A special section to ASSEMBLY

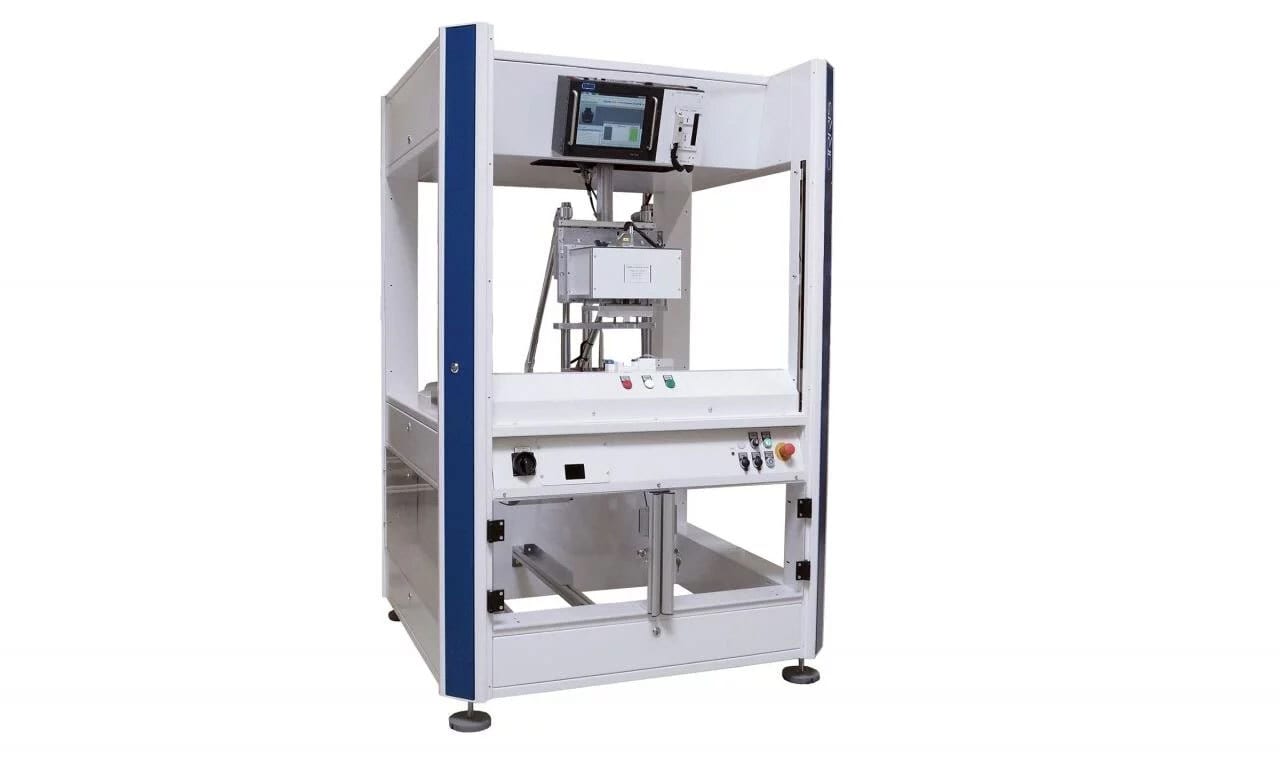

Basic Test Cell

The FlexiTest 2000 is a basic, flexible platform for automated test and inspection of low-volume electrical assemblies. The cell can be equipped with up to five in-feed axes. The cell is ideal for testing sample parts and pilot production runs. Once the design has been finalized, fixtures and programming for pilot production can be transferred to high-volume test equipment.

The cell can perform a variety of electrical tests, including continuity, high voltage, opens, resistance, reverse polarity, and short circuits. The cell can also check for the presence of parts, such has fastening pins, cable shoes, cable ties, clips, connectors, caps and covers. It can check pin height, pin material and swash circumference, and it can perform vacuum pressure tests and visual checks.

Schleuniger Inc.

Pull-Tester Checks Crimp Strength

The PT-150HA manual wire crimp pull tester is oriented horizontally. It’s ideal for testing crimp strength on wires up to size 10 for Mil-Spec applications and size 4 AWG for commercial and automotive applications. It can measure a maximum load of 150 pounds. It has a resolution of 0.1 pound, and it’s accurate to ±0.5 percent of full scale.

It can be used in conjunction with SPC software and other quality control technology. The digital display is fast and reliable. Gripping jaws and other components can be customized to facilitate installation and removal of test samples.

Daniels Manufacturing Corp.

Machine Dispenses Tape

The KTS 50 A dispenses lengths of tape for wire harness assembly. This compact machine handles tapes with a width of 9 to 50 millimeters. Dispensing speed can be adjusted to different tape materials.

Dispensing parameters are entered via a touch screen interface. Engineers can set five lengths, singly or in sequence. Up to 12 different sequences with user-defined adhesive tape lengths can be stored in memory. The tape length can be set between 30 and 9,999 millimeters. Once the tape has been pulled off, the machine outputs the next length of tape sequentially.

The machine is ideally suited for attaching cable harnesses to the roof lining or the vehicle body. It’s also good for manually bundling cable harnesses. Harness sections with different cross-sections can be processed in sequence, and the ideal tape length is always dispensed.

An air nozzle can be added as an option. Thin and light adhesive tapes fold back quickly. To prevent this, an air nozzle can be fitted as an option. It stabilizes the adhesive tape with an air blast. The air blast can be made stronger or weaker by means of a throttle.

Another option is a pressure roller for PVC adhesive tapes that have a high pull-off force. This presses the adhesive tape onto the feed roller, ensuring optimal processing.

One more option is a manual oiling device. Oil consumption varies, depending on the adhesive tape. The manual oiling device is recommended for use with fleece tape and thick textile tapes to achieve a consistent cut quality. No adhesive remains on the blade. In addition, the number of oiling cycles can be set individually. This prevents residues from forming on the adhesive tape as a result of excessive oiling.

Komax

Crimping Tool for Battery Terminals

This handheld tool crimps large F-crimp and ring terminals for batteries. This powerful hydraulic tool has an adapter system with different sets of tooling for the highest level of flexibility. The tool accepts large gauge wire ranging from 2 to 8 AWG. The crimping head has a snap closure and rotates 360 degrees. An LED illuminates the work area. It offers variable speed for positioning the wire and terminal. It is compatible with 20 standard ETCO products in loose piece form.

IETCO

Automate Assembly of Power Cables With Plugs

The PCC-Pro automatically terminates power cables with electrical plugs. Crimp connections are made with high precision on two- or three-core sheathed cables.

A closed insertion mask and color recognition support the machine operator in correctly inserting the cable ends. The cable ends are inserted manually and cut to a reference length and stripped by a stripping unit. A suction system removes the insulation and wire residues from the work area inside the machine.

Loose connector bridges are positioned correctly by a spiral-shaped conveyor. The components to be connected are automatically fed to the crimping process via a conveyor rail. The touch screen interface is intuitive and offers various languages.

An optional crimp force monitoring system with bad part cutter prevents the use of cables with incorrect crimps.

With a production rate of up to 1,450 pieces per hour, the crimping system is particularly suitable for series production.

Schaefer

Cable Tie Application Tool

HellermannTyton has updated its handheld cable tie application tools, the EVO 7 and 9. The new models, called the EVO 7i and 9i, offer visual and functional enhancements. The new tools have been tested to 1 million cycles.

The EVO 7i tensions and cuts cable ties ranging from 18 to 80 pounds. The heavier duty EVO 9i processes 50- to 255-pound ties, including wide strap ties. Both tools come in standard or short hand span models to accommodate all users. An additional model, the EVO 9HT, delivers even higher tensions for applications such as heavy equipment manufacturing.

A key feature of the EVO line is HellermannTyton’s patented Tension-Lock-Cut (TLC) technology, which freezes the tensioner before the cut is made, eliminating kick-back. That and an improved, ergonomic handle design help reduce repetitive strain injuries.

HellermannTyton