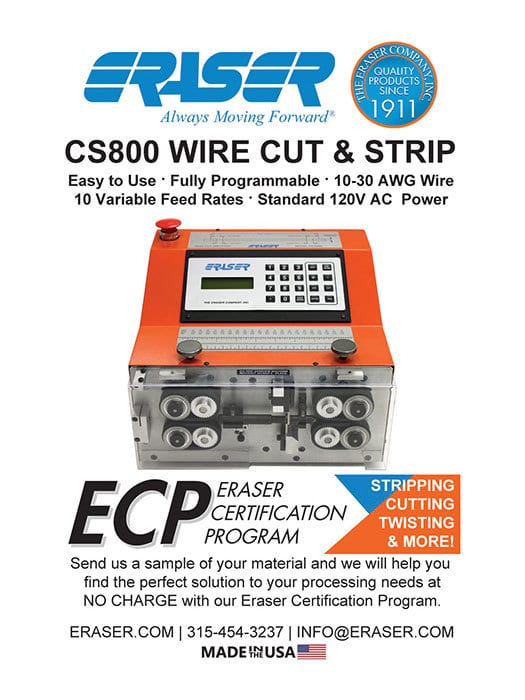

To assemble the harness, APL built a full-scale fixture that matched the curved surfaces of the spacecraft’s body. The harness could not be built on a traditional form board, because it would be wrapped in copper foil. Photo courtesy NASA

ASSEMBLY: What is the range of experience of your harness assemblers, in terms of years? How much training do assemblers receive, and how often?

Cole: Nearly 80 percent of our work force has 4 to10 years of experience. We are fortunate to have several employees with 15 to 20 years of assembly experience who are sprinkled between each of the different departments. Eight workers recently celebrated their one-year anniversary. Because we are an ISO 9001:2015 certified company, training and its documentation are an important part of our continuous improvement processes. Our assemblers receive several levels of training, including OHSA, company policy, MRP software, and workmanship standards. Once an employee is hired, they receive a mix of on-the-job and classroom training. Before a new employee is able to build a harness solo, he or she is trained according to the IPC/WHMA-A-620 Standard. In addition, training is refreshed on an as-needed and yearly basis, and supported by supervisors, and the quality and engineering departments. We also plan to develop and implement a mentorship program as an improvement goal for 2022. This will encourage a sense of belonging and knowledge sharing between new hires and experienced employees. Plus, each year we take advantage of state-sponsored incumbent training and technical-credential training programs offered by third parties.

ASSEMBLY: Do you have a low-volume, high-mix work environment, or a low-mix, high-volume one? And how do you handle that approach?

Cole: Our customer base is interesting. New customers typically require high-mix, low-volume products, while our repeat business emphasizes high-volume, low-mix. We effectively manage this mix by dedicating personnel and tooling to particular workcells. Also, our cross-training program allows us to rotate teammates in and out of cells, depending on what’s on the floor. For a high-volume application, for example, the team has a dedicated press to promote a one-piece flow process.

The main body of the Europa Clipper has been completed and was delivered to JPL in June. Over the next two years, engineers and technicians will finish assembling the spacecraft before testing it to make sure it can withstand the journey to Europa.

The main structure consists of two stacked aluminum cylinders dotted with threaded holes for bolting on the spacecraft’s cargo: the radio frequency module, radiation monitors, propulsion electronics, power converters, and wiring. The radio frequency subsystem will power eight antennas, including an enormous high-gain antenna that measures 10 feet wide.

The heavy-duty electronics vault, built to withstand the intense radiation of the Jupiter system, will be integrated with the main spacecraft structure along with the scientific instruments.

Inside the main body of the spacecraft are two tanks—one for fuel, one for oxidizer—and the tubing that will carry their contents to an array of 24 engines.

Connecting all the instruments, solar panels, communications gear and propulsion system requires a lot of wiring. In fact, the spacecraft’s wire harness consists of some 2,600 conductors and weighs 150 pounds. If stretched out, it would run almost 2,100 feet—more than twice the perimeter of a football field, says Jacklyn Perry, section supervisor for harness development at APL’s Space Exploration Sector.

Designing a wire harness for an interplanetary spacecraft is more challenging than designing a harness for a car or even an airplane.

In a clean room at APL, Europa Clipper’s propulsion module harness is transferred from the fixture to the spacecraft. Photo courtesy NASA

For starters, there’s the problem of radiation. Europa is in the thick of Jupiter’s radiation belts, says Perry, who served as lead engineer for Clipper’s propulsion module harness. With each orbit, the spacecraft will be exposed to more and more radiation. To put its exposure in perspective, a spinal X-ray generates a radiation dose of less than 0.2 rad. The Clipper’s wire harness will be exposed to 20 million rads.

Charged particles are another problem. “Charged particles build up in insulators, and a wire harness is 85 percent insulation,” explains Perry, who also helped design the harnesses for NASA’s Parker Solar Probe, which is currently orbiting the Sun, and for the forthcoming Dragonfly mission, which plans to land a rotorcraft on Saturn’s moon Titan in 2034. “Those particles will build up until, eventually, there’s a discharge. In the best-case scenario, the particles will discharge to ground. In the worst case, they will discharge into your wiring and blow out your electronics.

“A lot of shielding is needed to prevent that from happening. However, the materials that [resist radiation] are terrible in a charged environment, and the materials that won’t build up a charge will just crumble in [high-dose radiation]. We were between a rock and a hard place.”

Ultimately, engineers opted to wrap the wiring in copper tape and, in spots, even lead. “That didn’t help with our total mass, but what can you do?” says Perry.

On the plus side, however, the copper wrap will also prevent potential electromagnetic interference between the spacecraft’s power lines and telemetry lines.

Temperature extremes also had to be planned for. The Clipper would be exposed to temperatures ranging from -235 to 100 C. “That’s a big range to design for,” she says. “A lot of materials aren’t rated for those extremes, so we did a lot of cryogenic testing.”

Like all spacecraft, the Clipper will need to endure considerable vibration during launch. “Thankfully, a lot of materials had already been qualified from previous missions,” says Perry. “However, if we didn’t have that data, we had to do a lot of testing to make sure it will survive launch.”

While the finished spacecraft will go through acoustics and vibration testing prior to launch, APL engineers opted to do their own vibration testing just on the harness.

Similarly, shock is another factor that engineers needed to account for. To separate the spacecraft from the rocket will require an explosive charge. “At separation, the harness will see a shock load of 6,300 g at 10,000 hertz. That’s one heck of a slam,” notes Perry. “We tested all our connector interfaces to make sure they wouldn’t just fall apart. We also tested our tie-downs.”

Keeping it Clean

A plasma instrument sensor assembly is loaded into thermal vacuum chamber for testing at APL. The large number of wires that are visible demonstrate the intricate setup for the test. Photo courtesy NASA

One more challenge is contamination control. Since the spacecraft will be equipped with various imaging equipment, engineers had to prevent outgassing from adhesives, plastics and lubricants. “We baked all of our wiring before assembly, because once you put all those wraps on the wiring, it will take forever for the molecules to leak out,” explains Perry. “After assembly, we baked the finished harness, as well, since we added adhesive and other materials.”

Engineers also needed to prevent biologic contamination. An international treaty dating back to the early days of space exploration prohibits countries from introducing microbes from Earth onto other worlds that might harbor life. During assembly, engineers regularly tested the harness for biologic contamination. In addition, the finished harness was baked at 116 C for 25 hours. Once the harness was sterile, technicians from then on were required to wear clean room garb to work on it.

“We were masking before it was cool!” Perry quips.

A technician adjusts electrical connections on the Europa Clipper’s mass spectrometer.Photo courtesy NASA

Worlds Apart

Nearly 10 feet wide, the Europa Clipper’s high-gain antenna will send scientific data to Earth and allow ground controllers to send commands to the spacecraft.Photo courtesy NASA

One challenge of designing and assembling the Clipper’s wire harness had nothing to do with extreme radiation, cold or magnetic fields. It was geographic. With APL on the East Coast, JPL on the West Coast—and the solar panels being designed and built by Airbus in The Netherlands—conferring with colleagues wasn’t always easy. When it’s 8 a.m. on the East Coast, it’s 5 a.m. on the West Coast and 2 p.m. in the Netherlands.

“Until this project, I didn’t appreciate how much of the words that we used were jargon specific to APL,” admits Perry. “If I used a word to describe a specific part or process, it was not necessarily the same word our partners used, so we spent a couple of months stumbling over what we meant vs. what they meant.”

A relatively new technology—augmented reality—was instrumental in solving design problems. “For example, we were trying to solve a harnessing issue with one of our instruments. There were some tricky bend radius restrictions and handling constraints we needed to figure out. With augmented reality, we could have a conversation about it without having to fly anybody anywhere,” says Perry.

To assemble the harness, APL built a full-scale fixture that matched the curved surfaces of the spacecraft’s body. “We could not build the harness on a form board, because it would be wrapped,” Perry explains. “If we wrapped it flat and then tried to mount it in this curved configuration on the spacecraft, it would not have worked. We needed to wrap the harness in the shape it would be on the spacecraft.”

Augmented reality also helped with assembly. Technicians could use smart phones or tablets during assembly to superimpose images of the CAD model against the assembly in situ. They could toggle on or off different harnesses or bundles whenever a question came up.

“Our technicians loved it, and we’re going to use it for subsequent missions,” says Perry.

After baking, the fixture was mounted to a custom-built cart, which was wheeled into place and elevated into position next to the spacecraft. “The fixture gave the spacecraft an ‘air hug,’” she explains. “Then, we carefully transferred it from the fixture to the spacecraft. We stopped a lot to talk about who is doing what and when. There was a lot of coordination. Everyone had assigned roles. We had tie-downs preinstalled to receive the harness.”

ASSEMBLY ONLINE

For more information on spacecraft assembly, visit www.assemblymag.com to read these articles: