ASSEMBLY LINES

New Technology Enables Better Human-Robot Collaboration

MAGDEBURG, Germany—Engineers at the Fraunhofer Institute for Factory Operation and Automation (IFF) here have developed new technology that ensures safety in AI-generated robot movements and enables better human-machine collaboration.

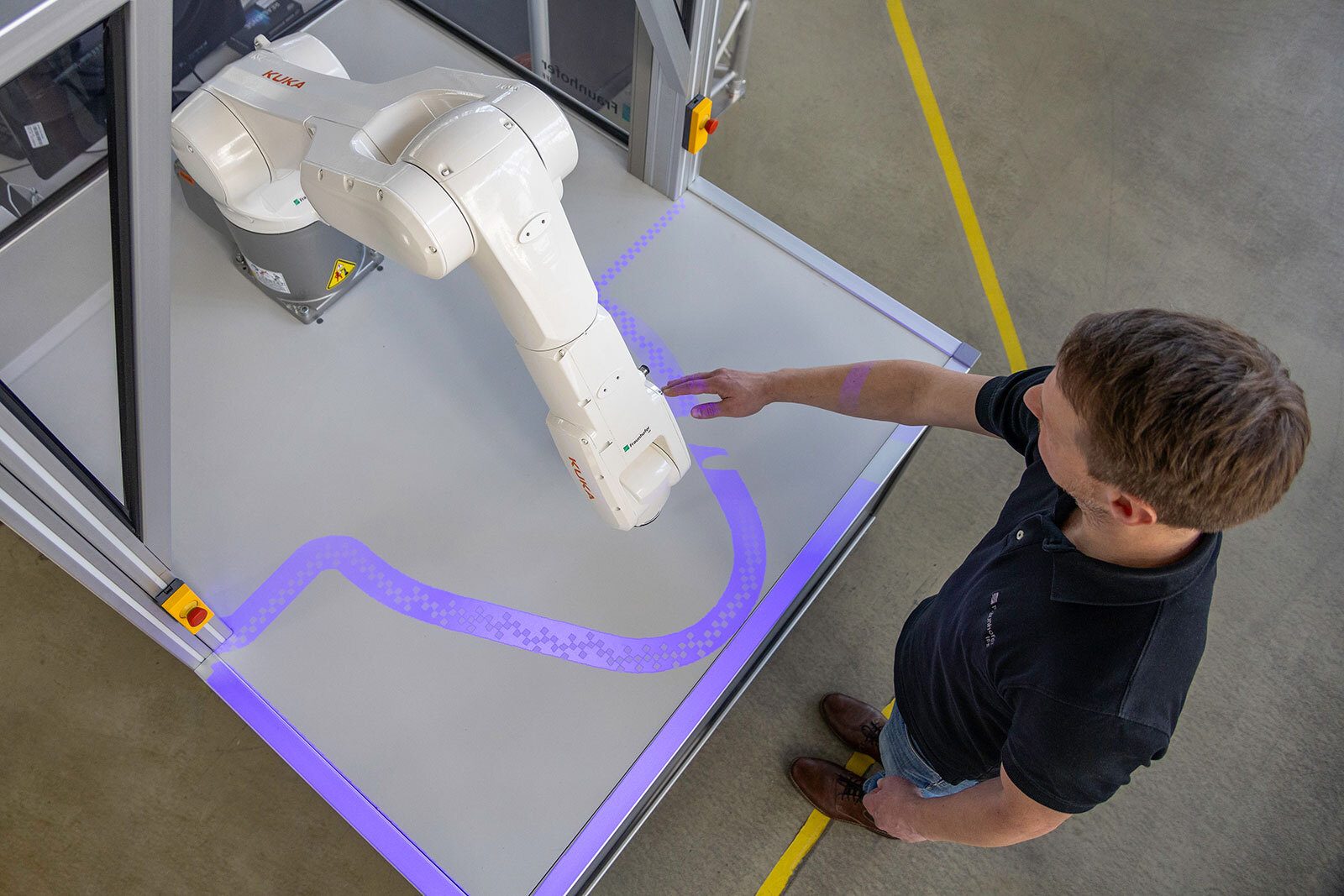

The technology, called PARU, uses advanced cameras and projectors to display visible warning and protective fields directly around a robot and recognize when people enter the safety zones. After the projector and the two cameras are calibrated, virtual expectation images are generated as the first step.

Then, the system projects a visible light curtain around the robot and the component that is to be picked up in accordance with the distance formula set out in the ISO/TS 15066 standard.

New safety technology generates visible light curtains around the area where a robot is working. The illuminated blue safety lines dynamically adjust to the machine’s movements, enabling safe interaction between humans and robots. Photo courtesy Fraunhofer IFF

“This light curtain acts as a safety line, visualizing for employees the protective space that humans must keep clear,” says Norbert Elkmann, Ph.D., head of the robotic systems department at Fraunhofer IFF. “If any part of a body comes into contact with the line, [work] is interrupted. The cameras recognize that there is a discrepancy between what they expect to see and the real-world image.

“Depending on the situation, the robot halts its movement right away or slows its speed,” explains Elkmann. “The safety areas are adjusted dynamically to the machine’s movements, as PARU always considers the robot’s current status, making it ideal for use in cognitive robotics.

“Our technology is unique,” claims Elkmann. “No other system allows for a smaller distance between humans and robots, while observing the specifications set by the applicable standards and also needing so little space. This is possible because the cameras and sensors recognize not only torsos, arms and heads, but even fingers.”

Another advantage is that the projection can show people where the robot will be moving as its next step, further enhancing trust in working with machines. The coded visible safety lines work independently of ambient lighting angles and conditions. If the cameras or projectors stop working, the entire system is automatically switched off.

Elkmann and his colleagues also recently developed a computer-aided system that makes human-robot collaboration applications efficient, cost-effective and safe.

“Digital assistants support the risk assessment and safety approval processes, and make it easier for new entrants in particular to comply accurately and efficiently with the full range of obligations under the EU’s Machinery Directive,” says Elkmann. “Unlike the collision measurement feature, the safety approval tool works entirely digitally. It takes parameters such as collision force and pain threshold into account to determine the robot’s maximum permitted speed.

“The modules can optionally be incorporated into any kind of robot controls or existing simulation environments for planning purposes to precisely align economic specifications with applicable safety requirements,” explains Elkmann. “This prevents planning errors and saves on engineering costs.”

The system was devised based on data collected from years’ worth of unique tests with subjects, which have yielded new threshold limits and other key biomechanical indicators for safe human-robot collaboration. Collision and clamping loads set on a specially designed pendulum were used to identify the pain threshold through tests of more than 100 human subjects.

AI’s Increasing Role in Manufacturing Spurs Call for New Policies

WASHINGTON—A new report by the National Association of Manufacturers (NAM) claims that more than 50 percent of U.S. companies plan to increase investments in artificial intelligence technology during the next two years. “Shaping the AI-Powered Factory of the Future” was conducted by NAM’s Manufacturing Leadership Council.

“The report reinforces the need for modernized, agile, pro-manufacturing AI policy so that manufacturers can continue to innovate on shop floors across America,” says Jay Timmons, president and CEO of NAM. “We look forward to continuing to champion AI leadership and manufacturing in America, which starts with adopting a pro-AI regulatory framework and pursuing policies that bolster innovation.”

According to Timmons, the growing importance of AI underscores the need for “a policy framework that supports [domestic] AI growth, innovation and leadership—one that streamlines compliance, fosters transparency and aligns energy, workforce, privacy and innovation rules with the realities of smart manufacturing.”

Manufacturers are using artificial intelligence technology to address labor shortages and improve product quality. Photo courtesy Beko B.V.

The NAM report claims that 51 percent of U.S. manufacturers already use AI in their operations, with 61 percent expecting investments will increase by 2027. By 2030, 80 percent of manufacturers predict AI will be essential to growing or maintaining their business.

However, the report also illustrates that manufacturers face ongoing barriers to using and scaling AI. Data quality and accessibility are the top challenges, with 65 percent of respondents reporting they lack the right data for AI applications and 62 percent citing data that is unstructured or poorly formatted.

Another recent study conducted by Rockwell Automation Inc. claims that 95 percent of manufacturers around the world are in the process of investing in AI to navigate uncertainty and accelerate smart manufacturing. Those companies are turning to technology such as machine learning and cloud-based systems to manage risks, improve performance and support their employees.

“Today’s technology advancements are unlocking new opportunities where the combined potential of people and technology will shape our collective future,” says Blake Moret, chairman and CEO of Rockwell Automation. “Manufacturers...are using smart manufacturing to navigate disruption and create new opportunities for speed and agility.”

Among the findings, 81 percent of manufacturers say external and internal pressures are accelerating digital transformation, with AI, cybersecurity and quality management ranking as the top investment areas.

More than one-third (41 percent) are using AI and automation to help close the skills gap and address labor shortages, while 50 percent are harnessing AI to support product quality initiatives.

Automotive Suppliers Facing Mounting Headwinds

MUNICH—Automotive suppliers are under increasing pressure as they continue to face challenging market conditions. According to a recently study conducted by Roland Berger and Lazard, stagnant production volumes, geopolitical uncertainty, increasing competition and rising cost pressures have driven average profitability down to just 4.7 percent.

Weak demand and challenging price negotiations with OEMs are placing additional strain on suppliers. While OEM profitability is still higher, it has also declined. That is predicted to put sustained pressure on supplier margins in the coming years.

“What we are currently observing in the European and North American automotive supplier industry can best be described as a phase of ‘stagformation,’” says Felix Mogge, a partner at Roland Berger. “On the one hand, suppliers are facing stagnant volume growth, while on the other, they are undergoing a fundamental transformation that requires them to urgently reshape their business models.

Stronger relationships can help automakers and suppliers better navigate industry uncertainty. Photo courtesy Toyota Motor Corp.

“While suppliers have slowly regained revenue growth since the Covid-19 pandemic, their profitability has structurally declined,” explains Mogge. “A significant portion of revenue growth has been driven by inflation, which has also increased costs.

“Overcapacity is putting pressure on the market, especially in Europe,” warns Mogge. “In contrast, China and South Asia are the primary drivers of modest global automotive growth. Slower-than-expected transition to EV adoption in Europe and North America is lagging behind expectations, preventing the realization of anticipated economies of scale. The EV market is attracting new players, increasing competitive pressure and cost challenges for suppliers.”

“The era of steady market growth is over and a more volatile environment will continue to put pressure on earnings and profits,” adds Florian Daniel, a partner at Roland Berger who worked on the Global Automotive Supplier Study. “However, suppliers can still succeed by implementing consistent efficiency improvement programs, forming partnerships to optimize and scale their portfolios, streamlining their product offering and focusing on strategic technologies.”

Another study conducted by Plante Moran claims that General Motors, Honda and Toyota have the best business relationships with suppliers in North America. Specifically, cost management, strategic alignment and stronger communication are seen as important factors in helping suppliers manage risk and uncertainty.

“Suppliers want balanced financial risk, and they want to know where they fit in OEMs’ future market strategies so they can align accordingly,” says Angela Johnson, Ph.D., principal in Plante Moran’s management consulting supplier relations analytics. “They perceive OEM behaviors—fairness, equity, accountability and then trust—through the impact of OEM decisions to their bottom line.

“What separates the top three from the bottom three OEMs is their ability to help suppliers reduce their costs to serve the OEM and manage uncertainty,” claims Johnson.

The top-three automakers in the study scored better in the basics: communication, responsiveness, accessibility, engagement and buyer knowledge. “These skills help suppliers operate more efficiently and, in turn, create strong relationships,” explains Johnson. “Stronger relationships enable OEMs and suppliers to work together and better navigate industry uncertainty with more equitable risk and cost sharing.”

“It’s all about balancing and aligning the various functional demands of the OEM—purchasing, manufacturing, engineering, design and finance—so there are fewer conflicting demands on the supplier and the OEMs’ team members,” adds Dave Andrea, principal in Plante Moran’s strategy and automotive and mobility consulting practice.

“Overall, OEMs that effectively address consistency, predictability and alignment of strategic goals are generally stronger, more profitable and become customers of choice for suppliers,” says Andrea. “And, because of their mutual dependency, these attributes are good for the suppliers, too.”

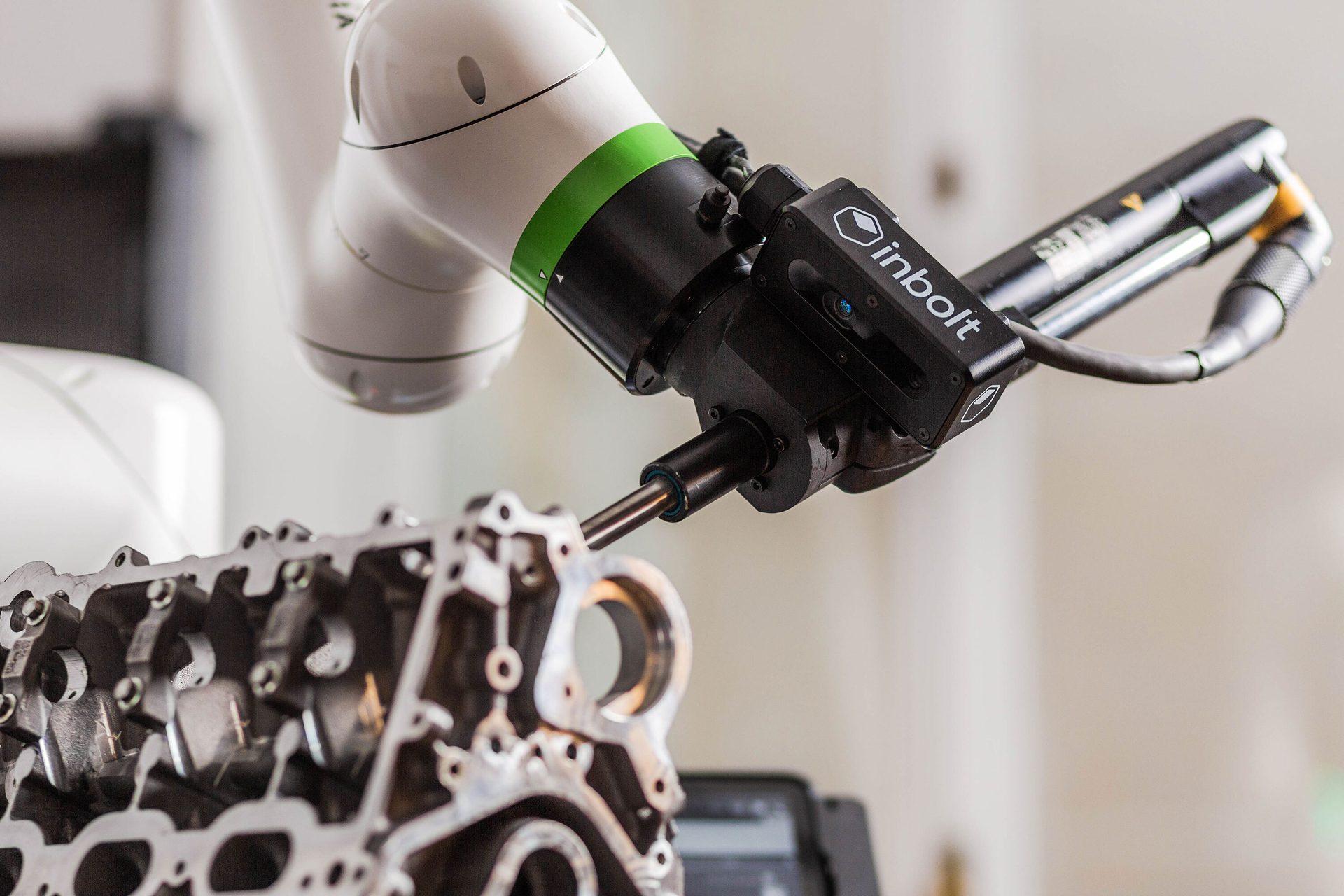

New System Enables Robots to Solve Complex Manipulation Problems

CAMBRIDGE, MA—Engineers at the Massachusetts Institute of Technology (MIT) and Nvidia Research have developed an algorithm that enables robots to think ahead and consider thousands of potential motion plans simultaneously. Instead of testing each potential action one at a time, like many existing approaches, this new method solves multistep manipulation problems in a matter of seconds.

In a factory setting, the technology could enable robots to rapidly determine how to handle parts that have different shapes or sizes without damaging them, knocking anything over or colliding with obstacles.

To enable super-quick decision making, the engineers harnessed the massive computational power of specialized processors called graphics processing units (GPUs). Their algorithm is designed for task and motion planning (TAMP).

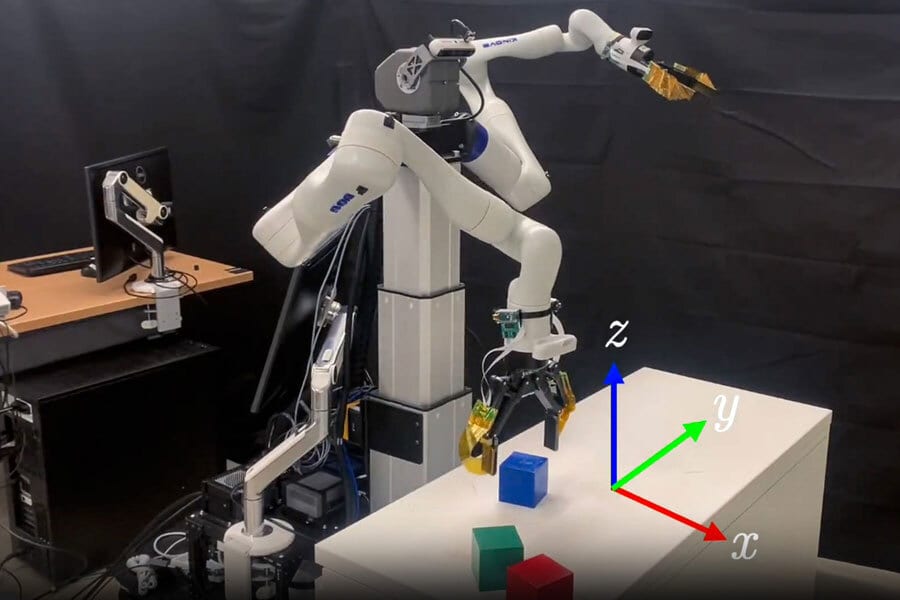

A new robot planning approach considers thousands of possible actions simultaneously, enabling the machine to rapidly determine how to manipulate and tightly pack items, such as these blocks, without damaging them. Illustration courtesy Massachusetts Institute of Technology

“The goal of a TAMP algorithm is to come up with a task plan for a robot, which is a high-level sequence of actions, along with a motion plan, which includes low-level action parameters,” says Caelan Garrett, Ph.D., a senior research scientist at Nvidia Research who worked on the project.

Garrett and his colleagues developed an algorithm called cuTAMP, which is accelerated using a parallel computing platform called CUDA. It simulates and refines thousands of solutions in parallel by combining sampling and optimization.

But, rather than sampling randomly, cuTAMP limits the range of potential solutions to those most likely to satisfy the problem’s constraints. This procedure allows cuTAMP to broadly explore options while narrowing down the sampling space.

Once cuTAMP has generated a set of samples, it performs a parallelized optimization procedure that computes a cost, which corresponds to how well each sample avoids collisions and satisfies the motion constraints of the robot, as well as any user-defined objectives.

It updates the samples in parallel, chooses the best candidates, and repeats the process until it narrows them down to a successful solution.

The system works across robot platforms and has been tested on a robotic arm at MIT and a humanoid robot at Nvidia. Since cuTAMP is not a machine-learning algorithm, it requires no training data, which could enable it to be readily deployed in many applications.

“You can give it a brand-new problem and it will probably solve it,” says Garrett. “In the future, [we] want to leverage large language models and vision language models within cuTAMP, enabling a robot to formulate and execute a plan that achieves specific objectives based on voice commands from a user.”