A special section to ASSEMBLY

Portable Benchtop Stripper

The Strip Series B300 quickly and reliably strips with cross-sections from 0.03 to 8 square millimeters. Repeat accuracy, mechanical precision, and short process cycles ensure high productivity in common stripping applications. This portable, ergonomic machine features a 5-inch color touch-screen interface for easy programming. Process parameters stored in the software allow out-of-the-box use for the common functions of stripping with full and partial pull-off and recutting. More complex applications, the storing of specific setups, or a customer-specific process parameterization can be achieved with an optional software upgrade.

The machine continually checks the axes for the nominal and actual values, which eliminates the need for referencing, increases quality, and saves time. The machine starts the strip as soon as the cable end touches the highly sensitive trigger sensor. A large, easy-to-empty waste container allows many work cycles without interruptions.

See this product at The ASSEMBLY Show, booth 419.

Schleuniger Inc.

Low-Voltage Harness Tester

The 8100 low-voltage harness tester is driven by Easy-Wire software, which provides maximum flexibility. The software provides efficient test setup and retrieval, operator access based on login, flexible test operation and reporting, and a test record archive. The system allows operators to view connector images with target pin locations during the assembly process or rework. All tests programmed for the company’s original CR tester are transferable to the 8100 and most 8100 tests can be used on the CR.

The device has a robust design to meet the rigors of the production environment. Bumpers protect casework and interface connectors. Test points are designed to maximize static protection.

Its compact size means it is nonintrusive at the workstation. It can be mounted on the back of a harness board, or it can be distributed with other 8100 units around the device to be tested. It is compatible with traditional interfacing as well as Cirris’ Smart-Lights.

The device offers up to 256 test points per base or expansion unit. It is expandable up to 100,000 test points. Expansion units can be distributed up to 200 inches from the base. The base units can be used separately or together to make a larger test point system.

Power for the base unit can be sourced from a PC USB connection, allowing for mobility using laptop battery power if needed.

See this product at The ASSEMBLY Show, booth 419.

Cirris Inc.

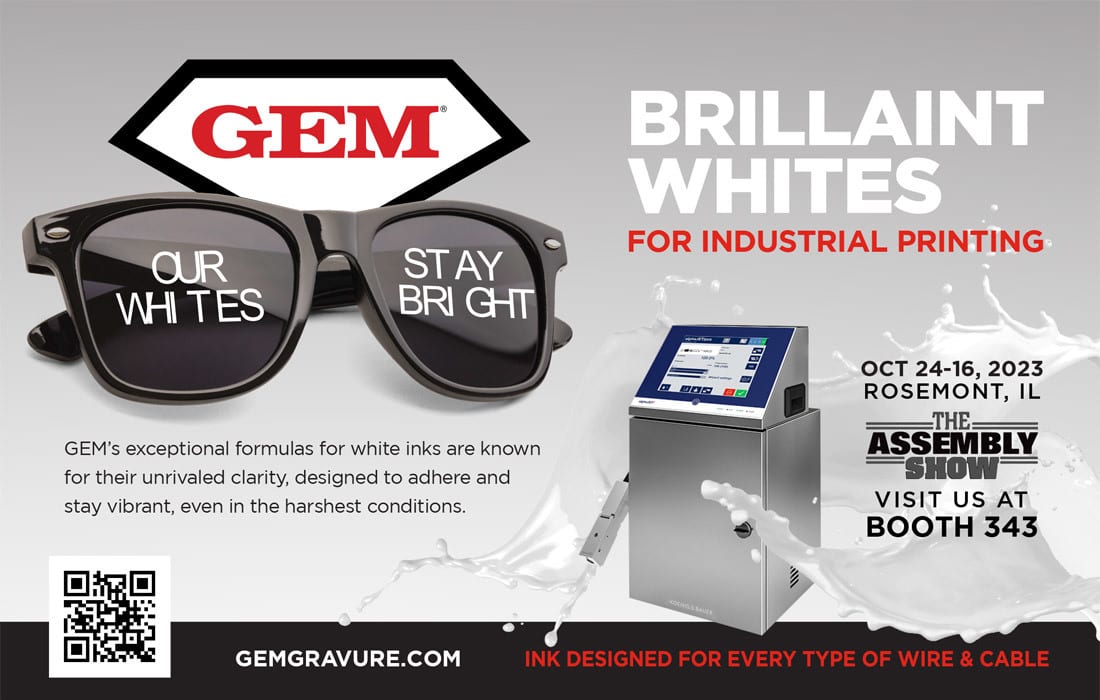

Continuous Inkjet Printer

The alphaJET 5 continuous inkjet printer applies alphanumeric text, 1D codes and 2D codes to wire, cable, hose and other products at high speeds. The Re-Solve Ultra solvent recovery system saves money and reduces waste. Smart Start technology optimizes nozzle closure, nozzle flushing and head heating, so if the printer is in stand-by mode for a long period of time, intermediate startup or intensive cleaning processes are not necessary before restarting. The printer accommodates a range of inks, including high-contrast, food-grade and highly adherent formulas.

The user-friendly color touch-screen display can be easily adapted to many languages. The printer has a variety of interfaces for connecting to other devices for automated production and inspection of printed parts. The pump motor is rated for 20,000 hours, the equivalent of approximately 11 years in a single-shift operation.

See this product at The ASSEMBLY Show, booth 343.

GEM Gravure

Device Automates Cable Tie Installation

The PAT 4.0 automatic cable tie installation system enables assemblers to install cable ties six times faster than a purely manual process. A user-friendly icon-based LCD touch screen simplifies user navigation and provides intuitive help screens to improve troubleshooting and minimize the learning curve for operators. The lightweight ergonomic tool head reduces operator fatigue and maximizes maneuverability while minimizing the risk of repetitive motion injury.

The system can be configured for factory network communication, industrial control applications, and robotics integration through a DI-RJ45 Ethernet connection, which provides production

data for analysis and troubleshooting, and an EI-25 pin D-Sub connection, which allows engineers to remotely control the system through industrial controls and robotic applications.

The maximum bundle diameter that can be tied ranges from 0.82 to 2.75 inches. Ties are available in three tensile strengths. Continuously molded cable ties are supplied on quick-change reels containing up to 5,000 ties.

Panduit Corp.

Open-Frame Crimp Tool

Qualified to AS22520/5, the HX4 open-frame crimp tool accepts a system of interchangeable dies that eliminate the need for separate fixed-die tools for each application. This eliminates the cost associated with maintaining and calibrating inventories of single-purpose tools.

A variety of military and proprietary dies are available for this tool. Crimping dies are snapped into the tool frame and retained in place by internal spring clips. They may be permanently secured, if desired, by pressing a roll pin into the holes provided. The tool frame is equipped with a positive ratchet assembly that controls complete handle movement in both directions.

Hexagonal crimp dies are available in a variety of combinations having single, double, and even triple cavity design. These dies accommodate most coaxial and triaxial connectors and contacts conforming to MIL-DTL-39012, AS39029 and numerous proprietary configurations. Other designs are available for coaxial connections requiring different termination techniques.

Dies in various crimp patterns are also available for insulated and uninsulated terminal lugs, wire splices and end caps relating to M7928, MS17143, MS25036, MS25181, MS27429, MS25274, MS20659, M81824, MS21003 through MS21015, and commercial part numbers. Several power contacts too large for conventional hand tools are also covered by interchangeable dies for the HX4.

See this product at The ASSEMBLY Show, booth 1339.

Daniels Manufacturing Corp.