A special section to ASSEMBLY

CONTACT

Austin

Lightweight battery-powered aircraft are ready for take-off.

The equipment needed to cut, strip, crimp and assemble that wiring is always changing. Here’s a look at some of the latest products.

New technologies include a fully automatic harness taping machine and a heavy-duty crimping tool

John Sprovieri // Chief Editor

Fully Automatic Taping Machine

The TM 300 from Polish company TechSpeed is a fully automatic machine for taping wire harnesses. The machine is available in two variants: the TM 300R with roller feed and the TM 300B with belt feed. The fully programmable machine has a user-friendly interface. A user-friendly interface lets operators switch between programs in seconds.

The machine can tape wire bundles with a maximum diameter of 20 millimeters. (As an option, the machine can be equipped to tape bundles as wide as 35 millimeters.) It can apply tapes ranging from 9 to 19 millimeters wide. The speed of the taping head is programmable. Maximum speed is 1,000 rpm.

The machine is available in the U.S. through Schleuniger.

See this company at The ASSEMBLY Show Oct. 21-23 in Rosemont, IL.

Schleuniger

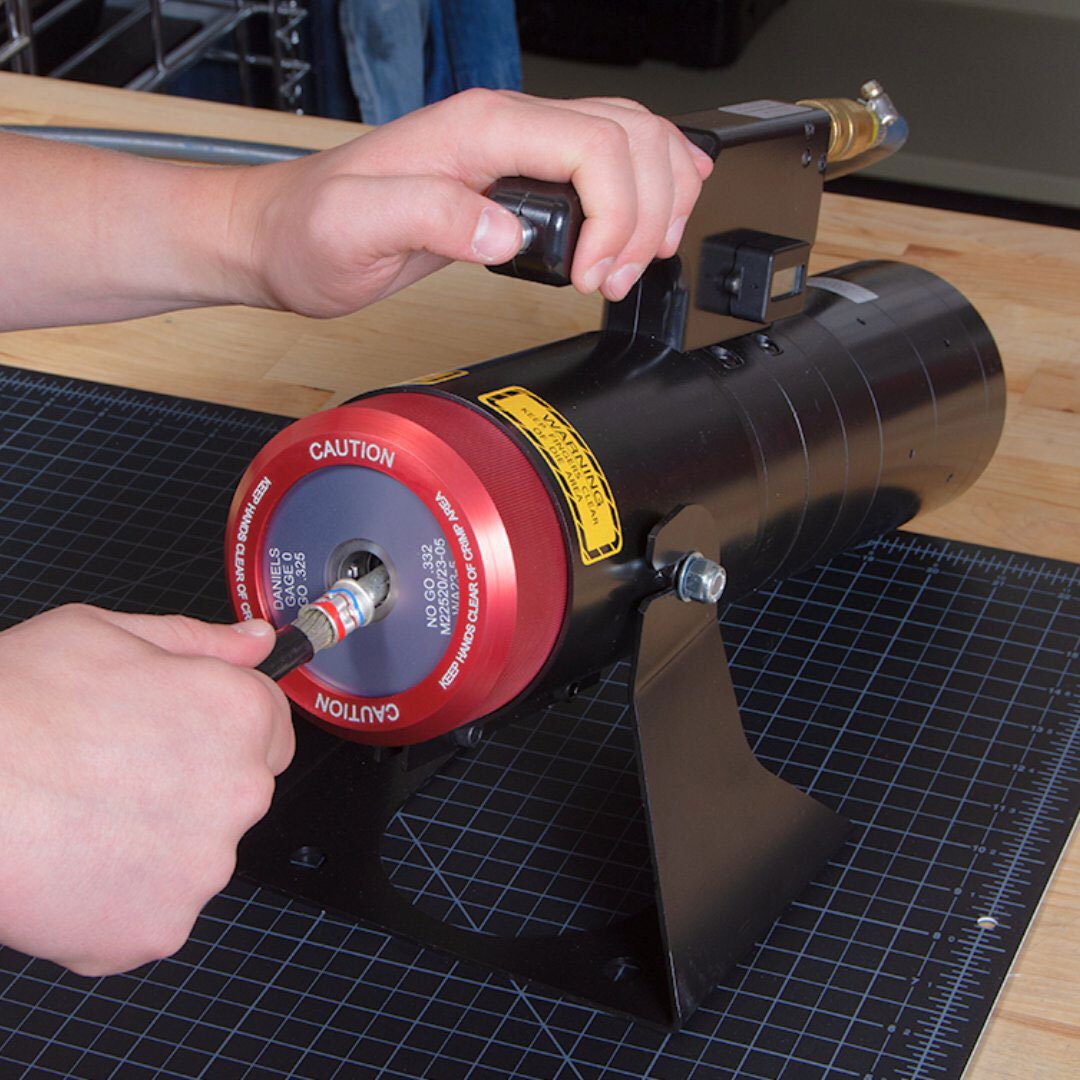

Heavy-Duty Pneumatic Crimp Tool

The WA23B is a heavy-duty four-indent pneumatic crimp tool. An enhanced version of the company’s WA23 tool, the WA23B has features designed to simplify operation. It can crimp large gauge machine contacts, uninsulated terminals and uninsulated splices between sizes 8 and 4. Its versatility and durability make it suitable for use in high-volume and high-mix environments. Compared with its predecessor, the WA23B is twice as fast, 18 percent lighter, and 2 inches shorter.

A dedicated gauging state simplifies field verification to ensure optimal tool performance. Cycle control eliminates the possibility of faulty crimps. The ergonomically designed handle and push button offer enhanced comfort during prolonged use. The tool is compatible with new and existing AS22520/23 dies and locators and most standard Pico 400 series dies and locators.

See this company at The ASSEMBLY Show Oct. 21-23 in Rosemont, IL.

Daniels Manufacturing Corp.

Connectors and Terminals Meet Domestic AI Center Requirements

A broad range of standard and custom connectors and terminals are available for power distribution, sensors and other AI data center requirements.

AI data center connectors include standard PCB contacts, insulated products, foil connectors, ring terminals, spades, disconnects, pins, and receptacles. Custom connectors and terminals can be manufactured to meet precise OEM specifications with regard to form, function, materials and packaging. ETCO offers rapid prototyping and 3D solid modeling analysis of new designs.

Connectors are stamped from brass, tinned steels, stainless, beryllium copper, phosphor bronze and other alloys with thicknesses from 0.008 to 0.09 inch and tolerances to 0.002 inch. Connectors can be supplied loose or in strip form for automated attachment equipment.

ETCO Inc.

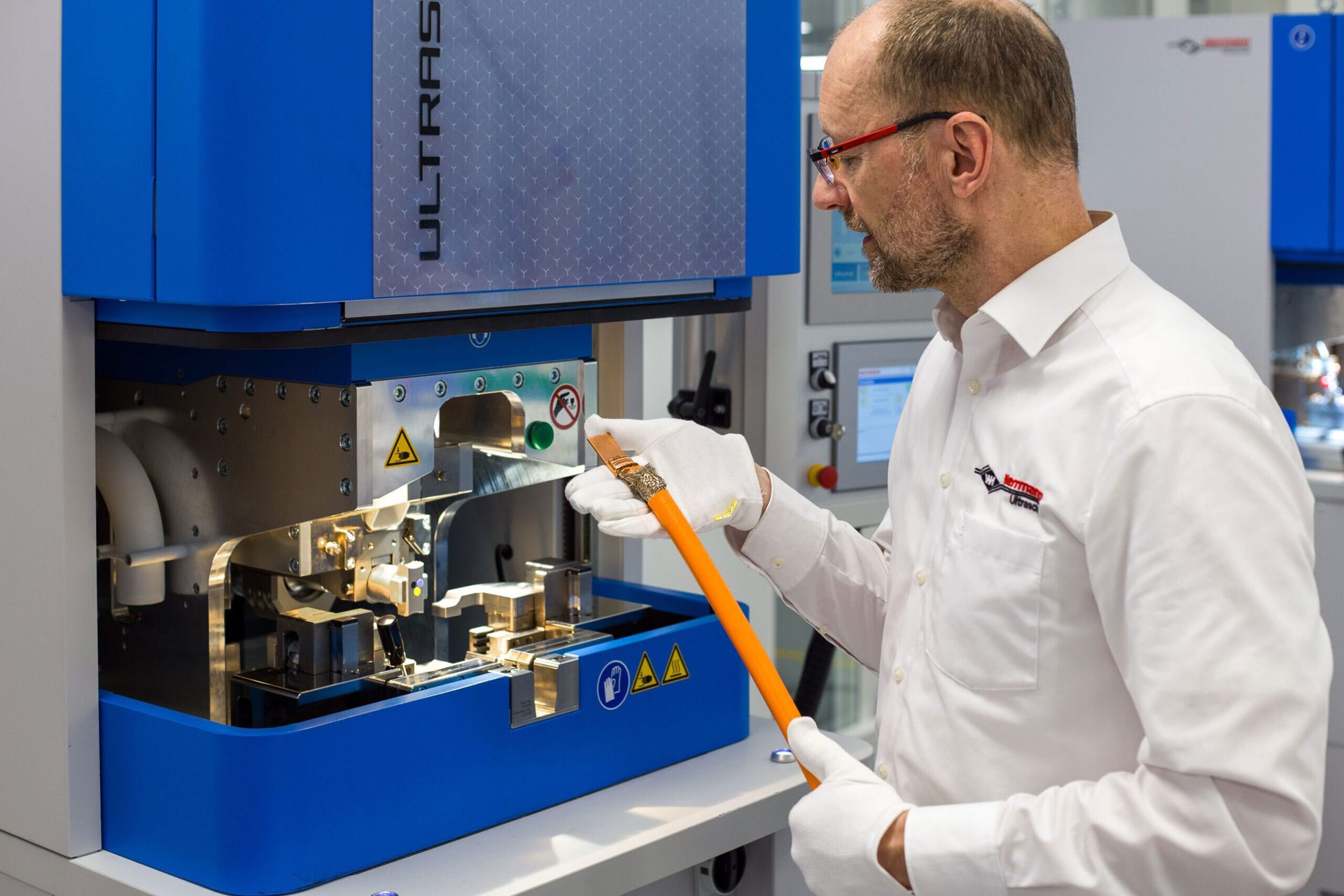

Ultrasonic Welder Splices, Terminates Wire, Cable

The Ultrasafe W is an ultrasonic welder for splicing and terminating wire and cable. Functional elements such as the cable clamp or cable end-stop can be aligned quickly and reliably. The sonotrode is will always be correctly aligned, since its position is fixed in the ultrasonic stack; this also simplifies application changes. Sensors ensure that the parts are correctly inserted into the machine. A special clamping mechanism keeps the parts in the correct position at all times.

This customizable and modular machine is designed to handle a wide range of applications. Tools can be quickly and conveniently changed. A new type of clamping system allows the tools to be changed quickly and without needing to be realigned. Maximum welding force is 10,000 newtons.

The machine has also been designed for better ergonomics. Thanks to a new lifting door, the machine offers a considerably enlarged working area. With 180 degrees of access, work in the machine, such as loading, reaching in or cleaning, can be carried out quickly and conveniently. The working height can be adjusted. An enlarged viewing window provides a clear view of the welding process. For safety, the door automatically moves down during welding. The sound-insulating housing protects against disturbing ambient noise that can occur during welding.

Herrmann Ultrasonics

Chemical Stripping Pots Remove Insulation From Magnet Wire

The DSP Series of chemical wire strippers can remove the insulation from magnet and enamel wire, including Litz wire, without damage to the wire.

The pots are designed specifically for use with Dip Strip, which starts as a solid crystal form and melts to a liquid when heated. Wires are immersed in the chemical, which will bubble slightly as the insulation is removed. The stripped wires are then rinsed in water and Dip Clean 2 metal cleaner to remove oxides and residue, and then again in water. Dip Strip does not corrode conductors as will acid strippers. The chemicals do not fume, and only normal ventilation is required.

Two models are available: the DSP1 and DSP2. These pots can hold 1 pound of Dip Strip. The DSP1 has a standard variable temperature control, while the DSP2 features an advanced feedback temperature control.

The Eraser Co. Inc.

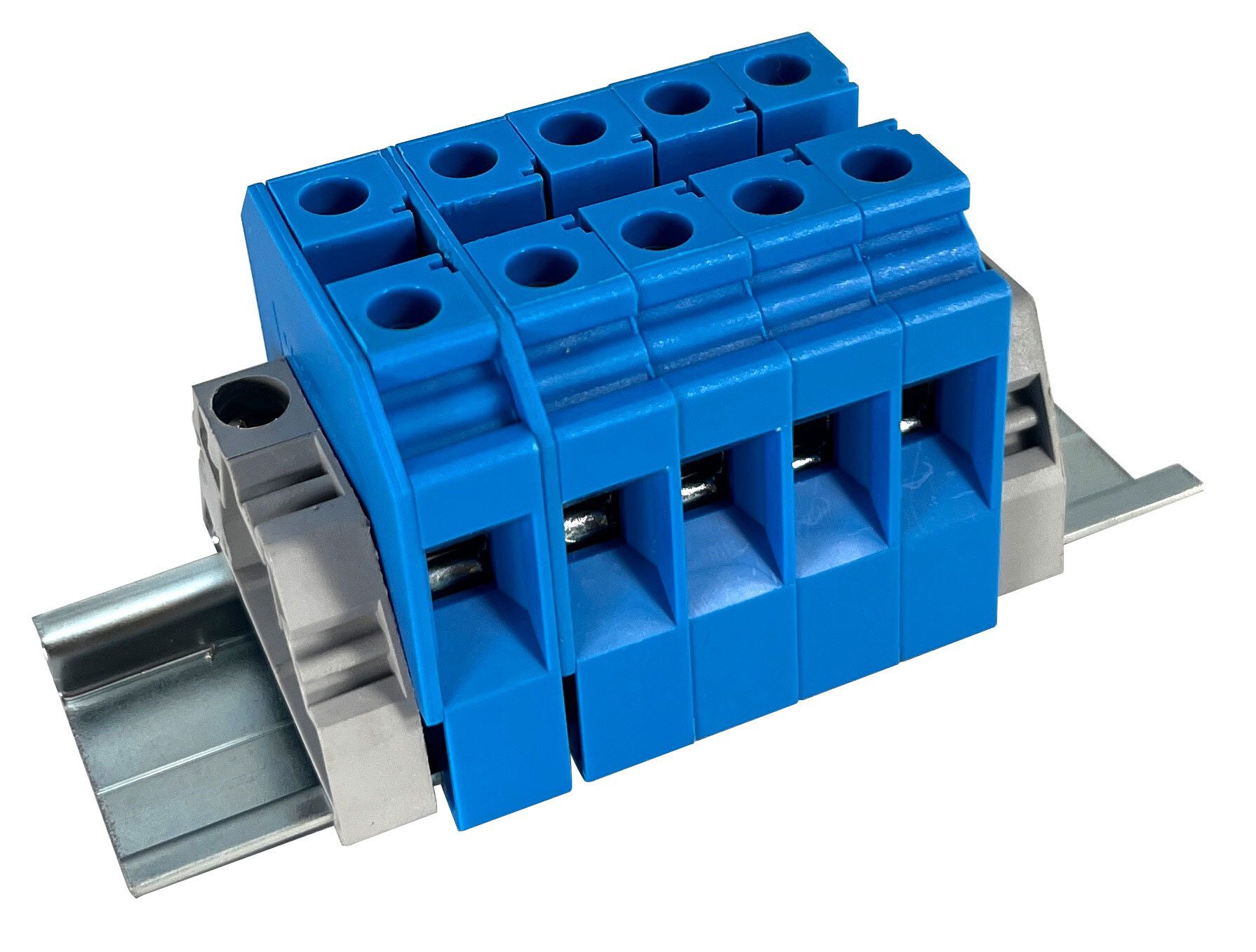

Terminal Blocks for Explosive Atmospheres

ATEX-IECEx terminal blocks are designed to provide greater safety and reliability in potentially explosive atmospheres. An extensive product line includes multiple connection technologies, providing versatile options for diverse industrial applications. The blocks consider both electrical sources of explosion and potentially explosive concentrations of gas, vapor, mist and dust in the air. They are approved for use in certified enclosures with a minimum IP54 rating.

The terminal blocks feature a maximum service temperature of 110 C, with an ambient temperature range of -60 to 66 C at mounting position. For some models, the ambient temperature range is -40 to 40 C, with a service temperature range of -40 to 85 C. The insulation material is polyamide 66, CTI 600 / Material Group 1. The blocks can accommodate wire sizes from 24 AWG up to 250 kcmil.

Specific products include:

• CP Series push-in terminal blocks with tool-less connection technology, a stainless steel push-in spring and universal push-in jumper system.

• CX Series spring and cage clamp terminal blocks, featuring a compact design and stainless steel spring. These blocks also utilize the universal push-in jumper system.

• CY Series screw clamp terminal blocks with a universal push-in jumper system, strong clamping system and snap-on ground blocks.

• CT Series screw clamp terminal blocks, featuring a traditional screw jumper system and a large range of block types for various applications.

Altech Corp.