SEE

IT

AT

Robotic Cell Automates Screwdriving Process

Manufacturers typically use manual or semiautomatic tools to drive screws. While there will always be a place for handheld screwdrivers, a growing number of manufacturers are investing in screwdriving robots.

Today, robots are less expensive and easier to use than in the past. The technology is well within the reach of small and midsize manufacturers.

That’s a good thing, because robots offer numerous advantages over manual assembly. For one thing, robots provide greater consistency than handheld screwdriving systems. They will always move to the same location and drive the screw with the same parameters. In addition, robots do not get tired and do not take breaks.

Any assembly with a good population of screws would be a candidate for automation. Any assembly that requires four to eight screws—particularly if they’re all installed from the same side—would be an ideal application for a screwdriving robot.

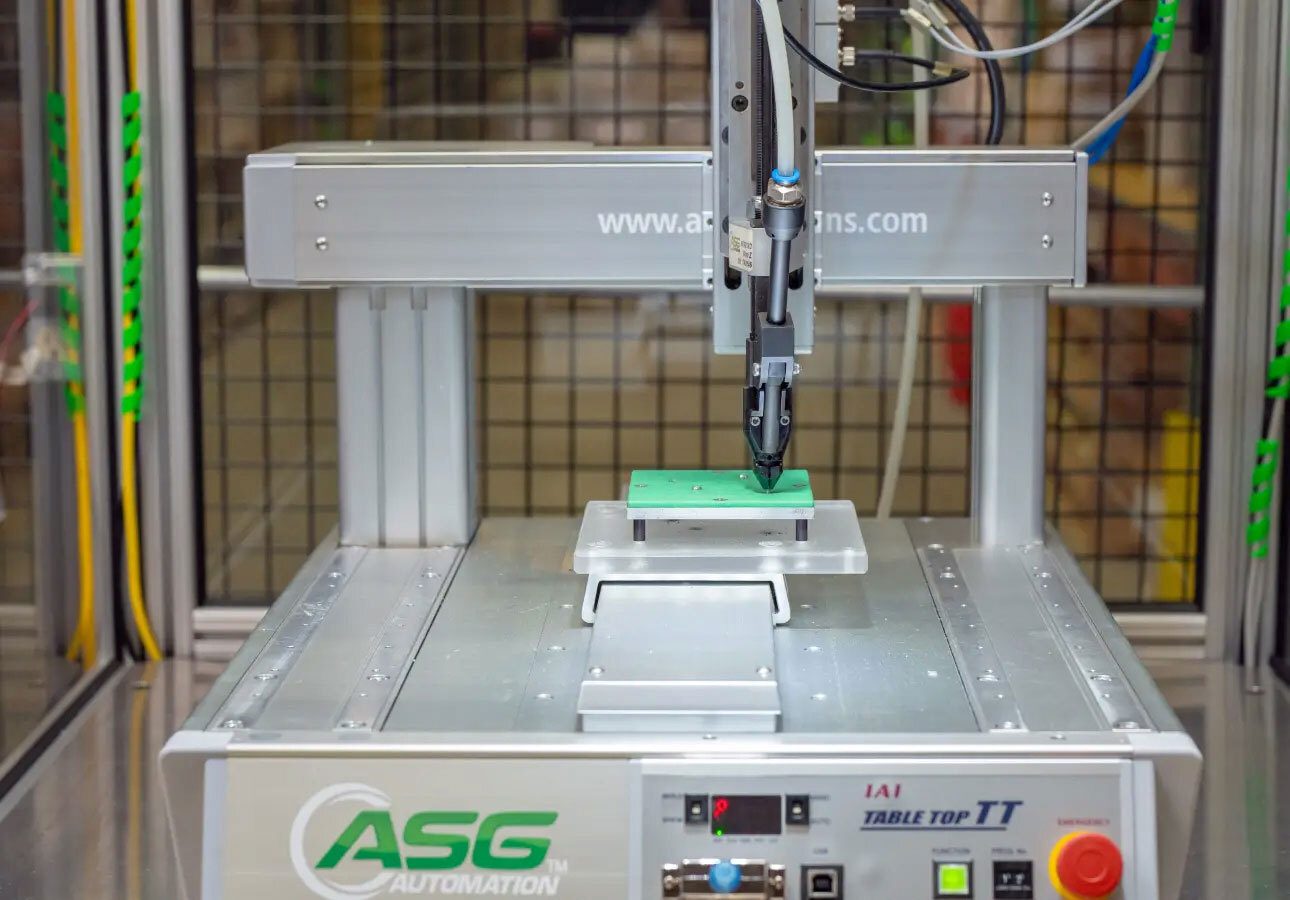

One of the newest screwdriving robots on the market is the AX-10 assembly cell from ASG, a Division of Jergens Inc. This customizable assembly cell features an aluminum extrusion frame and a tabletop three-axis Cartesian robot. The standard work envelope measures 400 by 400 by 150 millimeters, and other sizes are available. Each linear axis is driven by a ballscrew for superior accuracy and repeatability.

This customizable assembly cell features a tabletop three-axis Cartesian robot with a work envelope measuring 400 by 400 by 150 millimeters. Photo courtesy ASG

The robot can be equipped with a DC-electric screwdriver or a pneumatic tool. Either can equipped to work with an automatic screw feeder or a screw presenter. Photo courtesy ASG

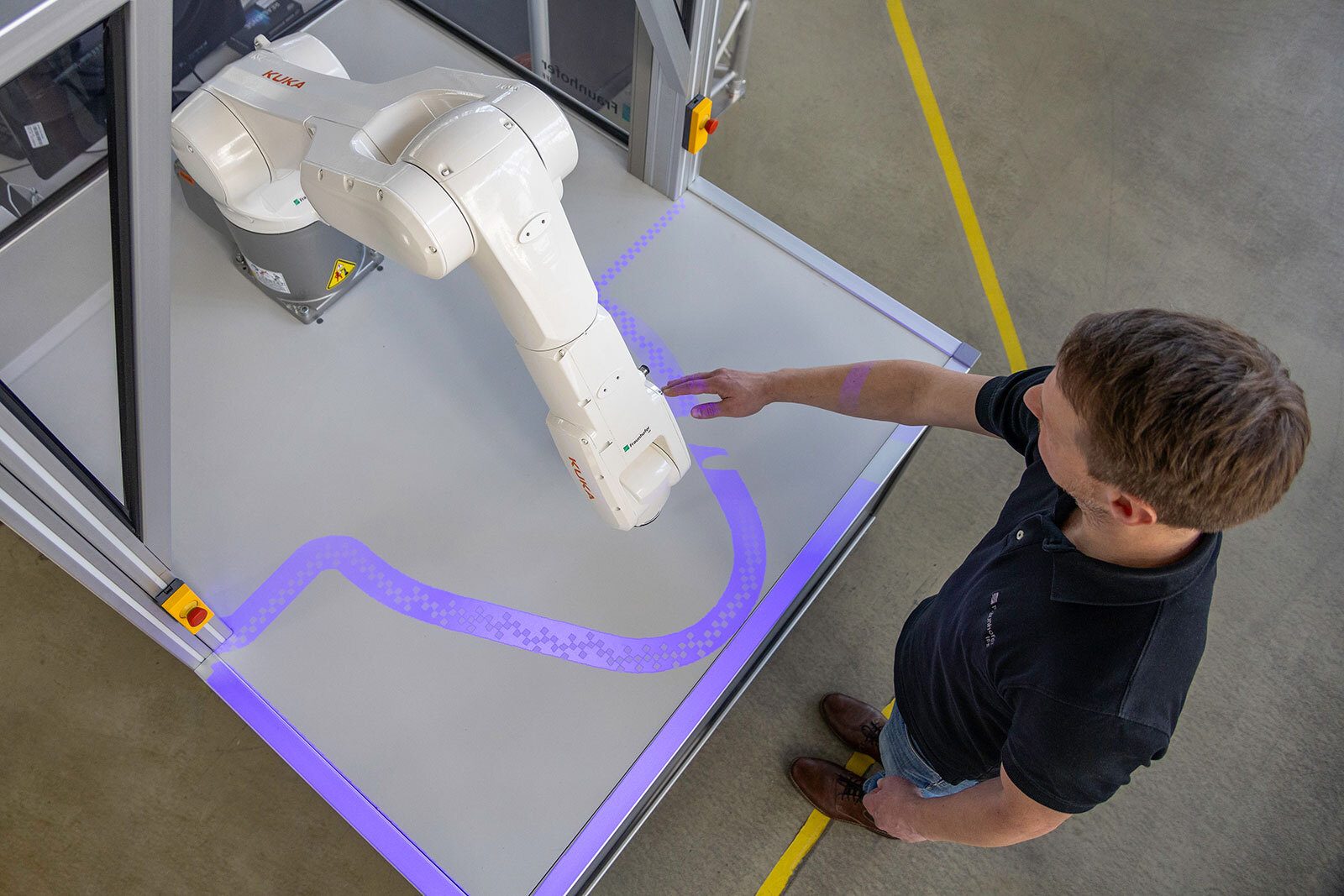

Alternatively, the cell can be equipped with a six-axis collaborative robot.

The robot can be equipped with ASG’s DC-electric X-PAQ screwdriving system or a pneumatic screwdriver. Either tool can equipped to work with an automatic screw feeder or a screw presenter.

The X-PAQ is ASG’s premium torque- and angle-controlled brushless DC electric screwdriver system. This tool system is used for applications requiring tight tolerances and heightened levels of traceability.

Screw presenters are suitable for screw sizes ranging from #000 to #10. Presenters are available with interchangeable rails or adjustable rails. Automatic screw feeder are fast, delivering a screw to the jaw set in less than half a second. Because of its simple design, the screw feeder is consistent and reliable, providing a virtually jam-free operation.

Other cell options include a signal light tower, a human-machine interface, a bar code scanner, additional lighting, and modular fixtures to accommodate multiple assemblies.

For more information on screwdriving technology, click https://asg-jergens.com or visit the company’s booth at The ASSEMBLY Show. ASG is one of numerous suppliers of fastening tools and systems that will be exhibiting at the show, which will take place Oct. 21-23 at the Donald E. Stephens Convention Center in Rosemont, IL. Others include Delta Regis Tools, Desoutter Industrial Tools, Nitto Kohki USA Inc., Sturtevant Richmont and TorqTec.

Besides suppliers of fastening tools, you’ll find 225 suppliers of automation, presses, robots, motion control technology, parts feeders, workstations, software and other assembly technologies. For more information, visit www.theassemblyshow.com.