CONTACT

Austin

Lightweight battery-powered aircraft are ready for take-off.

Four New Motion Control Products

John Sprovieri // Chief Editor

CONTACT

Austin

Lightweight battery-powered aircraft are ready for take-off.

The choice of pneumatic or electric actuators involves an evaluation of performance, component costs, system costs and productivity gains. Each has inherent advantages and disadvantages.

Electric linear actuators are intriguing, however, for their programmability, precision and energy savings.

Perhaps one of these new motion control products can play a role in your next machine design.

Electric Linear Actuator Is Compact

IAI America Inc. has introduced a compact version of its Elecylinder electric linear actuator. Three models are available: The EC-CRP series has a rod without guide. The EC-CGD series has a rod with a double guide. The EC-CTC series moves a small plate. The EC-CRP-3 has a 30-millimeter stroke, but is just 59.5 millimeters long and 36 millimeters wide.

The actuator has a built-in, compact controller circuit board. The actuator is driven by a powerful 24-VAC hollow servomotor. Position detection is done with a battery-free, hollow magnetic encoder with excellent environmental resistance.

A wireless teaching controller makes connection easy and operation simple. Acceleration, speed and deceleration can be set individually to enable smooth motion. Operation is even possible using only on-off signals, just like a solenoid valve.

Based on tests conducted by IAI, the Elecylinder consumes one-sixth the power of comparable pneumatic cylinders. In addition, pneumatic cylinders cannot operate at high velocity due to the impact at stroke ends which occurs when excess velocity is applied. The Elecylinder can start and stop smoothly at high velocity.

See this company at The ASSEMBLY Show Oct. 21-23 in Rosemont, IL.

IAI America Inc

Compact, PTFE-Free Linear Guide for Precise Positioning

The Drylin WWP linear guide features a PTFE-free locking carriage. Engineered from lubrication-free, high-performance polymers and aluminum, the guide offers a lightweight, hygienic and low-maintenance alternative to complex mechanical and electronic adjustment systems.

“Many manufacturers require a minimalist linear guide with a snap function that eliminates the need for levers or intricate mechanical and electrical components,” says Michael Hornung, product manager for Drylin linear and drive technology at Igus. “To meet this demand, the Drylin WWP linear guide has been developed to offer an uncomplicated and cost-effective solution.”

The guide features two key components: a polymer carriage that attaches to the moving object and an aluminum linear rail that facilitates smooth adjustments. Integrated polymer rings at set intervals along the rail interact with a preloaded steel ball on the carriage underside, creating an audible click when securing objects in position. The system’s maximum static load capacity is 100 newtons in the vertical direction and 50 newtons in the horizontal direction. For repositioning, an applied force disengages the ball, enabling movement until it locks into the next preset position.

The linear rails are available in lengths up to 3,000 millimeters and can be customized with hard anodized, silver anodized or black anodized finishes. Polymer carriages are available in two sizes.

Compared to traditional recirculating ball-bearing systems, the Drylin guide is more compact and lightweight, offering a weight reduction up to 65 percent vs. aluminum carriages. This design makes the guide ideal for applications where space and weight are at a premium, such as vehicle and aircraft interiors and furniture.

Igus GmbH

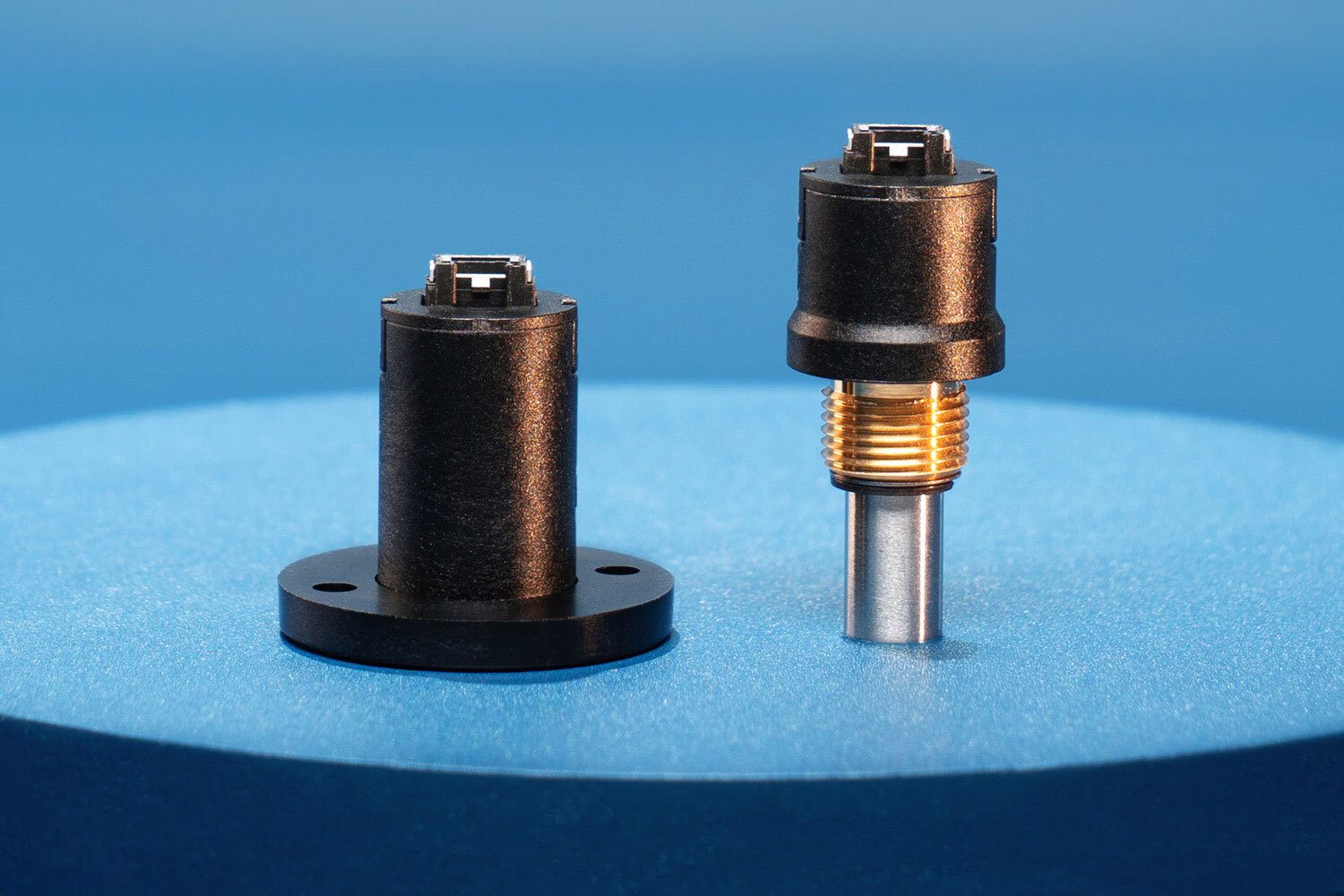

Miniature Absolute Encoders

US Digital has introduced two miniature absolute encoders: the MAE4 and the MA4. The MAE4 is a kit-style encoder designed to mount directly to existing shafts, while the MA4 is a shafted version. Both models deliver 12-bit resolution and offer a choice of analog or PWM outputs.

For quick assembly, the MAE4 magnetic absolute encoder features a push-on magnetic hub that supports seven shaft diameters: four metric (3, 4, 5 and 6 millimeters) and three imperial (0.125, 0.188 and 0.25 inch) and two shaft lengths (0.22 and 0.5 inch). It mounts to bolt circles of 0.75, 1.28 and 1.812 inch, making it easy to integrate into existing or space-limited applications.

The MA4 shafted miniature absolute encoder is molded from a rugged, glass-filled polymer, which makes it suitable for medical applications to meet sterilization requirements. The MA4’s shaft torque is also designed to provide the tactile feel of a potentiometer, ideal for manual front-panel interfaces.

The MAE4 and MA4 feature increased vibration and shock ratings and a latching connector for robust operation. The encoders are made in the USA.

US Digital

Linear Axes for Heavier Payloads

Bosch Rexroth has added a new, larger size to its lineup of compact linear motion modules. The new size, 280, can support items up to 250 kilograms, which makes it ideal for battery handling modules, machine tools, furniture, palletizing gantries and robotic transfer units.

The model 280 can move payloads of up to 250 kilograms over a length of 5,500 millimeters. The high acceleration of up to 5 g and a maximum speed of 5 meters per second are suited for short cycle times, while maintaining high degrees of precision. As configurable components, the modules can shorten the engineering of Cartesian robots and single and multi-axis motion systems. The modules can be paired with automation packages that include a motor, drive and controls, which speeds up commissioning and makes operating easier.

The increased load capacity allows the module to withstand more than four times the cantilevered forces as the 200 model.

Bosch Rexroth Corp.