Lean Manufacturing

Labor shortages are driving new demand for automation.

Options for Screwfeeding

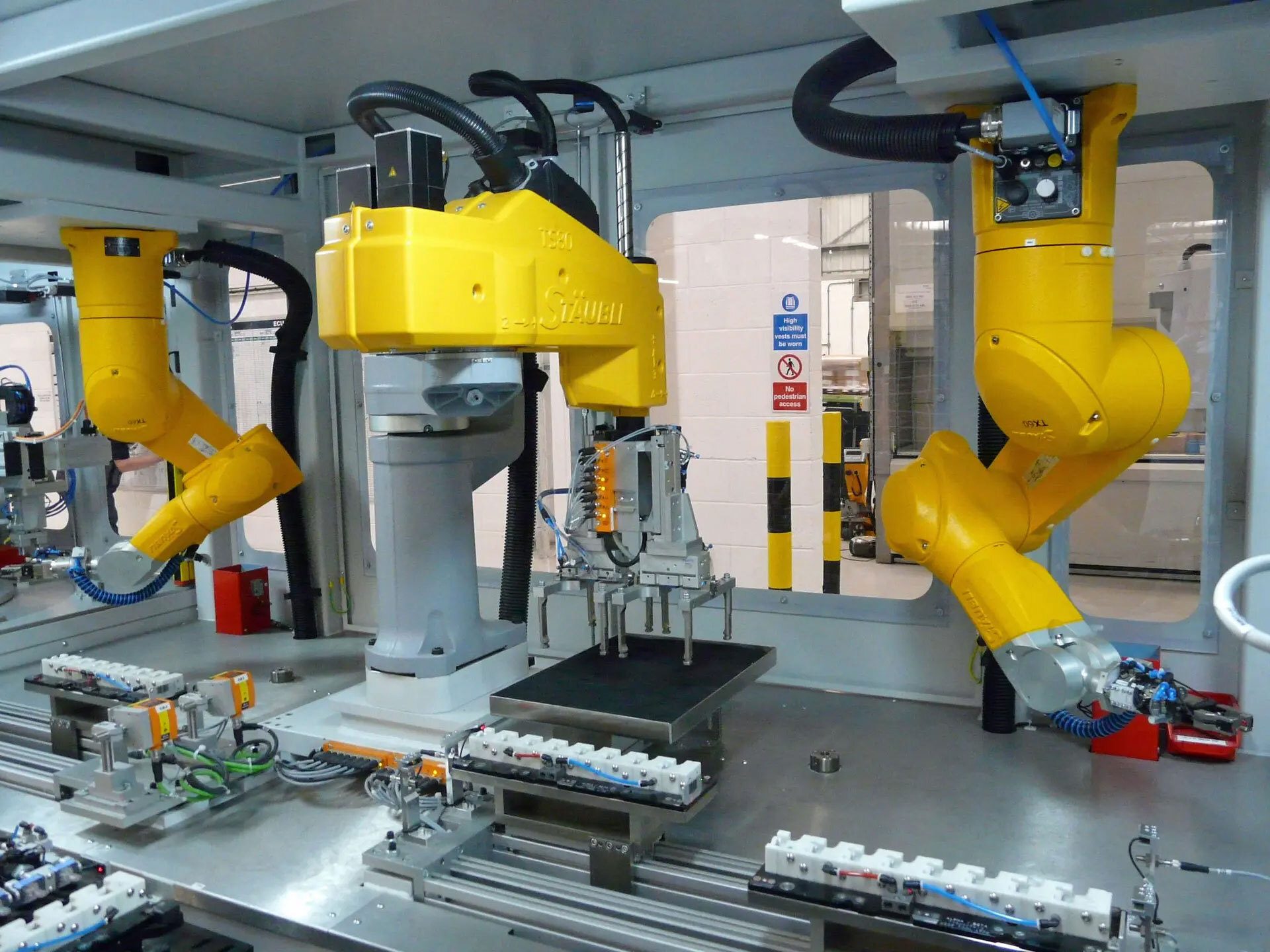

Kaizen creates ownership and accountability across the organization. Photo courtesy Lion Electric

Kaizen is a key tool for creating a culture of continuous improvement.

Kaizen Unlocks Hidden Value in Manufacturing

Ranjith Rajendran // Managing Director of the U.S. Private Equity Practice // TBM Consulting // Morrisville, NC

Private equity (PE) firms are investment management organizations that acquire ownership stakes in private companies with the goal of increasing their value and ultimately selling them for a profit. For years, most PE firms focused on financial engineering and leveraged buyouts to acquire companies and turn them around in just 24 to 36 months. The goal has historically been to find “quick wins” that deliver fast returns on investment (ROI).

Things are a little different today. Driven partly by market conditions, interest rates and longer-term opportunities, PE firms have shifted their focus to creating sustainable value. PE firms are now looking beyond equipment efficiencies and waste reduction toward holistic strategies that encompass their full portfolios.

As a result, cultural change has become a key ingredient in this new era of value creation. Historically ignored by PE firms, organizational culture is now on the radar of the savviest firms, which recognize its essential role in driving continuous improvement.

One of the best tools for creating a culture of continuous improvement is kaizen. More than just a set of practices for boosting productivity and reducing waste, kaizen can transform organizational culture to enhance team morale, engagement and commitment, ultimately driving innovation and sustained growth.

Kaizen is a proven methodology for creating small, incremental changes that aggregate to improve operational efficiency and ROI. Photo courtesy GE Appliances

Kaizen: A Strategic Fit for Private Equity

Kaizen is a proven methodology for creating small, incremental changes that aggregate to improve operational efficiency and ROI. It’s built on four key principles:

Continuous improvement—the belief that no process or system is perfect and there’s always room for improvement.

Employee empowerment—the notion that employees at all levels should identify areas for improvement and propose solutions.

Respect for people—collaboration and teamwork are central, with all employees treated as integral to the organization’s success.

Iterative processes—the idea that small steps, rather than radical changes, ensure sustainability and minimize disruption.

A kaizen program focuses on a specific area—a particular process or “problem”—and participants dive deep over a short period, typically five days or less. A cross-functional cohort is assembled, and participants are asked to leave no stone unturned. All ideas are welcome—nothing is too outlandish or unreasonable. The group settles on a tactic, tests and implements it, and measures the outcome. At the end of the program, the group, together with leadership, decides whether to keep, adjust or scrap the new process.

Kaizen delivers the speed and ROI that the PE turnaround cycle demands. PE firms typically aim for fast turnarounds and measurable results, and the “sprint” of a kaizen provides the intensity of focus, execution and proof PE firms and their manufacturing constituents need.

Notably absent is the focus on the typical key performance indicators in manufacturing, such as output, uptime, downtime, overall equipment effectiveness, cost per unit, cycle time, scrap rate, utilization, or on-time delivery. In kaizen, those are outputs of the process, not inputs, for driving value—and that’s where culture comes in.

Kaizens create a mindset of creative problem-solving. Photo courtesy BMW

The Culture-Kaizen Connection

Because of its focus on people and processes, kaizen is fundamentally a culture-change program, not just a productivity initiative. It’s designed to shift the organization’s way of thinking, operating and approaching challenges away from mechanics and metrics toward adaptability and agility.

Here’s how kaizen fuels cultural change to drive value:

Everyone has a voice. Unlike legacy thinking, where engineers dictate solutions, and those on the front lines obey, kaizen recognizes that everyone’s input has value because people see things from different angles. The ideal cohort follows the rule of thirds: one third from the point of impact (the manufacturing line, for example), one third from support roles (engineers or supervisors), and the remaining third are completely unrelated. The latter might be in sales, human resources, administrative assistants or even interns.

It shifts the mindset toward creative problem-solving. Kaizen allows an organization to adopt a laser focus on a specific problem. This approach helps people recognize that one of the key impediments to change is ingrained thinking, and in a kaizen, they can overcome that hurdle. In a kaizen, all initial ideas are welcome. Everything is on the table.

Often, employees feel heard for the first time. At one heavy equipment manufacturer, union members initially resisted wearing designated kaizen team caps. By the closing session, one union leader put on his hat and acknowledged it had been a transformative experience—not so much because he had gained wisdom, but because management had finally listened to front-line workers.

It creates ownership and accountability across the organization. Similarly, when diverse individuals from across the organization are engaged and recognized for their expertise and points of view, it creates ubiquitous empowerment and a deeper commitment to the organization’s success. This team approach encourages people to think like shareholders about how their work contributes to the entire organization’s success. Everyone’s empowered to speak up when they see an issue and offer a solution.

Unlike legacy thinking, where engineers dictate solutions, and those on the front lines obey, kaizen recognizes that everyone’s input has value. Photo courtesy BMW

It builds shared investment. In traditional PE scenarios, firms are often criticized for profiting from the work of the folks on the production floor. But with kaizen, the shared sense of ownership creates universal incentives for everyone to meet objectives. I have been part of many kaizens where the team comes out proud on Friday with a sense of outstanding accomplishments in short period.

It could be as simple as ergonomic or environmental improvements that result from refining processes to make the work easier or more comfortable. Sometimes, it’s a direct payback in the form of additional compensation or benefits. One company that hadn’t been able to fund its deferred profit-sharing program in years was finally able to do so through kaizens that ramped up profitability.

Scaling Kaizen Across the Portfolio

Just as some PE firms and manufacturers leverage tactics like artificial intelligence or procurement spending across their portfolio to create scale and value, the same can be done with kaizen. Not only can it be rolled out simultaneously within each portfolio company, but a firm could also leverage kaizen across portfolio companies to draw on expertise, diverse perspectives and fresh ideas.

Kaizen’s unique ability to make continuous improvement actionable—tackling immediate issues while developing the culture to sustain growth—turns culture into currency that spurs continued investment.

By implementing this approach, manufacturers and PE firms can ignite the lifeblood of the organization’s vitality and unlock hidden value for both investors and internal stakeholders, creating a cycle of continuous improvement that extends far beyond conventional cost-cutting measures.