A special section to ASSEMBLY

Before hairpins can be welded, the insulative enamel coating must be removed. Photo courtesy IMA Automation

Magnet Wire

Laser Stripping of

A new study compares laser technologies for removing the enamel coating from magnet wire prior to welding.

Ali Gökhan Demir, Ph.D. // Associate Professor of Mechanical Engineering // Polytechnic University of Milan // Milan, Italy

Daniele Nocciolini, Ph.D. // R&D Project Coordinator // IMA Automation // Bologna, Italy

Contemporary electric drives used in traction systems are based on hairpin windings. The high current density requires large cross-sections and high electric conductivity. Hence, copper bars are bent into various geometries, inserted into the stator, and electrically connected.

Conventionally, the electrical connection is done by laser welding. This noncontact process provides great flexibility in terms of hairpin size and geometry. It’s also fast, which is crucial, since a single stator can have up to 200 hairpins to be welded.

Before hairpins can be welded, the insulative enamel coating must be removed. This allows the conductive metal underneath to make a proper connection. If the coating gets into the melt pool, it can cause porosity, spatter formation and other weld flaws.

Several methods are available for removing the coating: cutting or scraping, chemical stripping, thermal stripping, and laser ablation. The latter is the preferred method. Laser ablation is a noncontact process, and it offers flexibility in terms of the size and shape of the stripped area. It’s also the most precise method. Cutting or scraping carries a risk of removing some of the copper along with the enamel.

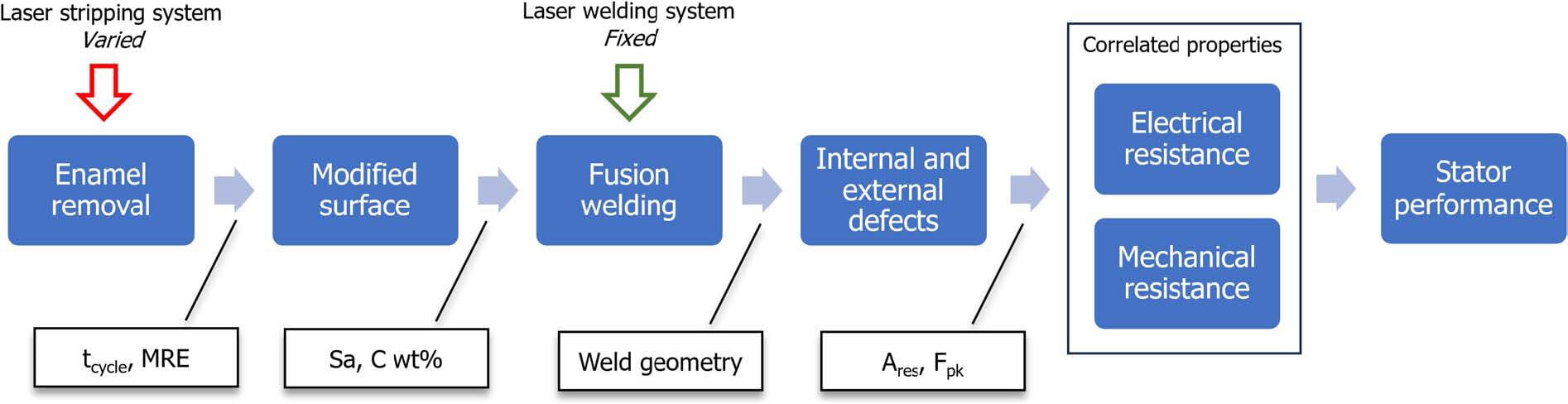

This diagram shows the relationship between the laser stripping process and final stator performance with intermediate effects and measurable quantities in the hairpin manufacturing cycle. Photo courtesy Polytechnic University of Milan

Laser ablation works in one of two ways. The laser can burn off the material directly, if the wavelength is sufficiently well-absorbed by polymer. Alternatively, the laser energy is absorbed by the metal at the polymer-metal interface, and the sudden heating causes shock waves that expel the coating in particles much larger than the beam size.

Several types of laser can be used to remove the enamel from magnet wire. Given the high cost of the technology relative to other stripping methods, we undertook a study to determine which laser technology is best for the job.

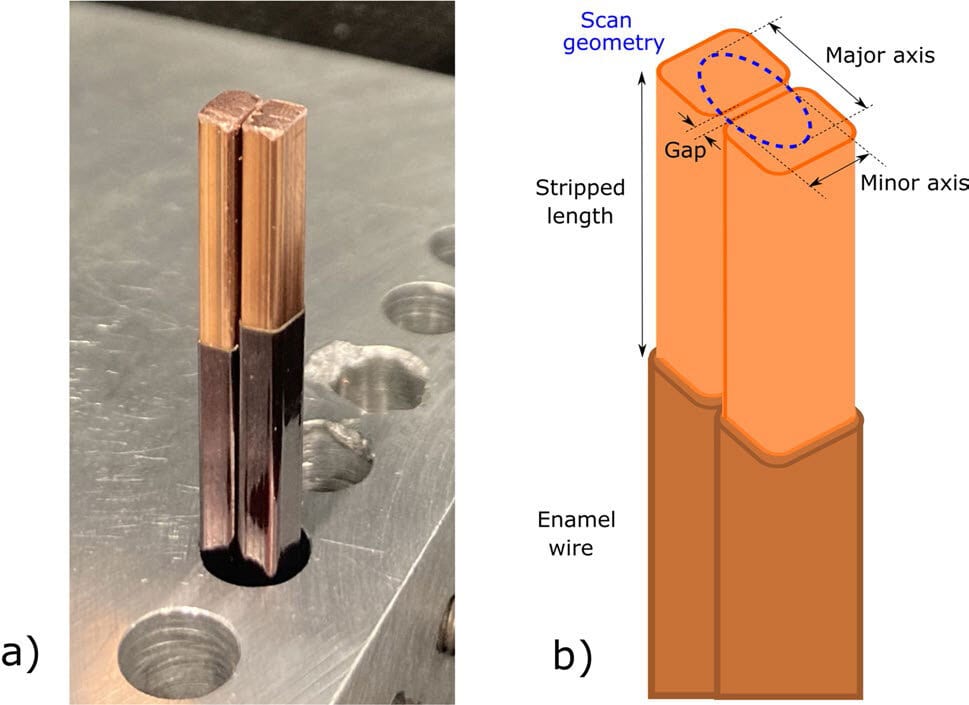

These images show (a) the specimens during the laser welding operation and (b) a schematic description of the weld scan trajectory. Photo courtesy Polytechnic University of Milan

Our Study

• We tested seven laser stripping systems. The benchmarked technologies span a range of wavelengths, from infrared to ultraviolet. Specifically, we tested the following setups:

• IR10, a CO2 laser with a wavelength of 10.6 microns, a maximum power of 300 watts, a pulse rate of less than 100 kilohertz, and a pulse duration of 2 to 150 microseconds. Capital cost is low.

• IR9, a CO2 laser with a wavelength of 9.36 microns, a maximum power of 400 watts, a pulse rate of less than 200 kilohertz, and a pulse duration of 2 to 800 microseconds. Capital cost is low.

• NIR, a fiber laser with a wavelength of 1.064 microns, a maximum power of 50 watts, a pulse rate of 20 to 80 kilohertz, and a pulse duration of 100 nanoseconds. Capital cost is low.

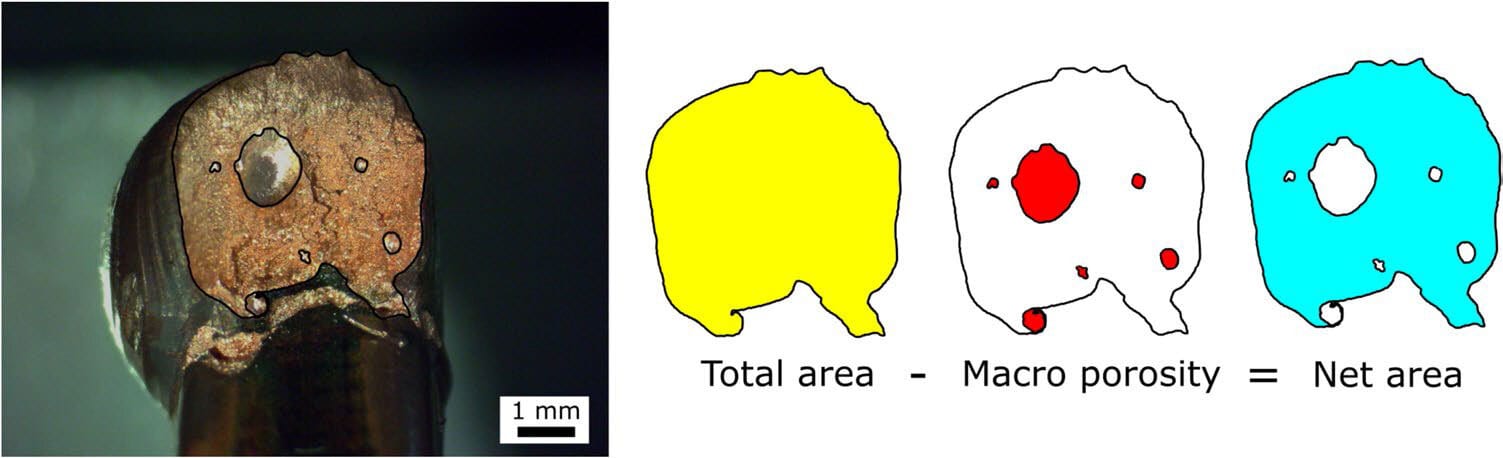

After tensile testing, we examined the fracture surfaces to learn more about how and why the joints failed. Photo courtesy Polytechnic University of Milan

• NIR-BS, a disk laser with a wavelength of 1.03 microns, a maximum power of 2,000 watts, a pulse rate of 5 to 250 kilohertz, and a pulse duration of 30 nanoseconds. Capital cost is high.

• VIS, a fiber laser with a wavelength of 0.532 micron, a maximum power of 100 watts, a pulse rate of 30,000 kilohertz, and a pulse duration of 1.2 nanoseconds. Capital cost is high.

• UV, an Nd:YAG laser with a wavelength of 0.355 micron, a maximum power of 30 watts, a pulse rate of 300 kilohertz, and a pulse duration of 25 nanoseconds. Capital cost is high.

• IR+NIR. In this setup, the IR10 and NIR lasers were used in series. The IR10 removes most of the coating, and the NIR removes any residual material.

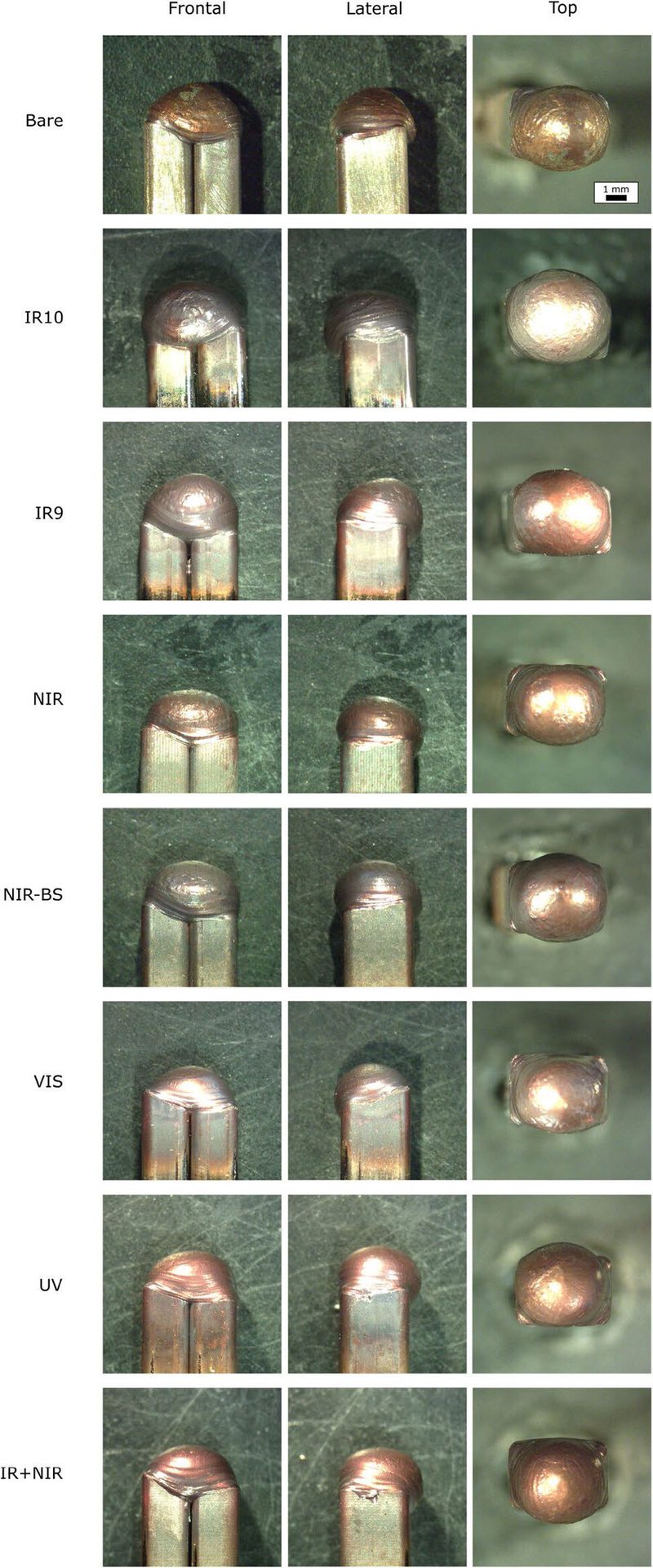

These optical microscopy images compare the welded hairpins. The welds are similar, regardless of which technology was used to strip the wire. Photo courtesy Polytechnic University of Milan

The hairpin material was electrolytic tough pitch copper (Cu-ETP) with an enamel coating for isolation. Cu-ETP is a widely used, high-conductivity copper known for its excellent electrical and thermal properties. The material was 3.87 millimeters wide and 2.66 millimeters thick. The enamel coating was polyamide-imide 95 microns thick.

The process parameters were chosen to remove the enamel in the shortest possible time. Each laser was run at its highest power. The spot diameter varied, depending on the laser. For example, with the IR9 and IR10 lasers, the spot diameter was 500 microns, which was ideal given the high absorptivity of the enamel to infrared wavelengths. On the other hand, with the NIR and NIR-BS lasers, the spot diameter was 39 to 50 microns to compensate for the low absorptivity of the enamel to near-infrared wavelengths. Similarly, scanning speed and hatch distance (the space between two passes of the laser beam) also varied, depending on the laser.

After stripping, the hairpin couples were laser welded using a 6-kilowatt fiber laser with a wavelength of 1.07 microns. All the hairpins were welded using the same parameters. As a control, we also welded hairpins made from copper that had never been coated with enamel.

Stripping quality was evaluated in terms of surface topography and chemistry. Peel tests were conducted to measure the strength of the welded joints. The porosity of the fracture surfaces was also evaluated to reveal the primary failure mechanism.

The results were compared in terms of quality, productivity and material removal efficiency. We then rated each system according to highest quality, highest productivity, and best capital cost.

The Results

We evaluated the surface roughness of the copper after stripping using optical and scanning electron microscopes. The lasers that were absorbed well by the enamel—IR10, IR9, VIS and UV—provided a smooth surface. The IR wavelengths are not absorbed by the underlying copper as effectively as other wavelengths, while the VIS and UV wavelengths do not generate further damage below the enamel. The NIR lasers roughened the copper surface, due to the relatively smaller beams and direct ablation of the underlying metal. A similar effect was seen with copper processed by the IR and NIR lasers consecutively.

We also examined the surface chemistry of the copper. Specifically, we looked for the presence of carbon, which would indicate polymer left behind after stripping. That’s important, because leftover polymer can decrease the strength of the welded joint.

We found much more carbon on the copper stripped by the IR10 and IR9 lasers than on the copper processed by the NIR, NIR-BS, VIS and UV lasers. The latter left behind the least amount of carbon. In fact, we found eight times more carbon on the copper stripped by the IR10 than on the copper stripped by the UV. The best performance, in terms of residual carbon, was provided by the combination of IR and NIR lasers.

The weakest joints were produced with the copper stripped with the IR10 laser. The strongest were produced with the copper stripped by the combination of IR and NIR lasers. Photo courtesy Polytechnic University of Milan

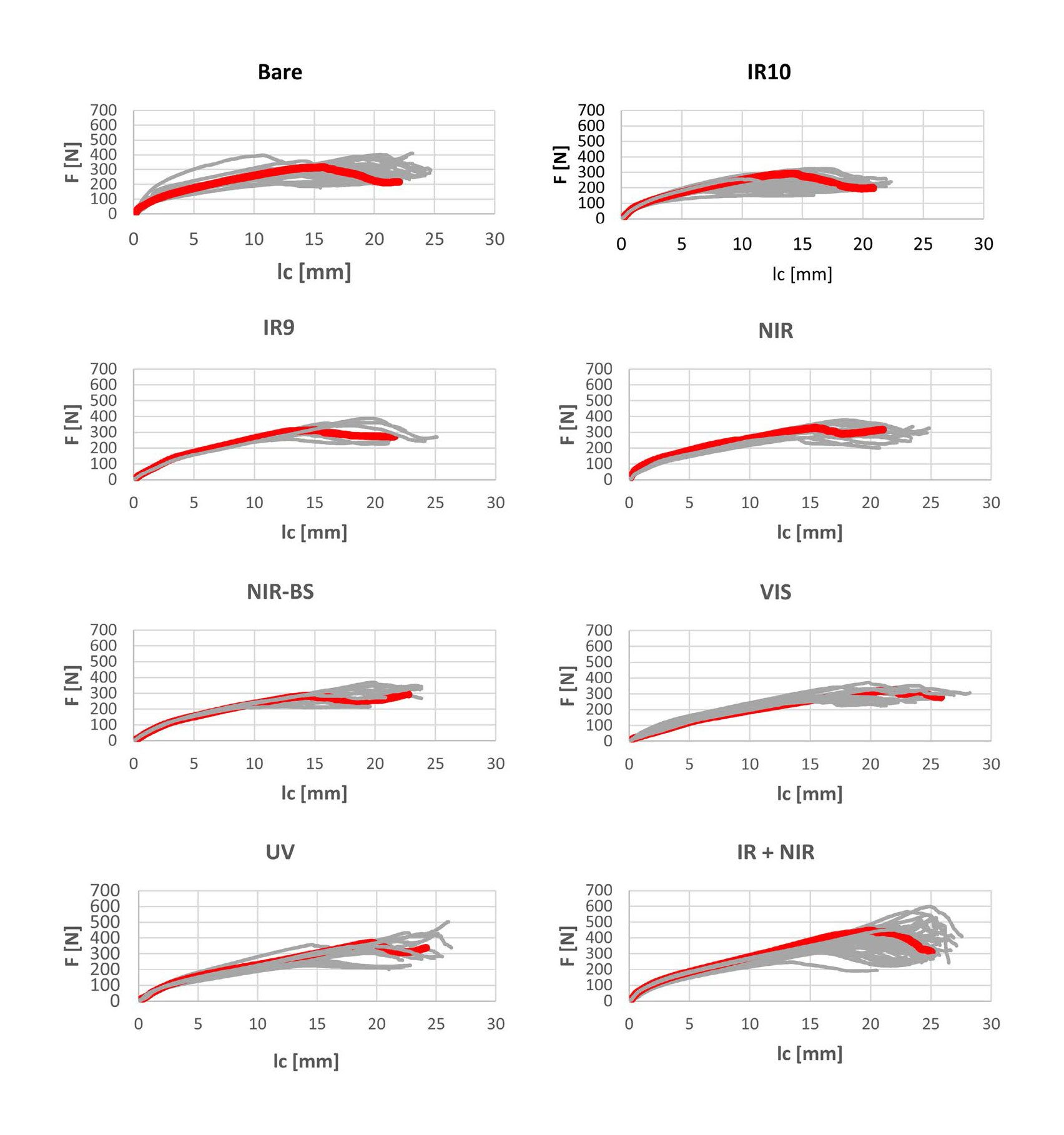

The results of tensile tests on the welds ranged from 150 to 600 newtons, indicating that stripping quality had a direct effect on mechanical strength. Tensile tests on welds made with bare copper averaged 315 newtons. The IR9, NIR, NIR-BS, UV and VIS lasers provided comparable results. On the other hand, the weakest joints were produced with the copper stripped with the IR10 laser (average, 262 newtons). The strongest joints were produced with the copper stripped by the combination of IR and NIR lasers (average, 409 newtons).

When we did a fracture analysis of the joints produced with the copper stripped with the IR10, we found small pores in the fracture surface. These indicate polymer gases trapped in the weld, which reduced the strength of the joint.

Conclusions

Ultimately, which laser technology to use for stripping magnet wire depends on what’s most important to the specific application or production facility. The combination of IR and NIR lasers produced copper with the lowest average carbon content and welds with the highest tensile strength, but it requires greater capital investment and more processing time.

On the other hand, the NIR-BS laser was the most productive, in terms of output per unit of time. The IR9 and IR10 lasers required the lowest capital investment but ultimately produced joints with less strength.

Editor’s note: This article is a summary of a research paper co-authored by Simone D’Arcangelo,

Leonardo Caprio, Barbara Previtali of Polytechnic University of Milan, as well as Davide Chesi and Rubino Corbinelli of IMA Automation. To read the entire paper, click here.