Assembly Presses

Labor shortages are driving new demand for automation.

Options for Screwfeeding

Hand-held presses are used for stationary applications that require multiple fastening locations. Photo courtesy BTM Co.

New materials enable new applications for an old joining process.

Clinching

What’s New With

Austin Weber // Senior Editor// webera@bnpmedia.com

Clinching is an old-school joining process that is commonly used to fabricate pieces of sheet metal. It’s a high-speed assembly technique that can eliminate the need for adhesive bonding, screwdriving or welding.

Clinching produces a round, button-like connection between two to four layers of sheet metal. The process can join metal sheets of different thicknesses. It can also join dissimilar materials, such aluminum, copper, stainless steel and titanium, without creating an isolating intermetallic phase. However, clinched joints are not as strong as spot welds.

There are two main methods of clinching: single-stroke and double-stroke. Single-stroke clinching deforms the overlapping sheet material plastically inside a die cavity, while double-stroke clinching deforms the material outside a rigid die cavity.

Force-controlled clinching typically takes less than 1 second. The process is insensitive to variations in material thickness, because squeezing takes places outside of the rigid die.

Clinching can be done manually with handheld tools or with robotic automation. A variety of benchtop, floor mounted and portable machines are available, including electric and pneumatic models.

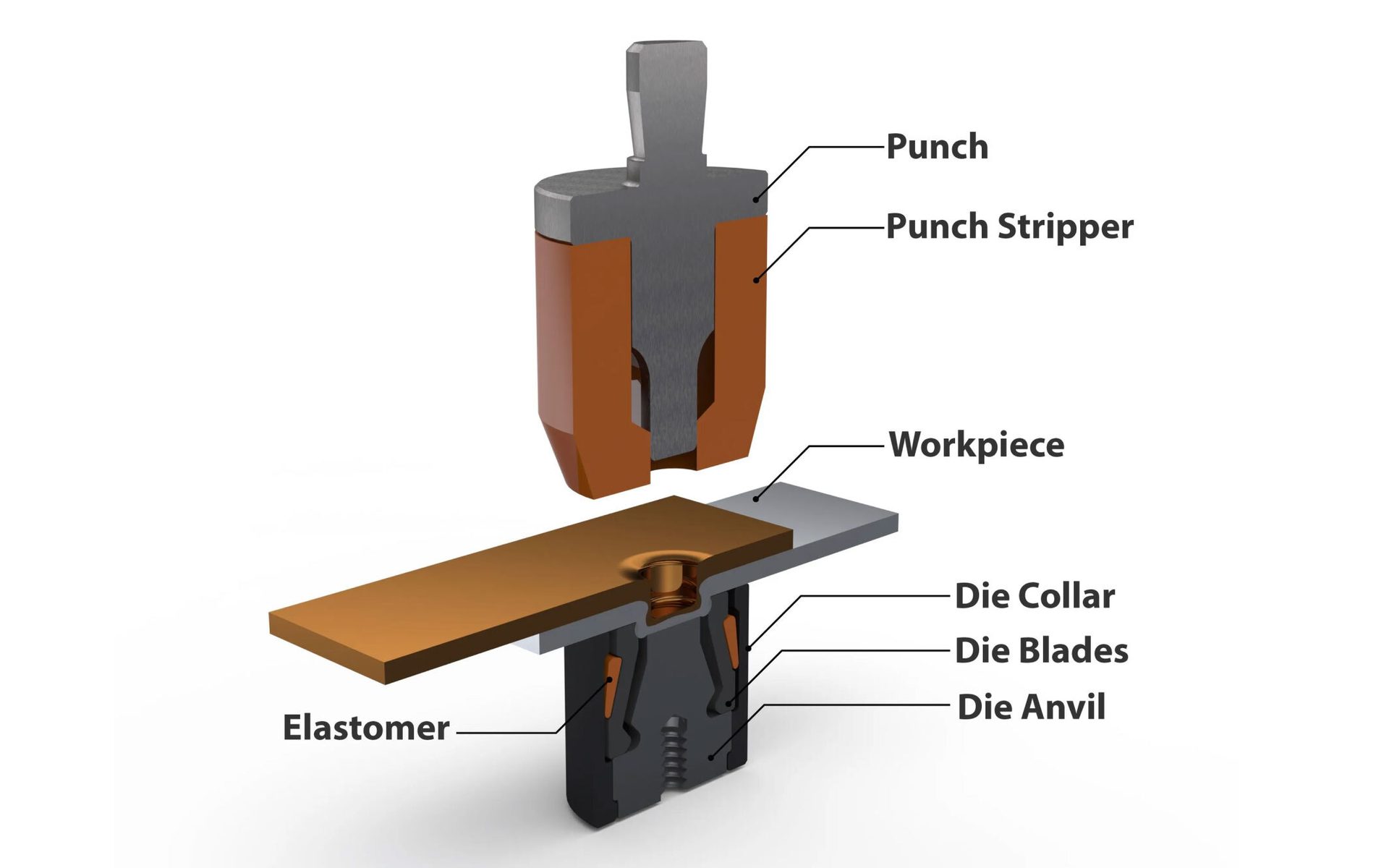

Sheet metal clinching uses a punch and a die to mechanically join material. Illustration courtesy Press Lock Technologies

Tooling consists of a punch and a die that are designed specifically for the materials to be joined. Material is pushed into the die, forming a mechanical interlock similar to a press stud.

There are two types of dies: solid, fixed-cavity dies, and dies with moving components. The punch forces the layers of sheet metal into the die cavity. The pressure exerted by the press forces the punch-side metal to spread outwards within the die-side metal. Joints typically range from 1.5 to 26 millimeters in diameter.

“One of the biggest advantages of clinching is its economical use of energy and materials,” says Byron Selorme, president of Press Lock Technologies. “When compared to spot welding, the total cost of ownership, including machinery price, consumables and maintenance, will yield considerable savings—up to 50 percent in some cases.

“The lack of heat in the clinching process allows options that would either be untenable with spot welding or would require considerable post-processing,” explains Selorme. “Take, for example, the joining of prepainted material. Paint impedes the conduction required for spot welding. Therefore, the paint needs to be removed before welding, and then touched up afterwards.

“The savings magnify when compared to arc welding,” claims Selorme. “[Often], I have seen major process improvements where the need for much more expensive skilled welding processes were removed. By changing the part design, simpler joining processes like clinching can often be used. [Benefits include] increased output, reduced weight and faster manufacturing.”

Clinching is popular, because it can join dissimilar materials and metal sheets of different thicknesses. Photo courtesy Tox Pressotechnik LLC

New Materials

One of the latest trends in clinching technology is the ability to process newer types of materials used in lightweighting applications. For instance, engineers are exploring how clinching can be used with advanced high-strength steels, in addition to thicker stainless steels, such as 12 or 14 gauge materials.

“Systems, processing techniques and tooling geometries for a wide range of dissimilar alloy and thickness combinations have changed in recent years, including high-strength materials and cast aluminum,” says Kris Lashbrook, sales and marketing coordinator at BTM Co. “We are now clinching material combinations that we have historically not been able to. That’s because the metallurgical and processing expertise required to solve these challenging applications is more scientific than in the past.

“We have seen a wide range of changes related to material types and thicknesses,” claims Lashbrook. “Recent examples include layers from 0.3 millimeter up to 7 millimeters, and total stack thicknesses up to 14 millimeters.

“Interest in our Custom-Loc and Special-Loc tooling families is growing rapidly, as we develop innovative geometries and configurations that address challenging joint requirements,” notes Lashbrook. “For example, we recently introduced a series of products that provide robust ways to join narrow flanges.

Clinching produces a round, button-like connection between one or more layers of sheet metal. Photo courtesy Press Lock Technologies

“Within our Custom-Loc family, we have a series of smaller, narrower tooling that accommodates applications with limited space around the joint,” explains Lashbrook. “Manufacturers are looking to reduce weight and material costs, and these tools help them meet those goals.”

In addition, sheet metal clinching technology has been undergoing major advancements in digitalization, automation and the ability to join different materials together.

“Currently, the biggest trend we’re seeing is a move to servo-electric clinching systems that come with built-in process monitoring and real-time quality control,” says Julie Wochos, Tox joining manager at Tox Pressotechnik LLC. “Many of those systems use advanced force and displacement monitoring with feedback control systems. That enables predictive maintenance and ensures consistent joint quality throughout production.

“Another exciting development is the hybrid joining method, where clinching is combined with adhesive bonding or other mechanical fastening techniques,” Wochos points out. “This has been especially useful in automotive weight reduction projects, where different material combinations, such as joining aluminum to steel, need reliable joining [methods].”

Recent developments in clinching have also significantly improved material compatibility, particularly with aluminum alloys and mixed-material applications. Engineers at Tox Pressotechnik, for instance, have been developing new tooling materials and die technology.

“These have greatly expanded the range of materials that can be clinched, including advanced high-strength steels and high-grade aluminum alloys,” says Wochos. “Modern clinching systems can now handle material combinations that were previously considered impossible to join, with improved coatings that extend tool life and make the process more reliable.

“Stack thickness capabilities have expanded considerably in recent years,” claims Wochos. “Clinching can now handle combined thicknesses up to 22 millimeters in specific applications.

“Thickness ratio limitations have also improved,” Wochos points out. “We can now clinch materials with thickness ratios beyond the traditional 3-to-1 limit. These improvements come from updated die designs, enhanced tooling materials and more precise control systems that can manage the higher forming forces required for thicker materials.”

Six-axis robots are used for high-speed clinching applications. Photo courtesy BTM Co.

Demanding Applications

Today, engineers in many industries want to join materials that are harder, have limited ductility and have challenging surface coatings.

“Manufacturers are demanding servo-electric clinching systems with integrated data collection and process monitoring capabilities more than ever,” says Wochos. “[They] want equipment that allows users to easily adjust parameters based on material variations, detect quality issues immediately and provide full traceability for industrial requirements.

“The key features they’re seeking include built-in statistical process control, predictive maintenance alerts and seamless integration for Industry 4.0,” explains Wochos. “They want intuitive software and data management functions, such as user-friendly interfaces with customizable dashboards and real-time visualization of process curves, final values and system notifications.

“Companies are also looking for clinching equipment designed for robotic integration,” Wochos points out. “Specifically, plug-and-play compatibility with major robot brands like ABB, Fanuc and Kuka.

“[Engineers want] compact, lightweight clinching units that can be easily mounted on robot arms, with standardized communication protocols and simplified programming interfaces,” notes Wochos. “Multistation flexibility is also crucial. They want systems that can handle different part geometries and material combinations, without extensive retooling.”

“Floor space conservation is a challenge for many manufacturers today,” adds Press Lock’s Selorme. “That’s why compact machines like our desktop Thor unit have increased in popularity.

“Also, there’s more demand for ways to automate processes in a cost-effective manner,” says Selorme. “Many of our customers are open to smaller steps in automation. So, machines that automate or improve a process, but are not overly complex, are very popular.”

Traditionally, clinching has been used to assemble many types of products, primarily in the automotive, appliance and HVAC industries. Quick operation, preservation of metal integrity and a wide range of installation systems make clinching popular for creating strong metal joints in car hoods and trunks, refrigerator and washing machine bodies and frames, and HVAC ductwork.

According to Selorme, electric vehicle battery enclosures are a growing application, such as hybrid assembly processes that combine adhesive bonding and clinching. But, that presents new challenges for engineers.

“Adhesive can impact clinch formation by increasing material flow,” says Selorme. “Adhesive acts as a lubricant to varying effects. Clinching affects the adhesive, since the clamping force reduces adhesive thickness surrounding the clinch location.

“However, with the correct balance of timing and thickness, the hybrid connection can see significant strength gains of 30 percent or more vs. using either bonding or clinching individually,” explains Selorme. “Clinching can also secure an assembly for movement further down the assembly line, while keeping the adhesive secure enough to cure in the assembly without losing part alignment.”