ASSEMBLY LINES

NAM Report Touts Vast Potential of AI for Manufacturers

WASHINGTON —The National Association of Manufacturers (NAM) has released a report on artificial intelligence. “Working Smarter: How Manufacturers Are Using Artificial Intelligence” examines why the technology is important and explains how leading companies are using it to improve productivity.

The report provides insights from manufacturers such as Hitachi, Johnson & Johnson and Schneider Electric on how AI can improve efficiency, product development, safety, predictive maintenance and supply chain logistics.

“So much of the media and policymaking conversation is focused on generative AI, but AI is far more than that for modern manufacturers,” says Jay Timmons, NAM president and CEO. “It’s infused increasingly throughout the shop floor, research and development, and beyond.

Leading manufacturers are harnessing artificial intelligence technology to improve their operations. Illustration courtesy Fraunhofer Institute

“Manufacturers are leading the way in the use and development of new AI technologies,” explains Timmons. “From developing more effective clinical trials and improving workplace safety to strengthening supply chain resiliency and supporting workforce training for employees, AI is unlocking new opportunities to strengthen our modern manufacturing workforce and improve the lives of all Americans.”

“All possible futures for modern manufacturing in the U.S. involve AI,” adds Kathy Wengel, executive vice president and chief technical operations and risk officer at Johnson & Johnson. “Given the importance of this generational technology, policymakers must develop sensible, carefully thought-out frameworks for various AI applications—and they should lean on manufacturers’ years of experience to engineer those frameworks.

“We need a policy environment that supports innovation and growth in manufacturing AI, because it will bolster U.S. competitiveness and leadership in this critical emerging field,” claims Wengel.

‘Smart Manufacturing 5.0’ Focuses on Human-Centric Factories

TORONTO—Manufacturers need to start transitioning from Industry 4.0 to Industry 5.0, according to a new report from Info-Tech Research Group. Like Industry 4.0, Industry 5.0 originated in Europe. It focuses on human-centric processes that place the well-being of people at the center of manufacturing activity.

According to Info-Tech, companies should adopt Smart Manufacturing 5.0, which combines the innovations of Industry 4.0 with a focus on human-centric, resilient and sustainable practices.

Manufacturers need to start transitioning from Industry 4.0 to Industry 5.0. Illustration courtesy Info-Tech Research Group

“While many organizations are still struggling to achieve Industry 4.0, Smart Manufacturing 5.0 offers a more efficient approach to modernizing production, enhancing workforce skills and overcoming legacy system obstacles,” says Kevin Tucker, research advisory practice lead at Info-Tech Research Group.

“Throughout the evolution of industry from 1.0 to 4.0, we have seen major changes that have significantly impacted the strategic decisions being made by organizations,” explains Tucker. “Most [large manufacturers] have now achieved some level of implementation that includes Industry 4.0 technologies, with cloud services being the most widely adopted.

“Now that we are in the midst of the next evolution…integrating technology and people has become crucial,” claims Tucker. “Embracing Smart Manufacturing 5.0 enables manufacturers to stay competitive, meet evolving market demands and drive long-term growth.

“Organizations must embrace Industry 4.0 tools and technologies and begin to focus on Smart Manufacturing 5.0 if they hope to achieve exponential growth or protect their market share from competitors who are doing so,” says Tucker.

“A more rapid adoption of Smart Manufacturing 5.0 and Industry 5.0 than of Industry 4.0 is anticipated,” notes Tucker. “[That is] due to the widespread acceptance of the integration of artificial intelligence, machine learning and humans as an essential component of any successful business model that prioritizes sustainability, quality, efficiency and the well-being of employees.”

Tucker advocates for a strategic approach, highlighting the importance of addressing legacy system integration, workforce skill development and data management. He says the goal of Smart Manufacturing 5.0 is to combine the best of Industry 4.0 with the attributes of Industry 5.0, creating factories that are safe, mass-customizable, collaborative, cognitive and environmentally friendly.

However, Tucker warns that achieving Smart Manufacturing 5.0 requires more than just integrating advanced technologies. “It demands a strategic transformation of manufacturing practices,” he points out. “By adopting these strategies, manufacturers can achieve greater efficiency, enhance product quality and promote sustainable operations.

“This forward-thinking approach enables manufacturers to meet current market demands and adapt to future challenges effectively,” notes Tucker. “Investing in Smart Manufacturing 5.0 and following this structured framework and principles [will ensure] that manufacturers can deliver innovative, high-quality products while maintaining a strong competitive edge in the dynamic industrial landscape.”

Intelligent Sensors Use AI for Predictive Maintenance

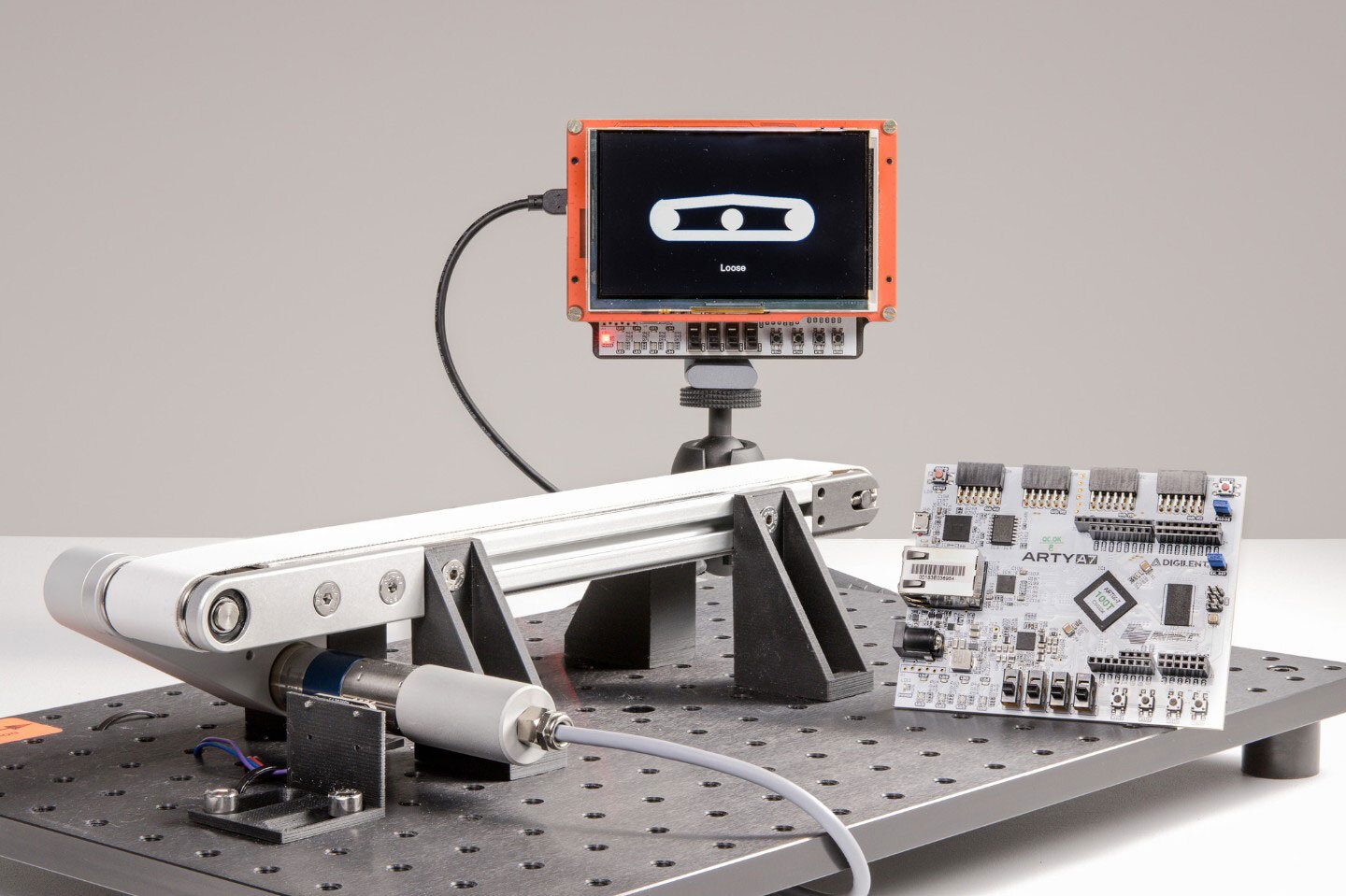

DRESDEN, Germany—Engineers at the Fraunhofer Institute for Photonic Microsystems (IPMS) here have developed a new system that combines sensor technology, data acquisition and AI-based data evaluation for condition monitoring and predictive maintenance. It opens up new possibilities for the preventive maintenance of plants and machines.

“Our [system] enables precise condition monitoring of machines through the use of sensors and intelligent data analysis,” says Marcel Jongmanns, Ph.D., project leader at Fraunhofer IPMS. “By integrating AI into the sensors, we can detect damage before it occurs, optimize maintenance intervals and minimize downtime.”

A new system combines sensor technology, data acquisition and AI-based data evaluation for condition monitoring and predictive maintenance. Photo courtesy Fraunhofer Institute for Photonic Microsystems

The system uses multimodal sensors that record accelerations in spatial directions and corresponding rotation rates. In addition, magnetic field sensors and acoustic or ultrasonic sensors are used to monitor industrial equipment.

According to Jongmanns, the system provides two main functions: Belt tension detection and jam detection. The AI models are based on extensive data analysis and enable accurate prediction of damage. To increase the accuracy of the models, real-time calibrations can be performed to adapt the system to new environments.

“Changing environmental influences can be directly modeled or taken into account in the analysis,” says Jongmanns. “This enables the integration of a large number of sensors and significantly increases the accuracy of predictions about the condition of the industrial equipment. Existing limitations in computing power for real-time modeling in embedded systems are overcome.”

New Technique Helps Robots Grasp the Unpredictable

CAMBRIDGE, MA—When robots come across unfamiliar objects, they often struggle to account for a simple truth: Appearances aren’t everything. They may attempt to grasp a block, only to find out it’s a literal piece of cake.

The misleading appearance of that object could lead the robot to miscalculate physical properties like its weight and center of mass, using the wrong grasp and applying more force than needed.

To address this issue, engineers at the Massachusetts Institute of Technology (MIT) Computer Science and Artificial Intelligence Laboratory (CSAIL) have developed a new way for robots to detect and interact with objects.

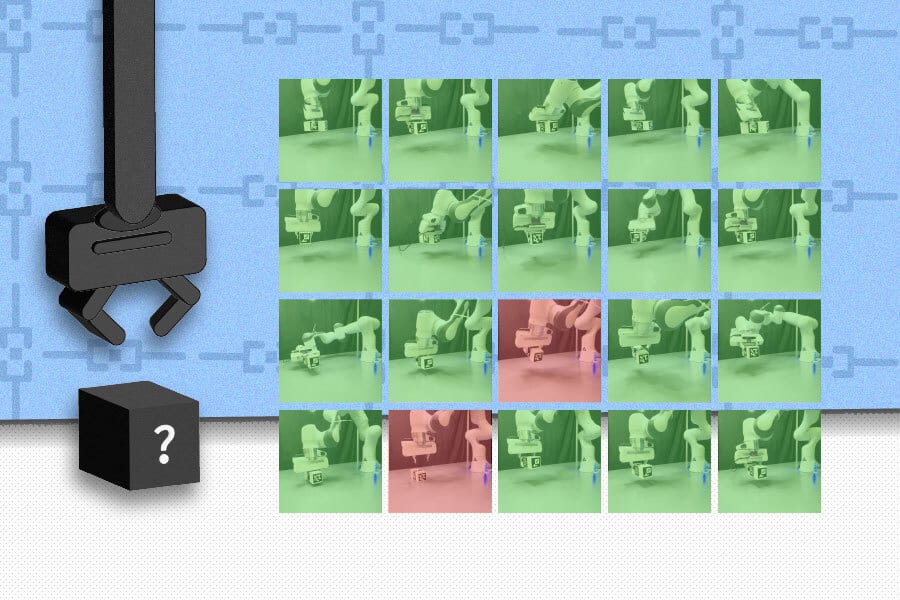

A new grasping process enables robots to detect and interact with unfamiliar objects. Illustration courtesy Massachusetts Institute of Technology

The Grasping Neural Process is a predictive physics model capable of inferring these hidden traits in real time for more intelligent robotic grasping. It trains robots to infer invisible physical properties from a history of attempted grasps, and then use the inferred properties to guess which grasps would work well in the future.

Typically, methods that infer physical properties build on traditional statistical methods that require many known grasps and a great amount of computation time to work well. The Grasping Neural Process enables robots to execute good grasps more efficiently by using far less interaction data. In addition, it finishes its computation in less than a tenth of a second, as opposed to seconds or minutes required by traditional methods.

“As an engineer, it’s unwise to assume a robot knows all the necessary information it needs to grasp successfully,” says Michael Noseworthy, an MIT Ph.D. student in electrical engineering and computer science who is heading up the research project. “Without humans labeling the properties of an object, robots have traditionally needed to use a costly inference process. Our model helps robots do this much more efficiently, enabling the [machine] to imagine which grasps will inform the best result.”

According to Noseworthy, robots that complete inference tasks have a three-part act to follow: Training, adaptation and testing. During the training step, robots practice on a fixed set of objects and learn how to infer physical properties from a history of successful (or unsuccessful) grasps.

The new CSAIL model amortizes the inference of the objects’ physics, meaning it trains a neural network to learn to predict the output of an otherwise expensive statistical algorithm. Only a single pass through a neural network with limited interaction data is needed to simulate and predict which grasps work best on different objects.

Then, the robot is introduced to an unfamiliar object during the adaptation phase. During this step, the Grasping Neural Process helps a robot experiment and update its position accordingly, understanding which grips would work best. This tinkering phase prepares the machine for the final step: Testing, where the robot formally executes a task on an item with a new understanding of its properties.