Fasteners

New Materials, New Fasteners

John Sprovieri // Chief Editor

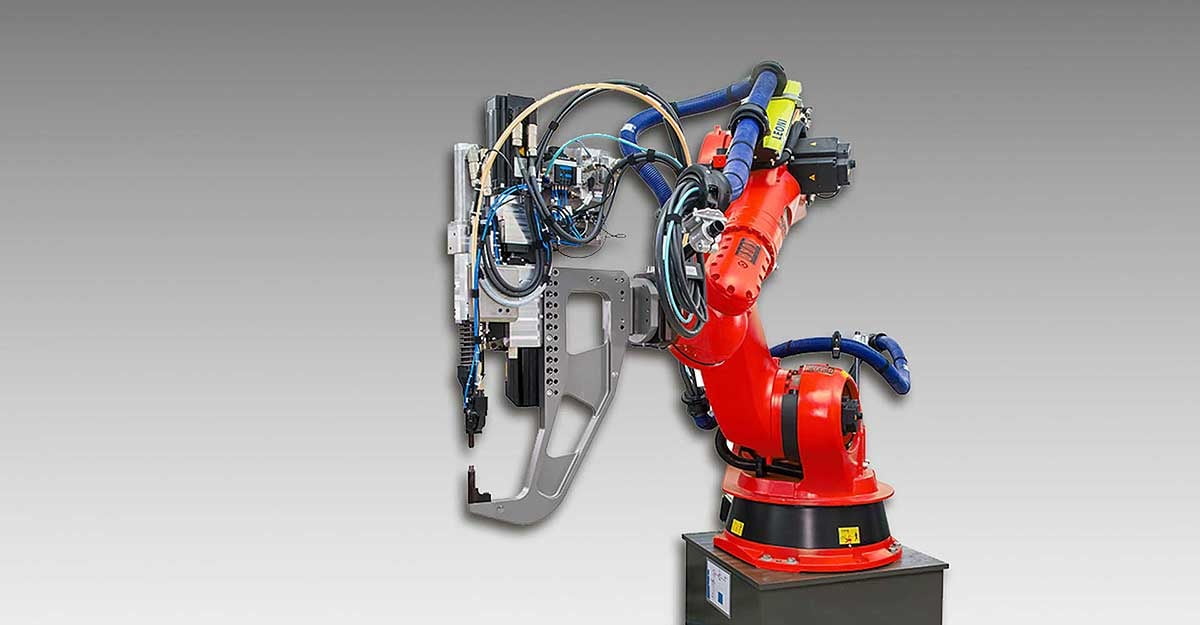

RIVTAC fasteners are installed with a six-axis robot equipped with a pneumatic setting tool. Photo courtesy Böllhoff Inc.

As automakers replace steel with lightweight materials, new fasteners will replace conventional screws.

Steel has been, is now, and will continue to be the predominant material for vehicle structures and body parts, such as doors, hoods, liftgates and fenders. But, other materials, such as aluminum, magnesium, plastics and composites, are becoming increasingly important.

According to the Center for Automotive Research, various steel alloys accounted for some 65 percent of the weight of an average vehicle structure in 2020. Aluminum alloys represented 13 percent, while plastics and composites made up 6 percent. By 2040, however, steel alloys will account for only 46 percent of that weight, while aluminum alloys will comprise 26 percent and plastics and composites will represent 15 percent.

Joining these disparate materials will require some innovative fasteners. The properties that make these space-age lightweight materials strong and stiff also make them difficult to assemble with conventional fasteners for plastics and sheet metal.

Here’s a look at some of the latest fasteners for the today’s lightweight automotive materials.

Self-Tapping Screw for CFRP

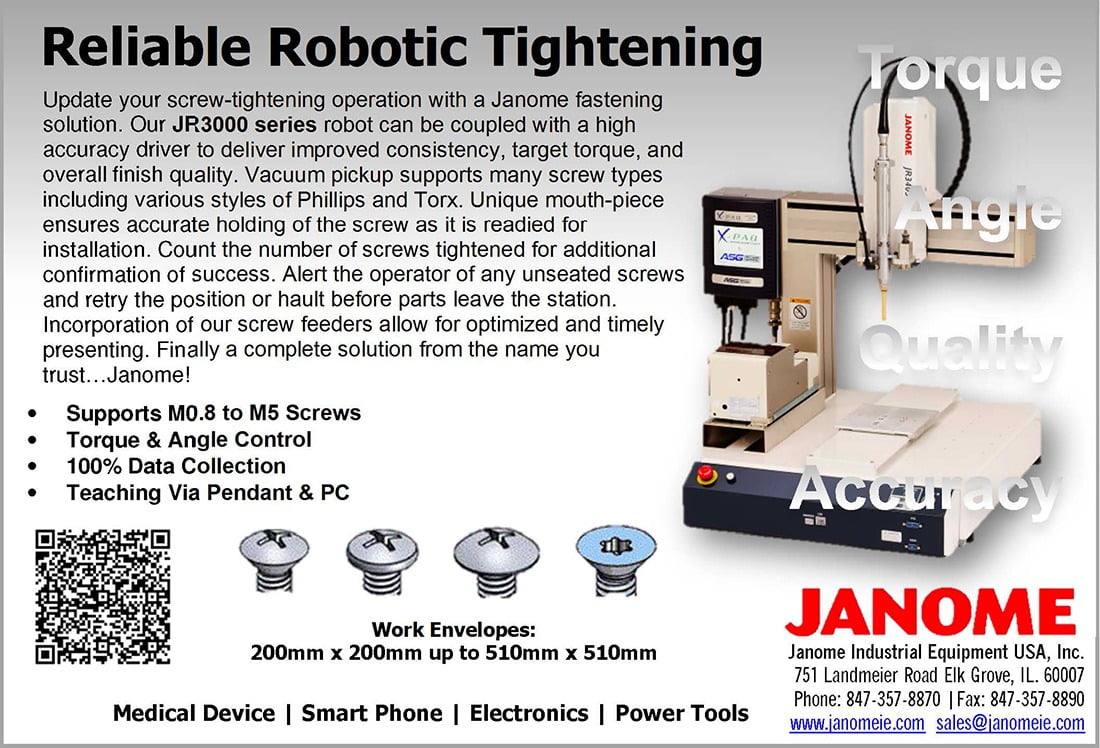

The Flowpoint Delta PT screw from EJOT GmbH & Co. is designed to fasten sheets of carbon-fiber-reinforced plastic (CFRP).

The new screw combines two EJOT technologies—the Delta PT screw for direct fastening into plastic and the FDS flow-drill screw for direct fastening into metal—into one fastener. The Flowpoint Delta PT screw is a self-piercing and self-tapping screw that penetrates both the clamped and mating materials without a pilot hole. The special point drills a hole in the materials and extrudes a boss. The optimized Delta PT thread geometry forms a strong female thread.

The installation process has six steps: rotation of the screw and application of an axial load; heating and penetration of the material; screw hole calibration and formation of an extrusion; thread forming; full thread engagement; and tightening.

The fastener produces a high-quality threaded joint without any part preparation steps. Available in steel, A2 or A4 stainless steel, aluminum and titanium, the fastener can be used with many varieties of CFRP. It can also be used to join mixed-material assemblies, such as aluminum and CFRP. Disassembly and reassembly are possible.

The fastener can be produced with a variety of head styles and drive recesses.

The Flowpoint Delta PT screw is designed to fasten carbon-fiber-reinforced plastic. Photo courtesy EJOT GmbH & Co.

Molded-In Fastener Provides Attachment Point in FRP

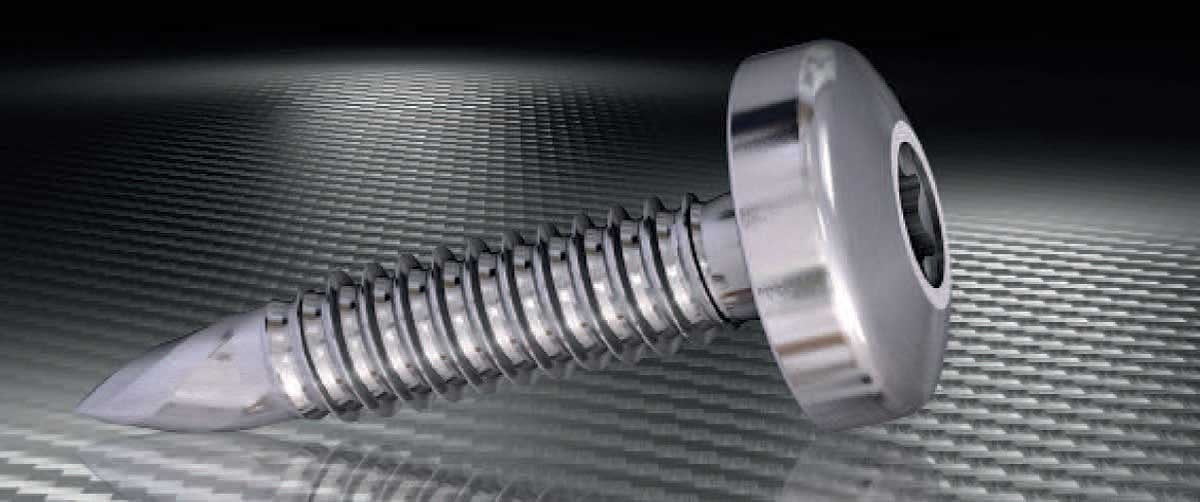

The IMTEC HR molded-in fastener from Böllhoff Inc. provides load-bearing female threads for attaching parts to fiber-reinforced plastic.

The disc-shaped fastener is placed into the mold for a composite structure and integrated during the molding process. It does not need to be installed in a particular orientation. It is compatible with most fibers and most thermoset and thermoplastic molding processes, including resin transfer molding, compression molding and injection molding.

For injection molding, the fastener is placed onto a pin fixed on the mold. The pin locates the fastener and protects the threads inside of it from being coated with resin. Next, the cloth is placed into the mold. The mold is closed, the plastic is injected, and the part is unmolded with the fastener integrated into it.

For compression molding, the process is the same except the pin is a plastic screw-off cap that also serves to push the fibers aside for inserting the fastener into the cloth, eliminating the need for drilling or punching a hole. This saves time and avoids cutting the fibers. The cap also protects interior threads during molding and is removed after the part is demolded.

To resist galvanic corrosion, IMTEC HR is available in zinc-plated steel and stainless steel. The latter is used mainly for CFRP. Different fastener versions are also available, including studs, nuts and spacers.

The fastener features eyelets and petals that are designed to embed in the composite during molding. This prevents the fastener from rotating when the mating screw is installed. In addition, since the fastener flange is located behind the fiber matrix, it does not impact the overall thickness of the part.

The fastener is strongly anchored in the composite material. Even under high mechanical stresses,

the insert will follow the deformation of the composite material but will not perforate it, owing to its high mechanical resistance and its energy absorption capacity. The risks of cracking are eliminated thanks to a balanced load distribution.

The fastener is recommended for assembling structural and semi-structural composite parts, such as doors, tailgates, floors and seat structures.

The IMTEC HR molded-in fastener provides load-bearing female threads for attaching parts to fiber-reinforced plastic. Illustration courtesy Böllhoff Inc.

Friction-Welded Fastener Joins Steel, Aluminum

EJOT has developed a friction-welding process, Ejoweld, that uses a rotating steel fastener to quickly join aluminum to steel without the need for punched or drilled holes in the parts.

Ejoweld is a thermomechanical process. Heat is generated through rotary friction between the threadless fastener and the base material. The fastener penetrates the upper layer, which can be aluminum or magnesium, and welds onto the base material, which is typically high-strength steel. The upper layer is trapped between fastener head and the base material.

Installation is a four-step process. After the sheets are clamped together, the fastener is positioned and spun at high speed against the upper layer under axial force. The amount of frictional heat generated in the process depends on the configuration of the fastener, the rotational speed, and the axial force.

Once the fastener has penetrated the upper layer, the rotational speed of the fastener is increased so it generates enough heat to clean and prepare the surface of the lower sheet for welding. The fastener then continues to rotate until enough heat is generated to soften both materials. Neither material reaches its melting temperature, and the process creates no sparks and little noise.

Finally, the rotation stopes and the axial load is increased and held, thereby upsetting the tip and lower portion of the shank to create a weld that securely holds both sheets at their interface. The entire process takes approximately 1 second.

For added strength, the process can be used in conjunction with adhesives.

The Ejoweld process is fully automatic. System components include a six-axis robot, a setting tool, a feeder for the fasteners, and a controller.

The fastener comes in three versions: the CFF, SRE and REF.

The CFF is for standard, high-strength joints. It has a wide, undercut head to allow displaced material to flow upward around the top of the penetration. The top layer can be any light metal with a yield strength of 150 to 320 newtons per square millimeter. It can be 1 to 4 millimeters thick. The base material can be any steel alloy with a yield strength of 270 to 1,800 newtons per square millimeter. It can be 1 to 2 millimeters thick.

The SRE is half the size of the CFF. It has a thinner head profile, so that the head embeds itself in the up-flowing material, creating a lower profile joint. It is ideal for narrow-flange applications, such as vehicle doors and roofs. The top layer can be any light metal with a yield strength of 150 to 320 newtons per square millimeter. It can be 1 to 2 millimeters thick. The base material can be any steel alloy with a yield strength of 600 to 1,800 newtons per square millimeter. It can be 1 to 2 millimeters thick.

The REF is for joining an aluminum or fiber-reinforced plastic sheet to an aluminum sheet. Whereas the CFF and SRE have solid shanks, the REF has a hollow shank.

The Ejoweld process does have some limitations. First, the installation equipment must access both sides of the stack. In addition, the head of the fastener protrudes above the plane of the top sheet, so a flush appearance is not possible.

EJOT has developed a friction-welding process, Ejoweld, that uses a rotating steel fastener to quickly join aluminum to steel without the need for punched or drilled holes in the parts. Photo courtesy EJOT GmbH & Co.

The Ejoweld process is fully automatic. System components include a six-axis robot, a setting tool, a feeder for the fasteners, and a controller.

The fastener comes in three versions: the CFF, SRE and REF.

The CFF is for standard, high-strength joints. It has a wide, undercut head to allow displaced material to flow upward around the top of the penetration. The top layer can be any light metal with a yield strength of 150 to 320 newtons per square millimeter. It can be 1 to 4 millimeters thick. The base material can be any steel alloy with a yield strength of 270 to 1,800 newtons per square millimeter. It can be 1 to 2 millimeters thick.

The SRE is half the size of the CFF. It has a thinner head profile, so that the head embeds itself in the up-flowing material, creating a lower profile joint. It is ideal for narrow-flange applications, such as vehicle doors and roofs. The top layer can be any light metal with a yield strength of 150 to 320 newtons per square millimeter. It can be 1 to 2 millimeters thick. The base material can be any steel alloy with a yield strength of 600 to 1,800 newtons per square millimeter. It can be 1 to 2 millimeters thick.

The REF is for joining an aluminum or fiber-reinforced plastic sheet to an aluminum sheet. Whereas the CFF and SRE have solid shanks, the REF has a hollow shank.

The Ejoweld process does have some limitations. First, the installation equipment must access both sides of the stack. In addition, the head of the fastener protrudes above the plane of the top sheet, so a flush appearance is not possible.

The Ejoweld process is fully automatic. System components include a six-axis robot, a setting tool, a feeder for the fasteners, and a controller. Photo courtesy EJOT GmbH & Co.

Tacks Join Steel, Nonferrous metals

RIVTAC fasteners from Böllhoff Inc. join thin, light aluminum, steel or nonferrous metal sheets to a thicker, heavier metal surface in milliseconds. A drilled or punched hole is not required in the top layer. Durable metal sheets and multiple layers can be joined, without any loss of material performance.

The fastener is made of steel that undergoes a cold-heading process. Its shank is then thread-rolled, and the whole fastener is heat-treated before being coated with zinc nickel for corrosion resistance. The finished fastener has a 450 HV10 rating, is 16 millimeters long and joins metal stacks that are 3 to 6 millimeters thick.

Installation system components include a vibratory bowl feeder, loading station, valve and power units, an HMI, and a 90-pound installation tool mounted on a six-axis robot. Before assembly begins, bulk fasteners are fed from the bowl into a rail on the loading station.

The tool’s setting head is then docked to the rail, where tacks are pushed from the rail into a magazine. During assembly, the nosepiece touches the metal surface, and a pneumatic cylinder pushes a tack out of the magazine at a speed of 20 meters per second. This velocity produces enough energy for the tack to penetrate the top and lower layers of the stack in just 6 milliseconds.

As it penetrates the stack, the tack displaces material into the threads on the shank, resulting in a form fit within the joint. When the tack reaches its final position, the cylinder raises back up to its starting position, and the cycle is repeated. Because of the high speed at which the tack joins metal stacks, it can be used with adhesives.

Process monitoring of each tack installation is possible via the HMI. The process-monitoring module measures, displays and analyzes tack force and material displacement during installation. It also enables operators to store, recall and transfer process-curve data.

RIVTAC fasteners join thin, light aluminum, steel or nonferrous metal sheets to a thicker, heavier metal surface in milliseconds. Photo courtesy Böllhoff Inc.

Thread-Forming Fastener for High Strength Steel

Semblex Corp. has introduced the Rolok HS thread-forming screw for joining high-strength steel. Its unique compound thread angle provides exceptional assembly performance while overcoming thread damage and collapse that plague traditional thread-rolling screws.

The fastener can roll threads into high-strength steels with a tensile strength of 500 to 1,200 megapascals. Each of its threads features three asymmetrical lobes that form mating threads in the nut or nut member. A large upper flank angle on the thread increases compressive strength and reduces shear loading, which prevents thread collapse. At the same time, a narrow lower flank angle allows serviceability with standard machine screws.

The fastener has a good drive-to-strip ratio and provides high resistance to vibration-related loosening. In addition, the fastener’s shank is tapered to provide self-alignment during installation.

The standard fastener is available with a 6 to 7 pitch lead, but a short taper variant with a 4 to 5 pitch lead can be produced on request.

Case hardening can be considered for nonsafety-critical applications when the mating material has a tensile strength of 800 megapascals or less. All other applications should use through-hardening with induction-hardened lead threads. A variety of coating and plating options are available to meet specific customer requirements for corrosion and joint performance.

The Rolok HS thread-forming screw is designed for joining high-strength steel. Photo courtesy Semblex Corp.

ASSEMBLY ONLINE

For more information on fastening and joining, visit www.assemblymag.com to read these articles:

Scroll to

read full story