FROM THE EDITOR

On May 30, the National Association of Manufacturers (NAM) released the results of its Manufacturers’ Outlook Survey for the second quarter of 2025. They were not good.

Manufacturers’ optimism has dropped to 55.4 percent, the lowest level since the height of the COVID-19 pandemic in the second quarter of 2020. Trade uncertainty remained the top business concern for the second consecutive quarter, cited by 77 percent of respondents.

Given that the Trump Administration’s shotgun approach to tariffs is the source of that uncertainty, the NAM recently unveiled a proposal, the U.S. Manufacturing Investment Accelerator Program, intended to boost domestic manufacturing investment.

Even if U.S. manufacturing was operating at full capacity, it could produce only 84 percent of the inputs necessary to meet demand. Photo courtesy Leonardo SpA

“President Trump’s administration is prioritizing policies that spur more investment and innovation in manufacturing in the U.S.—a goal that manufacturers share. As the administration pursues reciprocal trade deals, the NAM is seeking zero-for-zero tariff outcomes with our top export markets,” says NAM president and CEO Jay Timmons. “As these deals materialize, manufacturers need a runway of predictable access to the critical inputs necessary to make things in America, empowering them to invest, create jobs, grow and compete. The U.S. Manufacturing Investment Accelerator Program is a manufacturing ‘speed pass’ that will unlock long-term investments needed to maintain America’s edge in the global economy.”

The reasoning behind the NAM’s proposal is that the U.S. cannot produce everything and anything domestically. Even if U.S. manufacturing was operating at full capacity—every machine turned on, every job filled—it could produce only 84 percent of the inputs necessary to meet demand. That means that at least 16 percent of manufacturing inputs must be imported to grow domestic manufacturing.

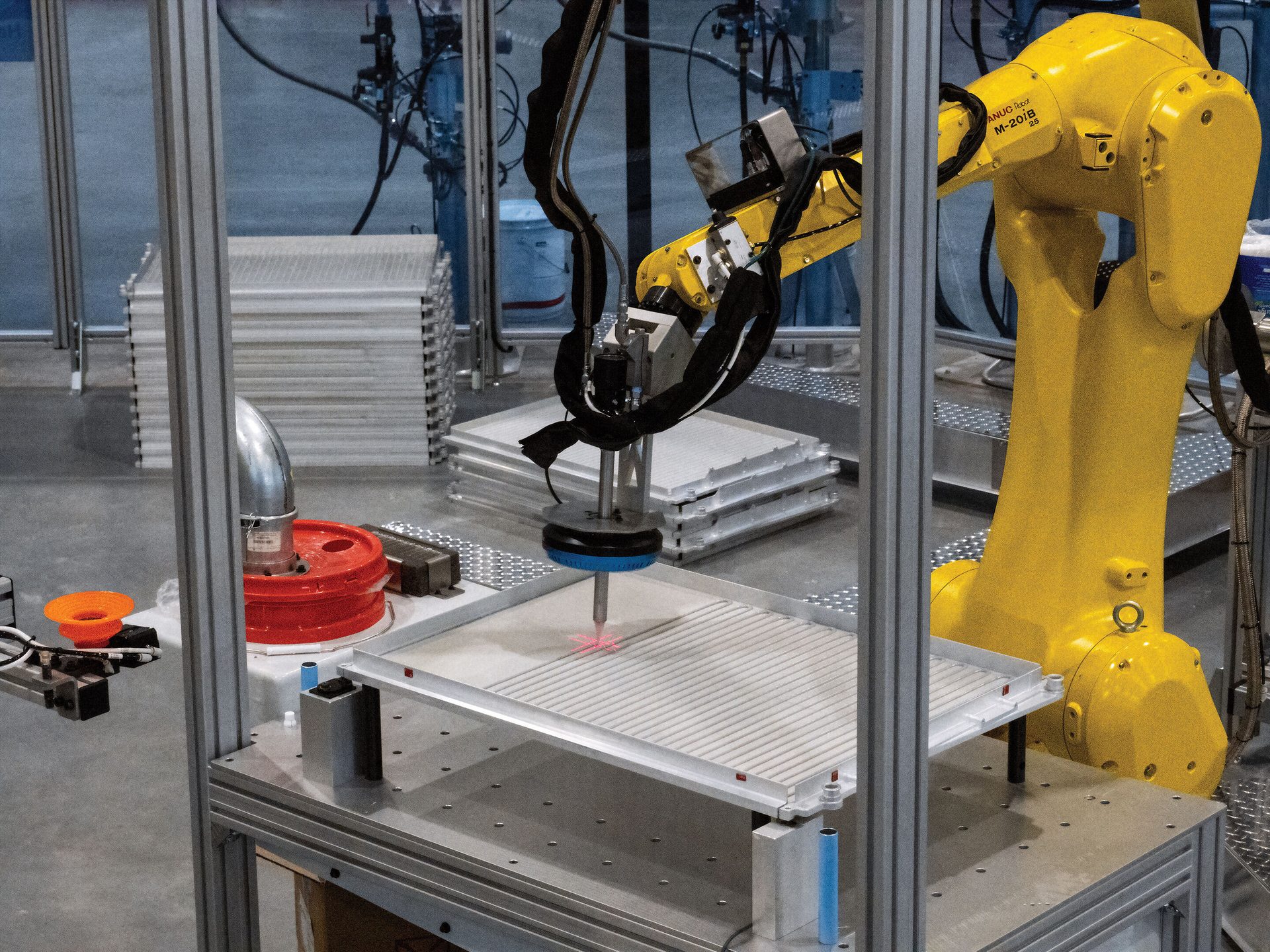

Tariffs on critical manufacturing inputs dramatically increase the cost of these must-use, must-import inputs, thus hindering the very investment needed to grow manufacturing jobs in the U.S. These inputs are raw materials, critical minerals and energy resources—as well as some manufacturing machinery, such as robots and machine tools, that are necessary to enable U.S. production.

The NAM argues that tariffs on industrial machinery, such as robots, that is not made in the U.S. are hindering growth of domestic manufacturing. Photo courtesy Lion Electric

“The [accelerator program] offers a way to bring in essential inputs that aren’t produced in the U.S. without added cost burdens—and it rewards manufacturers that expand production, invest in new equipment and create jobs here at home,” adds Timmons. “Every dollar of imported manufacturing inputs has a multiplier effect, generating $1.40 on average in manufacturing output in the U.S. This proposal is a practical, pro-growth approach that supports President Trump’s trade priorities and turns his goal to strengthen manufacturing in America for the long term into reality.”

Specifically, the accelerator program offers the following proposals:

• The administration should use existing authorities to issue general licenses that allow manufacturers to import essential inputs duty-free. These inputs include raw materials, machinery, components and R&D not readily available domestically. Eligible manufacturers would self-certify under defined criteria and be subject to post-entry verification by U.S. Customs and Border Protection. The Treasury Department, which has experience with general licensing frameworks, would be tasked with implementation.

• The administration should provide a rebate to offset tariff costs incurred on must-import inputs when manufacturers are investing or expanding manufacturing in the U.S. Rebates would apply to new or expanded manufacturing facilities; technological upgrades and equipment modernization; hiring of full-time manufacturing employees; and domestic R&D expenditures.

• To ensure the program remains responsive and effective in generating manufacturing expansion in the U.S., the NAM recommends convening a Quarterly Manufacturing Dialogue between manufacturers and key federal agencies, including U.S. Treasury, the Office of the U.S. Trade Representative, the Department of Commerce, and the Small Business Administration. This forum would allow for real-time feedback, operational updates and continuous improvement of the program to better serve manufacturers in America.

This makes sense to us. What do you think?