Plastic and Metal Welding

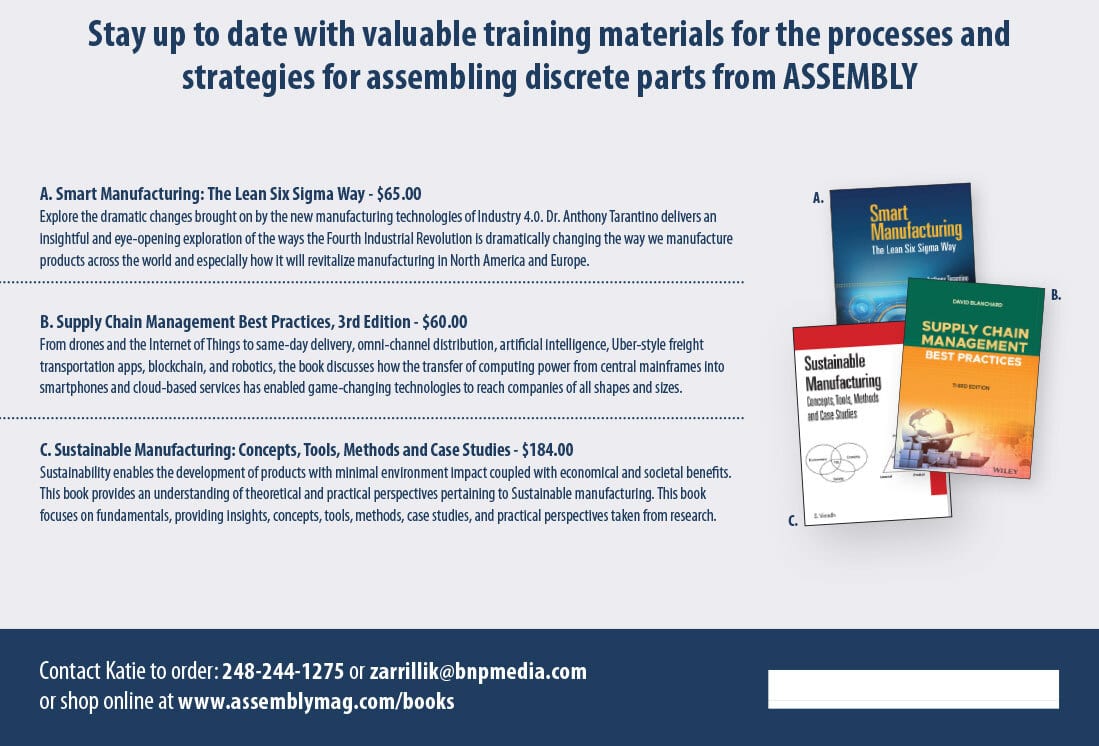

A robot loads a stamping into a fixture. Photo courtesy JR Automation

An assembly process that once required seven people now needs just two.

Robots Automate Assembly of

Brake Component

John Sprovieri // Chief Editor

Pentaflex Inc. is a contract manufacturer of metal stampings and assemblies located in Springfield, OH. Specializing in heavy-gauge and highly formed components, Pentaflex makes parts for myriad products, including cars, commercial trucks, agricultural machinery, solar energy installations, medical equipment, and military vehicles. The company’s customers include Ford Motor Co., Hendrickson USA, Navistar and Bobcat Co.

The company was founded by the late John C. McGregor in Springfield in 1972. The name Pentaflex is derived from the company’s five initial investors (penta), who because of their diverse professional backgrounds considered themselves to be very flexible (flex).

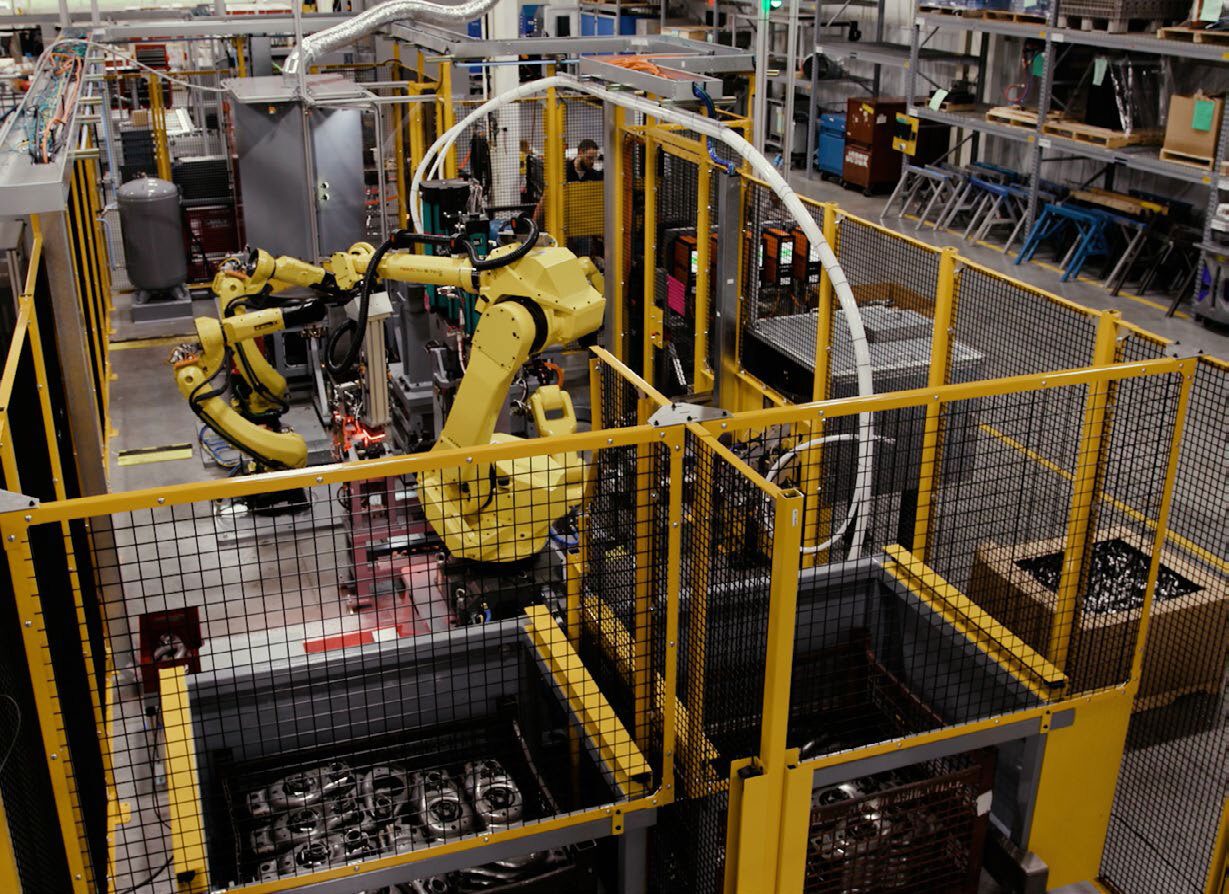

Thanks to automation, an assembly process that once required seven people now employs just two. Photo courtesy JR Automation

From the beginning, Pentaflex has focused on heavy-gauge metal stampings and assemblies. The company is unique in that it has always used high-tonnage hydraulic presses for production. This has allowed Pentaflex to produce heavy-gauge, deep-drawn and highly complex parts that many of its competitors decline to quote.

Over time, the company began offering additional value-added services, such as welding, machining, and the assembly of purchased components. Since something else had to happen to the stamping, management reasoned, why not do that work internally so the customer receives a subassembly that is ready to put into service without additional labor? This saves the customer time and money.

Like many startups, Pentaflex was originally located in a facility that was not built to house a metal stamping operation. As the company grew, the physical limitations of the original location became more pronounced, so in 2000 Pentaflex relocated to a new purpose-built facility.

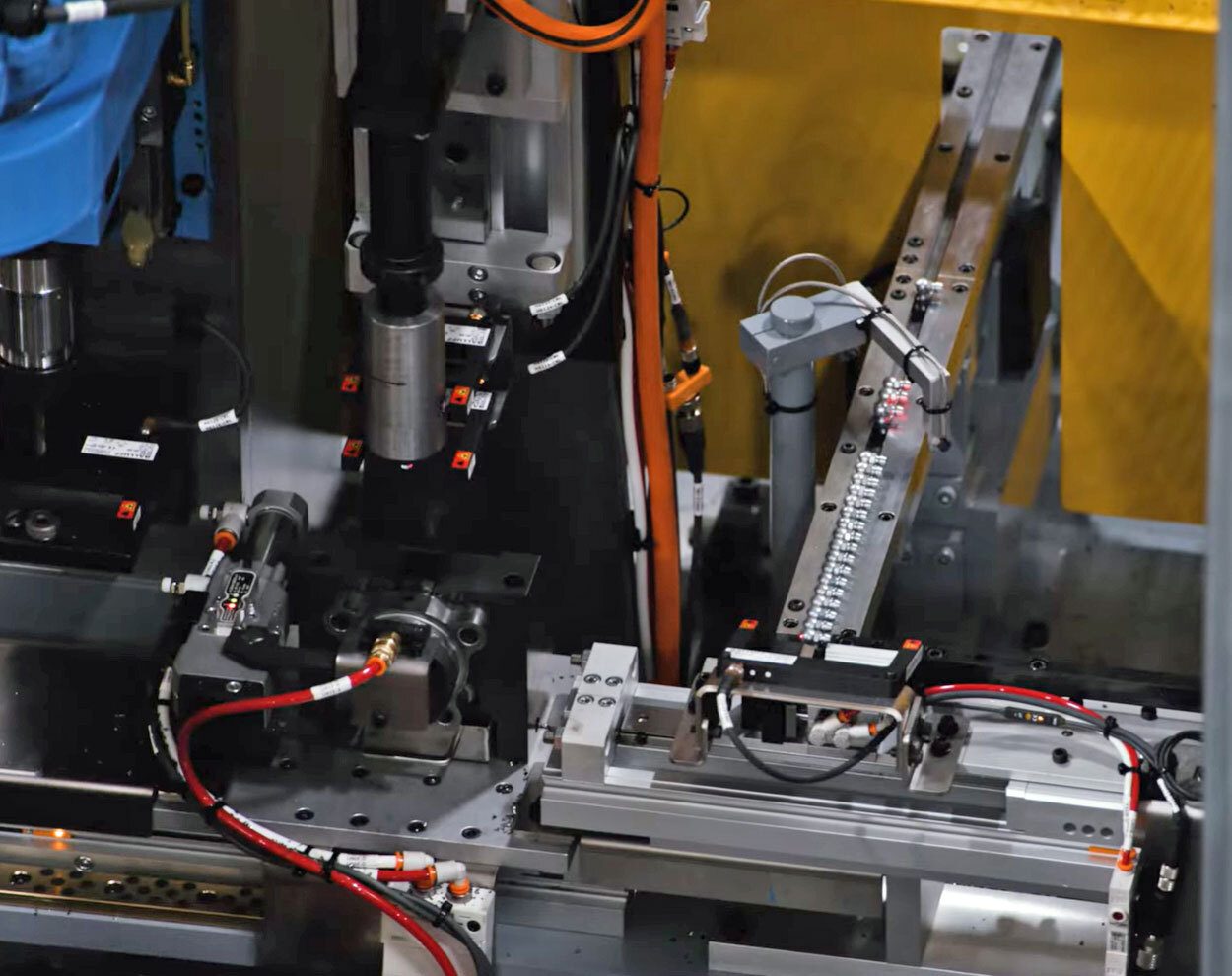

Zerk fittings queue up for insertion. Photo courtesy JR Automation

Along Came a Spider

One of the company’s products is a brake spider: a rigid metal component that serves as a foundation for drum brake systems, particularly on heavy-duty vehicles like semi-trucks and trailers. It’s mounted to the axle flange and provides support for various brake components.

The brake spider is permanently attached to the axle flange, providing a stable base for the entire brake assembly. It supports essential brake parts, such as the camshaft, pushrod, slack adjuster, brake shoe rollers, and return springs. It often includes anchor pins and supports the brake shoes, which press against the brake drum to slow or stop the vehicle.

A safety-critical assembly, a brake spider is typically made from durable materials, like forged steel and iron alloys. Its parts are both stamped and welded.

Pentaflex has been making brake spiders for one customer for 40 years. The current process required seven skilled workers to assemble, inspect and pack the component. With aging equipment, and an ongoing challenge to hire and retain skilled workers, Pentaflex was ready to invest in automation.

A worker loads metal stampings into the assembly system. Photo courtesy JR Automation

“We wanted to do something to move our technology forward and keep our customer happy,” says Ross McGregor, president and CEO of Pentaflex. “The labor market had been shrinking since 2019, and it was only getting tighter. By automating the process, we would be able to reduce labor, increase output, become more profitable, and have better process control. Some of

our equipment was aging, and it had to be replaced anyway, so it made sense to look at automation and robotics to help us improve our situation and keep our customer happy.

“This would be a major investment for a company our size, so we wanted to make sure we did it right.”

Pentaflex contracted with systems integrator JR Automation in Holland, MI, to automate the assembly process.

“JR has an excellent reputation in the automation arena,” says McGregor. “The company’s approach was completely different—I would say immersive. The JR team came to Pentaflex to get a complete understanding of what was required to make this part. They analyzed our existing

process before they even came up with ideas about how they could automate it. The detail they went through to get us on board was really well-done. I knew that the JR team was not going to be satisfied until they saw the line operating correctly at our factory, and that gave us a lot of confidence.”

The JR design team worked side-by-side with Pentaflex engineers to view the current process and understand what was required to make quality parts. The team then developed ideas and options for automating the process from end to end. The result was a semiautomatic system employing two skilled workers for loading parts and robots to transport parts between the process stations.

The main processes include welding, boring, zerk installation, retainer fastening, and bushing insertion. At the end of the line, a six-axis robot automatically unloads finished assemblies into containers. The entire process takes 20 seconds from initial load to pack-out.

Because the brake spider is a safety-critical part, Pentaflex wanted to conduct quality control checks in-line and collect data on process parameters to validate and document the quality of finished assemblies.

The automated line is “a real game changer,” says McGregor. “Previously, we were making this particular product using seven people per shift, and now we’ve been able to take that down to two.

“We understand that by investing in automation, you also have to invest in your employees’ technical skills to fully utilize this technology. However, needing only two people to run the line, as opposed to seven is going to make things a lot easier for scheduling and meeting our customer’s schedules. It also gives us the flexibility to use [the extra five] people elsewhere in the facility.”

By investing in automation, Pentaflex was able to adjust production scheduling to better meet customer schedules. In-line quality inspection and data collection has improved overall process control and enables the operations team to address part issues in the moment.

“I would have no qualms recommending JR Automation,” says McGregor. “I don’t know how we could have gotten any more attention from the JR team. We felt like this was as much a priority for JR as it was for us. Looking back on all those meetings and all that effort, it all seems worthwhile now.”

For more information on automated assembly systems, click www.jrautomation.com.

ASSEMBLY ONLINE

For more information on automated assembly, visit www.assemblymag.com to read these articles: