Potting Compounds for Automotive Applications

Henkel has introduced three new potting compounds to protect automotive components from moisture and fluid ingress.

Loctite SI 5035 is a one-part silicone potting compound that provides corrosion-free protection to sensitive components, such as control unit connectors. This flowable sealant has two curing mechanisms. It cures quickly when exposed to visible or ultraviolet light. A secondary, moisture-curing mechanism ensures curing of the adhesive in shadowed areas. SI 5035 forms a medium strength, flexible rubber sealant that can withstand high pressure testing immediately after UV curing.

Loctite AA 5832 is a dual-cure polyacrylate potting compound for sealing against automatic transmission fluids and oil. This one-component, low-viscosity material is used for potting and sealing various automotive and electronic components, such as control unit connectors, mechatronics and ADAS components. It cures when exposed to UV light and moisture.

Loctite PE 8086 AB is a thermally conductive potting material for encapsulating electrical components, such as motor stators, actuators, transformer coils and transmission actuators from thermal shock. This two-component epoxy offers high thermal conductivity, low mixed viscosity, excellent electrical insulation at high and room temperatures, and resistance to automatic transmission fluid. PE 8086 AB maintains optimal operating temperatures to ensure peak performance and mitigates long-term performance degradation due to high temperatures and environmental factors. It is a solvent-free product that produces no VOCs during the curing process.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

Henkel Adhesives

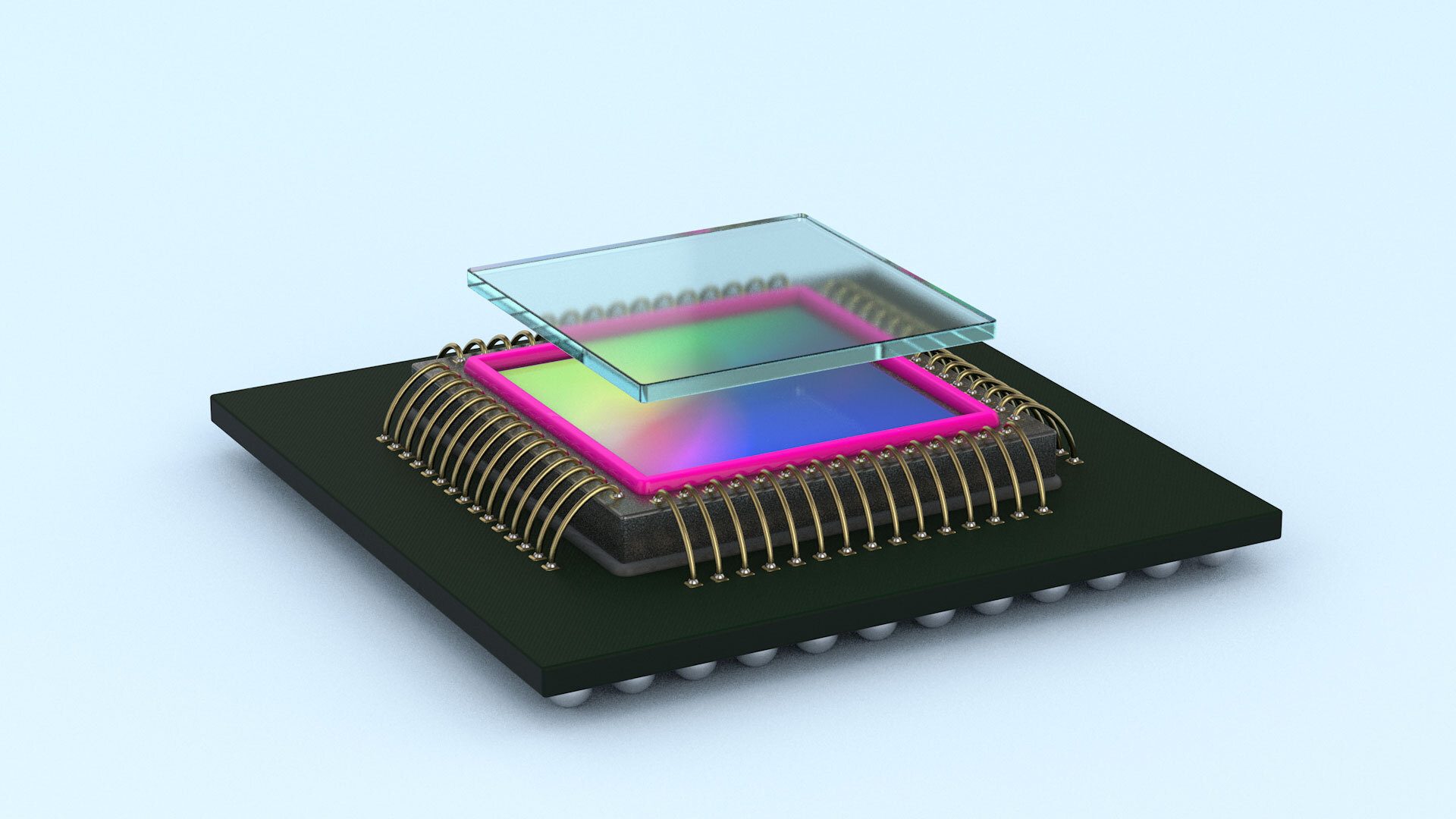

Sealant for CMOS Image Sensors

DELO Dualbond EG6290 is a new sealant for CMOS image sensors, which are often used in driver monitoring systems.

The adhesive was specially designed for the glass-on-die assembly method. The glass filter is fixed directly onto the chip, as is typical with iBGA image sensor packaging.

Compared to previous products, the material has a significantly higher Young’s modulus of 2,350 megapascals and a significantly higher adhesion value. With a glass transition temperature of more than 130 C, the adhesive exhibits mechanically consistent behavior—even at high application temperatures—and can compensate for temperature-dependent pressure changes. The material meets the requirements of the AEC-Q100 Grade 2 automotive standard.

The adhesive is applied via needle dispensing. Thanks to its high thixotropy index, narrow and high bond lines can be precisely dispensed, onto which the glass filter is then joined.

Curing takes place in two successive process steps: First, the adhesive is exposed to light with a wavelength of 365 or 400 nanometers. Then, the glass filter is fixed within a few seconds. The adhesive typically fully cures in 15 minutes at 130 C. Due to the rapid curing reaction, the matrix in the adhesive builds up quickly, which ensures the image sensor package is reliably sealed.

Both the dual-curing process and the comparatively low curing temperature help to minimize the pressure that usually occurs when bonding glass filters.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL..

DELO Industrial Adhesives

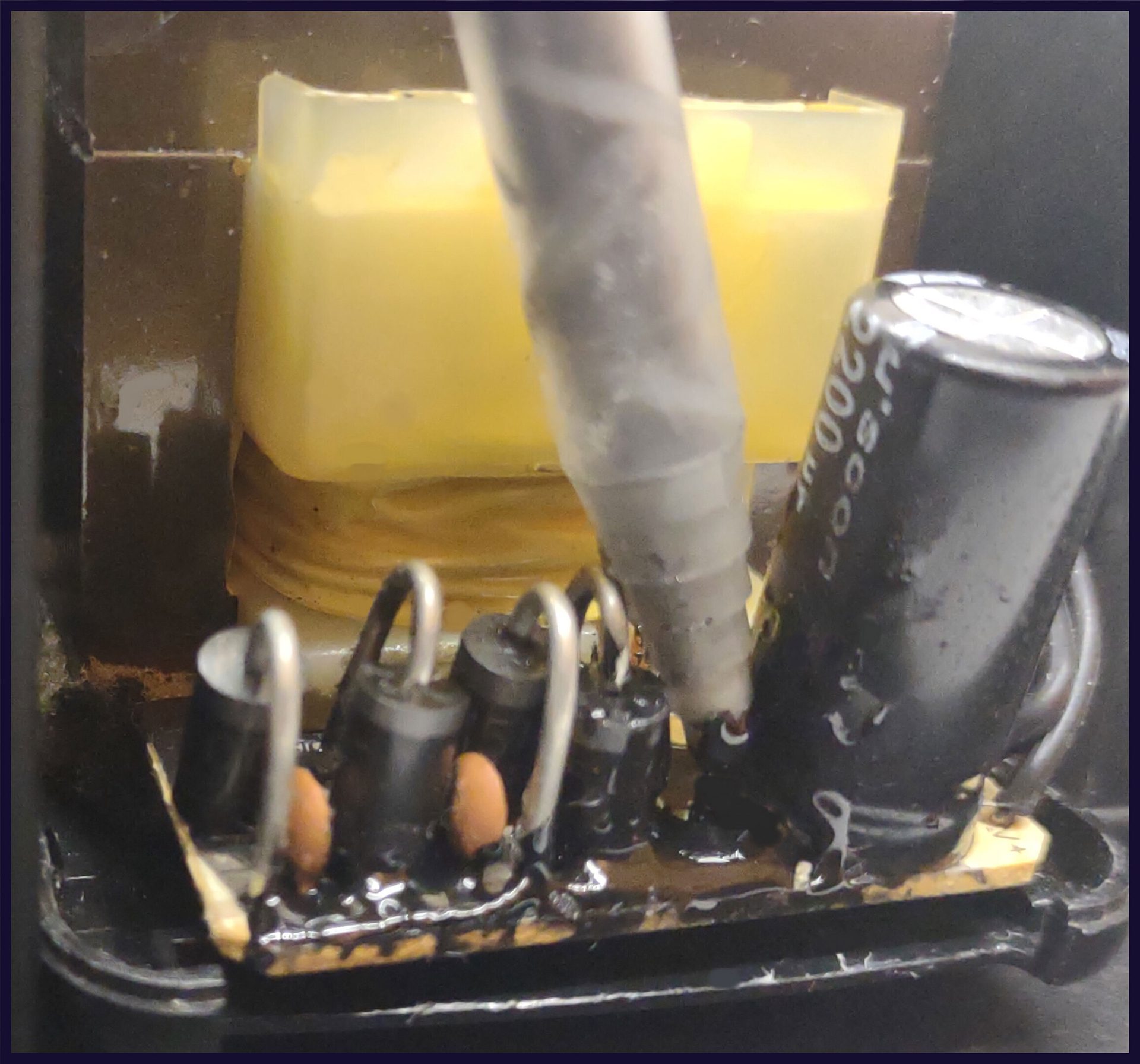

Potting Compound Resists Cracks

Designed for temperature cycling from -55 to 180 C, EC-1015HP epoxy potting compound provides significantly better crack resistance than traditional rigid epoxies. A low-viscosity encapsulant that cures with heat, the epoxy is used for large and small potting applications with fragile components. Its low coefficient of thermal expansion of 34 ppm/C keeps stresses to a minimum. It offers superior bond strength to most substrates as well as high chemical and moisture resistance.

EC-1015HP has a high thermal conductivity of 1.2 watts per meter-Kelvin with a glass transition temperature of 162 C. It is ideal for protection of electrical components with a volume resistivity of 1016 ohm-centimeter and a dielectric strength of 450 volts per mil.

This formulation can be used in densely packaged power supplies, integrated circuits, tightly packed coils and transformers without the cracking issues associated with most epoxies.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

EpoxySet Inc.

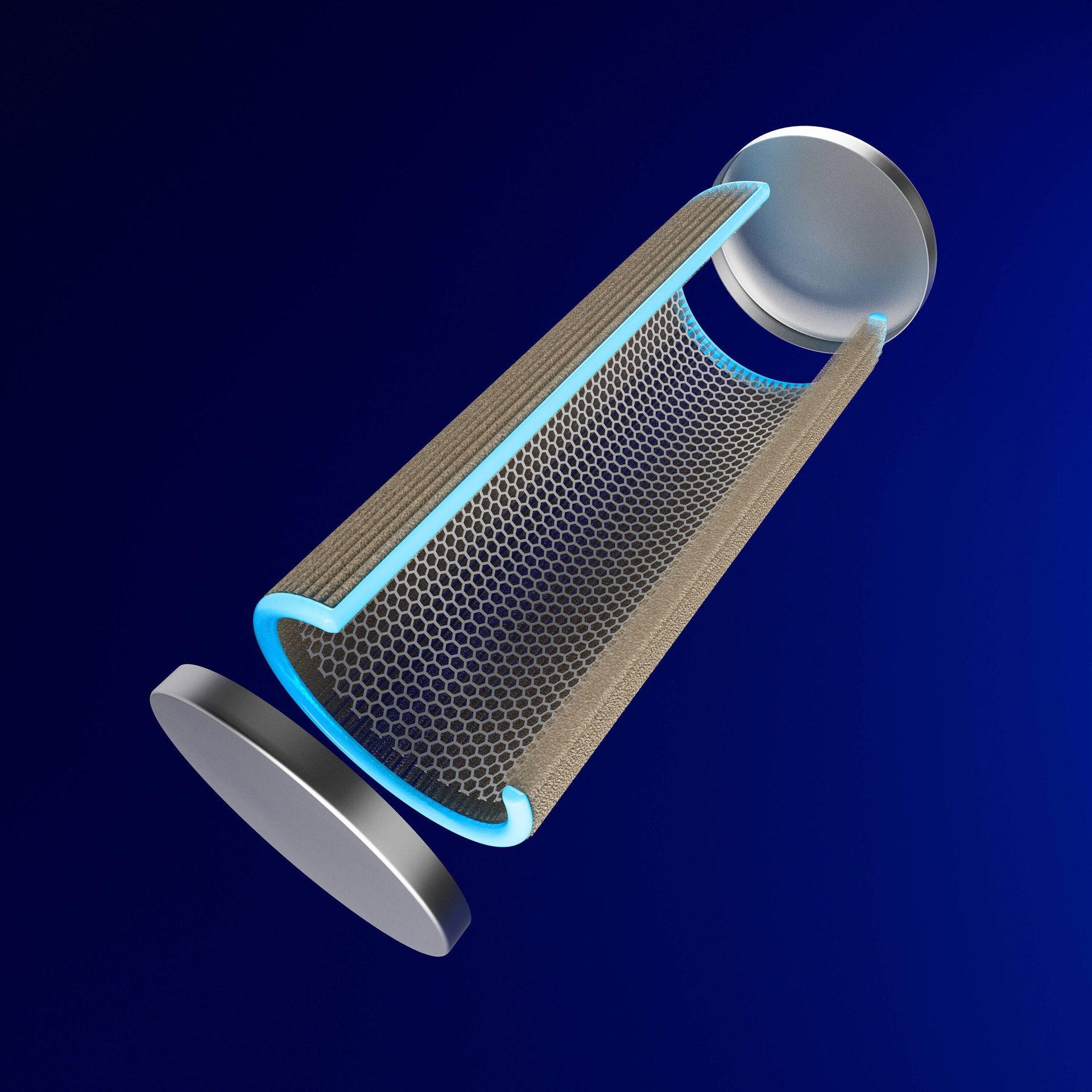

Media-Resistant Epoxy for Filter Bonding

Panacol has developed a new epoxy specifically for bonding filters for oil, gas and particle filtration. Structalit 5826 VT is highly resistant to fluids and media and is suitable for bonding filters used in shipbuilding and engine construction, exhaust gas purification systems, and the renewable energy industry.

Structalit 5826 VT is a high-viscosity, one-component epoxy. High viscosity allows the adhesive to be applied easily between the filter and filter cap, as well as on the longitudinal seam of the filter fabric, without undesirable run-off. Despite its high viscosity, the adhesive effectively penetrates the filter fabric to create a strong, resilient bond.

The epoxy is cured thermally, requiring only a few minutes in an oven at 150 C. It can also be hardened with an induction curing process. With a temperature resistance of up to 200 C, this adhesive is suitable for use in a variety of liquid, gas or particle filters.

Epoxy-based adhesives generally possess higher resistance to environmental and media attack. Structalit 5826 VT was created to be particularly resistant to oils and liquids. It has passed reliability testing in fluids according to DIN 53521, and it has passed oil resistance tests after 1,000 hours of aging.

Panacol