Manufacturing Software

Labor shortages are driving new demand for automation.

Options for Screwfeeding

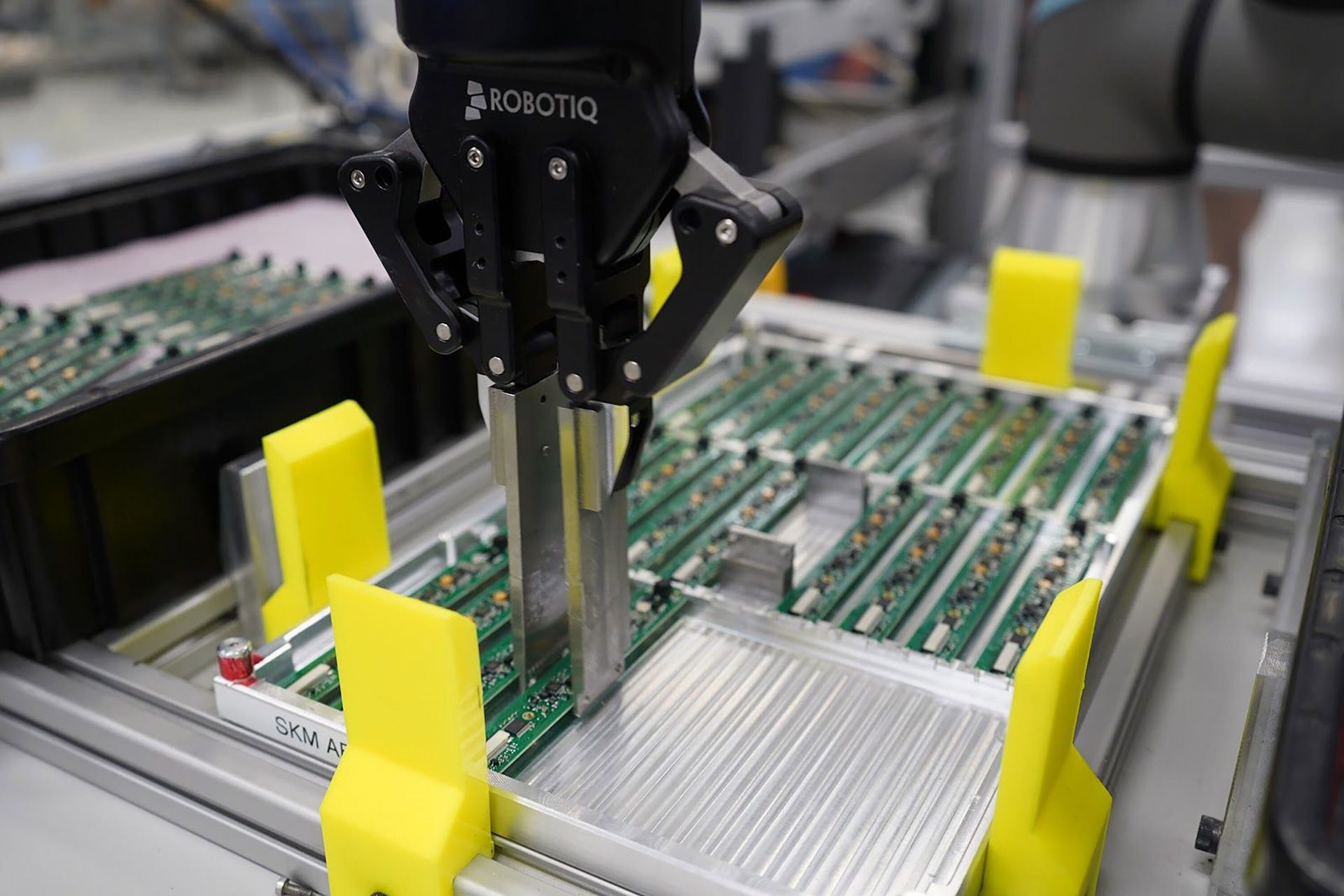

Lithos introduced PICO into its facilities in 2021, and has since digitized more than 260 processes, connected more than 50 stations, and integrated more than 115 assembly tools. Photo courtesy PICO MES

Digital ecosystem provides systematic controls for work instructions, change management and data collection

MES Helps Battery Maker Achieve ISO 9001 Certification

Paul Day // Contributing Writer

Based in Hayward, CA, Lithos Energy Inc. manufactures high-performance battery systems for demanding applications, including off-road vehicles; defense technology; watercraft; and agriculture, mining and construction equipment.

Since durability and performance are critical for these applications, Lithos has integrated a manufacturing execution system from PICO MES to ensure that high quality standards are met.

Lithos leveraged the traceability and change management functions of the PICO MES to create a structured, digitized approach to establishing its QMS. Photo courtesy PICO MES

Lithos introduced PICO into its facilities in 2021, and has since digitized more than 260 processes, connected more than 50 stations, and integrated more than 115 assembly tools to automate data capture and error-proof assembly across multiple battery system production lines. For example, Lithos has integrated PICO with various testing equipment, such as leak test instruments from Cincinnati Test Systems and hi-pot testers from Vitrek.

Lithos enjoyed tremendous growth in 2024, taking on new projects of increased complexity. Lithos recognized the need to establish a foundation for its quality management system (QMS) while ramping up production in 2025. As such, Lithos decided to pursue an ISO 9001 certification.

ISO 9001 is a globally recognized standard that provides a framework for organizations to consistently deliver high-quality products and services. ISO 9001 certification is granted by independent, accredited bodies after a successful audit. Certified companies have demonstrated a commitment to quality and continuous improvement.

To meet that goal, Lithos would have to automate.

“In the battery industry, keeping track of non-conformances is critical, but it’s surprising how many companies still rely on paper to do it,” says Angelo Menotti, head of quality at Lithos.

In his role, Menotti is responsible for ensuring that products consistently meet or exceed customer expectations. To achieve this, he relies on PICO’s digital ecosystem to provide systematic controls for work instructions, change management and data collection.

Full backwards traceability provides instant access to every part’s complete genealogy, allowing for the creation of “digital product passports” to demonstrate process efficiency and product quality. Photo courtesy PICO MES

MES at the Center of the QMS

Lithos leveraged the traceability and change management functions of the PICO MES to create a structured, digitized approach to establishing its QMS. Instead of relying on fragmented paper documents and spreadsheets, PICO allows for automated data collection from every build and enables quick access to critical process and product quality information necessary to prove adherence to ISO 9001 standards.

Primarily, Lithos measures first-pass yield, incident rates, and non-conformance for the ISO 9001 certification. Centralizing this data in one place mitigates the risk of mismatched data that often stems from using multiple factory systems.

“PICO integrates all key ISO 9001 manufacturing requirements and is our tool of choice in proving product genealogy, process control, and build instructions,” says Menotti. “This not only simplified compliance, but also established a sustainable framework for continuous improvement.”

Lithos Energy manufactures high-performance battery systems for off-road vehicles; defense technology; watercraft; and agriculture, mining and construction equipment. Photo courtesy Lithos Energy Inc.

Specifically, PICO helped Lithos secure ISO 9001 certification by:

• Eliminating paper-based processes. Digital work instructions help standardize work across different production lines and allow for tighter revision control when process updates are required.

• Reducing operator burden and human error. Integrated devices and tools automatically capture data as operators assemble battery systems, ensuring accurate data reporting and error-proof products.

• Spending less time searching for data. Full backwards traceability provides instant access to every part’s complete genealogy, allowing for the creation of “digital product passports” to demonstrate process efficiency and product quality.

“If you are still living in the manual world, you are probably operating 10 to 20 times slower than digital factories,” Menotti says, adding that PICO’s traceability and change control capabilities have proven to be key in streamlining not only certification processes, but customer audits as well.

“Since all manufacturing data is centralized, we can quickly compile comprehensive reports that include a product’s complete build history, from build and test values, to work instruction revisions,” Menotti continues. “Our customers trust the data we share because we can clearly show where defects started, how they spread, and how to prevent them in the future.”

Assembling a “build book” for a product starts with tracing that product’s data in PICO by searching a part or serial number, pulling the report, and entering the information into a template. From start to finish, this process takes one hour per product, Menotti hopes to make this process instantaneous with the click of a button through future integrations with PICO.

Lithos has integrated PICO with various testing equipment, such as leak test instruments from Cincinnati Test Systems and hi-pot testers from Vitrek. Photo courtesy PICO MES

The Results

Lithos has greatly reduced the labor and time requirements of gathering and documenting assembly data by eliminating the burden of maintaining paper records. Through digital traceability, managers have instant access to all of the process documentation, build data, and analytics they need to provide a high level of confidence to customers.

With a solid foundation for its QMS in place, Lithos is looking to achieve additional quality certifications, such as the IATF 16949 for the automotive industry, and continue to integrate systems with the PICO environment to optimize processes. As Lithos heads into a season of increased production, the company’s focus will be to solidify its digital ecosystem and capitalize on the influx of data for continuous improvement across process efficiency and product quality.

“Overall, the transparency and consistency PICO offers have significantly improved our audit outcomes and customer confidence,” says Menotti.

What Manufacturers Can Learn From Lithos

Many manufacturers still rely on pen and paper to document their processes and collect data solely because of the fear of the unknown that surrounds factory digitization. However, digitizing processes and automating data collection is becoming a necessity if manufacturers wish to stay competitive and agile. Fortunately, as Lithos has demonstrated, digitizing processes has significant compounding effects when coupled with features such as traceability. It serves as the first step towards unlocking data insights that not only drive efficiency gains on the shop floor, but stimulate growth across the entire business.

For a deep dive on how Lithos Energy achieved ISO 9001 certification in six months, tune in June 12 to view a webinar featuring Menotti and experts from PICO MES.

To see of video of the Lithos Energy story, click here. To get started with free digital work instructions software, click here. To download the free traceability implementation checklist, click here.

Inspection System

ASSEMBLY ONLINE

For more information on MES software, visit www.assemblymag.com to read these articles: